Summary of Contents for SCHUNK ROTA-S flex

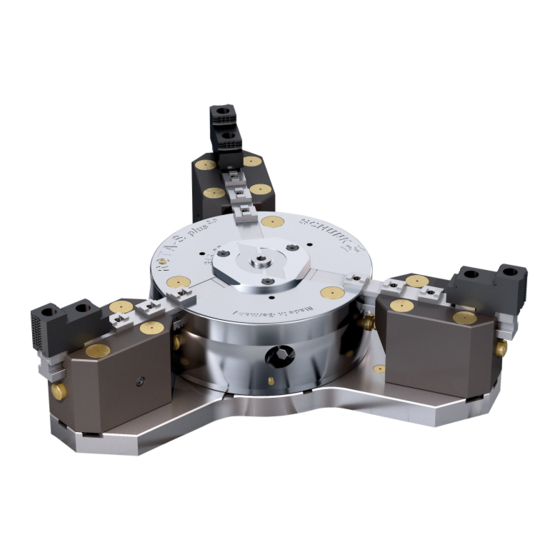

- Page 1 Translation of Original Operating Manual Manual Lathe Chucks ROTA-S flex Assembly and Operating Manual...

- Page 2 Imprint Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Technical changes: We reserve the right to make alterations for the purpose of technical improvement. Document number: 0889139 Version: 06.00 | 14/04/2022 | en...

-

Page 3: Table Of Contents

Handling and jaw change ................... 28 Important notes on the ROTA-S plus or ROTA-S plus 2.0 manual chuck .... 29 Checking the ROTA-S plus or ROTA-S plus 2.0 manual chuck...... 29 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... - Page 4 10 Spare parts ROTA-S flex .................. 32 11 Assembly drawing.................... 33 12 Spare parts ROTA-S plus 2.0 .................. 34 13 Assembly drawing.................... 35 14 Spare parts ROTA-S plus.................. 36 15 Assembly drawing.................... 37 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139...

-

Page 5: General

Non-observance can lead to irreversible injury and even death. CAUTION Dangers for persons! Non-observance can cause minor injuries. CAUTION Material damage! Information about avoiding material damage. WARNING Warning about hand injuries 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 6: Applicable Documents

General terms of business Katalogdatenblatt des gekauften Produkts Calculation of the jaw centrifugal forces ("Technology" chapter in the lathe chuck catalog) The above mentioned documents can be downloaded at www.de.schunk.com. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 7: Basic Safety Instructions

This product may pose a danger to persons and property if, for example: • It is not used as intended; • It is not installed or maintained properly; 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... - Page 8 The larger the clamping diameter, the difference in the linear • expansion coefficient of the workpiece compared to steel and the temperature range, the greater the loss of clamping force. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139...

- Page 9 Wear safety gloves. • Observe the safety and accident prevention regulations during • operation of the chuck, especially in connection with machining centers and other technical equipment. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139...

-

Page 10: Notes On Safe Operation

• Only operate the lathe chuck when all protective equipment has been fitted and is in full working order. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... - Page 11 (clamping force, coefficient of friction, wear characteristics). (For product information about LINOMAX plus, see the "Accessories" chapter of the SCHUNK lathe chuck catalog or contact SCHUNK.) 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139...

- Page 12 Work must be carried out by qualified specialist personnel with the relevant safety training. Use of special chuck jaws When using special chuck jaws, please observe the following rules: 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139...

-

Page 13: Constructional Changes, Attachments Or Modifications

Persons in training may be assigned to machines and technical equipment in which a chuck is mounted only if they are under the constant guidance and supervision of qualified specialists. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 14: Organizational Measures

When using this product, you must comply with the relevant health and safety at work rules and you must use the required personal safety equipment (minimum: category 2). 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 15: Warranty

• Observe the maximum number of clamping cycles • Observe the specified maintenance and lubrication intervals, } 9 [/ 30] Parts touching the workpiece and wear parts are not included in the warranty. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 16: Torques Per Screw

Tightening torques for mounting screws used to attach top jaws onto the chuck (screw quality 12.9) Screw size M10 M12 M14 M16 M20 M24 Max. admissible torque M (Nm) 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 17: Scope Of Delivery

Screws and T-nuts for mounting on the machine table 1 Allan key (up to size 1200 only) 1 Ratchet with adapter 1 Operating Manual ROTA-S flex 1 Operating Manual ROTA-S plus 2.0 or ROTA-S plus 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 18: Technical Data

The recommended speed is valid for ROTA-S flex with long base jaws and SCHUNK stepped block jaws, hard, type STF. In this the base jaws are inserted flush with outer diameter of the chuck. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 19: Clamping Force / Speed Diagrams

Measuring point F / 3 Clamping force per jaw Center of gravity Center of gravity radius Max. jaw center of gravity eccentricity in axial Actuating force direction 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... - Page 20 Technical data ROTA-S flex 550 (with long jaws) ROTA-S flex 700 (with long jaws) ROTA-S flex 1000 (with long jaws) 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139...

-

Page 21: Calculations For Clamping Force And Speed

Mass of one top jaw [kg] Safety factor for clamping force Mass of chuck jaw set [kg] Safety factor for machining Centrifugal force torque [Nm] Σ Max. clamping force of chuck [N] 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 22: Calculation Of The Required Clamping Force In Case Of A Given Rpm

Minimum required clamping force Speed of rotation Reduction in effective clamping force by the magnitude of the total centrifugal force, for gripping from the outside inwards. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... - Page 23 The centrifugal torque of the base jaws M can be found in the table "Chuck data"} 6.1 [/ 18]. The centrifugal torque of the top jaws M is calculated as per: 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139...

-

Page 24: Calculation Example: Required Initial Clamping Force For A Given Speed

For the centrifugal torque of the top jaw, the following applies: Centrifugal torque for one jaw: The chuck has 3 jaws, the total centrifugal torque is: 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 25: Calculation Of The Permissible Speed In Case Of A Given Initial Clamping Force

= 1495 is smaller than the maximum permissible RPM of the chuck n = 3200 (see "Chuck data" } 6.1 table [/ 18]). This calculated RPM may be used. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 26: Grades Of Accuracy

6.3, as well as uneven lubricant application. In order to prevent damage resulting from these residual risks, the entire rotor is to be dynamically balanced in accordance with DIN ISO 21940-11. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 27: Attachment Of The Entire Manual Chuck

Risk of injury from mounting screw brass caps (items 9 and 10) being flung out when chuck turns. The mounting screw brass caps (items 9 and 10) must only be applied for stationary use of the chuck. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 28: Function

If standard jaws are used on the toolholder, the cover (item 4) cannot be mounted. With the ROTA-S flex 1000 size, ensure that the indicator pin is not covered by the cover when screwing on the cover (item 4) -... -

Page 29: Checking The Rota-S Plus Or Rota-S Plus 2.0 Manual Chuck

8.3 Checking the ROTA-S plus or ROTA-S plus 2.0 manual chuck See the ROTA-S plus or ROTA-S plus 2.0Assembly and Operating Manual contained in the scope of delivery. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 30: Maintenance

"Handling and jaw change" Unscrew the screws (item 33) and remove the guideway extension (item 4). Screw out the screws (item 33) and undo the ROTA-S flex from the baseplate (item 3), taking it off to the front. For further disassembly and assembly of the chuck, see the ROTA- S plus or ROTA-S plus 2.0 Assembly and Operating Manual. -

Page 31: At Least Once A Month

Before installation, lubricate all individual components with LINOMAX special grease. This cleaning procedure should be performed about every 200 operating hours, depending on the extent of stress on the chuck. 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 32: Spare Parts Rota-S Flex

Cylindrical screws Cylindrical screws Cylindrical screws Nut for T-slot Cylindrical screws Cylindrical screws O-ring Feather keys Mounting bolts Wiper Locking screw Spanner wrench 65/83 Ratchet with adapter 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 33: Assembly Drawing

Assembly drawing 11 Assembly drawing ROTA-S flex 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... -

Page 34: Spare Parts Rota-S Plus 2.0

Flat lens head screw (starting from size 200) Lubrication nipples Compression spring for indicator O-ring Cylindrical pin Eye bolt (starting from size 250) 1 Insert Assembly key 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... - Page 35 Assembly drawing 13 Assembly drawing ROTA-S plus 2.0 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139...

- Page 36 Lubrication nipple for spindle Lubrication nipple for chuck body Screw DIN EN ISO 4762 (cover) Screw DIN EN ISO 4762 Safety disk (from size ROTA-S plus 500) Compression spring Set-screw 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139...

-

Page 37: Assembly Drawing

Assembly drawing 15 Assembly drawing ROTA-S plus 06.00 | ROTA-S flex | Assembly and Operating Manual | en | 0889139... - Page 40 Translation of Original Operating Manual H.-D. SCHUNK GmbH & Co. Spanntechnik KG Lothringer Str. 23 D-88512 Mengen Tel. +49–7572-7614-0 Fax +49-7572-7614-1099 info@de.schunk.com schunk.com Folgen Sie uns I Follow us...

Need help?

Do you have a question about the ROTA-S flex and is the answer not in the manual?

Questions and answers