Table of Contents

Advertisement

Quick Links

INSTALLATION

AND OPERATION

MANUAL

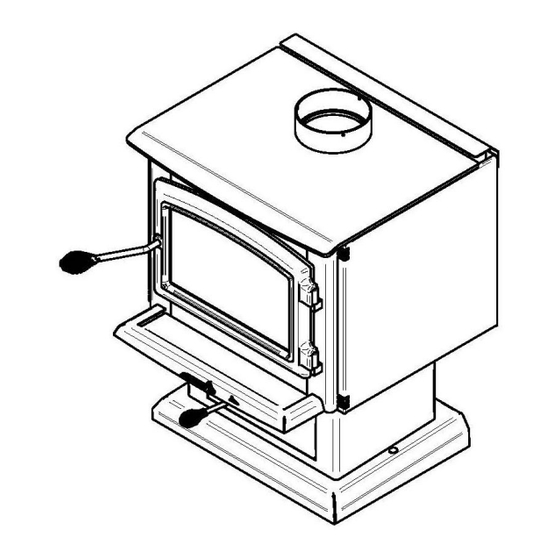

Solution 1.6

(Model EB00037)

Distributed by:

My Fireplace Australia Pty Limited

Factory 2, 5-7 Hogan Court, Pakenham,

Victoria 3810

Phone number 03 59 415 008

www.myfireplaceaustralia.com.au

READ AND KEEP THIS MANUAL FOR REFERENCE

This manual is available for free download on the distributor's web site. It is a copyrighted

document. Re-sale is strictly prohibited. The distributor may update this manual from time to time

and cannot be responsible for problems, injuries, or damages arising out of the use of information

contained in any manual obtained from unauthorized sources.

45838A

Printed in Canada

27-04-2016

Advertisement

Table of Contents

Summary of Contents for Enerzone Solution 1.6

- Page 1 INSTALLATION AND OPERATION MANUAL Solution 1.6 (Model EB00037) Distributed by: My Fireplace Australia Pty Limited Factory 2, 5-7 Hogan Court, Pakenham, Victoria 3810 Phone number 03 59 415 008 www.myfireplaceaustralia.com.au READ AND KEEP THIS MANUAL FOR REFERENCE This manual is available for free download on the distributor’s web site. It is a copyrighted document.

- Page 2 Consult your local city, borough or shire council about restrictions and installations requirements in your area and the need to obtain a permit. KEEP THIS INSTRUCTION MANUAL FOR FUTURE REFERENCE. Solution 1.6 Installation and Operation Manual...

-

Page 3: Table Of Contents

Zone Heating and How to Make it Work for You ..............9 The Benefits of Low Emissions and High Efficiency ............... 9 Enerzone’s Commitment to You and the Environment ............10 2.4.1 What is Your New Wood fire Made Of? ................10 Fuel .................... - Page 4 The Relationship Between the Flue System and the House ..........33 8.4.1 Why Inside Flue Systems are Preferred ................33 8.4.2 Why the Flue System Should Penetrate the Highest Heated Space ........ 34 Installing the flue Connector ....................34 Solution 1.6 Installation and Operation Manual...

- Page 5 Keep your sales invoice. We also recommend that you register your warranty online at www.myfireplaceaustralia.com.au Registering your warranty online will help us track rapidly the information we need on your wood fire. Solution 1.6 Installation and Operation Manual...

-

Page 6: Part A - Operation And Maintenance

SALT WATER DRIFTWOOD, OR o RAILROAD TIES. • DO NOT ELEVATE THE FIRE BY USING A GRATE IN THIS WOOD FIRE. • THIS APPLIANCE SHOULD BE MAINTAINED AND OPERATED AT ALL TIMES IN ACCORDANCE WITH THESE INSTRUCTIONS. Solution 1.6 Installation and Operation Manual... -

Page 7: General Information

* Burn time and heating capacity may vary subject to location in home, flue system draft, flue system diameter, locality, heat loss factors, climate, fuels and other variables. ** Sideways: through the door you see the sides of the logs. Solution 1.6 Installation and Operation Manual... - Page 8 Solution 1.6 Installation and Operation Manual...

-

Page 9: Zone Heating And How To Make It Work For You

2.2 ZONE HEATING AND HOW TO MAKE IT WORK FOR YOU Your new Enerzone Solution 1.6 wood fire is a space heater, which means it is intended to heat the area it is installed in, as well as spaces that connect to that area, although to a lower temperature. -

Page 10: Enerzone's Commitment To You And The Environment

2.4 ENERZONE’S COMMITMENT TO YOU AND THE ENVIRONMENT The Enerzone team is committed to protecting the environment, so we do everything we can to use only materials in our products that will have no lasting negative impact on the environment. -

Page 11: Fuel

The most common standard length of firewood is 400 mm (16”). The pieces should be a consistent length, with a maximum of 25 mm (1”) variation from piece to piece. Solution 1.6 Installation and Operation Manual... -

Page 12: Piece Size

• firewood that is ready to burn has a moisture content between15 and 20% by weight and will allow your wood fire to produce its highest possible efficiency Solution 1.6 Installation and Operation Manual... -

Page 13: Judging Firewood Moisture Content

NEVER LOAD YOUR WOOD FIRE UP TO THE BAFFLE. ALWAYS LEAVE 5 TO 10 CENTIMETERS TO ALLOW PROPER COMBUSTION THROUGH SECONDARY AIR OPENINGS (NEVER PUT WOOD ABOVE THE FIREBRICK LINING ON THE FIREBOX). THIS WILL ALSO PREVENT OVERFIRING OF YOUR WOOD FIRE. Solution 1.6 Installation and Operation Manual... -

Page 14: Your First Fires

DO NOT LEAVE THE WOOD FIRE UNATTENDED WHEN THE DOOR IS SLIGHTLY OPENED DURING IGNITION. ALWAYS CLOSE THE DOOR AFTER IGNITION. Solution 1.6 Installation and Operation Manual... -

Page 15: The Top Down Fire

Do not expect steady heat output from your wood fire. It is normal for its surface temperature to rise after a new load of wood is ignited and for its temperature to gradually decline as the fire Solution 1.6 Installation and Operation Manual... -

Page 16: Ash Removal

There are two reasons for this raking of the coals. First, it concentrates them near where most of the combustion air enters the firebox and where they can ignite the new Solution 1.6 Installation and Operation Manual... -

Page 17: Firing Each New Load Hot

Second, the flow rate of exhaust through the wood fire and flue slows down, which gives more time for the transfer of heat Solution 1.6 Installation and Operation Manual... -

Page 18: Building Different Fires For Different Needs

You will need to fire the load hot for long enough to fully char the log surfaces before you can turn the air down. Make sure the fire is flaming brightly before leaving the fire to burn. Solution 1.6 Installation and Operation Manual... - Page 19 Shorter burn cycles make it easier to match the heat output of the wood fire to the heat demand of the space. Solution 1.6 Installation and Operation Manual...

-

Page 20: Maintaining Your Wood Heating System

If you see brown streaks coming from the edge of the glass, it is time to replace the gasket around the glass. Visit your wood fire retailer to get the self-adhesive glass gasket and follow the instructions below for installation. Solution 1.6 Installation and Operation Manual... -

Page 21: Door Adjustment

3. Remove or add one washer (A) as needed. Keep the removed washer for future adjustment. 4. Re-install the key path pin in the key-way and slide the latch along it. 5. Secure with the nut. Solution 1.6 Installation and Operation Manual... -

Page 22: Replacing The Door Gasket

Do not abuse the glass door by striking or slamming shut. DO NOT USE THE WOOD FIRE IF THE GLASS IS BROKEN. Solution 1.6 Installation and Operation Manual... -

Page 23: Cleaning And Painting The Wood Fire

Even if creosote forms slowly in your system, the flue system should be cleaned and inspected at least once each year. Solution 1.6 Installation and Operation Manual... -

Page 24: Cleaning The Flue System

If so, have the damaged ones replaced. Check the firebrick for damage at least annually and replace any broken or damaged ones with new ones. Inspection and cleaning of the flue system is facilitated by the removable baffle. Solution 1.6 Installation and Operation Manual... -

Page 25: Part B - Installation

DO NOT CONNECT TO OR USE IN CONJUNCTION WITH ANY AIR DISTRIBUTION DUCTWORK UNLESS SPECIFICALLY APPROVED FOR SUCH INSTALLATION. • DO NOT CONNECT THIS UNIT TO A FLUE OR FLUE SYSTEM SERVING ANOTHER APPLIANCE. Solution 1.6 Installation and Operation Manual... -

Page 26: Regulations Covering Wood Fire Installation

6.2 REGULATIONS COVERING WOOD FIRE INSTALLATION IT IS RECOMMENDED THAT THE INSTALLATION OF YOUR ENERZONE WOOD FIRE BE CARRIED OUT BY A QUALIFIED SPECIALIST INSTALLER. IF ANY ELECTRICAL WORK IS REQUIRED, IT MUST BE CARRIED OUT BY A LICENSED ELECTRICIAN. -

Page 27: Clearances To Heat-Sensitive Materials

Bottom of appliance to ceiling height must be at least 2,400 mm in all cases. The clearance between the flue and a wall are valid only for vertical walls and for vertical flue. Solution 1.6 Installation and Operation Manual... -

Page 28: Floor Protector

**The floor protector shall extend not less than 200 mm from each side of any ash removal or fuel loading openings unless the floor protector forms an abutment with a wall or heat shield at a lesser distance. Solution 1.6 Installation and Operation Manual... -

Page 29: Reducing Wall And Ceiling Clearances Safely

1- Masonry may be used as a heat shield material. 2- Where heat shields are used to reduce appliance clearance dimensions, additional flue shielding may also be required. Refer to AS/NZS 2918:2001. 3- Non standard installations – Refer to AS/NZS 2918:2001 for guidance. Solution 1.6 Installation and Operation Manual... - Page 30 0.60 NOTES: 1- Masonry may be used as a heat shield material. 2- Where heat shields are used to reduce appliance clearance dimensions, additional flue shielding may also be required. Refer to AS/NZS 2918:2001. Solution 1.6 Installation and Operation Manual...

-

Page 31: The Flue System

It is essential the flue pipe is manufactured from stainless steel that meet the specifications stated in AS/NZS 2918, as stainless steel can be damaged by excessive stress in the lock forming process or by faulty machinery. Solution 1.6 Installation and Operation Manual... -

Page 32: Masonry Flue Systems

8 m (25 feet) in height. When passing through a combustible wall, the use of an insulated listed thimble is required. 8.3 MINIMUM FLUE SYSTEM HEIGHT Flue heights and lengths from AS/NZS 2918:2001 Solution 1.6 Installation and Operation Manual... -

Page 33: The Relationship Between The Flue System And The House

Outside flue systems are a problem because when even when no fire is burning, there is no fire burns they will go into cold downdraught if normally upward flow in the system. the wood fire is installed low in the house. Solution 1.6 Installation and Operation Manual... -

Page 34: Why The Flue System Should Penetrate The Highest Heated Space

Straight assemblies are less likely to cause problems like smoke roll-out when the door is opened for loading. They are also more stable and easier to maintain than assemblies with elbows. Horizontal runs of flue should be avoided where possible because they reduce flue system draft. Solution 1.6 Installation and Operation Manual... - Page 35 Use 45 degree elbows where possible, instead of 90 degree elbows. Solution 1.6 Installation and Operation Manual...

- Page 36 A straight flue offers the least restriction to gas flow and results in stronger draft. Straight assemblies also need less maintenance because there are no corners to collect creosote. The flue must be in good condition. Solution 1.6 Installation and Operation Manual...

-

Page 37: Appendix 1: Installing The Optional Door Overlay

4 included screws (B). To facilitate the installation, do not tighten the screws until they are all installed. Note: It is not necessary to remove the glass or any other component to install the overlay Solution 1.6 Installation and Operation Manual... -

Page 38: Appendix 2: Installing Trims

APPENDIX 2: INSTALLING TRIMS Your freestanding ENERZONE wood fire is equipped with decorative u-shaped trims. See installation instructions below: 1- Remove the 7 screws that secure the side panels and the rear top air deflector. 2- Slide the panels towards the front to release them from the front brackets. -

Page 39: Appendix 3: Installing The Optional Fresh Air Intake Kit (Ac01336)

This wood fire is may be connected to a fresh air intake KIT (D) (AC01336). The insulated fresh air intake pipe (E) (AC02090), sold separately. When installed with a fresh air intake kit, the wood fire must be anchored to the floor. Installation of AC01336: Wall installation Solution 1.6 Installation and Operation Manual... -

Page 40: Appendix 4: Installation And Use Of Blower And Thermodisc

CAUTION: ENSURE THAT THE BLOWER’S POWER CORD IS NOT IN CONTACT WITH ANY SURFACE OF THE WOOD FIRE TO PREVENT ELECTRICAL SHOCK OR FIRE DAMAGE. DO NOT RUN THE POWER CORD BENEATH THE WOOD FIRE. Solution 1.6 Installation and Operation Manual... -

Page 41: Appendix 5: Installation Of Secondary Air Tubes And Baffle

A. Make sure the notch reaches the end of the key way. 3- Repeat step 1 and 2 for the other secondary air tubes*. 4- To remove the tubes use the above steps in reverse order. Solution 1.6 Installation and Operation Manual... - Page 42 Type of tube Front ► 30 holes of 3.55 mm Solution 1.6 Middle front ► 30 holes of 3.8 mm Middle rear ► 30 holes of 3.8 mm Rear ► 20 holes of 3.25 mm Solution 1.6 Installation and Operation Manual...

-

Page 43: Appendix 6: Exploded Diagram And Parts List

APPENDIX 6: EXPLODED DIAGRAM AND PARTS LIST Solution 1.6 Installation and Operation Manual... - Page 44 BUILD TO ORDER PL54611 REAR PLATE 30131 BLACK METAL SCREW #10 X 1/2" TYPE "A" PAN QUADREX 30418 FINISHING PLUG 3/8" PL54683 FRONT DASH 99999 BUILD TO ORDER SE54684 ASH DRAWER ASSEMBLY PL54683 FRONT DASH Solution 1.6 Installation and Operation Manual...

- Page 45 3" X 9" X 1 1/4'' REFRACTORY BRICK PL54512 FRONT SECONDARY AIR TUBE PL54728 MIDDLE FRONT SECONDARY AIR TUBE PL54728 MIDDLE REAR SECONDARY AIR TUBE PL54730 REAR SECONDARY AIR TUBE 21396 BAFFLE C-CAST BOARD (17-1/8'' X 9-3/4'' X 1-1/4'') Solution 1.6 Installation and Operation Manual...

- Page 46 Solution 1.6 Installation and Operation Manual...

-

Page 47: Enerzone Product Warranty

(with each of the below periods commencing on the date the Enerzone product was purchased by you as a brand new product from a retailer located in Australia): WARRANTY APPLICATION... - Page 48 Goods presented for repair may be replaced by refurbished goods of the same type rather than being repaired. Refurbished parts may be used to repair the goods. Enerzone products are designed and supplied for normal domestic use. We will not be liable to you under this warranty for business loss or damage of any kind whatsoever.

Need help?

Do you have a question about the Solution 1.6 and is the answer not in the manual?

Questions and answers