Rotax 912 i Series Service Instruction

Hide thumbs

Also See for 912 i Series:

- Maintenance manual (448 pages) ,

- Installation manual (206 pages) ,

- Operator's manual (90 pages)

Advertisement

Quick Links

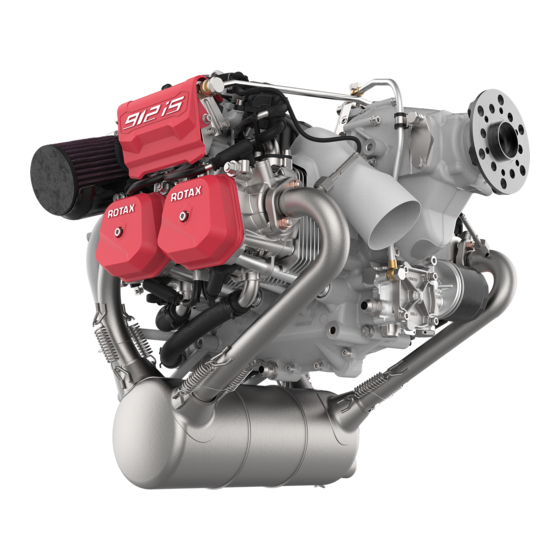

SI-912 i-029 / SI-915 i-012

SI-916 i-007

Introduction of new double ignition coils and new wiring

harnesses for ROTAX

and 916 i (Series)

ATA System: 74-20-00 Ignition system

1) Planning information

To obtain satisfactory results, procedures specified in this publication must be accomplished with

accepted methods in accordance with prevailing legal regulations.

BRP-Rotax GmbH & Co KG cannot accept any responsibility for the quality of work performed in

accomplishing the requirements of this publication.

1.1) Applicability

All versions of ROTAX

912 i Series

915 i Series

916 i Series

On engines with S/N higher than those listed above, new ignition coils and wiring harnesses have

already been fitted in serial production.

1.2) Concurrent ASB/SB/SI and SL

In addition to this Service Instruction the following documents must be observed and complied

with:

-

in general all relevant Alert Service Bulletins (ASB), Service Bulletins (SB), Service Instructions

(SI), Service Letters (SL), Service Instruction - Parts and Accessories (SI-PAC) with relevance to

perform this maintenance, repair or overhaul task.

1.3) Reason

In the course of further development and standardization, the power connectors on double ignition

coils have been changed from two individual Faston connectors to a single sealed Tyco connector.

In addition, the wiring harness has been changed to accommodate the new Tyco connectors at

each double ignition coil.

1.4) Subject

Introduction of new double ignition coils and new wiring harnesses for ROTAX® Engine Type 912 i

(Series), 915 i (Series) and 916 i (Series).

1.5) Compliance

NONE - For Information Only (It is not mandatory to retrofit non-applicable (see section 1.1)

engines to the new double ignition coils and wiring harness).

1.6) Approval

The technical content of this document is approved under the authority of the DOA ref.

EASA.21J.048.

08 February 2024

Initial Issue

Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

Engine Type 912 i (Series), 915 i (Series)

®

engine types:

®

Engine type

from S/N 10002783

Current valid documentation see:

www.flyrotax.com

SERVICE INSTRUCTION

Serial number

74-20-00

Page 1 of 15

Advertisement

Need help?

Do you have a question about the 912 i Series and is the answer not in the manual?

Questions and answers