Summary of Contents for SMC Networks LEHF32EK2-64-XA147

- Page 1 No:LEH*-OMA0002-B PRODUCT NAME Electric Gripper unit MODEL / Series / Product Number LEHF32EK2-64-XA147...

-

Page 2: Table Of Contents

No:LEH*-OMA0002-B Table of Contents Safety Instructions ..............2 1. Electric Gripper unit detail drawing ......4 2. Specification ................5 3. JXC Controller – UR Control box connection ..5 3.1 Controller wiring and connection ......... 5 3.2 Connect to UR control box ............5 4. -

Page 3: Safety Instructions

No:LEH*-OMA0002-B Gripper unit Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of "Caution", "Warning" or "Danger". They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC) , and other safety regulations. - Page 4 No:LEH*-OMA0002-B Gripper unit Safety Instructions Caution 1.The product is provided for use in manufacturing industries. The product herein described is basically provided for peaceful use in manufacturing industries. If considering using the product in other industries, consult SMC beforehand and exchange specifications or a contract if necessary.

-

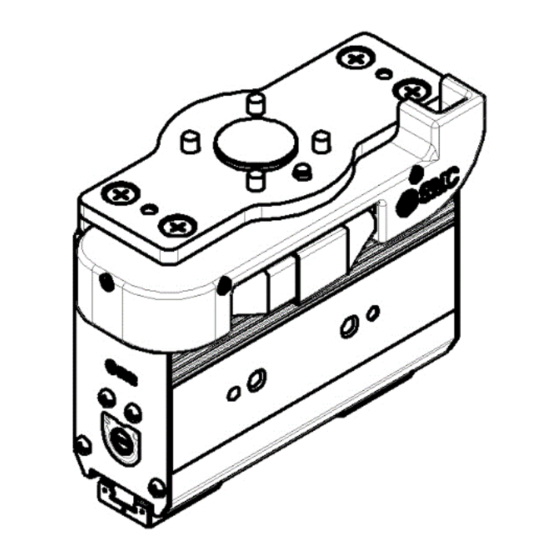

Page 5: Electric Gripper Unit Detail Drawing

No:LEH*-OMA0002-B 1. Electric Gripper unit detail drawing M6x12 Cross recessed countersunk head screw Tightening torque:5.2±10% Flange (ISO 9409-1-50-4-M6) 6x10 Parallel pin M6x12 Cross recessed Countersunk head screw Tightening torque:5.2±10% Electric gripper Cable cover M3x20 Hexagon socket head cap screw Tightening torque:0.32±10% - 4 -... -

Page 6: Specification

No:LEH*-OMA0002-B 2. Specification Actuator:LEHF32EK2-64 * Please check the LEHF Series catalog from our website (www.smcworld.com). Controller:JXC*1 * Please check the LEHF Series catalog from our website (www.smcworld.com). Plugin software PolyScope Version 5.11(e-series only) 3. JXC Controller – UR Control box connection 3.1... -

Page 7: Urcap

No:LEH*-OMA0002-B 4. URCap 4.1 Install URcap 1. Insert the USB memory to which the downloaded file is copied into the teach pendant. 2. Press the menu (hamburger menu icon) in the header and select [Settings]. 3. Click the System and select URCaps. 4. - Page 8 No:LEH*-OMA0002-B 2. Press the "Connect" button to start communication. It may take 2 to 3 seconds. 3. When the controller is connected, the LED light will turn green. - 7 -...

-

Page 9: Installation Settings

No:LEH*-OMA0002-B 4.3 Installation Settings Press the [Installation] tab and select "SMC Electric Gripper Unit" from the [URCaps] menu. Then, perform the installation setting "Installation Settings" of the electric gripper URCap. 1. Popup a message window and stop operation in error. Select whether to popup a message window and stop operation when the electric gripper unit detects an error. - Page 10 No:LEH*-OMA0002-B 2. Various status signal output to digital output port. Select whether to output a status signal to the digital output port when "Gripping success", "Gripping failiure", or "workpiece drop” is detected. <“Enable” is selected> Selection of the digital output port is enabled. If any of "Gripping success", "grip failure", or "workpiece drop"...

- Page 11 No:LEH*-OMA0002-B <Disable is selected> The selection of the digital output port is disabled. If any of "Gripping success", "Gripping failure", or "workpiece drop" is detected, no status signal is output. 3. Return to origin Perform return to origin. It is necessary to perform a return to origin operation at the first connection when the items below are applicable.

-

Page 12: Programs

No:LEH*-OMA0002-B 4.4 Programs URCap nodes can be selected in the URCaps tree. The electric gripper unit URCap has three types of program commands. 1. Activate command Used to initialize the electric gripper. It needs to be executed only once before executing the Grip command or Release command. During the activation, if an error occurs in communication with the electric gripper or if an alarm occurs in the electric gripper, a pop-up error message will be displayed and the operation will stop. - Page 13 No:LEH*-OMA0002-B (2) Settings Set the parameters required to grip the workpiece with outer diameter / inner diameter. ・Gripping Position Set the gripping position of the workpiece. [Minimum value]: 2.00mm [Maximum value]: 62.00mm [Initial value]: 2.00mm - Speed Set the moving speed of the workpiece to the gripping position. [Minimum value]: 5mm/sec [Maximum value]: 30mm/sec [Initial value]: 5mm/sec - Force Set the pushing force.

- Page 14 No:LEH*-OMA0002-B (3) Gripper Control Controls the electric gripper position. If the LED lamp is green, the electric gripper is controllable. - Current Position Displays the current position of the electric gripper. - "Open Jog” button Performs the opening operation of the electric gripper while the button is pressed. - “Close Jog”...

- Page 15 No:LEH*-OMA0002-B (4) Operation Status The test operation executed by the "Execute" button is displayed. - "Execute": Test run is being executed - "Success": Workpiece gripping successful, test operation completed normally - "Failure": Workpiece gripping error occurred, test operation abnormally ended. - "Workpiece lost": Detects workpiece drop after successful workpiece gripping.

- Page 16 No:LEH*-OMA0002-B (2) Settings Set the parameters required to open the workpiece. - Position Set the target position [Minimum value]: 1.00mm [Maximum value: 64.00mm [Initial value]: 1.00mm - Speed Sets the speed to travel to the target position. [Minimum value]: 5mm/sec [Maximum value]: 100mm/sec [Initial value]: 5mm/sec - “Execute”...

- Page 17 No:LEH*-OMA0002-B (4) Operation Status The test operation executed by the "Execute" button is displayed. - "Execute": Test run is being executed - "Success": Workpiece gripping successful, test operation completed normally - "Failure": Workpiece gripping error occurred, test operation abnormally ended. - "Workpiece lost": Detects workpiece drop after successful workpiece gripping.

-

Page 18: Manual Operation

No:LEH*-OMA0002-B 4. Workpiece drop detection From the execution of the Grip command to the next Release command, the grip status of the workpiece is monitored and the workpiece drop is detected. (1) Conditions for starting the workpiece drop detection. - "Various status signal output to digital output port." in "Installation Settings" of the electric gripper URCap is valid. -

Page 19: Alarm Detection And Trouble Shooting

No:LEH*-OMA0002-B 5. Alarm detection and trouble shooting 5.1 Alarm detection When an alarm occurs, an "Alarm Code" is displayed. For details of "Alarm Code", refer to "Electric Controller JXC Series Instruction Manual Alarm Detection". 5.2 Trouble shooting If a malfunction occurs, refer to "Electric Controller JXC Series Instruction Manual Troubleshooting" and check the appropriate item. -

Page 20: Dimensions And Center Of Gravity

No:LEH*-OMA0002-B 6. Dimensions and Center of gravity 6.1 Dimensions - 19 -... -

Page 21: Center Of Gravity

No:LEH*-OMA0002-B 6.2 Center of gravity Center of gravity and weight Weight [g] 2410 -10.0 66.0 - 20 -... - Page 22 No:LEH*-OMA0002-B Revision history -: First edition [April 2022] A: [April 2023] B: [April 2023] 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPAN Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362 URL https://www.smcworld.com Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer. ©...

Need help?

Do you have a question about the LEHF32EK2-64-XA147 and is the answer not in the manual?

Questions and answers