Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for 2VV HRFS1-100-XS0S Series

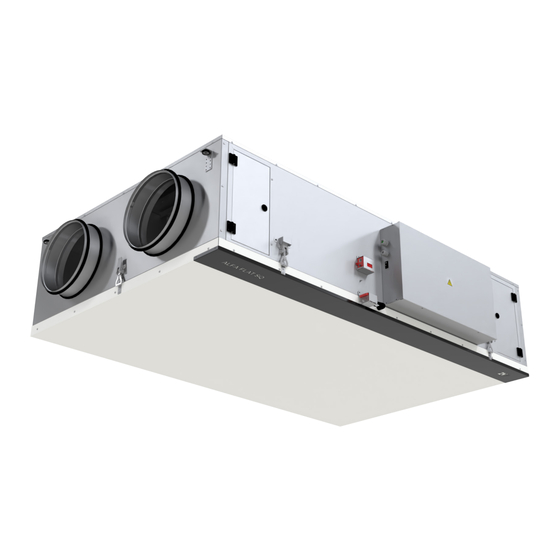

- Page 1 HRFS1 INSTALLATION MANUAL ver.1 09-03-23...

-

Page 2: Table Of Contents

5. TECHNICAL PARAMETERS 6. INSTALLATION 7. COMMISSIONING 8. MAINTENANCE 9. SERVICE 10. TROUBLESHOOTING 11. LIQUIDATION 12. CONCLUSIONS 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23... -

Page 3: Before Starting

The assessment was conducted pursuant to harmonized European standards included in the relevant EC Declaration of Conformity. The current and full version of the EC Declaration of Conformity can be found at www.2vv.cz 2VV. Creating innovative solutions for you and your business since 1995. -

Page 4: Unpacking

2 hours, without turning it on, so that its inner temperature can match the surroundings. 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. -

Page 5: Main Components

Main power switch Regulation Fans El. pre/post-heater Filters Condensate drain RIGHT VERSION LEFT VERSION Top view Top view 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23... -

Page 6: Dimensions

4. DIMENSIONS Right version Top view Left version Top view 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23... -

Page 7: Technical Parameters

Characteristics of electric preheater ΔT (°C) Type Voltage [V] Frequency [Hz] Rated input [kW] 50/60 HRFS1-100...-E... 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23... -

Page 8: Installation

-20° C ~ +60° C and with a relative humidity of 90%. 1200(50*) All the dimensions in the table are in mm 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23... - Page 9 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

- Page 10 YOU WILL NEED ● 4 M8 lock nuts ● 4 threaded rods ● 4 dowels of suitable type and size (depending on the material of the ceiling and the weight of the unit) ● drill with bits of suitable type and size ● pliers and wrenches 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23...

- Page 11 If condensation occurs outside the unit, increase the ventilation in the surroundings of the unit. CONNECTING THE CONDENSATE DRAIN Condensate pump 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23...

- Page 12 = number of phases IP = electrical protec- regulator cover. av = Air flow tion Serial number 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23...

- Page 13 Supply air damper - 230V output 2A fused 230V output for accessories Exhaust air flap - 230V output 4A fan fuse 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23...

- Page 14 CONTROL PANEL RJ45 plug - Ethernet, Modbus TCP, BACnet Modbus RTU (A-25, B-26, 28 or 66-GND) 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23...

- Page 15 (+12V- 27, GND- 28, CANH- 29, CANL- 30) Control panel MODBUS RTU (A-25, B-26, 28 or 66-GND) 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23...

- Page 16 For details on the power supply, refer to the docu- • cable with three conductors mentation of the given accessory. ● CABLE: cable with three conductors of a cross section min. 0.5 mm . Maximum length 50 m. Not included! 24 V 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23...

-

Page 17: Commissioning

After complete download of these data, the unit is ready for operation. 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. -

Page 18: Maintenance

Failure to properly clean (change) the filters may re- duce the performance of the unit and damage the fan. 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. -

Page 19: Service

The location of the safety thermostat is indicated with the marking: RESET located in each unit. RESET RESET 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23... - Page 20 The information can be found on the label next to the fuse or directly on the fuse. READ CAREFULLY! When the power supply is resumed after an outage, the unit returns to the status it was before the outage. The unit always remembers its operational status and settings. If you aren’t able to find or remove the cause of the malfunction, or if the repairs require an intervention on the device, contact an authorised service. 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23...

-

Page 21: Troubleshooting

In service menu 1616 / 18-HW test open the closing dampers and set up 50% on Extract fan, then measure DC voltage signal between terminals 31 and 32 (Extract fan) and check the measured airflow on the HW test screen 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. - Page 22 Check by measurement the functionality of the safety thermostat with automatic reset and then the functionality of the emergency thermostat 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

- Page 23 Check the setting of the time schedule modes that there is not selected automatic mode in case the quality sensor is not physi- cally connected. In such case, delete the particular time schedule and set it up again 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

- Page 24 Check the sensor’s connection to the electronic board – Module A, terminals 45-46 If the connection ok and the fault persists, replace the sensor 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

- Page 25 Check the sensor’s connection to the electronic board – Module B, terminals 44-45 If the connection ok and the fault persists, replace the sensor 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

- Page 26 Check the sensor’s connection to the electronic board – Module B, terminals 40-41 If the connection ok and the fault persists, replace the sensor 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

- Page 27 If the signal LED is flashing on the F module and all pressure sensors are in failure, check the correct connection of the I-BUS cable or functionality of the I-BUS cable itself 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

- Page 28 If the device is equipped with C module and there is pressor sensor failure on more than one, check the correct addressing on all of the pressure sensors (see correct addressing at Errors 26-31) 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

- Page 29 If the signal LED is flashing on the G module and the connection is faultless, the module G is faulty and needs to be replaced 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

- Page 30 If not, the filter calibration must be done (it takes cca 35min.) Start the unit again 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23...

- Page 31 If the device is equipped with other C modules check the correct addressing on all of the pressure sensors (see correct addressing at Errors 26-27) 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

- Page 32 The HEPA air filter would need to be replaced soon What to do / check: Order a new HEPA filter and replace it 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. ver.1 09-03-23...

- Page 33 -up anyway, if during this process the return water temperature gets below 15°C the device switches back to “Water heater waiting for hot water” process. 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

- Page 34 Beware of: When the duct temperature drops below +50°C the heater output is activated for the requested temp. 2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995.

-

Page 35: Liquidation

2VV. Creating innovative solutions for you and your business since 1995. 2VV. Creating innovative solutions for you and your business since 1995. - Page 36 CONTACT Address 2VV, s.r.o., Nádražní 794, 533 51 Pardubice - Rosice, Czech Republic Internet: http://www.2vv.cz/...

Need help?

Do you have a question about the HRFS1-100-XS0S Series and is the answer not in the manual?

Questions and answers