Table of Contents

Advertisement

Quick Links

M

A

X

P

M

A

X

P

∫ A copy of this manual must remain

on board for consultation.

- 1

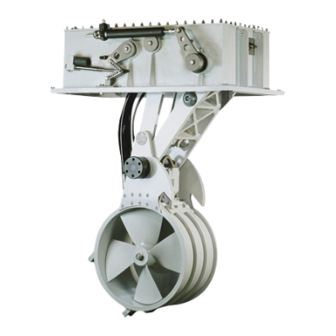

INSTALLATION MANUAL RETRACT R 600

MAX POWER

O

W

E

R

O

W

E

R

S

E

R

I

E

S

S

E

R

I

E

S

F

O

R

_

_

_

F

O

R

_

_

_

B

U

I

L

T

B

B

U

I

L

T

B

D

E

L

I

V

E

R

D

E

L

I

V

E

R

FOR

R

E

T

R

R

E

T

R

T

H

R

U

S

T

E

T

H

R

U

S

T

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Y

_

_

_

_

_

_

_

_

_

_

Y

_

_

_

_

_

_

_

_

_

_

E

D

E

D

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Last update: December 2013

A

C

T

R

A

C

T

R

R

S

E

R

S

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

6

0

0

6

0

0

Advertisement

Table of Contents

Summary of Contents for MAX power RETRACT R600 Series

- Page 1 MAX POWER ∫ A copy of this manual must remain on board for consultation. Last update: December 2013 INSTALLATION MANUAL RETRACT R 600...

-

Page 2: Installation Procedures

RAISE/LOWER POWER PACK INSTALLATION TRANSMISSION LUBE OIL TANK INSTALLATION HYDRAULIC POWER SYSTEM INSTALLATION ELECTRICAL SYSTEM INSTALLATION CONTROL SYSTEM CONTROL SYSTEM MAX POWER SUPLLY CONTROL SYSTEM PLC (NON MAX POWER SUPLLY) CHECKS, TESTS & ADJUSTMENTS BEFORE LAUNCHING AFTER LAUNCHING OPERATION AND USE OPERATING PROCEDURE... -

Page 3: Important General Information

MAX POWER INTRODUCTION AFTER SALES SERVICE ADDRESS : MAX POWER Via Philips 5, 20900, Monza (MI), Italy TEL : + 39 039 200 1973-936 FAX: + 39 039 2004299 RETRACT SERIAL N° S 0 1. R600. _. _ _ IMPORTANT GENERAL INFORMATION With a constant concern of improving our products, we reserve the right to make changes to this manual without prior notification. - Page 4 IMPORTANT: All Test readings must be filled out on the form provided and sent to Max Power by fax no later than one week after the water tests have been completed so that the Max Power standard warranty is correctly validated. This form is attached at the end of this manual.

- Page 5 MAX POWER IMPORTANT: Always check and make sure that there is enough room to allow for complete removal of the RETRACT unit, and room for the connection of the hydraulic piping. LOCATION OF THE AUXILIARY EQUIPMENT The transmission lube oil tank and the hydraulic directional valve should be located near the RETRACT unit, but in an accessible and dry place.

-

Page 6: Construction Of Hull Opening & Closing Plate

MAX POWER IMPORTANT: In both cases, the top surface of the mounting base (the flange) must be given particular attention and machined perfectly flat in order to accept the « O » ring seal of the RETRACT base flange and ensure perfect water tightness. - Page 7 The nylon washers avoid stainless steel contact with the aluminium case. The nuts should be NYLOCK self-locking type. The 4 lifting lugs provided by MAX POWER should be put in a small plastic bag, along with the hydraulic pipe plugs, for storage and future use by the ships crew.

- Page 8 All the hydraulic power equipment, such as the piping, reservoir, pump, directional valve, etc. should be installed in compliance with the usual rules of accessibility to enable periodic checks and maintenance. MAX POWER recommends the use of ISO GRADE 15 to 32 hydraulic oils for the power circuit. PRESSURE PIPING...

-

Page 9: Directional Control Valve

Mounting the reservoir too low could result in oil draining back, or overflowing the tank. Be sure to allow enough space above the reservoir to service the filter. If the reservoir is not supplied by MAX POWER, then provide a return filter of 60 microns and a suction strainer. - Page 10 CONTROL SYSTEM PLC (NON MAX POWER SUPLLY) If the max power control box is not used an integrated PLC can be used to replace it. If this is the case The PLC must be programmed to follow the following sequences.

- Page 11 ISO GRADE 15 to 32 hydraulic oils for the power circuit. This mineral oil has already been used by Max Power during the run in tests and consequently the RETRACT motor and piping are already filled with this kind off oil.

-

Page 12: After Launching

The transmission is already filled with oil at the time of delivery. → Max Power uses HYPIOD HD 80W/90 oil in the transmission; therefore, fill the transmission lube oil header tank with similar grade oil. The function of this lubricant tank is to ensure a constant pressure, as well as a visual control of the oil-level. -

Page 13: Troubleshooting Guide

MAX POWER Use the thruster as required. If the alarm buzzer sounds and the green light are still on during operation, stop the thruster immediately. This alarm indicates that a problem has occurred on one of the auxiliary alarms. When finished reverse the above operation: move the joystick away from yourself (forward or up), the green light will extinguish, the alarm sounds until the red light illuminates indicating that the RETRACT is fully retracted. - Page 14 MAX POWER MAINTENANCE OF THE RETRACT Regular checks 1. Lower and raise several times every month 2. Transmission lubricating oil reservoir level. 3. Hydraulic power oil reservoir level. 4. Hydraulic hoses for chaffing and leaks. Control panels, like all external equipment, should be protected from the sun and weather when not in use.

- Page 15 MAX POWER PROJECT MANAGER’S TEST RESULTS FORM To be filled out and Faxed to MAX POWER - 15 INSTALLATION MANUAL RETRACT R 600...

-

Page 16: Max Power

MAX POWER TEST RESULT FORM (part 1) This form must be filled out and faxed to MAX POWER within a week after launching so that the MAX POWER standard warranty is validated. From: MAX POWER ……………………………… Via Philips 5, 20900 Monza, Italy ………………………………... - Page 17 MAX POWER When all the tests have been completed as per the manual, please record the following measurements where applicable. With the engine(s) running, thruster in the down position, but not running: Record the voltage at the remote control box: …………………...

- Page 18 MAX POWER TECHNICAL DATA SHEET R600 (100HP) OILS – LUBRIFICATION Drive leg Litres Type EP 90 Gear oil Recommended grease Molycote HV silicone OIL – HYDRAULIC Flow 200 lpm Maximum Pressure 250 bar Oil type Hydraulic Viscosity 46 csst UNIT SPECIFICATIONS...

- Page 19 MAX POWER 1250 1 070 - 19 INSTALLATION MANUAL RETRACT R 600...

- Page 20 MAX POWER - 20 INSTALLATION MANUAL RETRACT R 600...

- Page 21 MAX POWER Positioning Turning center As long as possible The Retract must be paralell with the botom of the hull A minimum immersion depth of one full turbine diameter should be respected and the thrusters should be as far forward or aft as possible.

- Page 22 MAX POWER Mating surfaces must be flat O Ring seal only Allow For Flexible seal Closing plate made from alloy - 22 INSTALLATION MANUAL RETRACT R 600...

- Page 23 MAX POWER REVISION PART NO. 3RD ANGLE PROJECTION 1 & 2 3 & 4 5 6 7 & 8 Hull parts Thruster parts in box Thruster parts in the yacht Mouvment Mechanical end of travel ( stop ) Locking sequence...

- Page 24 MAX POWER To obtain a perfect hull plate fit follow these instructions Take the finished and formed hull plate and place four piles of beading compound on it and push the plate into place(3). Hold the plate in place until total curing of the compound. Then lower the thruster and remove the bracket hull plate assembly now glued together.

- Page 25 1 The reinforced hull plates to be manufactured by the shipyard and 2 The adjustable thrust pads are supplied by max power, but will need adjustment to suit the thrust pads. The thrust pads must be at exactly 90° to the hull flange and strong enough to support at least a one-tone load.

- Page 26 MAX POWER 70 bar max REVISION R600 Up / Down unit diagram TITLE REF. MATERIAL 03/05/01 Max Power DRAWN CHECK RELEASE POWER DATE DATE DATE - 26 INSTALLATION MANUAL RETRACT R 600...

- Page 27 The hydraulic hoses should be crimp connected, and pressure tested. HYDRAULIC HOSES: (as recommended for Max Power equipment) PPD: Supply feeder hose from pump to hydraulic directional valve; High pressure (HP) 1 ,1/4’ DAR: Supply from hydraulic directional valve to the retract; HP thermo plastic hose 1 , ¼’...

- Page 28 The warranty as outlined above is only applicable to Max Power manufactured thrusters and optional equipment as used in marine pleasure industry. The supplier holds the exclusive right to test the product and...

Need help?

Do you have a question about the RETRACT R600 Series and is the answer not in the manual?

Questions and answers