Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for 2VV HRRU1

- Page 1 HRRU1 INSTALLATION...

-

Page 2: Before You Start

It was assessed according to harmonized European standards listed in the relevant EC declaration of conformity were applied. For the current and full version of the EC declaration of conformity visit www.2vv.cz FCC CLASS A CERTIFICATION NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device under Part 15 of the FCC Rules. -

Page 3: Technical Data

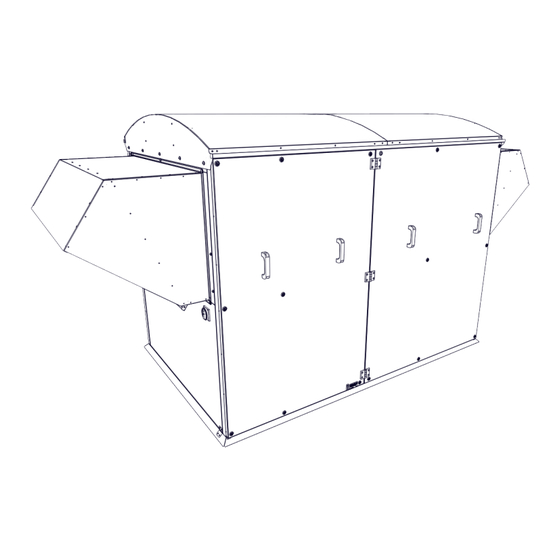

1. BEFORE YOU START SELECT UNIT LOCATION SAFE INSTALLATION DISTANCE TECHNICAL DATA ATTENTION! The unit is designed for indoor or outdoor installation and All materials used within a distance of less than 100 mm • can be installed in an outdoor, unprotected environment from the ventilation unit must be non-flammable (do not with a temperature range of -20°C to +60°C. - Page 4 2. MAIN COMPONENTS ROOF PRE-FILTER PREHEATER HEAT RECOVERY SUPPLY FILTER BYPASS EXTRACT FAN EXHCANGER EXHAUST AIR DAMPER INTAKE AIR DAMPER MAIN SWITCH EXTRACT FILTER CONDENSATE DRAIN TRAP SUPPLY FAN CONTROLS BOX...

-

Page 5: Main Components

2. MAIN COMPONENTS ANTI-RAIN BLIND ACCESS DOOR PANEL FOR MAINTENANCE GROMMET FOR WIRING EGRESS CONDENSATE DRAIN FITTINGS CONTROL PANEL SIPHON... - Page 6 3. DIMENSIONS...

-

Page 7: Technical Parameters

5. TECHNICAL PARAMETERS ELECTRICAL CHARACTERISTICS Input Current Voltage Phases Frequency Weight Model power per phase [qty] [Hz] protection [kg] [kW] HRRU1-500 50/60 20,3 29,4 IP 43 FAN CHARACTERISTICS (1 FAN) Input Current Voltage Phases Frequency Speed Model power per phase [qty]... -

Page 8: Installation

4. INSTALLATION INSTALLATION ROOF INSERT [ACCESSORY] • Connecting lifting rods to a crane, forklift, The roof insert is recommended accessories simplifying etc. the connection of the unit to the air duct passing through • Lift the HRV from the pallet and lower it the opening in the roof of the building to the prepared mounting location. - Page 9 4. INSTALLATION ROOF INSETR DIMENSIONS...

-

Page 10: Electrical Installation

4. INSTALLATION ELECTRICAL INSTALLATION POWER WIRING ATTENTION! Before starting to repair or modify the HRV unit, make Two sets of supply cables exit the wiring outlets for sure that the main switch is switched off! connection to the disconnect panels (preheater panel and control/fan panel) as shown in the diagrams below. - Page 11 4 INSTALLATION POWER WIRING Plug and route the power cable through the cable tray into the grommet at the bottom of the unit as shown in the picture below.

- Page 12 4 INSTALLATION ELECTRICAL ACCESSORIES Connect el. accessories of the unit to the terminal box located in inside the controls box according to the diagram of el. wiring and terminal indications. Modbus TCP, BACnet Control panel Control panel 2 2. 2 2. 2 1.

- Page 13 4. INSTALLATION READ CAREFULLY! The wiring diagram is located inside the main cabinet cover (connection side) on the heat exchanger. Each accessory must be connected with the supplied cable or a cable that meets the specifications of each individual component. 16 17 18 19 B (1-2) WATER PUMP (1 - Lint, 2 - Lout)

- Page 14 4. INSTALLATION CONTROL PANEL TECHNICAL DATA To activate the unit, it is necessary to connect the remote BOOST BUTTON [A;13-14] control with the unit using a control cable (data cable) • Low-voltage switching contact: maximum possible contact load 12 V, 0.4 A. Slacken the bolt on the bottom of the remote control •...

-

Page 15: Read Carefully

Connect the other end to the main cont- min 200mm rol unit. For details of the protocol (ModBUS) see 2VV. A controller may also be connected to the unit connected to the a BMS control system... - Page 16 4. INSTALLATION...

-

Page 17: First Operation

ATTENTION! Any interventions or modifications to unit wiring are pro- • hibited and may lead to warranty loss! We recommendusing 2VV approved accessories only. • ACTIVATION To activate the unit (Stand by mode), it is necessary to turn the main switch on (ON= red OFF= green). After acti- vation, the display on the control panel lights up and data download will start. -

Page 18: Maintenance

6. MAINTENANCE ATTENTION! READ CAREFULLY! Warning icon filter replacement disappears • It is recommended to perform a visual inspection of the automatically filter at least once every 3 months. If the user interface panel indicates a clogged filter alarm, replace all filters immediately. ATTENTION! REPLACING FILTERS Device functionality might be reduced or impaired, if the... - Page 19 7. FAULTS REMOVAL ATTENTION! In case of power failure and subsequent recovery of the mains power supply, the unit returns to the state before such failure. The unit always remembers the operating status and all setups. If you fail to find or remove the cause of the fault, or if the repair requires intervention in the device, contact the authorised service ELECTRIC HEATING OVERHEAT...

- Page 20 7. FAULTS REMOVAL ATTENTION! Before starting maintenance and repairs, the unit must be disconnected from the power supply, the supply voltage must be blocked and the service switches must be in position 0 (OFF)! Do not attempt a repair unless you are familiar with the exact procedure. Contact a qualified service centre. TECHNICAL DATA Usually indicated error messages on the display.

- Page 21 DESCRIPTION UNIT STATUS LIKELY PROBLEM SOLUTION Check that the input error is correctly connected to the electronics or, if 14 - ADB module error Unit is working Failure of adiabatic module necessary, that the adiabatic module is operating correctly Check that the input error is correctly connected to the electronics or, if 15 - Heat pump error Unit is working...

- Page 22 7. FAULTS REMOVAL DESCRIPTION UNIT STATUS LIKELY PROBLEM SOLUTION Check that the sensor is correctly connec- 25 – Room temperature sensor Room temperature sensor ted to the electronics or test it measuring its Unit is working failure (T_Room) failure resistance (the resistance value at +20°C is around 10kW) Check the supply point for mechanical damage or whether it is clogged by dirt,...

- Page 23 7. FAULTS REMOVAL DESCRIPTION UNIT STATUS LIKELY PROBLEM SOLUTION 50 - Inlet filter clogged > 80% Unit is working Clogged filter Filter change recommended 51 - Exhaust filter clogged > Unit is ventilating Clogged filter Filter change recommended The automatic protection of the water exchan- The anti-freeze protection of ger has been activated in order to prevent 70 - Anti-freeze protection of...

-

Page 24: Decommissioning Of The Product - Disposal

8. MAINTENANCE IF THE FAULT PERSISTS DECOMMISSIONING PRODUCT - DISPOSAL If you are unable to rectify the fault, contact your supplier. Dispose of the product before disposal. Older units also contain materials that can be reused. Take them to a co- READ CAREFULLY! llection yard. - Page 25 To use the heat recovery unit correctly and safely, you must read this manual and follow the instructions. For any questions or requests for clarification, please do not hesitate to contact our sales or technical support department. CONTACT Address 2VV, s.r.o., Nádražní 794 533 51 Pardubice - Rosice, Czech Republic Internet : http://www.2vv.cz/...

Need help?

Do you have a question about the HRRU1 and is the answer not in the manual?

Questions and answers