Subscribe to Our Youtube Channel

Summary of Contents for Ingersoll-Rand LS2-600H

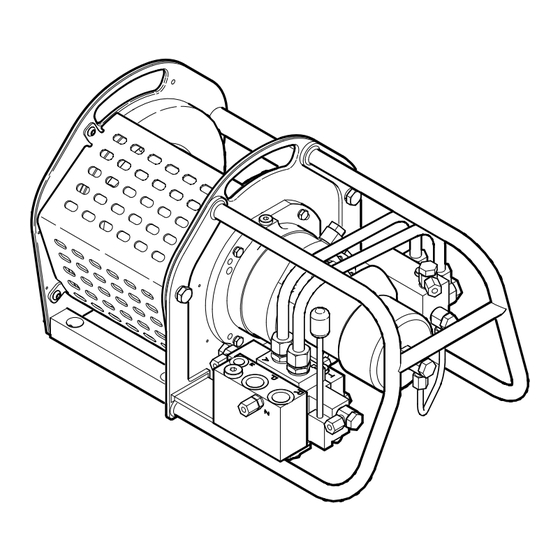

- Page 1 Product Maintenance Information Liftstar Hydraulic Winch Model LS2–600H and PS2–1000H (Dwg. MHP2827) Save These Instructions Form MHD56361 Edition 4 January 2014 43801737 2014 Ingersoll Rand ©...

-

Page 2: Periodic Inspection

Only allow trained technicians to perform maintenance on this product. For additional information contact factory or nearest Ingersoll Rand Ingersoll Rand Distributor. For additional supporting documentation refer to Table 1 ‘Product Information Manuals’ on page 2. Manuals can be downloaded from http://www.ingersollrandproducts.com. The use of other than genuine Ingersoll Rand replacement parts may result in safety hazards, decreased performance and increased maintenance and will invalidate all warranties. - Page 3 Table 3: Maintenance Interval Chart Normal Application The following work can be completed by owner maintenance personnel System Hydraulic Filter Inspect system hydraulic filter every 45 days or 125 hours. Grease Fittings Lubricate grease fittings every 180 days or 500 hours. It is recommended that the following work be completed by an Ingersoll Rand trained service technician.

-

Page 4: Inspection Report

INSPECTION REPORT Ingersoll Rand Model LS2–600H and PS2–1000H Hydraulic Winch Date: Model Number: Inspected by: Serial Number: Reason for Inspection: (Check Applicable Box) 1. Scheduled Periodic Inspection: (_____ Months _____ Years) Operating Environment: 2. Discrepancy(s) noted during Frequent Inspection 3. Discrepancy(s) noted during maintenance Normal ____ Heavy ____ Severe ____ 4. -

Page 5: Troubleshooting

TROUBLESHOOTING This section provides basic troubleshooting information. Determination of specific causes to problems are best identified by thorough inspections performed by personnel instructed in safety, operation and maintenance of this equipment. The chart below provides a brief guide to common winch symptoms, probable causes and remedies. SYMPTOM CAUSE REMEDY... -

Page 6: Maintenance

MAINTENANCE WARNING 0.047 inch minimum • Never perform maintenance on the winch while it is supporting a load. (1.2 mm minimum) • Before performing maintenance, tag controls: WARNING - DO NOT OPERATE - EQUIPMENT BEING REPAIRED. • Only allow Ingersoll Rand trained technicians to perform maintenance on this product. -

Page 7: Cleaning, Inspection And Repair

5. Inspect filter elements that have been removed from the system for signs of 16. Remove spacers (45) and (46). other system damage. 17. Remove the drum (10) from the winch. 6. Do not return to the system any fluid that has leaked out. 18. - Page 8 4. Inspect all bearings for play, distorted races, pitting and roller or ball wear or Disc Brake Assembly damage. Inspect bearings for freedom of rotation. 5. Inspect all threaded items and replace those having damaged threads. Refer to Dwgs. MHP2824 and MHP2825. 6.

-

Page 9: Operational Tests

Free Spool Assembly Winch Guard Installation Refer to Dwg. MHP2620. Refer to Dwg. MHP2826. 1. Install bearing (251) onto shaft (245) secure with retainer ring (252). To install a wire rope guard or reverse the position of the guard use the following 2. -

Page 10: Torque Chart

TORQUE CHART Standard Coarse Thread Torque SAE Grade 5 SAE Grade 8 Size Lubricated PTFE Lubricated PTFE 1/4-20 8-10 12-14 9-10 5/16-18 17-20 13-15 25-28 18-21 11-13 3/8-16 31-35 23-26 14-16 44-49 33-37 20-22 7/16-14 49-56 37-42 22-25 70-79 52-59 31-36 1/2-13 75-85... -

Page 11: Service Notes

SERVICE NOTES Form MHD56361 Edition 4... - Page 12 www.ingersollrandproducts.com...

Need help?

Do you have a question about the LS2-600H and is the answer not in the manual?

Questions and answers