Summary of Contents for Kemppi Minarc T 223 ACDC

- Page 1 Minarc T 223 ACDC Operating manual - EN Minarc T 223 ACDC © Kemppi 1922350 / 2413...

-

Page 2: Table Of Contents

Minarc T 223 ACDC Operating manual - EN CONTENTS 1. General 1.1 Equipment description 1.2 Minarc T 223 ACDC power source 1.2.1 Minarc T 223 ACDC welding performance 1.3 Cooling unit (optional) 2. Installation 2.1 Installing cooling unit (optional) 2.2 Installing equipment on cart (optional) 2.3 Connecting earth return cable... - Page 3 Minarc T 223 ACDC Operating manual - EN 5. Technical data 5.1 Minarc T 223 ACDC power source 5.2 Master Cooler 05M cooling unit 5.3 TIG guide tables 5.4 Minarc T 223 ACDC ordering info © Kemppi 1922350 / 2413...

-

Page 4: General

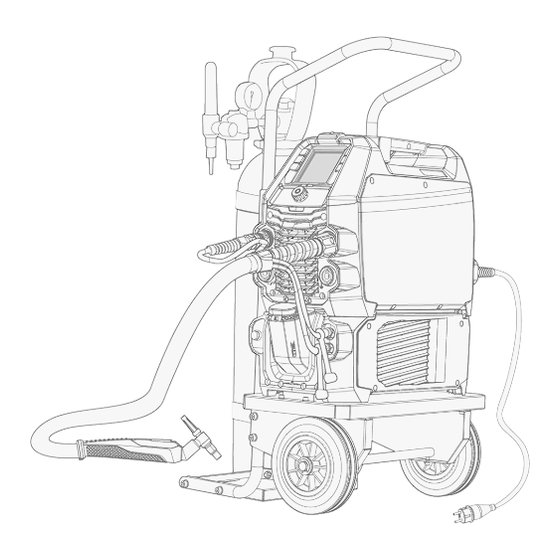

Cooler 05M cooling unit and an optional cart. The Minarc T 223 ACDC power source is suitable for TIG and pulsed TIG welding with both direct current (DC) and altern- ating current (AC), as well as MMA welding with DC current. Minarc T 223 ACDC can also be used for post-weld cleaning and polishing to remove impurities from the welded area. -

Page 5: Equipment Description

>> Multi-voltage and generator compatible power source >> A VRD (voltage reduction device) model version, where the VRD function is locked on is also available. For the power source part descriptions, refer to "Minarc T 223 ACDC power source" on the next page. Control panel •... -

Page 6: Minarc T 223 Acdc Power Source

Minarc T 223 ACDC Operating manual - EN 1.2 Minarc T 223 ACDC power source Front Lifting handle (also for mechanical lifting when the power source is not installed on a cooling unit or cart) Control panel (and hinged control panel cover) - Page 7 Minarc T 223 ACDC Operating manual - EN Rear Shielding gas hose connector Remote control connector Power switch Mains cable Rear locking interface >> For locking on top of the cooling unit or on the cart. © Kemppi 1922350 / 2413...

-

Page 8: Minarc T 223 Acdc Welding Performance

Operating manual - EN 1.2.1 Minarc T 223 ACDC welding performance The following describes the welding performance of Minarc T 223 ACDC. For technical data, refer to "Minarc T 223 ACDC power source" on page 54. Minarc T 223 ACDC welding performance (40°C) -

Page 9: Cooling Unit (Optional)

Minarc T 223 ACDC Operating manual - EN 1.3 Cooling unit (optional) The cooling unit is not available for Minarc T 223 ACDC with 110...120 V supply voltage. Front Front locking interface >> For locking to the power source Cooler container cap... - Page 10 Minarc T 223 ACDC Operating manual - EN Rear Rear locking interface >> For locking to the power source Rear locking interface >> For locking on the cart. © Kemppi 1922350 / 2413...

-

Page 11: Installation

There can be potential difficulties in ensuring electromagnetic compatibility in those locations, due to conducted as well as radiated radio-frequency disturbances. Minarc T 223 ACDC: This equipment complies with IEC 61000-3-12 and can be connected to public low-voltage sys- tems. -

Page 12: Installing Cooling Unit (Optional)

Minarc T 223 ACDC Operating manual - EN 2.1 Installing cooling unit (optional) The cooling unit is not available for Minarc T 223 ACDC with 110...120 V supply voltage. The cooling unit must be installed by authorized service personnel. Tools needed: Remove the small connector cover in the rear of the power source. - Page 13 Minarc T 223 ACDC Operating manual - EN Fix the units together with two screws (M5x12) in the front. Connect the cooling unit cables. Replace the small connector cover. © Kemppi 1922350 / 2413...

-

Page 14: Installing Equipment On Cart (Optional)

Operating manual - EN 2.2 Installing equipment on cart (optional) Minarc T 223 ACDC has two transport unit options: a 2-wheel cart with a gas bottle rack (T22M) and a 2-wheel cart without a gas bottle rack (T32A). You can install the power source on the T22M cart with or without the cooling unit. - Page 15 Minarc T 223 ACDC Operating manual - EN Fix the power source to the cart with two screws (M5x12) in the front. To install the power source and the cooling unit on the T22M cart: Install the cooling unit on the cart.

- Page 16 Minarc T 223 ACDC Operating manual - EN Fix the cooling unit to the cart with two screws (M5x12) in the front. Install the power source on top of the cooling unit. Refer to "Installing cooling unit (optional)" on page 12 for install- ation details.

- Page 17 Minarc T 223 ACDC Operating manual - EN For lifting the equipment, refer to "Lifting equipment" on page 43. © Kemppi 1922350 / 2413...

-

Page 18: Connecting Earth Return Cable

Minarc T 223 ACDC Operating manual - EN 2.3 Connecting earth return cable Keep the work piece connected to earth to reduce the risk of injury to users or damage to electrical equipment. Connect the earth return cable to the earth return cable connector on the power source. -

Page 19: Connecting Tig Welding Torch

Minarc T 223 ACDC Operating manual - EN 2.4 Connecting TIG welding torch Minarc T 223 ACDC is designed to be used with the Kemppi Flexlite TX TIG welding torches. For more information, refer Kemppi Userdoc. Connect the control cable (1) and welding cable (2) to the corresponding connectors in the power source. Secure by turning the connectors clockwise. -

Page 20: Connecting Mma Electrode Holder

Minarc T 223 ACDC Operating manual - EN 2.5 Connecting MMA electrode holder Connect the MMA electrode holder to the corresponding connector in the power source. © Kemppi 1922350 / 2413... -

Page 21: Installing Remote Control

Remote controls are optional. Connect the remote control to the Minarc T 223 ACDC power source or the Flexlite TX welding torch. To enable remote operation, set the remote mode in the control panel (refer to "Minarc T 223 ACDC con- trol panel"... -

Page 22: Installing Gas Bottle And Testing Gas Flow

- Install the welding torch to the power source before installing and testing the gas bottle. Contact your local Kemppi dealer for choosing the gas and the equipment. Without gas bottle cart:Place the gas bottle in a suitable, secure location. - Page 23 Minarc T 223 ACDC Operating manual - EN Open the gas bottle valve. Start gas test by long-pressing the control panel's control knob button in the main view. By default, the gas test time is 20 s. During the gas test, you can adjust the time (between 0 ... 60 s, step 1 s) by turn- ing the control knob.

-

Page 24: Operation

Minarc T 223 ACDC Operating manual - EN 3. OPERATION Before using the equipment, ensure that all the necessary installation actions have been completed according to your equipment setup and instructions. Welding is forbidden in places where there is an immediate fire or explosion hazard! The welding device is intended for use in environments where the risk of electric shock is not increased. -

Page 25: Preparing Welding System For Use

If the machine is left unused for a longer period, detach the mains plug to disconnect it from the mains. Preparing cooler Fill the coolant container inside the cooler with Kemppi cooling liquid and bleed the cooler before use. For instructions on filling and bleeding the cooler, refer to "Preparing cooler" below. - Page 26 Minarc T 223 ACDC Operating manual - EN To fill the cooler: Open the cooler cap. Fill the cooler with coolant. Do not fill over the max. marking. Close the cooler cap. To bleed the cooler: Connect the bleeding hose included in the cooler delivery package to the coolant outlet connector.

- Page 27 Minarc T 223 ACDC Operating manual - EN © Kemppi 1922350 / 2413...

-

Page 28: Minarc T 223 Acdc Control Panel

3.2 Minarc T 223 ACDC control panel This section describes the controls and features of the Minarc T 223 ACDC control panel. You can access different parameter adjustments and setups by pressing the physical buttons (2-7 in the figure below). - Page 29 Minarc T 223 ACDC Operating manual - EN >> Long press: Toggles between remote control modes (hand/foot pedal remote, torch remote and remote control OFF). A remote control must be connected to the welding device or welding torch. Factory reset To reset the device to factory settings, long-press the Trigger logic button (4) and the Process and remote control button (7) simultaneously.

-

Page 30: Main View

Torch remote control After each weld, a weld summary ("Weld data" on page 35) is displayed for 5 s. To update the control panel software, contact your local Kemppi service. 3.2.1 Main view Main view is the main welding view. The content displayed depends on the welding process and features and functions used. -

Page 31: Welding Parameters

Minarc T 223 ACDC Operating manual - EN Control knob functions in the main view: • TIG: >> Welding current adjustment >> Long press of the control knob button starts gas test (during the gas test, you can adjust the gas test time by turning the control knob) •... - Page 32 Minarc T 223 ACDC Operating manual - EN Adjusting welding parameters Turn the control knob so that the orange line appears at the desired welding parameter (here the Upslope para- meter is used as an example). Press the control knob button to select the welding parameter for adjustment.

- Page 33 For more information, refer to "Trigger logic func- tions" on page 37. For information on setting Minilog to ON, refer to "Minarc T 223 ACDC control panel" on page 28. Downslope 0.0 ... 1.5 s, step 0.1 Downslope is a welding function that Default = 0.1 s...

-

Page 34: Memory Channels

Minarc T 223 ACDC Operating manual - EN Water cooling OFF/Auto/ON When ON is selected, the coolant is cir- Default = Auto culated continuously, and when Auto is selected, the coolant is circulated only during welding. Remote control min Min = Current limit minimum... -

Page 35: Weld Data

Minarc T 223 ACDC Operating manual - EN Saving changes to memory channel Adjust a parameter value. The channel number framed by a dashed line indicates that the set parameters are different from the ones currently saved on the active memory channel: Long-press the memory channels button. -

Page 36: Additional Guidance To Functions And Features

Minarc T 223 ACDC Operating manual - EN 3.3 Additional guidance to functions and features This section summarizes some of the Minarc T 223 ACDC functions and features and how to use them. 3.3.1 TIG processes and current modes AC TIG AC (alternating current) TIG is a TIG current mode where the polarity of the electrode alternates rapidly between positive and negative. -

Page 37: Ignition Modes In Tig Welding

Minarc T 223 ACDC Operating manual - EN >> To take pulse TIG into use, press the pulse TIG button in the control panel. >> To adjust the pulse frequency, long-press the pulse TIG button. The value ranges are listed in the following table. - Page 38 Minarc T 223 ACDC Operating manual - EN In 2T cleaning/polishing, pressing the trigger down ignites the current. Releasing the trigger switches the current off. In 4T welding, pressing the trigger starts the pre gas, and releasing the trigger ignites the arc. Pressing the trigger again switches the arc off.

-

Page 39: Mma Functions And Features

Minarc T 223 ACDC Operating manual - EN 3.3.4 MMA functions and features MMA antifreeze MMA antifreeze function automatically decreases the welding current significantly when the electrode is touching the workpiece. The function can be used to prevent the MMA electrode from getting too hot when it is in contact with the workpiece. -

Page 40: Using Remote Control

To enable remote control operation, select the remote control mode by long-pressing the control panel's Process and remote control button (refer to "Minarc T 223 ACDC control panel" on page 28). The hand or foot pedal remote control can be used simultaneously with the TXR20 torch remote control. - Page 41 Minarc T 223 ACDC Operating manual - EN When the TXR10 remote control is used, current adjustment from the control panel is not possible. TXR20 torch remote control To adjust current, pull/push the rocker switch. When the TXR20 torch remote control is used, the remote control symbol is not displayed and current can be adjusted on the control panel.

-

Page 42: Cleaning And Polishing Weld

Choose the cleaning liquid (e.g., 10...60 % phosphoric acid) and the neutralization liquid (e.g., water) based on the application. To clean/polish a weld: Attach Kemppi's MAX WeldClean cleaning tool to a TIG welding torch body (for more information, refer to Kemppi Userdoc). -

Page 43: Lifting Equipment

Minarc T 223 ACDC Operating manual - EN 3.6 Lifting equipment If a gas bottle is installed on cart, DO NOT attempt to lift the cart with the gas bottle in place. Transportation handle: The transportation handle can be used for mechanical lifting (for moving only, not for hanging) when the device is not mounted on a cooling unit or cart. - Page 44 Minarc T 223 ACDC Operating manual - EN 2-wheel cart: Ensure that the welding equipment is properly secured to the cart. Connect the hoist hook to the lifting handle on the cart. Do not lift the device when it is installed on the T32A cart.

-

Page 45: Maintenance

Minarc T 223 ACDC Operating manual - EN 4. MAINTENANCE When considering and planning routine maintenance, consider the operating frequency of the welding system and the working environment. Correct operating of the welding machine and regular maintenance helps you avoid unnecessary downtime and equip- ment failure. -

Page 46: Daily Maintenance

Minarc T 223 ACDC Operating manual - EN 4.1 Daily maintenance Disconnect the power source from the mains before handling electrical cables. Welding machine maintenance Follow these maintenance procedures to maintain the proper functioning of the welding machine: • Check that all covers and components are intact. -

Page 47: Periodic Maintenance

Minarc T 223 ACDC Operating manual - EN 4.2 Periodic maintenance Only qualified service personnel is allowed to carry out periodic maintenance. Only an authorized electrician is allowed to carry out electrical work. Before removing the cover plate, disconnect the power source from the mains and wait for about 2 minutes before discharging the capacitor. -

Page 48: Service Workshops

Minarc T 223 ACDC Operating manual - EN 4.3 Service workshops Kemppi Service Workshops complete the welding system maintenance according to the Kemppi service agreement. The main aspects in the service workshop maintenance procedure are: • Cleanup of the machine •... -

Page 49: Troubleshooting

Minarc T 223 ACDC Operating manual - EN 4.4 Troubleshooting The problems listed and the possible causes are not definitive, but suggest some typical situations that may turn up during normal use of the welding system. Welding device: Problem Recommended actions The welding device does not power up Check that the mains cable is plugged in properly. -

Page 50: Error Codes

Too long welding session with high power or Do not turn off the cooler. Let the liquid circulate until the high ambient temperature. fans cool it down. If fans are not running, contact Kemppi ser- vice. No cooling liquid or circulation is blocked. -

Page 51: Installing And Cleaning Power Source Air Filter (Optional)

Minarc T 223 ACDC Operating manual - EN 4.6 Installing and cleaning power source air filter (optional) An optional power source air filter can be purchased separately. The air filter comes with a fixed casing designed to be mounted directly onto the power source air intake. -

Page 52: Disposal

The owner of the equip- ment is obliged to deliver a decommissioned unit to a regional collection center, as per the instructions of local author- ities or a Kemppi representative. By applying these European Directives you improve the environment and human health. -

Page 53: Technical Data

5. TECHNICAL DATA Technical data: • For Minarc T 223 ACDC power source technical data, refer to "Minarc T 223 ACDC power source" on the next page. • For cooling unit technical data, refer to "Master Cooler 05M cooling unit" on page 57. -

Page 54: Minarc T 223 Acdc Power Source

Minarc T 223 ACDC Operating manual - EN 5.1 Minarc T 223 ACDC power source Minarc T 223 ACDC GM Minarc T 223 ACDC GM Feature Value Mains connection voltage 220...240 V ±10 % Mains connection voltage MV low range 110...120 V ±10 %... - Page 55 520 x 250 x 379 mm Weight without accessories 16.8 kg Standards EN IEC 60974-1, -3, -10 IEC 61000-3-12 Minarc T 223 ACDC GM AU (VRD locked on) Minarc T 223 ACDC GM AU Feature Value Mains connection voltage 230...240 V ±10 %...

- Page 56 Minarc T 223 ACDC Operating manual - EN Output at +40 °C, rated max current, TIG 220 A Output at +40 °C, 60% TIG 170 A Output at +40 °C, 100% TIG 160 A Output, duty cycle % at rated max current, TIG...

-

Page 57: Master Cooler 05M Cooling Unit

Minarc T 223 ACDC Operating manual - EN 5.2 Master Cooler 05M cooling unit Master Cooler 05M Feature Value Supply voltage 380...460 V ±10 % Supply voltage MV low range 220...230 V ±10 % Maximum supply current [I 0.7 A... -

Page 58: Tig Guide Tables

Minarc T 223 ACDC Operating manual - EN 5.3 TIG guide tables The tables in this chapter are given only as a general guidance. The information provided is based solely on the use of WC20 (grey) electrode and Argon gas. -

Page 59: Minarc T 223 Acdc Ordering Info

Minarc T 223 ACDC Operating manual - EN 5.4 Minarc T 223 ACDC ordering info For Minarc T 223 ACDC ordering information and optional accessories, refer to Kemppi.com. © Kemppi 1922350 / 2413...

Need help?

Do you have a question about the Minarc T 223 ACDC and is the answer not in the manual?

Questions and answers