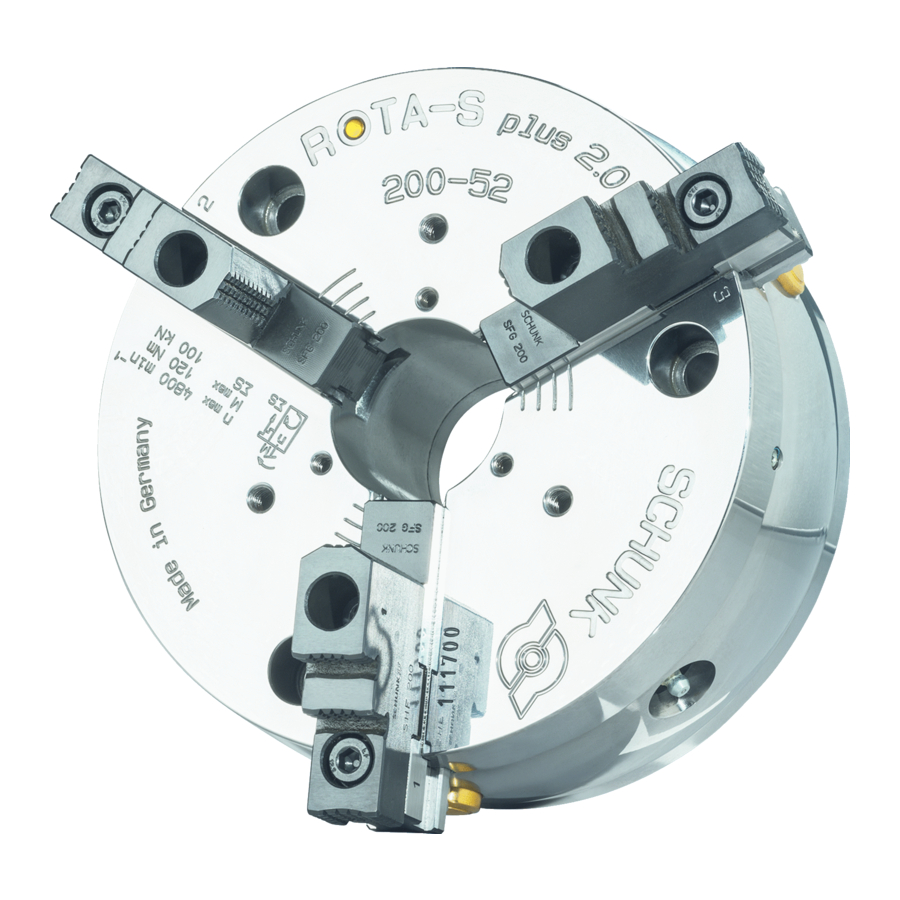

SCHUNK ROTA-S plus 2.0 Series Assembly And Operating Manual

Manual chuck with jaw lock

Hide thumbs

Also See for ROTA-S plus 2.0 Series:

- Assembly and operating manual (40 pages) ,

- Assembly and operating manual (44 pages)

Summary of Contents for SCHUNK ROTA-S plus 2.0 Series

- Page 1 Translation of the original manual Manual chuck ROTA-S plus 2.0 with jaw lock Assembly and Operating Manual Superior Clamping and Gripping...

- Page 2 Imprint Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Technical changes: We reserve the right to make technical improvements. Document number: 0889002 Version: 07.00 |2/24/2021|en-US Dear Customer Dear Customer, Thank you for putting your trust in our products and our family-owned company, the leading technology supplier of robots and production machines.

-

Page 3: Table Of Contents

Table of Contents Table of Contents 1 About this Manual ....................5 1.1 Illustration of safety notes ..................5 1.2 Applicable documents ....................6 2 Basic safety notes ..................... 7 2.1 Appropriate use ......................7 2.2 Inappropriate use ..................... 7 2.3 Notes on particular risks ................... - Page 4 Table of Contents 9 Maintenance ......................35 9.1 Disassembling and assembling the chuck .............. 35 9.2 Jaw change ......................37 9.3 At least once a month .................... 37 9.4 In the case of decreasing clamping force or after about 200 operating hours ..38 9.5 Maintenance intervals ....................

-

Page 5: About This Manual

About this Manual About this Manual This manual contains important information for the safe, correct use of the product. The manual is an integral part of the product and must be kept accessible by personnel at all times. Personnel must have read and understood this manual before beginning any work. -

Page 6: Applicable Documents

• Catalog data sheet for purchased product * • Calculation of the jaw centrifugal forces, in the chapter "Technology" of the lathe chuck catalog * The documents indicated with an asterisk (*) can be downloaded from schunk.com. 07.00|0889002_ROTA-S plus 2.0 with jaw lock |en-US... -

Page 7: Basic Safety Notes

Report any failures and damage immediately and repair without delay to keep the extent of the damage to a minimum and prevent compromising the safety of the product. Only original SCHUNK spare parts may be used. Appropriate use This product is intended for clamping workpieces on lathes and other suitable machine tools. -

Page 8: Notes On Particular Risks

Basic safety notes Notes on particular risks This product may pose a danger to persons and property if, for example: • it is not used as intended; • it is not installed or maintained properly; • the safety and installation instructions, local applicable safety and accident prevention regulations or the EC Machinery Directive are not observed. - Page 9 Basic safety notes WARNING Risk of injury due to dropping the chuck during transport, installation or removal. • Take special care in the danger zone when transporting, installing or removing the lathe chuck. • Note the relevant load securing regulations for working safely with cranes, ground conveyors, lifting gear and load-handling equipment.

-

Page 10: Notes On Safe Operation

Basic safety notes CAUTION Risk of damage due to incorrect choice of clamping position for chuck jaws on workpiece. If an incorrect clamping position is chosen for the chuck jaws on workpiece, the base and top jaws may break. • Make sure that the workpiece is clamped concentrically. •... - Page 11 (clamping force, coefficient of friction, wear characteristics). (For product information about LINOMAX plus, see the "Accessories" chapter of the SCHUNK lathe chuck catalog or contact SCHUNK.) 07.00|0889002_ROTA-S plus 2.0 with jaw lock |en-US...

- Page 12 Basic safety notes • Use a suitable high-pressure grease gun to ensure that you reach all the greasing areas. • To ensure correct distribution of the grease, move the lathe chuck to its end positions several times, lubricate again, and then check the clamping force.

- Page 13 • If the lathe chuck is involved in a collision, it must be subjected to a crack test before using it again. Damaged parts must be replaced with original SCHUNK spare parts. • Renew the chuck jaw mounting bolts if there are signs of wear or damage.

-

Page 14: Structural Changes

• Structural changes should only be made with the written approval of SCHUNK. Personnel qualification The lathe chuck must only be installed, removed, started up, operated and serviced by qualified specialist personnel with the relevant safety training. -

Page 15: Personal Protective Equipment

Only allow specialists to remedy malfunctions. Spare parts Only ever use original SCHUNK spare parts. Environmental regulations Comply with the applicable legal norms when disposing of waste. Personal protective equipment... -

Page 16: Warranty

Technical data Warranty If the product is used as intended, the warranty is valid for 60 months from the date of delivery from the production facility or 50 000 cycles* under the following conditions: • Refer to the applicable documents, (... -

Page 17: Technical Data

Functional monitoring must be performed according to the guidelines of the insurance association. The recommended speed is valid for ROTA-S plus 2.0 with SCHUNK stepped block jaws, hard, type STF. For this, the base jaws are inserted flush with outer diameter of the chuck. -

Page 18: Clamping Force Rpm Diagrams

In the determination process, the maximum actuating force was applied and the jaws were set flush with the outer diameter of the chuck. The chuck is in perfect condition and lubricated with SCHUNK LINOMAX plus special grease. Should one or several of above-mentioned parameters be changed, the diagrams will no longer be valid. - Page 19 Technical data Clamping force RPM diagram ROTA-S plus 2.0 160-42 - 3 jaws Clamping force RPM diagram, ROTA-S plus 2.0 200-62 - 3 jaws Clamping force RPM diagram ROTA-S plus 2.0 250-52 - 3 jaws 07.00|0889002_ROTA-S plus 2.0 with jaw lock |en-US...

- Page 20 Technical data Clamping force RPM diagram, ROTA-S plus 2.0 315-92 - 3 jaws Clamping force RPM diagram ROTA-S plus 2.0 160-42 - 2 jaws Clamping force RPM diagram, ROTA-S plus 2.0 200-62 - 2 jaws 07.00|0889002_ROTA-S plus 2.0 with jaw lock |en-US...

- Page 21 Technical data Clamping force RPM diagram ROTA-S plus 2.0 250-52 - 2 jaws Clamping force RPM diagram, ROTA-S plus 2.0 315-92 - 2 jaws 07.00|0889002_ROTA-S plus 2.0 with jaw lock |en-US...

-

Page 22: Calculating The Clamping Force And Rpm

Technical data Calculating the clamping force and RPM Missing information or specifications can be requested from the manufacturer. Legend Total centrifugal force [N] Centrifugal torque of top jaws [kgm] Effective clamping force [N] Centrifugal torque of base jaws [kgm] Minimum required clamping force Speed of rotation [RPM] spmin Initial clamping force [N]... - Page 23 Technical data Reduction in effective clamping force by the magnitude of the total centrifugal force, for clamping from the outside inwards. The required effective clamping force for machining F calculated from the product of the machining force F and the safety factor S .

-

Page 24: Calculation Example: Required Initial Clamping Force Fsp0 For A Given Rpm N

Technical data NOTICE For safety reasons, in accordance with DIN EN 1550, the centrifugal force may be a maximum of 67% of the initial clamping force. The formula for the calculation of the total centrifugal force F For this, n is the given speed of rotation in . -

Page 25: Calculation Of The Permissible Speed Of Rotation Nperm In Case Of A Given Initial Clamping Force Fsp0

Technical data Note: Masses of the jaw mounting screws and T-nuts are not taken into account. First the required effective clamping force F is calculated using the machining force stated: Initial clamping force during shutdown: Calculation of total centrifugal force: For two-part chuck jaws, the following applies: Centrifugal torque of base jaw and top jaw specified in "Chuck data"... -

Page 26: Accuracy Classes

Technical data NOTICE The calculated permissible RPM may not exceed the maximum RPM inscribed on the chuck for safety reasons! Example of calculation: Permissible RPM for a given effective clamping force The following data is known from previous calculations: • Initial clamping force during shutdown F = 17723 N •... -

Page 27: Attachment Of The Manual Lathe Chuck

Attachment of the manual lathe chuck Attachment of the manual lathe chuck The item numbers specified for the corresponding individual components relate to the drawing in chapter "Drawings" ( 12, Page 41). Handling prior to attachment Before mounting on the lathe, remove the base jaws from the chuck, then re-install the base jaws and turn the spindle several times as far as it will go to the right and left. -

Page 28: Assembly Of The Manual Lathe Chuck

Attachment of the manual lathe chuck NOTICE When mounting with the intermediate flange, never allow the outer rim of the chuck body to make contact. The flange must support on the entire surface. ROTA-S plus 2.0 chucks are delivered with different short taper mountings. -

Page 29: Function

Function Function The item numbers specified for the corresponding individual components relate to the drawing in chapter "Drawings" ( 12, Page 41). Handling and jaw change NOTE: For rotating lathe chucks, the centrifugal forces applied can cause the indicator pin to emerge from the chuck body. When the lathe chuck comes to a stop, the indicator pin must be reinserted. - Page 30 Function Oil the cleaned pressure bolt; do not grease with chuck grease! • Adjust exchanged jaws until the desired clamping diameter has been reached. The slides (item 12) must snap in when doing this. NOTICE Actuating the chuck if a jaw is not engaged will damage the chuck! Manually move the jaw back and forth without actuating the pressure bolt.

-

Page 31: Important Notes

Function Jaw change If you turn the spindle to the right, the indicator pin (item 17) will protrude from the chuck body (item 1) (gold-colored pin). WARNING If the indicator pin protrudes, the entire serration of the wedge bars (items 5 and 6) no longer engages into the base jaws. The base jaws are not sufficiently engaged by the wedge bars. -

Page 32: Checking The Chuck

Function • Regularly adjust the lathe chuck during operation to compensate for loss of clamping force caused by vibrations. • Following a longer period of shutdown (more than 8 hours), always re-tension the clamped chuck in order to compensate for the spindle settling and the resulting loss of clamping force. •... -

Page 33: True Running Check

Function True running check (on delivery of ROTA-S plus 2.0 with STF/SHF hard jaws ground on the chuck) To check the radial and axial run-out accuracy, hardened and ground test pins or test disks are clamped (see Fig. "True running check"). - Page 34 Function True running check 07.00|0889002_ROTA-S plus 2.0 with jaw lock |en-US...

-

Page 35: Maintenance

For this reason, it is recommended to regularly clean the chuck and lubricate it using SCHUNK LINOMAX plus special grease. CAUTION Allergic reactions if lubricating grease comes into contact with the skin. - Page 36 Maintenance WARNING Risk of injury due to dropping the manual lathe chuck during transport, installation or removal During transport and when installing or detaching the manual chuck, ensure it does not fall off. • Remove the jaws from the guideways (see chapter "Handling and jaw changes"...

-

Page 37: Jaw Change

Maintenance Replace damaged parts with original SCHUNK spare parts only! Before installation, lubricate all individual components with LINOMAX plus grease. Assembly The chuck is assembled in the reverse order. Observe the following when doing this: • Do not forget any parts! Even small components are essential for the safety of the lathe. -

Page 38: In The Case Of Decreasing Clamping Force Or After About 200 Operating Hours

In this case, disassemble the chuck, carefully clean all parts with degreasing agent and check for wear and damage. Replace damaged parts with original SCHUNK spare parts only! Before installation, lubricate all individual components with SCHUNK LINOMAX plus special grease. -

Page 39: Disposal

• Dispose of the chuck's metal parts as scrap metal. Alternatively, you can return the chuck to SCHUNK for proper disposal. 07.00|0889002_ROTA-S plus 2.0 with jaw lock |en-US... -

Page 40: Spare Parts

Spare parts Spare parts When ordering spare parts, it imperative to state the type, size, and, above all, the manufacturing no. of the chuck. Seals, sealing elements, screw connections, springs, bearings, screws, wiper bars and parts that come into contact with the workpiece are not covered by the warranty. -

Page 41: Assembly Drawing

Assembly drawing Assembly drawing 07.00|0889002_ROTA-S plus 2.0 with jaw lock |en-US...

Need help?

Do you have a question about the ROTA-S plus 2.0 Series and is the answer not in the manual?

Questions and answers