Rotax 912 Series Maintenance Manual

Hide thumbs

Also See for 912 Series:

- User manual ,

- Maintenance manual (456 pages) ,

- Installation manual (199 pages)

Table of Contents

Advertisement

Quick Links

Maintenance Manual

Before starting any maintenance work, please, read the Maintenance

Manual completely as it contains important safety relevant information.

These technical data and the information contained therein are property of ROTAX

must not be reproduced, neither in entirety nor partially, and passed on to third parties without

previous consent in writing by ROTAX

partial reproduction.

Approval of translation has been done to best knowledge and judgement - in any case the

Recommended price: ATS 400,--

ROTAX

part no.:

899 372

®

AIRCRAFT ENGINES

(Line Maintenance)

for

ROTAX

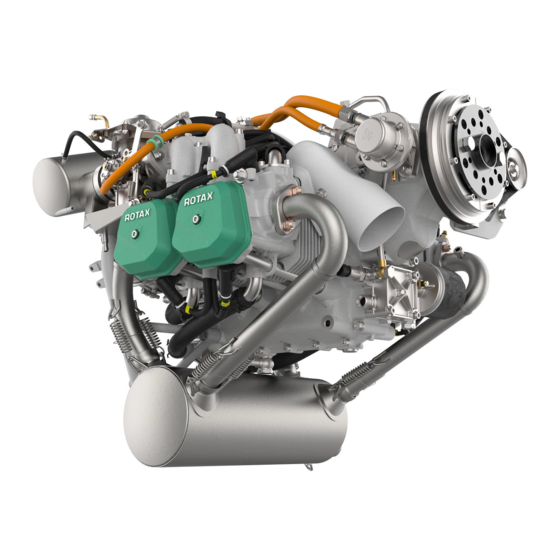

Type 912 Series

WARNING

GmbH. This text must be written on every complete or

®

Copyright - ROTAX

original text in German language is authoritative.

Engine

®

Edition: 0 of 1998 09 01

GmbH

®

www.rotax-aircraft-engines.com

00337

GmbH and

®

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Rotax 912 Series

- Page 1 Before starting any maintenance work, please, read the Maintenance Manual completely as it contains important safety relevant information. Edition: 0 of 1998 09 01 These technical data and the information contained therein are property of ROTAX GmbH and ® must not be reproduced, neither in entirety nor partially, and passed on to third parties without previous consent in writing by ROTAX GmbH.

-

Page 2: Table Of Contents

5.3.1) Use for intended purpose ..........00-00-00 / 16 5.3.2) Instruction ................. 00-00-00 / 17 6) List of the current pages ................ 00-00-00 / 18 7) Table of amendments ................00-00-00 / 20 00-00-00 Effectivity: 912 Series page 2 Rev. 1, Jan. 01/2002... - Page 3 AIRCRAFT ENGINES MAINTENANCE MANUAL 00-00-00 Effectivity: 912 Series page 3 Rev. 1, Jan. 01/2002...

-

Page 4: Introduction 00-00-00

AIRCRAFT ENGINES MAINTENANCE MANUAL 2) List of chapters INTRODUCTION ..........00 MAINTENANCE SCHEDULE/ CHECKS ..05 MAINTENANCE ..........12 00-00-00 Effectivity: 912 Series page 4 Rev. 1, Jan. 01/2002... - Page 5 AIRCRAFT ENGINES MAINTENANCE MANUAL 00-00-00 Effectivity: 912 Series page 5 Rev. 1, Jan. 01/2002...

-

Page 6: Index

Lapping fleece 05-00-00 / 10 Special checks 05-50-00 / 1, 05-50-00 / 2 Leakage check 12-00-00 / 5 Submerging in water 05-50-00 / 6 List of sections 00-00-00 / 4 00-00-00 Effectivity: 912 Series page 6 Rev. 1, Jan. 01/2002... - Page 7 Time limits for engine operation 05-10-00 / 2 Trouble shooting 05-00-00 / 6 V-belt tension 12-00-00 / 10 Valve lapping paste 05-00-00 / 11 Verification of carburetor actuation 12-00-00 / 25 Wiring 12-00-00 / 36 00-00-00 Effectivity: 912 Series page 7 Rev. 1, Jan. 01/2002...

-

Page 8: Introduction

In this Manual the maintenance of engine type 912 Series is described. NOTE: 912 Series includes all types of 912 engines like 912 A, 912 F, 912 S, 912 UL, 912 ULS and 912 ULSFR. Before carrying out maintenance work on the engine, carefully read the Maintenance Manual. - Page 9 AIRCRAFT ENGINES MAINTENANCE MANUAL 00-00-00 Effectivity: 912 Series page 9 Rev. 1, Jan. 01/2002...

-

Page 10: Conversion Table And Abbreviations

1 Pa = 1N/m 1 bar = 100 000 Pa (1000 hPa) 1 bar = 14,5037 lbf/in (psi) 1 lbf/in (psi) = 0,0689 bar 1 in HG = 33,8638 hPa 00-00-00 Effectivity: 912 Series page 10 Rev. 1, Jan. 01/2002... - Page 11 Federal Aviation Administration on illustrations this sign indicates the location of the current serial Federal Aviation Requirements number or special part coding hours Installation Manual Illustrated Parts Catalog International Standard Atmosphere 00-00-00 Effectivity: 912 Series page 11 Rev. 1, Jan. 01/2002...

-

Page 12: Safety Notice

AIRCRAFT ENGINES MAINTENANCE MANUAL 5) Safety notice This manual has been prepared as a guide to correctly service and maintain all ROTAX ® 912 aircraft engines. This edition was primarily published to be used by aircraft mechanics who are already familiar with all service procedures relating to ROTAX made aircraft engines. - Page 13 Where precise accuracy is not required, some conversions are rounded off for easier use. Because of our ongoing commitment to product quality and innovation. ROTAX ® reserves the right at any time, and without incuring obligation, to remove, replace or discontinue any design, specification, feature or otherwise.

-

Page 14: Repeating Symbols

Heavy Maintenance (separate Manual p/n 899 601): Heavy maintenance details removal, installation and repair of components or parts normally considered beyond the capabilities of the average line main- tenance facility. 00-00-00 Effectivity: 912 Series page 14 Rev. 1, Jan. 01/2002... -

Page 15: Technical Documentation

Overhaul Manual 912 A / F Alert Service Bulletins Service Bulletins Service Instructions Service Letters Any reference to a document refers to the latest edition issued by ROTAX , if not ® stated otherwise. The rapid technical progress and variations of installation might render present laws and regulations inapplicable or inadequate. -

Page 16: 1) Use For Intended Purpose

This also increases the engine time between overhaul efficiency. WARNING: Never run the engine without propeller, this inevitably causes engine damage and is an explosion hazard. 00-00-00 Effectivity: 912 Series page 16 Rev. 1, Jan. 01/2002... -

Page 17: 2) Instruction

(see IPC) or suitable equivalent in the manufactuer’s opinion otherwise, any limited warranty by ROTAX ® null and void (see Warranty Conditions). All Spare parts are available at the authorized ROTAX ® Distribution- and Service centers. 00-00-00 Effectivity: 912 Series page 17 Rev. - Page 18 2002 01 01 ACG-approv. 2002 01 01 05-20-00 ACG-approv. 2002 01 01 ACG-approv. 2002 01 01 ACG-approv. 2002 01 01 ACG-approv. 2002 01 01 ACG-approv. 2002 01 01 ACG-approv. 2002 01 01 00-00-00 Effectivity: 912 Series page 18 Rev. 1, Jan. 01/2002...

- Page 19 2002 01 01 2002 01 01 2002 01 01 2002 01 01 2002 01 01 2002 01 01 2002 01 01 2002 01 01 2002 01 01 2002 01 01 00-00-00 Effectivity: 912 Series page 19 Rev. 1, Jan. 01/2002...

-

Page 20: Table Of Amendments

2002 01 01 englisch version 05-20-00 1,2,4 up to 13,14 2002 01 01 not required 05-50-00 1up to 12 2002 01 01 12-00-00 1 up to 41 2002 01 01 not required 00-00-00 Effectivity: 912 Series page 20 Rev. 1, Jan. 01/2002... - Page 21 2.2.1) Engine cleaning ..............05-20-00 / 6 2.2.2) Visual inspection of the engine ......... 05-20-00 / 6 2.2.3) Verification of engine suspension ........05-20-00 / 8 2.2.4) Engine external parts ............05-20-00 / 8 05-00-00 Effectivity: 912 Series page 1 Rev. 1, Jan. 01/2002...

- Page 22 2.9) Oil pressure below minimum value ..........05-50-00 / 10 2.10) Oil specification not respected ............05-50-00 / 11 2.11) Spark plug not in accordance with specification ......05-50-00 / 12 05-00-00 Effectivity: 912 Series page 2 Rev. 1, Jan. 01/2002...

-

Page 23: Maintenance

® ® authorized for use. Installation and/or use of such products may possibly change or negatively influence the operational characteristics of the engine. For dam- ages resulting from use of non-genuine parts and accessories ROTAX refuses ® any liability. Non-authorized modifications as well as the use of components and auxiliary components not corresponding to the installation instructions exclude any liability by the engine manufacturer. -

Page 24: Authorized Personnel

Including: Suitable work environment to prevent contamination or damage to engine parts or modules. Suitable tools and fixtures as outlined in the ROTAX Maintenance Manual. ® Reasonable and prudent maintenance practices are utilized. And the Requirements of the applicable regulatory authority regarding maintenance procedures are met. -

Page 25: Procedure Notes

Before each re-assembly check units for missing parts. Only use adhesives, lubricants, cleaning agents and solvents indicated in the maintenance instruc- tions. If not respected, damage may be the consequence. 05-00-00 Effectivity: 912 Series page 5 Rev. 1, Jan. 01/2002... -

Page 26: Trouble Shooting

Take care of the markings, do not remove them prior to re-assembly. 2.4) Trouble shooting In the Operator’s Manual, possible troubles as well as feasible remedies are listed. See section 12 in the Operator’s Manual of the engine type 912. 05-00-00 Effectivity: 912 Series page 6 Rev. 1, Jan. 01/2002... - Page 27 AIRCRAFT ENGINES MAINTENANCE MANUAL 05-00-00 Effectivity: 912 Series page 7 Rev. 1, Jan. 01/2002...

-

Page 28: Consumable Materials

After assembly it cures under hermetical conditions with metal contact within several hours. This gives a sealing completely adapted to the surface structure of the parts to be sealed. 05-00-00 Effectivity: 912 Series page 8 Rev. 1, Jan. 01/2002... - Page 29 To avoid leakage current ..........250 g Is used on all electrical connections, to avoid current leak- age. After assembly is complete, apply Lithium grease to the connection as anti-corrosive. 05-00-00 Effectivity: 912 Series page 9 Initial issue, Sept. 01/98...

- Page 30 Before reapplying LOCTITE, clean surfaces with nitro-thinner or degreasing agent (CASTROL ZA 30 or OMV-SOFT SOL). When using solvents, mind the safety regulations for per- sons and environment. 05-00-00 Effectivity: 912 Series page 10 Initial issue, Sept. 01/98...

- Page 31 This paste, produced by various manufacturers, is a fine granulate lapping paste for valve seats and valves. The paste is usually available in 3 different granulate sizes. Use as per manufacturer’s directives. 05-00-00 Effectivity: 912 Series page 11 Rev. 1, Jan. 01/2002...

-

Page 32: Acceptable Methods, Techniques And Practices

When using a self-locking nut, take care that the polyamide insert ring on nuts according to DIN 985 as well as the securing element on nuts according to DIN 980 is positioned towards outside. fig. 1 00144 05-00-00 Effectivity: 912 Series page 12 Rev. 1, Jan. 01/2002... -

Page 33: Time Limits

MAINTENANCE MANUAL CHAPTER 05-10 TIME LIMITS 1) General note These checks, related to limited periods of operation, are planned to help avoid engine troubles by the use of preventive maintenance. 05-10-00 Effectivity: 912 Series page 1 Rev. 1, Jan. 01/2002... -

Page 34: Time Limits For Engine Operation

(SI) for the respective engine type. For extensions already effective refer to the engine log book or to the maintenance records. Extension or exceeding of the TBO by 5 % or 6 months is allowed whichever comes first. 05-10-00 Effectivity: 912 Series page 2 Rev. 1, Jan. 01/2002... - Page 35 AIRCRAFT ENGINES MAINTENANCE MANUAL The shipment to an authorized ROTAX overhaul facility must include the following: ® - Engine log book - Maintenance records of the engine (i.e. all maintenance check lists, and reports of operation, of maintenance, of findings and of oil analyses).

-

Page 36: Time Limit For Rubber Parts

The coolant must be renewed every two years. See chapter 12-00-00, para 3. 5) Annual inspection Perform a 100 hr. check at intervals of 100 hours of operation or once every 12 months, whichever comes first.See chapter 05-10-00, para 2. 05-10-00 Effectivity: 912 Series page 4 Rev. 1, Jan. 01/2002... -

Page 37: Scheduled Maintenance Checks

AVGAS. Furthermore, Rotax recommends at each maintenance event the following checks (if not already specified by the aircraft builder), because possible malfunctions could influence engine operation unfavourably. -

Page 38: Maintenance Schedule Procedures

A/C owners Replacement of equipment (e.g. carburetor, fuel pump, hydraulic governor etc.) has to be entered into the engine Log book stating S/N, TSN and date. 05-20-00 Effectivity: 912 Series page 2 Rev. 1, Jan. 01/2002... - Page 39 AIRCRAFT ENGINES MAINTENANCE MANUAL 05-20-00 Effectivity: 912 Series page 3 Rev. 1, Jan. 01/2002...

-

Page 40: Inspection Sheet/Maintenance Schedule

This check is applicable (circle one) 25h* 100h 200h 600h Next check due at: ______________________ hr. (TS__) (engine hr.) * shaded column first 25 hr. only (from new or O/H engines) 05-20-00 Effectivity: 912 Series page 4 Rev. 1, Jan. 01/2002... - Page 41 AIRCRAFT ENGINES MAINTENANCE MANUAL page 2 of 10 05-20-00 Effectivity: 912 Series page 5 Rev. 1, Jan. 01/2002...

-

Page 42: Maintenance Schedule

Verify coolant level, replenish as necessary. Inspect radiator cap. Inspect rubber plate on expansion tank base for secure fit. See Chapter 12-00-00, para 3.1 05-20-00 Effectivity: 912 Series page 6 Rev. 1, Jan. 01/2002... - Page 43 Verify routing for kinks and restrictions including restricted elbows. See Chapter 12-00-00, para 2.2 i) Verify the complete electrical wiring system including tight fit of connnectors, damage and wear. See Chapter 12-00-00, para 6.1 05-20-00 Effectivity: 912 Series page 7 Rev. 1, Jan. 01/2002...

-

Page 44: 3) Verification Of Engine Suspension

Inspect oil level. See Chapter 12-00-00, para 5.1 b) Inspection of the magnetic plug See Chapter 12-00-00, para 5.4 05-20-00 Effectivity: 912 Series page 8 Rev. 1, Jan. 01/2002... - Page 45 Refill oil tank with approx. 3 litres of oil. For oil quality refer to OM and SI-18-1997 See Chapter 12-00-00, para 5.2 for engine operation with AVGAS and/or severe operating condition. See SI-18-1997. 05-20-00 Effectivity: 912 Series page 9 Rev. 1, Jan. 01/2002...

- Page 46 2.2.8) Cleaning of the cooling system a) Flushing of the cooling system. See Chapter 12-00-00, para 3.3 2.2.9) Check of the air filter a) Inspection of the air filter. See Chapter 12-00-00, para 2.4 05-20-00 Effectivity: 912 Series page 10 Rev. 1, Jan. 01/2002...

- Page 47 See Chapter 13 of Heavy MM, p/n 899 601 e) Inspect carburetor synchronization. Mechanical and pneumatic synchronization. See Chapter 12-00-00, para 4.1 05-20-00 Effectivity: 912 Series page 11 Rev. 1, Jan. 01/2002...

- Page 48 Inspect compression by differential pressure method. Test pressure ___ hPa (psi) pressure drop cyl. 1 _____ cyl. 2 _____ (% or fraction) cyl. 3 _____ cyl. 4 _____ See Chapter 12-00-00, para 2.5 05-20-00 Effectivity: 912 Series page 12 Rev. 1, Jan. 01/2002...

- Page 49 _____hr. (TSN__,TSO__) was carried out according to recommendations of the engine manufacturer and was recorded in the Engine Log book. (location) , (date) (completed by) Test person (certificate no. - if applicable) 05-20-00 Effectivity: 912 Series page 13 Rev. 1, Jan. 01/2002...

- Page 50 AIRCRAFT ENGINES MAINTENANCE MANUAL 05-20-00 Effectivity: 912 Series page 14 Rev. 1, Jan. 01/2002...

- Page 51 (e.g. hydraulic governor) is applicable. After each special check/repair work, an engine test run and a leakage check must be conducted. WARNING: Observe without fail all the specified instructions. 05-50-00 Effectivity: 912 Series page 1 Rev. 1, Jan. 01/2002...

- Page 52 2.1.1) Propeller gearbox with integrated overload clutch Inspection of engine for damage. If any damage is detected, inspect, repair or overhaul the engine in accordance with the ROTAX instructions for continued airworthi- ® ness. - The scope of work depends on the seriousness of the damage.

- Page 53 WARNING: Do not exceed 800 Nm (590 ft.lb.) otherwise internal damage can occur. If the torque is below or above this value, inspect, repair or overhaul the propeller gearbox in accordance with the ROTAX instructions for continued airworthi- ® ness.

- Page 54 AIRCRAFT ENGINES MAINTENANCE MANUAL 05-50-00 Effectivity: 912 Series page 4 Rev. 1, Jan. 01/2002...

- Page 55 Detailed inspection of affected engine components. WARNING: If one of the above failures should arise even only for a short time, a detailed inspect is necessary. Localize trouble and rectify. 05-50-00 Effectivity: 912 Series page 5 Rev. 1, Jan. 01/2002...

- Page 56 WARNING: Every 25 h checks of air filter, coolant radiator and oil cooler are necessary. Flying in areas of extreme climatic conditions or in extreme altitudes requires correction of carburetor jetting and of the cooling system. This requires consul- tation with the A/C manufacturer and authorized ROTAX Distributor. ® 05-50-00...

- Page 57 The whole engine must be inspected, repaired or overhauled in accordance with the ROTAX instructions for continued airworthiness. ® - Inspect push rods for straightness. - Inspect all systems for correct function. - Detailed inspection of affected engine components. 05-50-00 Effectivity: 912 Series page 7 Rev. 1, Jan. 01/2002...

- Page 58 At short term exceeding of the cylinder head temperature of up to 180°C (360°F): The whole cooling system must be inspected, repaired or overhauled in accordance with the ROTAX instructions for continued airworthiness. ® - Inspect the system for correct function.

- Page 59 With oil temperature in excess of 140°C (280°F) for max. 15 min. The whole cooling system must be inspected, repaired or overhauled in accordance with the ROTAX instructions for continued airworthiness. ® - Inspect the system for correct function.

- Page 60 If no cause for the low oil pressure is found after the above checks, carry out an oil change. If after the previous checks and oil change the oil pressure is still too low, repair or overhaul the engine in accordance with the ROTAX instructions for ®...

- Page 61 ROTAX instructions for continued airworthiness. ® - Detailed inspection of all gearbox components. NOTE: An entry by the pilot in the engine logbook of all pertinent details is required. 05-50-00 Effectivity: 912 Series page 11 Rev. 1, Jan. 01/2002...

- Page 62 MAINTENANCE MANUAL 2.11) Spark plug not in accordance with specification If by error any of the 8 spark plugs were employed which are not according to specification of the engine manufacturer and/or not genuine Rotax parts, the ® following verification will be necessary.

-

Page 63: Table Of Contents

4.1.2) Mechanical synchronization..........12-00-00 / 18 4.1.3) Pneumatic synchronisation ..........12-00-00 / 20 4.2) Idle speed adjustment ..............12-00-00 / 24 4.3) Verification of carburetor actuation ..........12-00-00 / 25 12-00-00 Effectivity: 912 Series page 1 Rev. 1, Jan. 01/2002... - Page 64 6.1) Check of wiring ................12-00-00 / 36 6.2) Verification or replacement of spark plugs ........12-00-00 / 38 7) Propeller gearbox ................... 12-00-00 / 40 7.1) Checking of the friction torque ............12-00-00 / 41 12-00-00 Effectivity: 912 Series page 2 Rev. 1, Jan. 01/2002...

-

Page 65: General Note

For reasons of clarity, only headlines and keywords are listed in the Maintenance Schedule. Please find further explanation if needed on the following pages. As far as feasible, the content has been coordinated with the systems. 12-00-00 Effectivity: 912 Series page 3 Rev. 1, Jan. 01/2002... -

Page 66: Engine Cleaning

CAUTION: When cleaning the engine, the dissolved residues of fuel, oil and other environment-contaminating agents are rinsed off. Collect the cleaning water and dispose in avoidance with applicable environmental regulations. 12-00-00 Effectivity: 912 Series page 4 Rev. 1, Jan. 01/2002... -

Page 67: Leakage Check

Inspect all hoses, especially in the area of hose clamps and hose connections for porosity, damages or kinks. If damage is noticed, replace hose immediately. WARNING: Avoid overstressing of fastening elements and secure till hand tight. 12-00-00 Effectivity: 912 Series page 5 Rev. 1, Jan. 01/2002... -

Page 68: Check Of The Engine Suspension

Inspect engine isolating mounts including for heat damage, wear and cracks. WARNING: Adhere to specified tightening torques of screws and nuts with- out fail. Overtightening or too loose connection could cause serious engine damage. 12-00-00 Effectivity: 912 Series page 6 Rev. 1, Jan. 01/2002... -

Page 69: Check Of The Air Filter

After soaking period, rinse with cold water from inside to outside, shake off and let it dry naturally. WARNING: Do not dry over naked flame or with hot air gun. 12-00-00 Effectivity: 912 Series page 7 Rev. 1, Jan. 01/2002... - Page 70 Only use dry type air filters which are specified by the aircraft manufacturer. WARNING: Attach new filter, free of grease at connection faces, and wire- secure against loss. 00183 fig. 2 12-00-00 Effectivity: 912 Series page 8 Rev. 1, Jan. 01/2002...

-

Page 71: Check Of Compression

2 bar (29 psi). If readings are below 6 bar (90 psi), the whole engine must be inspected, repaired or overhauled in accordance with the ROTAX instructions for contin- ®... -

Page 72: Check Of V-Belt Tension

Then tighten the screws (1) and (2). Torque screws M8 to 22 Nm (195 in.lb) and screw M10 to 35 Nm (310 in.lb). Inspect V-belt tension as per drawing below. fig. 5 00354 12-00-00 Effectivity: 912 Series page 10 Rev. 1, Jan. 01/2002... -

Page 73: Locking Of The Crankshaft

Verify free rotation of the crankshaft by turning the crankshaft with a wrench A/F 24 on the hex.screw (5) on the magneto side end. 01280 04625 B3/4 Drehzahlmesser rev. counter A1/2 A3/4 B1/2 fig. 2 fig. 1 12-00-00 Effectivity: 912 Series page 11 Rev. 1, Jan. 01/2002... -

Page 74: Test Run Of Engine

WARNING: When stopping the engine, switch off ignition and remove the ignition key. 12-00-00 Effectivity: 912 Series page 12 Rev. 1, Jan. 01/2002... - Page 75 CAUTION: If the oil filter has been replaced, re-tighten by hand after the test run. Inspect engine for oil, fuel or coolant leaks and repair as necessary. 12-00-00 Effectivity: 912 Series page 13 Rev. 1, Jan. 01/2002...

-

Page 76: Cooling System

WARNING: Always allow engine to cool down to outside air temperature before start of any work. Severe burns and scalds may result if this is not respected. 12-00-00 Effectivity: 912 Series page 14 Rev. 1, Jan. 01/2002... -

Page 77: Renewal Of The Coolant

WARNING: Never open radiator cap when the cooling system is hot. For safety’s sake, cover cap with a cloth and open slowly. Sudden opening of the cap would provoke exit of boiling coolant and result in severe scalds. 12-00-00 Effectivity: 912 Series page 15 Rev. 1, Jan. 01/2002... -

Page 78: Expansion Tank, Radiator Cap

1 pressure release valve 2 return valve 3 rubber seal 4 pressure spring 5 connection to overflow bottle 6 opening pressure of the radiator cap 7 sealing face 8 tube connections 12-00-00 Effectivity: 912 Series page 16 Rev. 1, Jan. 01/2002... -

Page 79: Overflow Bottle

00396 fig. 6/4 3.6) Equipment (including radiator, radiator hoses, hose clamps, cooling air guide). CAUTION: Equipment is to be verified in accordance with the Maintenance Manual of the aircraft builder. 12-00-00 Effectivity: 912 Series page 17 Rev. 1, Jan. 01/2002... -

Page 80: Fuel System

(2) and the carburetor idle stop (3), gently turn the idle screw clockwise until contact is made with the 0,1 mm feeler gauge. From this point turn each idle speed adjustment screw (2) clockwise 1,5 turns. 12-00-00 Effectivity: 912 Series page 18 Rev. 1, Jan. 01/2002... - Page 81 (6) . See Chapter 12-00-00, para 4.2. CAUTION: An idle speed too low will result in gear box damage and with an idle speed too high the engine is harder to start. 12-00-00 Effectivity: 912 Series page 19 Rev. 1, Jan. 01/2002...

-

Page 82: 3) Pneumatic Synchronisation

(2) accordingly to achieve the proper idle speed i.e.: if the idle speed is too high, the idle screw must be turned in less than one complete turn. 12-00-00 Effectivity: 912 Series page 20 Rev. 1, Jan. 01/2002... - Page 83 RPM. CAUTION: Respect the indication of the instrument manufacturer. Refit the slotted head screw M3,5x5 as required. 12-00-00 Effectivity: 912 Series page 21 Rev. 1, Jan. 01/2002...

- Page 84 AIRCRAFT ENGINES MAINTENANCE MANUAL fig. 9 01393-1 12-00-00 Effectivity: 912 Series page 22 Rev. 1, Jan. 01/2002...

- Page 85 AIRCRAFT ENGINES MAINTENANCE MANUAL 12-00-00 Effectivity: 912 Series page 23 Rev. 1, Jan. 01/2002...

-

Page 86: Idle Speed Adjustment

CAUTION: If satisfactory engine idling can not be achieved, inspection of the idle jet or additional pneumatic synchronisation will be necessary. 02726 fig. 9/1 fig. 9/1 02725 12-00-00 Effectivity: 912 Series page 24 Rev. 1, Jan. 01/2002... -

Page 87: Verification Of Carburetor Actuation

WARNING: With carburetors levers not connected, the carburetor is in full throttle position. Never start the engine without carburetor Bow- den cable connected, as the home position of the CD-carburetor is with throttle fully open. ~1 mm fig. 9/3 00352 12-00-00 Effectivity: 912 Series page 25 Rev. 1, Jan. 01/2002... -

Page 88: Lubrication System

CAUTION: For longer flights replenish oil to max. mark to warrant more oil reserve. Difference between "max." and "min." - is = 0,75 l (1,6 liq.pt). fig. 15 01276 12-00-00 Effectivity: 912 Series page 26 Rev. 1, Jan. 01/2002... -

Page 89: Oil Change

Re-assembly of the oil tank in reversed sequence of disassembly. Fit drain screw (1) M12x12 with a new sealing ring (7) tighten to 25 Nm (220 in.lb) and safety wire. fig. 16 02730 12-00-00 Effectivity: 912 Series page 27 Rev. 1, Jan. 01/2002... -

Page 90: 2) Venting Of The Lubrication System

Never overfill, otherwise oil would escape through the vent tube during operation. At oil level inspect, do not exceed the max. mark. NOTE: For further helpful information refer to SI-04-1997, Venting of the lubrication system, current issue. 12-00-00 Effectivity: 912 Series page 28 Rev. 1, Jan. 01/2002... - Page 91 AIRCRAFT ENGINES MAINTENANCE MANUAL fig. 16/1 04233 12-00-00 Effectivity: 912 Series page 29 Rev. 1, Jan. 01/2002...

-

Page 92: Oil Filter Replacement And Inspection

WARNING: Always allow engine to cool down to outside air temperature before start of any work. Severe burns and scalds may result if this is not respected. * or equivalent 12-00-00 Effectivity: 912 Series page 30 Rev. 1, Jan. 01/2002... - Page 93 If the filter mat is clogged by foreign matter, the lubricating oil flows unfiltered via the bypass incorporated in the oil filter, to points of lubrication. CAUTION: To warrant the function of the oil circuit and the forced flow lubrication, use genuine ROTAX oil filter only or suitable equiva- ®...

- Page 94 AIRCRAFT ENGINES MAINTENANCE MANUAL 12-00-00 Effectivity: 912 Series page 32 Rev. 1, Jan. 01/2002...

-

Page 95: Inspection Of The Magnetic Plug

At vagne findings, flush the lubrication circuit and fit a new oil filter. Afterwards conduct engine test run and inspect the oil filter once more. Larger accumulation of chips on the magnetic plug requires repair or overhaul of the engine in accordance with the ROTAX instructions for continued airwor- ®... - Page 96 AIRCRAFT ENGINES MAINTENANCE MANUAL 12-00-00 Effectivity: 912 Series page 34 Rev. 1, Jan. 01/2002...

-

Page 97: Flushing Of The Lubrication Circuit

Reconnect negative terminal of aircraft battery. 5.6) Equipment (including oil cooler, oil hoses, clamps etc.) CAUTION: Inspect all the equipment in accordance with the Maintenance Manual of the aircraft builder. 12-00-00 Effectivity: 912 Series page 35 Rev. 1, Jan. 01/2002... -

Page 98: Electric System

Inspect all 8 ignition cables to spark plug connector for damage and tight fit. Inspect resistor plug connector for tight fit on spark plug. Repair or replace as necessary. 12-00-00 Effectivity: 912 Series page 36 Rev. 1, Jan. 01/2002... - Page 99 AIRCRAFT ENGINES MAINTENANCE MANUAL 12-00-00 Effectivity: 912 Series page 37 Rev. 1, Jan. 01/2002...

-

Page 100: Verification Or Replacement Of Spark Plugs

WARNING: Flush with water in case of contact with eyes or skin. May be harmful if swallowed. Always replace both spark plugs of a cylinder and do not interchange spark plugs between cylinders. 12-00-00 Effectivity: 912 Series page 38 Rev. 1, Jan. 01/2002... - Page 101 Indicates the following: mixture too lean leaking valves NOTE: Operation with leaded fuels (e.g. AVGAS 100LL) can result in increased wear of the spark plugs. Reduce renewal intervals accordingly. 12-00-00 Effectivity: 912 Series page 39 Rev. 1, Jan. 01/2002...

-

Page 102: Propeller Gearbox

This design is similar to the one in connection with the overload clutch but without backlash. For this reason the friction torque method cannot be applied on engines without overload clutch. 12-00-00 Effectivity: 912 Series page 40 Rev. 1, Jan. 01/2002... -

Page 103: Checking Of The Friction Torque

Remove crankshaft locking pin. See Chapter 12-00-00, para 2.7. Reconnect negative terminal of aircraft battery. WARNING: If the above mentioned friction torque is not achieved, ispect, repairor overhaul the gearbox in accordance with the ROTAX ® instructions for continued airworthiness.

Need help?

Do you have a question about the 912 Series and is the answer not in the manual?

Questions and answers