Summary of Contents for Hettich Chiller To Dancer

- Page 1 Instructions for use Cold trap Chiller To Dancer Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 1 / 31...

- Page 2 © 2024 by Hettich AG All rights reserved. No part of this document may be reproduced in any form without written permission from the publisher. Subject to change! Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 2 / 31...

-

Page 3: Table Of Contents

6.2.2 Installation requirements 6.2.3 Setting up the device Filling the tank 6.3.1 Method Connecting the device 6.4.1 Connecting the process 6.4.2 Connecting to the master device Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 3 / 31... - Page 4 Pump is not running, but fan is running Fan not running, but pump is running Compressor does not start Compressor switches off The device has lost performance Disposal Revision history Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 4 / 31...

-

Page 5: Terms And Symbols Used

Attention, general danger point. This symbol indicates safety-relevant information and indicates potentially dangerous situations. Failure to observe these instructions may result in property damage. Note symbol: Wear gloves! Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 5 / 31... -

Page 6: Intended Use And Function

The manufacturer's expected lifespan of the device is five (7) years. The lifespan of some parts and accessories may vary (see chapter 8.2 Maintenance plan). Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 6 / 31... -

Page 7: Storage And Transfer

This manual serves as a comprehensive guide for the construction, function, transport, operation and maintenance of the Chiller To Dancer. It places particular emphasis on its use as a cold trap in the system with the master device CombiDancer II or DancerPlus and the vacuum pump. -

Page 8: Requirements For Operating Personnel

If not ALL instructions in this manual are followed, no warranty claim can be made against the manufacturer. The manufacturer rejects all warranty claims in the event of unauthorized modifications or installation of unauthorized components. Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 8 / 31... -

Page 9: Safety Instructions

Before using the device and accessories, read and follow the operating instructions. Only persons who have read and understood the operating instructions may operate the device. If the Chiller To Dancer is brought into the operating room from a cold environment, condensation may form. In this case, allow the device to acclimatize. -

Page 10: Improper Use

The machine may only be used for its intended purpose and only when in a safe and perfect condition. Faults that may affect safety must be eliminated immediately. The device must not be put into operation until these faults have been eliminated. Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 10 / 31... -

Page 11: Device Overview

Device overview Technical data Manufacturer Christof Fischer Kälte-Klima AG on behalf of Hettich AG, Model Chiller To Dancer Type CH.1000 UDI-DI Mains voltage 100-240V (3.5-1.5A), 50-60Hz Power consumption max. 1000W Device fuse Overvoltage category II (according to IEC 60364-4-443) Device protection class... -

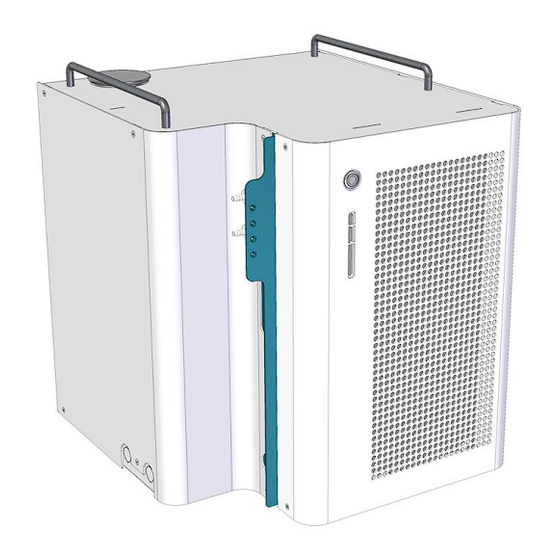

Page 12: Component Overview

12. Air outlet rear 13. Cooling coil (evaporator) 14. Tank container with insulation 15. Circulation pump * Disassembly is only permitted by authorized personnel. Illustration 1: Component overview Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 12 / 31... -

Page 13: Functionality

The cold secondary medium is sucked out of the tank (16) by the pump (18) and fed into a cooling process (6). The heated secondary medium enters the Chiller To Dancer via 7 and flows back into the tank. -

Page 14: Transport And Storage

To return the device or device components via local device dealers, a Return Material Authorization (RMA) number must be requested. For transport conditions see chapter 4.1 Technical data. Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 14 / 31... -

Page 15: Storage

It is recommended to affix a note to the device indicating the date, signature and cleaning/disinfecting solution used. warning In addition, the conditions set out in the previous chapter apply. Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 15 / 31... -

Page 16: Installation And Operation

Installation and operation This section describes the installation process and initial installation of the device. If you have any questions about installation, please contact Hettich AG customer service. Unpacking and lifting If the packaging arrives damaged, this must be confirmed by the transport company and the device must be specifically inspected. -

Page 17: Installation And Connecting

8 g/m³. The device must not be installed outdoors. A collecting tray (for glycol and/or condensate) must be installed below the device. Read the instruction manual. Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 17 / 31... -

Page 18: Setting Up The Device

The ethylene glycol-water mixture should be adjusted so that its freezing point is at least 20 K below the lowest glycol temperature of the cooling process (see also chapter4.1Technical data). Glycol ready mix in container for the Chiller To Dancer (CH.Z099) Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx... -

Page 19: Method

Be careful not to damage the container insulation. c. Make sure the lower outlets are aligned d. Attach the supply hose to the pump into the L-cutout provided. Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 19 / 31... - Page 20 6. Install the left side panel, making sure that no hoses are pinched or kinked. Illustration 5: Filling nozzle Illustration 6: Level indicator Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 20 / 31...

-

Page 21: Connecting The Device

Connecting to the master device The Chiller to Dancer is connected to the master device CombiDancer II or DancerPlus via a 9-pin D-Sub cable. The glycol temperature is measured and controlled by the master device via this interface. Use the original cable and secure the plug with the fastening screws. -

Page 22: Starting And Operating The Device

Start-up - enable cooling and operation The Chiller To Dancer is equipped with an on/off push button on the front. This in turn has a ring light (white). The device is switched on at the push of a button and this is indicated by the active ring lighting (green). -

Page 23: Cleaning And Care

The device and accessories must not be cleaned in a dishwasher or autoclave. Disinfection must always be preceded by cleaning of the relevant components. Observe the concentration and exposure time of the disinfectant according to the manufacturer's instructions. Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 23 / 31... -

Page 24: Cleaning And Disinfection Plan

Regularly check the condenser fins through the air inlet on the front. If necessary, remove the right side panel without power and carefully remove any dirt from the fins using a vacuum cleaner. Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx... -

Page 25: Secondary Circuit

Risk of contamination for the user due to insufficient cleaning or failure to follow cleaning instructions. Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 25 / 31... -

Page 26: Maintenance Plan

Spare parts and accessories Order number Description CH.1000 Chiller To Dancer CH.E100 CH.Z020 Hettich drain pump set CH.Z099 3.0l glycol ready mix in container for the Chiller To Dancer Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 26 / 31... -

Page 27: Emptying The Secondary Circuit

1. Switch off the device using the on/off button so that the ring lighting no longer lights up green. 2. Unscrew the flow hose (upper connection) only at the emission condenser, not at the Chiller To Dancer. Insert it into a suitable collecting vessel and secure it. -

Page 28: Install Tank

20 K. ➢ Check pump level (at least level 2) ➢ Check the temperature sensor at the pump outlet of the secondary medium for contact Hettich AG, Seestrasse 204, 8806 Baech, Switzerland IFU_Chiller to Dancer_en_rev2.0.docx Page 28 / 31... -

Page 29: Fan And Pump Are Not Running, Release Light Is Not Lit

➢ Make sure that the on/off button is pressed and the ring lighting is active ➢ Make sure that a cooling request is present on the master device and sent to the Chiller To Dancer. ➢ Check that the device is operating within its specifications (environmental conditions) ➢... -

Page 30: The Device Has Lost Performance

➢ Check the secondary circuit for contamination and clean if necessary. ➢ Check ethylene glycol mixture ➢ Check pump stage (stage 2) ➢ Check the sight glass in the cooling circuit for bubbles. If bubbles are constantly visible, contact Hettich AG customer service. 10. Disposal Before disposing of the device, device components or accessories, it is necessary to decontaminate and clean it for the safety of people, the environment and property. -

Page 31: 11. Revision History

Revision description Date version First version as a template for Hettich 30.08.2020 Footer page X of Y, doc. name adjusted with rev., chapter 1 added & wording, chapter 2 changed to chapter 1.3, chapter 3 changed to chapter 1.4.0 and note symbols added, chapter 4 changed to chapter 1.5.0 and wording changed, chapter 10 changed to chapter 2.0 and expanded,...

Need help?

Do you have a question about the Chiller To Dancer and is the answer not in the manual?

Questions and answers