Table of Contents

Advertisement

Quick Links

Installation and Operation Manual

X-TMF-SLA7800-MFC-eng

Part Number: 541B046AAG

August, 2009

®

Brooks

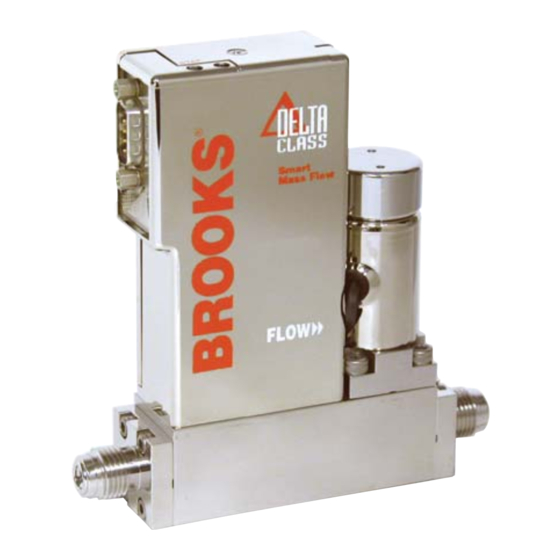

Models SLA7850 - SLA7860

Mass Flow Controllers & Meters

Model SLA7850S

Analog I/O

9-pin D-Connector

VCR Fittings

Model SLA7850D

Digital I/O

DeviceNet Downport

SLA7800 Series

5

Model SLA7850S

Analog I/O

15-pin D-Connector

VCR Fittings

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Brooks Instrument SLA7850

- Page 1 Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 ® Brooks Models SLA7850 - SLA7860 Mass Flow Controllers & Meters Model SLA7850S Model SLA7850S Analog I/O Analog I/O 15-pin D-Connector 9-pin D-Connector VCR Fittings VCR Fittings Model SLA7850D...

- Page 2 Essential Instructions Read this page before proceeding! Brooks Instrument designs, manufactures and tests its products to meet many national and international standards. Because these instruments are sophisticated technical products, you must properly install, use and maintain them to ensure they continue to operate within their normal specifications.

- Page 3 We appreciate this opportunity to service your flow measurement and control requirements with a Brooks Instrument device. Every day, flow customers all over the world turn to Brooks Instrument for solutions to their gas and liquid low-flow applications. Brooks provides an array of flow measurement and control products for various industries from biopharmaceuticals, oil and gas, fuel cell research and chemicals, to medical devices, analytical instrumentation, semiconductor manufacturing, and more.

- Page 4 Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 5: Table Of Contents

Contents Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 Paragraph Page Number Number Section 1 Introduction Scope ............................... 1-1 Purpose ............................1-1 Description ............................1-1 Specifications ........................... 1-2 Section 2 Installation General ............................. 2-1 Receipt of Equipment ........................2-1 Recommended Storage Practice ...................... - Page 6 Contents Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 Figures Figure Page Number Number General Wiring ..........................1-5 Model SLA7850S MFC Analog I/O 9-pin D-Connector with VCR Fittings........1-7 Model SLA7850S MFC Analog I/O 9-pin D-Connector with Downport Connections(C-seal) ... 1-7 Model SLA7850S MFC Analog I/O 15-pin D-Connector with VCR Fittings.

-

Page 7: Section 1 Introduction

X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 1-1 Scope Thank you for purchasing a Brooks Instrument SLA7800 Series device. This manual Part Number 541B046AHG is a complete installation and operation manual for your instrument. 1-2 Purpose ® The Brooks SLA7800 Series are mass flow measurement devices designed for accurately measuring and rapidly controlling flows of gases. -

Page 8: Specifications

1-4 Specifications PERFORMANCE CHARACTERISTICS: Fow Ranges Models SLA7850/SLA7860 Any range from 0-3 sccm to 0-50 slpm N WARNING Do not operate this instrument in excess of the specifications listed below. Failure to heed this warning can result in serious personal injury and/or damage to the equipment. - Page 9 Flow Ranges Pressure PED Module H Controller Equivalent Ratings Category Models Min. F.S. Max F.S. Unit SLA7850/ 50,000 sccm 100 Bar SLA7860 Mounting Attitude Sensitivity 0.2% of FS maximum deviation after rezeroing Leak Integrity Inboard to Outboard: 1x10 atm scc/sec Helium max.

- Page 10 Section 1 Introduction Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 Differential Pressure Range 5-50 psid (broader depending on the customer conditions; consult factory for details.) (34.5-344.7 kPa) (259-2586 torr) * For flows above 30 slpm N eq., 30 psid minimum required.

-

Page 11: General Wiring

Section 1 Introduction Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 RS-485 Communications The Brooks Digital Series is equipped with RS-485 communication capability. Refer to Table 1-3 (Analog I/O pin connections), that enables the device to communicate via a personal computer for process control. - Page 12 The Brooks Digital Series is also available with DeviceNet communication capability. DeviceNet is an open digital protocol capable of high speeds and easy system connectivity. Brooks Instrument has several of its devices available on this popular networking standard, and is a member of ODVA (Open DeviceNet Vendors Association), the governing standard body for DeviceNet.

-

Page 13: Model Sla7850S Mfc Analog I/O 9-Pin D-Connector With Vcr Fittings

Section 1 Introduction Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 *MFM Outline drawing is identical to the MFC, except without the valve. Figure 1-2 Model SLA7850S MFC Analog I/O 9-pin D-Connector with VCR Fittings. *MFM Outline drawing is identical to the MFC, except without the valve. Figure 1-3 Model SLA7850S MFC Analog I/O 9-pin D-Connector with Downport Connections (C-seal). -

Page 14: Model Sla7850S Mfc Analog I/O 15-Pin D-Connector With Vcr Fittings

Section 1 Introduction Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 *MFM Outline drawing is identical to the MFC, except without the valve. Figure 1-4 Model SLA7850S MFC Analog I/O 15-pin D-Connector with VCR Fittings. *MFM Outline drawing is identical to the MFC, except without the valve. Figure 1-5 Model SLA7850S MFC Analog I/O 15-pin D-Connector with Downport Connections (C-seal). -

Page 15: Model Sla7850D Mfc Devicenet Digital I/O With Downport Connections(C-Seal)

Section 1 Introduction Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 *MFM Outline drawing is identical to the MFC, except without the valve. Figure 1-6 Model SLA7850D MFC DeviceNet Digital I/O with VCR Fittings. *MFM Outline drawing is identical to the MFC, except without the valve. Figure 1-7 Model SLA7850D MFC DeviceNet Digital I/O with Downport Connections (C-seal). - Page 16 Section 1 Introduction Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 *MFM Outline drawing is identical to the MFC, except without the valve. Figure 1-8 Model SLA7850S MFC 15-pin D-Connector Analog I/O with 1-1/2" Downport Connections (W-seal). 1-10...

-

Page 17: Section 2 Installation

If the packing case is damaged, the local carrier should be notified at once regarding his liability. A report should be submitted to your nearest Product Service Department. Brooks Instrument 407 W. Vine Street P.O. Box 903... -

Page 18: Return Shipment

Instrument must have been purged in accordance with the following: All flow instruments returned to Brooks requires completion of Form RPR003-1, Brooks Instrument Decontamination Statement, along with a Material Safety Data Sheet (MSDS) for the fluid(s) used in the instrument. -

Page 19: Gas Connections

Section 2 Installation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 2-7 Gas Connections Standard inlet and outlet connections supplied on the SLA7800 Series devices are 1/4"(M) VCR or Downport surface mount per Semi 2787 or Semi F82-0304. -

Page 20: Electrical Interface (Analog I/O)

Section 2 Installation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 d. The SLA7800 Series device can be installed in any position. However, mounting in orientations other than the original factory calibration (see calibration data sheet supplied with the instrument) can result in a ±0.2% maximum full scale shift after rezeroing. - Page 21 Section 2 Installation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 Refer to Section for pin connections Refer to Figures 2-1, 2-2, 2-3, 2-4, 2-5, 2-6 and 2-7 for electrical I/O connections (The Brook’s MFC acts as a current sink to a setpoint input signal. The 0/4- 20 mA setpoint signal should be “driven”...

- Page 22 Section 2 Installation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 15 PIN MALE D-CONNECTOR *BROOKS READ OUT MFC / MFM FUNCTION WIRE SIDE SUB D (15 PIN) COLOR Setpoint, Common Input (-) BLACK Flow Signal, 0(1)-5 volt, Output (+) WHITE TTL Alarm , Open Collector, Output (+) Flow Signal, 0(4)-20 mA, Output (+)

-

Page 23: Recommended Wiring Configuration For Current Signals (Non-Isolated Power Supply)

Section 2 Installation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 Figure 2-3 Recommended Wiring Configuration for Current Signals (Non-Isolated Power Supply) Figure 2-4 Recommended Wiring Configuration for Current Signals (Isolated Power Supply) -

Page 24: Common Electrical Hookups For 9-Pin D-Connector Voltage I/O Version

Section 2 Installation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 Analog I/O Pin Connections for 9-pin D-Connector: Function 9-pin D-conn Valve Override, Input Flow Signal, 0-5 volt, Output (+) Power Supply, +13.5 Vdc to +27 Vdc (+) Power Supply, Common (-) Not connected Setpoint, 0-5 Vdc, Input (+) -

Page 25: Operation Check Procedure (Analog I/O)

Section 2 Installation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 2-11 Operation Check Procedure (Analog I/O) a. Mount the MFC in its final orientation. b. Apply power to the MFC and allow approximately one hour for the instrument to warm up and stabilize its temperature. -

Page 26: Operation Check Procedure (Devicenet I/O)

Section 2 Installation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 2-13 Operation Check Procedure (DeviceNet I/O) a. Mount the MFC in its final orientation. b. Apply power to the MFC and allow approximately one hour for the instrument to warm up and stabilize its temperature. -

Page 27: Section 3 Operation

Section 3 Operation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 3-1 Overview This section contains the following information: • Theory of Operation • Features 3-2 Theory of Operation for Flow Measurement The thermal mass flow measurement system consists of two components: the restrictor and the flow sensor. -

Page 28: Features

SLA7800 Series August, 2009 3-3 Features Note: All Model SLA7850 mass flow controllers are configured at the factory according to customer order and do not require adjustment. Not all features are available on all instruments. The SLA7800 Series is a full-featured digital MFC. The SLA7800 Series performs much like a traditional analog MFC, but with improved accuracy, step response and valve control. -

Page 29: Adaptive Valve Control

Section 3 Operation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 3-4 Adaptive Valve Control The SLA7800 Series offers a feature, called adaptive valve control, which allows the instrument to learn about the process gas and operating conditions. -

Page 30: Externally Accessible Adjustment

Section 3 Operation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 F. Zeroing the MFC (Self-zero) It may be desirable to re-zero the flow sensor if it is operated at its temperature extremes or if it is positioned in an attitude other than that specified on the customer order. -

Page 31: Flow Control System Block Diagram

Section 3 Operation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 Figure 3-3 Flow Control System Block Diagram. - Page 32 Section 3 Operation Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 33: Section 4 Maintenance & Troubleshooting

Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 4-1 Overview No routine maintenance is required on the SLA7800 Series devices. If an in-line filter is used, the filtering elements should be periodically replaced. This section provides the following information: •... - Page 34 Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 4-2 Troubleshooting Analog or DeviceNet Version This section contains suggestions to help diagnose MFC related problems in the gas distribution system and answers commonly asked questions. Failure of the flow rate or flow signal to achieve the setpoint.

- Page 35 Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 Flow rate in excess of 100% at zero setpoint. Valve Override pin set to open. If valve override (VOR) pin is active, the valve will be forced open or closed. Set this pin to its normal level before setting a setpoint.

- Page 36 Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 What is the purpose of the Rotary Switchess on top of the SLA7800 Series MFC? Two of the rotary switches are labeled ‘ADDRESS’. These two switches are used to configure the MAC ID of MFC when used on the DeviceNet network.

- Page 37 This scale shift can be approximated by using the ratio of the molar specific heat of the two gases or by sensor conversion factor. Consult factory or nearest Brooks Instrument rep for a list of sensor conversion factors. To change to a new gas, multiply the output reading by the ratio of the gas factor for the desired gas by the gas factor for the calibration gas used.

-

Page 38: Bench Troubleshooting Circuit

Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 Then 75 x 0.74 = 55.5 sccm of (CO In order to calculate the conversion factor for a gas mixture, the following formula should be used: Where, = percentage (%) of gas 1 (by volume) = percentage (%) of gas 2 (by volume) -

Page 39: Orifice Sizing

Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 4-4 Orifice Sizing The flow controller's orifice is factory-sized to a preselected gas, operating pressure and flow range. Note that the orifice is marked with its size in thousandths of an inch. - Page 40 Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 Restrictors The SLA7800 Series MFC uses two types of restrictor assemblies depending on full scale flowrate and expected service conditions. Wire mesh for Nitrogen equivalent flow rates above 3.4 slpm. These restrictor assemblies are made from a cylinder of wire mesh and are easily cleaned if they become contaminated in service.

-

Page 41: Restrictor Sizing

Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 4-1 Overview No routine maintenance is required on the SLA7800 Series devices. If an in-line filter is used, the filtering elements should be periodically replaced. This section provides the following information: •... - Page 42 Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 4-2 Troubleshooting Analog or DeviceNet Version This section contains suggestions to help diagnose MFC related problems in the gas distribution system and answers commonly asked questions. Failure of the flow rate or flow signal to achieve the setpoint.

- Page 43 Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 Flow rate in excess of 100% at zero setpoint. Valve Override pin set to open. If valve override (VOR) pin is active, the valve will be forced open or closed. Set this pin to its normal level before setting a setpoint.

- Page 44 Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 What is the purpose of the Rotary Switchess on top of the SLA7800 Series MFC? Two of the rotary switches are labeled ‘ADDRESS’. These two switches are used to configure the MAC ID of MFC when used on the DeviceNet network.

- Page 45 This scale shift can be approximated by using the ratio of the molar specific heat of the two gases or by sensor conversion factor. Consult factory or nearest Brooks Instrument rep for a list of sensor conversion factors. To change to a new gas, multiply the output reading by the ratio of the gas factor for the desired gas by the gas factor for the calibration gas used.

- Page 46 Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 Then 75 x 0.74 = 55.5 sccm of (CO In order to calculate the conversion factor for a gas mixture, the following formula should be used: Where, = percentage (%) of gas 1 (by volume) = percentage (%) of gas 2 (by volume)

- Page 47 Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 4-4 Orifice Sizing The flow controller's orifice is factory-sized to a preselected gas, operating pressure and flow range. Note that the orifice is marked with its size in thousandths of an inch.

- Page 48 Section 4 Maintenance & Installation and Operation Manual X-TMF-SLA7800-MFC-eng Troubleshooting Part Number: 541B046AAG SLA7800 Series August, 2009 Restrictors The SLA7800 Series MFC uses two types of restrictor assemblies depending on full scale flowrate and expected service conditions. Wire mesh for Nitrogen equivalent flow rates above 3.4 slpm. These restrictor assemblies are made from a cylinder of wire mesh and are easily cleaned if they become contaminated in service.

-

Page 49: Ce Certification Of Mass Flow Equipment

CE mærkning af Masse Flow udstyr Dato Januar-1996. Brooks Instrument har gennemført CE mærkning af elektronisk udstyr med succes, i henhold til regulativet om elektrisk støj (EMC direktivet 89/336/EEC). Der skal dog gøres opmærksom på benyttelsen af signalkabler i forbindelse med CE mærkede udstyr. - Page 50 Installation and Operation Manual X-TMF-SLA7800-MFC-eng CE Certification of Mass Flow Equipment Part Number: 541B046AAG SLA7800 Series August, 2009 English Brooks Instrument 407 West Vine St. Hatfield, PA 19440 U.S.A. Subject Addendum to the Instruction Manual. Reference CE certification of Mass Flow Equipment Date January-1996.

- Page 51 Installation and Operation Manual X-TMF-SLA7800-MFC-eng CE Certification of Mass Flow Equipment Part Number: 541B046AAG SLA7800 Series August, 2009 Français Brooks Instrument 407 West Vine St. Hatfield, PA 19440 U.S.A. Sujet Annexe au Manuel d’Instructions. Référence Certification CE des Débitmètres Massiques à Effet Thermique.

- Page 52 : Januari 1996 Dames en heren, Alle CE gemarkeerde elektrische en elektronische produkten van Brooks Instrument zijn met succes getest en voldoen aan de wetgeving voor Electro Magnetische Compatibiliteit (EMC wetgeving volgens 89/336/EEC). Speciale aandacht is echter vereist wanneer de signaalkabel gekozen wordt voor gebruik met CE gemarkeerde produkten.

- Page 53 Januar 1996 Til den det angår Brooks Instrument elektrisk og elektronisk utstyr påført CE-merket har gjennomgått og bestått prøver som beskrevet i EMC forskrift om elektromagnetisk immunitet, direktiv 89/336/EEC. For å opprettholde denne klassifisering er det av stor viktighet at riktig kabel velges for tilkobling av det måletekniske utstyret.

- Page 54 Section A Installation and Operation Manual X-TMF-SLA7800-MFC-eng CE Certification of Mass Flow Equipment Part Number: 541B046AAG SLA7800 Series August, 2009 Suomi Brooks Instrument 407 West Vine St. Hatfield, PA 19440 U.S.A. Asia : Lisäys Käyttöohjeisiin Viite : Massamäärämittareiden CE sertifiointi Päivämäärä...

- Page 55 Installation and Operation Manual X-TMF-SLA7800-MFC-eng Part Number: 541B046AAG SLA7800 Series August, 2009 THIS PAGE WAS INTENTIONALLY LEFT BLANK...

- Page 56 Europe +31 (0) 318 549 290 Asia +81 (0) 3 5633 7100 Due to Brooks Instrument's commitment to continuous improvement of our products, all specifications are subject to change without notice. TRADEMARKS Brooks ..............Brooks Instrument, LLC DeviceNet ......Open DeviceNet Vendors Association, Inc.

Need help?

Do you have a question about the SLA7850 and is the answer not in the manual?

Questions and answers