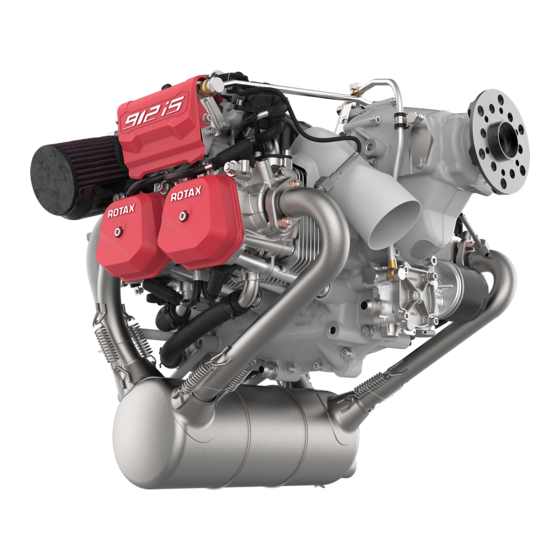

Rotax 912 i Series Service Instructions Manual

Introduction of a new connector for regulator b for rotax

Hide thumbs

Also See for 912 i Series:

- Maintenance manual (448 pages) ,

- Installation manual (206 pages) ,

- Operator's manual (90 pages)

Advertisement

Quick Links

SI-912 i-024

SI-915 i-006

Introduction of a new connector for regulator B for ROTAX

Engine Type 912 i, 915 i A and 915 i B (Series)

ATA System: 76-10-00 Fuse Box

1) Planning information

To obtain satisfactory results, procedures specified in this publication must be accomplished with

accepted methods in accordance with prevailing legal regulations.

BRP-Rotax GmbH & Co KG cannot accept any responsibility for the quality of work performed in

accomplishing the requirements of this publication.

1.1) Applicability

All versions of ROTAX

NOTE:

NOTE:

NOTE:

1.2) Concurrent ASB/SB/SI and SL

In addition to this Service Instruction the following Service Bulletin/Service Instruction must be

observed and complied with:

Service Bulletin-SB-912 i-006, title "Exchange of stator assy.", current issue.

Service Instruction-SI-912 i-004, title "Replacement of regulator A and regulator B", current issue.

1.3) Reason

In the course of further development and standardization, a new connector for rectifier regulator B

has been introduced. The new connector allows higher current draw.

1.4) Subject

Introduction of a new connector for regulator B for ROTAX

915 i B (Series).

1.5) Compliance

NONE - For Information Only.

1.6) Approval

The technical content of this document is approved under the authority of DOA ref.

EASA.21J.048.

03 July 2019

Initial Issue

Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

engine types:

®

Engine type

912 i Series

915 iSc A

915 iS A

915 iSc B

On engines with S/N higher than the ranges listed above, new style connector has

already been fitted in serial production.

On engines with S/N lower than the ranges listed above, the regulator B or stator assy.

connections can be modified for exchange or repair of the relevant component. The

modifications on the rectifier regulator B can be performed at a maintenance, repair or

operation (MRO) event as per section 3.

It is NOT mandatory to retrofit engines with old style regulator B and stator connector.

Current valid documentation see:

www.flyrotax.com

SERVICE INSTRUCTION

Serial number

optional

from S/N 9127323

from S/N 9132300

from S/N 9122524

Engine Type 912 i, 915 i A and

®

®

76-10-00

Page 1 of 18

Advertisement

Summary of Contents for Rotax 912 i Series

- Page 1 To obtain satisfactory results, procedures specified in this publication must be accomplished with accepted methods in accordance with prevailing legal regulations. BRP-Rotax GmbH & Co KG cannot accept any responsibility for the quality of work performed in accomplishing the requirements of this publication.

- Page 2 Updates and current revisions can be downloaded for free. 1.12) Other Publications affected None. 1.13) Interchangeability of parts All parts are interchangeable with relevant modifications. 03 July 2019 76-10-00 Initial Issue Page 2 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 3 SI-912 i-024 SI-915 i-006 SERVICE INSTRUCTION 2) Material Information 2.1) Material Price and availability will be provided on request by ROTAX Authorized Distributors or their inde- ® pendent Service Centers. 2.2) Company support information None. 2.3) Material requirement and credit per engine...

- Page 4 SI-912 i-024 SI-915 i-006 SERVICE INSTRUCTION 2.6) Special tooling/lubricants- /adhesives- /sealing compounds Price and availability will be supplied on request by ROTAX Authorized Distributors or their inde- ® pendent Service Centers: Qty/ Part Milspec no. Description Application engine Adjustable crimp tool M22520/1-01 n.a.

- Page 5 Heavy (MMH) Chapter 76-10-00 section Fuse box installation for the respective engine type. For the modification of old style connector the following assembly steps do apply: 03 July 2019 76-10-00 Initial Issue Page 5 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 6 Using fine-nosed pliers, pull the retaining wedge (5) from the connector housing. 3 Retaining sleeve 4 Sealing ring 5 Retaining wedge Fig. 2 03 July 2019 76-10-00 Initial Issue Page 6 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 7 ) (8). Stripped wires must seat fully into crimp pin and have approximately 1 mm (0.039 in.) insulation gap (9). 03 July 2019 76-10-00 Initial Issue Page 7 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 8 Wire strands must be visible in witness hole (11) and crimps must be between the witness hole and the end of the crimp-barrel (12). 03 July 2019 76-10-00 Initial Issue Page 8 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 9 Slide plastic sleeve (16) into the back of connector housing, aligning the keyway (17). 13 Screw cap 14 Rubber seal 15 Position letter 16 Sleeve 17 Key Fig. 7 03 July 2019 76-10-00 Initial Issue Page 9 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 10 (20). Place plastic sealing plug into empty position in rear seal (21). 20 Connector cap 21 Sealing plug Fig. 9 03 July 2019 76-10-00 Initial Issue Page 10 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 11 Cut each wire at crimped pins (5). Ensure that wires are still clearly numbered and pull rectangular rubber seal (6) from the wires. 03 July 2019 76-10-00 Initial Issue Page 11 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 12 Stripped wires must seat fully into crimp pin and have approximately 1 mm (0.039 in.) gap to insulation (9). 7 10 mm (0.390 in.) 8 12 AWG 9 1 mm (0.039 in.) Fig. 13 03 July 2019 76-10-00 Initial Issue Page 12 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 13 Wire strands must be visible in withness hole (11) and crimps must be between the witness hole and the end of the crimp-barrel (12). 11 Witness hole 12 Crimps Fig. 15 03 July 2019 76-10-00 Initial Issue Page 13 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 14 Push each wire into connector until its pin snaps securely in place. NOTE: Correctly secured pins will travel further into connector (18) and lock in place. Removal requires using extractor tool. 03 July 2019 76-10-00 Initial Issue Page 14 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 15 Push the rubber seal into the plastic ring and screw on connector cap (20). Place plastic sealing plug into empty position in rear seal (21). 19 Cap 20 Plug Fig. 18 03 July 2019 76-10-00 Initial Issue Page 15 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 16 O-ring is not necessary in this application and may be discarded. Place connector through connector bracket (4). Attach with connector nut (5). Tightening torque 10 Nm (89 in.lb). 03 July 2019 76-10-00 Initial Issue Page 16 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

- Page 17 ® In any case the original text in English language and the metric units are authoritative. 3.6) Inquiries Inquiries regarding this Service Instruction should be sent to the ROTAX Authorized Distributor ® of your area. A list of all ROTAX Authorized Distributors or their independent Service Centers is provided on ®...

- Page 18 Exploded views are not technical drawings and are for reference only. For specific detail, refer to the current documents of the respective engine type. 03 July 2019 76-10-00 Initial Issue Page 18 of 18 Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

Need help?

Do you have a question about the 912 i Series and is the answer not in the manual?

Questions and answers