Table of Contents

Summary of Contents for MAX power RETRACT R600

- Page 1 MANUAL MAX POWER RETRACT R600 SERIES THRUSTERS BUILT BY________________ DELIVERED _______________ A copy of this manual must remain on board for consultation. INSTALLATION MANUAL RETRACT R 600 Last update: November 2023...

-

Page 2: Table Of Contents

CONTENTS INTRODUCTION CONTACTING MAX POWER IMPORTANT GENERAL INFORMATION CHECK LIST FOR THE PROJECT MANAGER DETERMINING BEST EQUIPMENT LOCATION OF THE RETRACT THRUSTER UNIT OF THE AUXILIARY EQUIPMENT INSTALLATION PROCEDURES CONSTRUCTION OF THE MOUNTING BASE THRUST PLATES CONSTRUCTION OF HULL OPENING & CLOSING PLATE... -

Page 3: Important General Information

INTRODUCTION AFTER SALES SERVICE ADDRESS : MAX POWER Via Philips 5, 20900, Monza (MI), Italy TEL : + 39 039 200 1973-936 Email: RETRACT SERIAL N° S 0 1. R600. _. _ _ IMPORTANT GENERAL INFORMATION With a constant concern of improving our products, we reserve the right to make changes to this manual without prior notification. -

Page 4: Determining Best Equipment Location

IMPORTANT: All Test readings must be filled out on the form provided and sent to Max Power by email no later than one week after the water tests have been completed so that the Max Power standard warranty is correctly validated. This form is attached at the end of this manual. -

Page 5: Installation Procedures

IMPORTANT: Always check and make sure that there is enough room to allow for complete removal of the RETRACT unit, and room for the connection of the hydraulic piping. LOCATION OF THE AUXILIARY EQUIPMENT The transmission lube oil tank and the hydraulic directional valve should be located near the RETRACT unit, but in an accessible and dry place. -

Page 6: Construction Of Hull Opening & Closing Plate

IMPORTANT: In both cases, the top surface of the mounting base (the flange) must be given particular attention and machined perfectly flat in order to accept the « O » ring seal of the RETRACT base flange and ensure perfect water tightness. The bolts fixing the RETRACT onto the mounting flange must be inserted from top to bottom. -

Page 7: Final Fitting Of The Retract Unit To The Mounting Base

RAISE / LOWER POWER PACK INSTALLATION The Max Power raise/lower powerpack, ref. 313352, consists of a 1,1 kw 4 poles 3Ph 380/400V- 50HZ AC motor, a fixed displacement 6.2cc gear pump (flow 9 LPM) and a 30 lt vertical rectangular oil tank. The AC motor of the powerpack will need to be supplied by a switchboard and protected by a dedicated circuit breaker. -

Page 8: Hydraulic Power System Installation

HYDRAULIC POWER SYSTEM INSTALLATION Hydraulic power system general A RETRACT R600 can take up to 200 LPM of hydraulic flow this will causes on a normal installation 250 bar pressure at the thruster’s inlet ports. NOTE variations of approximately 10% are possible depending on hull shape and immersion depth. -

Page 9: Electrical System Installation

Mounting the reservoir too low could result in oil draining back, or overflowing the tank. Be sure to allow enough space above the reservoir to service the filter. If the reservoir is not supplied by MAX POWER, then provide a return filter of 60 microns and a suction strainer. -

Page 10: Control Panel And Control Box Functions

24 volts from the control box. Switching the thruster system ON is achieved by a two-pole 40A circuit breaker, which is located inside the R600 control box (ref. 636543, supplied by Max Power). CONTROL PANEL AND CONTROL BOX FUNCTIONS The R600 thruster unit has a mechanical lock, which must be disengaged before the thruster is used and reengaged when the thruster is no longer required. - Page 11 STEP 2 - ACTIVATE: PRESS ON/OFF BUTTON & PUSH JOYSTICK RIGHT FOR 1 SECOND After Activation When the lock is disengaged and the thruster is activated properly the LED light of the up\green button will be ON indicating that the thruster is in the up position and ready to be used. Down thruster movement Press down\red button to move the thruster to the down position.

-

Page 12: Checks, Tests & Adjustments

MAX POWER recommends the use of for the power circuit. This mineral oil has already been used by Max Power during the run in tests and consequently the RETRACT motor and piping are already filled with this kind off oil. -

Page 13: After Launching

The transmission is already filled with oil at the time of delivery. Max Power uses HYPIOD HD 80W/90 oil in the transmission; therefore, fill the transmission lube oil header tank with similar grade oil. The function of this lubricant tank is to ensure a constant pressure, as well as a visual control of the oil-level. - Page 14 REMEDY: Check pressure. Consult hydraulic technician THIRD CAUSE: Propeller problem (plastic bag, rope, etc.) PROBLEM: The turbine retracts, but the alarm does not stop or the red light does not illuminate. PROBABLE CAUSE: An object such as a line, or other flotsam is caught between the closing plate and the hull.

-

Page 15: Maintenance Of The Retract

MAINTENANCE OF THE RETRACT Regular checks 1. Lower and raise several times every month 2. Transmission lubricating oil. 3. Hydraulic power oil reservoir level. 4. Hydraulic hoses for chaffing and leaks. 5. Condition of the anodes Control panels, like all external equipment, should be protected from the sun and weather when not in use. - Page 16 PROJECT MANAGER’S TEST RESULTS FORM To be filled out and Faxed to MAX POWER INSTALLATION MANUAL RETRACT R 600...

- Page 17 TEST RESULT FORM (part 1) This form must be filled out and faxed to MAX POWER within a week after launching so that the MAX POWER standard warranty is validated. Date: ………………………… REFERENCE: S _ _ .R6_ _. _ _ _ _ 10.Shipyard that installed the RETRACT: ………………………………………………...

- Page 18 When all the tests have been completed as per the manual, please record the following measurements where applicable. With the engine(s) running, thruster in the down position, but not running: Record the voltage at the remote control box: ………………… Volts With the engine(s) running and the thruster running (either direction): ...

- Page 19 TECHNICAL DATA SHEET R600 (111,7HP) OIL – LUBRIFICATION Drive leg Litres Type EP 90 Gear oil Recommended grease Molycote HV silicone OIL – HYDRAULIC Flow 200 lpm (test 75 lpm) Maximum Pressure 250 bar (test 120 bar) ISO GRADE 15 to 32 Oil type mineral oil Viscosity...

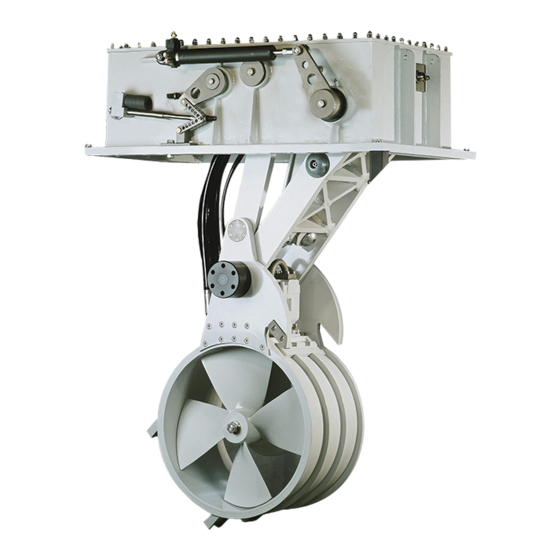

- Page 20 IF IN DOUBT PLEASE ASK R600 111,7hp PROPELLER POWER MAX 83 KW THRUST 1000KG HYDRAULIC PRESSURE 250 BAR HYDRAULIC FLOW 200 LPM Boyancy Foam Construction point Construction point Hull Opening A minimum immersion depth of one full turbine diameter should be respected and the thrusters should be as far forward or aft as possible.

- Page 21 FLANGE Construction point Construction point MAX POWER...

- Page 22 MAX POWER Positioning The Retract must be parallel with the bottom of the hull A minimum immersion depth of one full turbine diameter should be respected and the thrusters should be as far forward or aft as possible. The flow of water that is displaced by the thruster in this position must not interfere with the hull of the boat.

- Page 23 MAX POWER Mating surfaces must be flat O Ring seal only Allow For Flexible seal Closing plate made from alloy INSTALLATION MANUAL RETRACT R 600...

- Page 24 MAX POWER 1 & 2 3 & 4 5 6 7 & 8 Hull parts Thruster parts in box Thruster parts in the yacht Movement Mechanical end of travel ( stop ) 1 2 & 3 6 & 7 4 & 5...

- Page 25 MAX POWER To obtain a perfect hull plate fit follow these instructions Take the finished and formed hull plate and place four piles of beading compound on it and push the plate into place (3). Hold the plate in place until total curing of the compound. Then lower the thruster and remove the bracket hull plate assembly now glued together.

- Page 26 1 The reinforced hull plates to be manufactured by the shipyard and 2 The adjustable thrust pads are supplied by max power, but will need adjustment to suit the thrust plates. The thrust pads must be at exactly 90° to the hull flange and strong enough to support at least a one-tone load.

- Page 27 MAX POWER Hydraulic Diagram raise/lower powerpack INSTALLATION MANUAL RETRACT R 600...

- Page 28 Service Centers 1) Definitions Authorized Repair Number – The number given by Max Power on reporting a fault with your thruster Dealer – An authorized Max Power sales center End User – The boat supplied with supplied equipment and the owner thereof Installer – The authorized center responsible for the installation of your thruster Manufacturer –...

- Page 29 ORIGIN OF PROBLEM PRIOR TO CONTACTING THE DEALER/INSTALLER Contact your dealer/installer to report the problem. If you do not know who this is contact the nearest Max Power distributor If you are in foreign waters, please contact the nearest Max Power distributor...

- Page 30 MAX POWER INSTALLATION MANUAL RETRACT R 600...

- Page 31 Connect the 2 x 24V RAM ACTUATORS from starboard and port respectively: RAM 1 RAM 2 CAUTION: The Max Power raise/lower powerpack, ref. 313352, consists of a 1,1 kw 4 poles 3Ph 380/400V- 50HZ AC motor, which will need to be supplied by a switchboard and protected by a dedicated circuit breaker.

Need help?

Do you have a question about the RETRACT R600 and is the answer not in the manual?

Questions and answers