Table of Contents

Advertisement

Quick Links

Installation

and Operation

Manual

Safety tested according to ULC S627,

UL 1482 and UL 737 standards by an

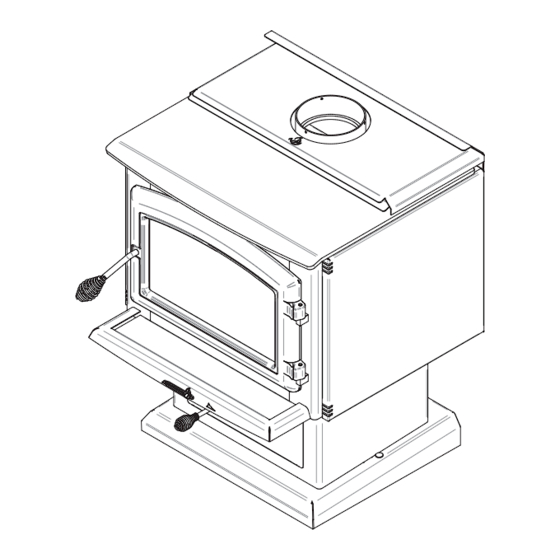

SOLUTION 2.3

accredited laboratory.

(EB00041 model)

US Environmental Protection Agency

phase II certified wood stove compliant

with 2020 cord wood standard.

MOBILE

HOME

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION REQUIREMENTS IN

LOCAL AREA.

READ THIS ENTIRE MANUAL BEFORE INSTALLATION AND USE OF THIS WOOD STOVE. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH.

READ AND KEEP THIS MANUAL FOR REFERENCE

Printed in Canada

45923A

Advertisement

Table of Contents

Summary of Contents for Enerzone EB00041

- Page 1 Operation Manual Safety tested according to ULC S627, UL 1482 and UL 737 standards by an SOLUTION 2.3 accredited laboratory. (EB00041 model) US Environmental Protection Agency phase II certified wood stove compliant with 2020 cord wood standard. MOBILE HOME CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION REQUIREMENTS IN LOCAL AREA.

- Page 3 It is also highly recommended to register the warranty online at https://www.enerzone-intl.com/en/warranty/warranty-registration/ Registering the warranty will help to quickly find the information needed on the unit. Installation and Operation Manual - Solution 2.3...

-

Page 4: Table Of Contents

TABLE OF CONTENTS PART A - OPERATION AND MAINTENANCE ................7 1. Safety Information ........................7 2. General Information ........................8 2.1 Performances ........................8 2.2 Specifications ........................9 2.3 Dimensions ........................10 2.4 Zone Heating and How to Make it Work for You ..............15 2.5 The Benefits of Low Emissions and High Efficiency ............15 2.6 The SBI Commitment to You and the Environment ............15 3. - Page 5 Appendix 7: Optional Fire Screen Installation ................56 Appendix 8: optional Blower and thermodisc installation ............57 Appendix 9: Air Tubes and Baffle Installation ................58 Appendix 10: Exploded Diagram and Parts List ............... 60 ENERZONE Limited Lifetime Warranty ..................63 Dealer: Installer: Phone Number: Serial Number: Installation and Operation Manual - Solution 2.3...

- Page 6 CERTIFICATION PLATE Page 6 Installation and Operation Manual - Solution 2.3...

-

Page 7: Part A - Operation And Maintenance

PART A - OPERATION AND MAINTENANCE 1. Safety Information • Operate only with the door fully closed or fully open with the fire screen in place. If the door is left partly open, gas and flame may be drawn out of the opening, creating risks from both fire and smoke. -

Page 8: General Information

2.1 Performances Values are as measured per test method, except for the recommended heating area, firebox volume, maximum burn time and maximum heat output. Model Solution 2.3 (EB00041) Fuel Type Dry Cordwood Recommended heating area (sq. ft. 500 to 2,100 ft... -

Page 9: Specifications

2.2 Specifications Maximum log length 20 in (508 mm) east-west Flue outlet diameter 6 in (150 mm) Recommended connector pipe diameter 6 in (150 mm) Type of chimney ULC S629, UL 103 HT (2100 °F) Baffle material C-Cast Approved for alcove installation Approved for mobile home installation Shipping weight (without option) 375 lb (170 kg) -

Page 10: Dimensions

2.3 Dimensions 2.3.1 Stove Dimensions With Leg Kit AC01206 or AC01208 26" 660mm 13" 330mm 6 5/8" 168mm 8 3/4" 224mm 16 1/4" 413mm 6" Ø 150mm 9 7/8" 252mm 25 5/8" 651mm 28 1/4" 717mm Figure 1: Top view Figure 2: Front view 10 7/8"... - Page 11 2.3.2 Stove Dimensions With Leg Kit AC01293 or AC01294 26" 660mm 13" 330mm 6 5/8" 168mm 8 3/4" 224mm 16 1/4" 413mm 6" Ø 150mm 10" 254mm 25 5/8" 651mm 26 5/8" 675mm Figure 4: Top view Figure 5: Front view 10 7/8"...

- Page 12 2.3.3 Stove Dimensions With Leg Kit AC01295 or AC01296 26" 660mm 13" 330mm 6 5/8" 168mm 8 3/4" 224mm 16 1/4" 413mm 6" Ø 150mm 11" 281mm 25 1/4" 641mm 25 5/8" 651mm Figure 7: Top view Figure 8: Front view 10 7/8"...

- Page 13 2.3.4 Stove Dimensions With Pedestal 26" 660mm 13" 330mm 6 5/8" 168mm 8 3/4" 224mm 16 1/4" 413mm 6" Ø 150mm 12 7/8" 326mm 21 1/2" 547mm 25 5/8" 651mm Figure 10: Top view Figure 11: Front view 10 7/8" 278mm 33 1/2"...

- Page 14 2.3.5 Combustion Chamber Dimensions 9 3/4" 248mm 17 1/2" 444mm 21" 533mm Figure 13: Door opening Figure 14: Front view - Combustion chamber 3/16" 3/8" 10mm 11 7/8" 301mm 16 1/2" 419mm Figure 15: Side view - Combustion chamber Page 14 Installation and Operation Manual - Solution 2.3...

-

Page 15: Zone Heating And How To Make It Work For You

2.4 Zone Heating and How to Make it Work for You This stove is a space heater, which means it is intended to heat the area it is installed in, as well as spaces that connect to that area, although to a lower temperature. This is called zone heating and it is an increasingly popular way to heat homes or spaces within homes. -

Page 16: Fuel

The paint coating on the stove is very thin. Its VOC content (Volatile Organic Compounds) is very low. VOCs can be responsible for smog, so all the paint used during the manufacturing process meets the latest air quality requirements regarding VOC reduction or elimination. The air tubes are stainless steel, which can also be recycled. -

Page 17: How To Prepare Or Buy Good Firewood

3.1 How to Prepare or Buy Good Firewood 3.1.1 What is Good Firewood? Good firewood has been cut to the correct length for the stove, split to a range of sizes and stacked in the open until its moisture content is down to 15% to 20%. 3.1.2 Tree Species The tree species the firewood is produced from is less important than its moisture content. - Page 18 Wood should be split to a range of sizes, from about 3" to 6" (75 mm to 150 mm) in cross section. Having a range of sizes makes starting and rekindling fires much easier. Often, the firewood purchased from commercial suppliers is not split small enough to fuel the fire. It is sometimes advisable to resplit the wood before stacking to air dry.

-

Page 19: Operating Your Stove

3.1.7 Manufactured Logs Do not burn manufactured logs made of wax impregnated sawdust or logs with any chemical additives. Manufactured logs made of 100% compressed sawdust can be burned with caution in the number of these logs burned at one time. Start with one manufactured log and see how the stove reacts. -

Page 20: The First Fires

Potential causes of smoke spillage are described in Section «8. The Venting System» of this manual. See «Appendix 7: Optional Fire Screen Installation» for installation instructions. OPERATING THE STOVE WITH A FIRE SCREEN INCREASES POSSIBILITIES OF GENERATING CARBON MONOXIDE. CARBON MONOXIDE IS AN ODOURLESS GAS THAT IS HIGHLY TOXIC WHICH CAN CAUSE DEATH AT HIGH CONCENTRATION IN AIR. -

Page 21: Lighting Fires

As hotter and hotter fires are burnt, more of the painted surfaces reach the curing temperature of the paint. The smell of curing paint does not disappear until one or two very hot fires have been burnt. 4.4 Lighting Fires Each person heating with wood develops its own favorite way to light fires. -

Page 22: Maintaining Wood Fires

4.4.4 Using Fire Starters Commercial fire starters can be used instead of newspaper. Some of these starters are made of sawdust and wax and others are made of specialized flammable solid chemicals. Always follow the package directions when using. Gel starter can also be used, but only to light a fire, in a cold combustion chamber without hot embers inside. - Page 23 Ashes can contain hot embers that can stay hot for several days. If the ashes are disposed of by burial in soil or otherwise locally dispersed, they should be kept in the closed metal container until they are completly cooled. No other waste should be placed in this container. NEVER STORE ASHES INDOORS OR IN A NON-METALIC CONTAINER OR ON A WOODEN DECK.

-

Page 24: Building Different Fires For Different Needs

4.5.5 Controling the Air Intake Once the firewood, firebox and chimney are hot, air intake can be reduced to achieve a steady burn. As the air intake is reduced, the burn rate decreases. This has the effect of distributing the thermal energy of the fuel over a longer period of time. - Page 25 Sprecial attention must be paid when building fires like this since if the air intake is reduced too quickly, the fire could smoulder. The wood must be flaming brightly before leaving the fire to burn. 4.6.4 Maximum Burn Cycle Times The burn cycle time is the period between loading wood on a coal bed and the consumption of that wood back to a coal bed of the same size.

-

Page 26: Maintaining Your Wood Heating System

5. Maintaining Your Wood Heating System 5.1 Stove Maintenance This stove will give many years of reliable service if used and maintained properly. Some of the internal components of the firebox, such as firebricks, baffle and air tubes, will wear over time under intense heat. - Page 27 The gasket seal may be improved with a simple latch mechanism adjustment: Unscrew the nut (A). Remove the door latch (B) and the key path pin (C). Remove or add one washer (D) as needed. Keep the removed washer for future adjustment. Re-install the key path pin (C) in the key-way and slide the latch (B) along it.

- Page 28 Remove the door and place it face-down on something soft like a cushion of rags or a piece of carpet. Remove the old gasket from the door by pulling and prying it out with an old screw driver. Then use the screwdriver to scrape the old gasket adhesive from the door gasket groove. Apply a bead of approximately ¼"...

-

Page 29: Chimney Maintenance

5.1.6 Firebricks Before installing the firebrick, ensure that none are broken or damaged in any way, and replace the damaged ones. Check the firebrick for damage at least annually and replace any broken or damaged ones with new ones. 5.2 Chimney Maintenance 5.2.1 Why Cleaning the Chimney Is Necessary Wood smoke can condense inside the chimney, forming a inflammable deposit called creosote. -

Page 30: Part B - Installation

PART B - INSTALLATION 6. Safety Information and Standards • The information given on the certification label affixed to the appliance always overrides the information published, in any other media (owner’s manual, catalogues, flyers, magazines and web sites). • Mixing of appliance components from different sources or modifying components may result in hazardous condtions. -

Page 31: Clearances To Combustible Material

7. Clearances to Combustible Material The clearances shown in this section have been determined by test according to procedures set out in safety standards ULC S627 (Canada), UL 1482 (U.S.A.) and UL 737 (U.S.A.). When the stove is installed so that its surfaces are at or beyond the minimum clearances specified, combustible surfaces will not overheat under normal and even abnormal operating conditions. - Page 32 Figure 23: Clearances -Side Figure 24: Clearances - Top Figure 25: Clearances - Corner Page 32 Installation and Operation Manual - Solution 2.3...

- Page 33 APPLIANCE CLEARANCES (INSTALLATION APPLIANCE CLEARANCES (INSTALLATION WITH SINGLE WALL PIPE CONNECTOR) WITH DOUBLE WALL PIPE CONNECTOR) Canada Canada 14 ½" (368 mm) 11" (279 mm) 6" (152 mm) 6" (152 mm) 17" (432 mm) 16" (406 mm) 17" (432 mm) 16"...

- Page 34 7.2.2 Clearances With Lowered Ceiling APPLIANCE CLEARANCES (INSTALLATION APPLIANCE CLEARANCES (INSTALLATION WITH SINGLE WALL PIPE CONNECTOR) WITH DOUBLE WALL PIPE CONNECTOR) Canada Canada 14 ½" (368 mm) 11" (279 mm) 9" (229 mm) 9" (229 mm) 19" (483 mm) 18" (457 mm) 19"...

- Page 35 7.2.4 Clerances Inside an Alcove APPLIANCE CLEARANCES (INSTALLATION DISTANCES FROM PIPE CONNECTOR WITH WITH DOUBLE WALL PIPE CONNECTOR) DOUBLE WALL PIPE CONNECTOR Canada Canada 9" (229 mm) 9" (229 mm) 12 ¼" (311 mm) 12 ¼" (311 mm) 19" (483 mm) 19"...

-

Page 36: Floor Protector

7.3 Floor Protector This stove is designed to prevent the floor from overheating. However, it must be placed on a non-flammable surface to protect the floor from hot embers that may fall during loading. The floor protection must be a continuous, non combustible material, such as steel with a minimum thickness of 0.015"... -

Page 37: Reducing Wall And Ceiling Clearances Safely

7.4 Reducing Wall and Ceiling Clearances Safely It is often desired to use as little space as possible when installing a woodstove. To do this, it is possible to reduce the clearances safely and install the stove closer to the walls by permanently installing a heat shield between the stove and the flammable material. - Page 38 Figure 29: Heat shield clearances Figure 30: Heat shield clearances Figure 31: Heat shield clearances Page 38 Installation and Operation Manual - Solution 2.3...

- Page 39 CLEARANCES MAY BE REDUCED BY THESE PERCENTAGES TYPE OF SHIELD SIDES AND REAR TOP (CEILING) CAN /USA CAN /USA MIN. MIN. Sheet metal, a minimum of 24 gauge (0.61 mm) in thickness , spaced out at least 25 mm (1 in)* by non-combustible spacers 12"...

-

Page 40: The Venting System

8. The Venting System 8.1 General The venting system, made of the chimney and the connecting pipe between the stove and the chimney, acts as the engine that drives the wood heating system. Even the best stove will not function safely and efficiently if it is not connected to a suitable chimney. The heat in the flue gases that pass from the stove and chimney connector into the chimney is not waste heat. - Page 41 8.2.2 Factory-Built Metal Chimneys in Mobile Homes For use in a mobile home, this stove is to be connected to a 6" double wall factory built chimney pipe conforming to UCL-S629, standards for 650°C Factory-built chimney. The total length of the flue system should be at least 12 feet including elbows, from the top of the stove.

-

Page 42: Minimum Chimney Height

8.3 Minimum Chimney Height The top of the chimney should be tall enough to be above the air turbulence caused when wind blows against the house and its roof. The chimney must extend at least 1 m (3 ft.) above the highest point of contact with the roof, and at least 60 cm (2 ft.) higher than any roof line or obstacle within a horizontal distance of 3 m (10 ft.). -

Page 43: Supply Of Combustion Air

8.4.2 Why the Chimney Should Penetrate the Highest Heated Space When it is cold outside, the warm air in the house is buoyant so it tends to rise. This creates a slight pressure difference in the house. Called ‘stack effect’, it produces a slightly negative pressure in the lower part of the house (compared to the outside) and a slightly positive pressure zone in the high part of the house. -

Page 44: Installing The Chimney Connector

Contrary to commonly expressed concerns, almost all tightly-sealed new houses have enough natural leakage to provide the small amount of air needed by the stove. The only case in which the wood stove may not have adequate access to combustion air is if the operation of a powerful exhaust device (such as a kitchen range exhaust) causes the pressure in the house to become negative relative to outdoors. - Page 45 8.6.1 Installation of Single Wall Chimney Connector The chimney connector assembly has been called ‘the weak link’ in the safety of wood heating systems because failure to install the connector properly (which has been common in the past) can result in house fires. The best flue pipe assembly is one that rises straight up from the stove to the base of the chimney with no elbows.

- Page 46 • Each joint in the assembly must be fastened with at least three screws. • The assembly must have allowance for expansion: elbows in assemblies allow for expansion; straight assemblies should include an inspection wrap with one end unfastened, or a telescopic section. •...

-

Page 47: Appendix 1 : Legs Installation

APPENDIX 1 : LEGS INSTALLATION Remove the door, the firebricks, and the ash plug from the stove. DETAIL A Put the stove on its back. Remove and dispose of the two freight supports (D). Keep the nuts (C) and washers (B) for step 4. Installation and Operation Manual - Solution 2.3 Page 47... - Page 48 Install the legs (E) on the legs supports (F). Secure with the washers (G) and nuts (H) supplied with the leg assembly. DETAIL A With the nuts (K) and washers (J) removed in step 1; secure both leg assemblies to the stove. Page 48 Installation and Operation Manual - Solution 2.3...

- Page 49 Put the stove on its legs, open and install the ash drawer included with the kit. Put back the firebricks, the spacers, the cast iron ash plug and the door on the stove. See step 1. The baffle and the bricks must be put back at the right place after the final positioning of the stove Installation and Operation Manual - Solution 2.3 Page 49...

-

Page 50: Appendix 2 : Pedestal Installation

APPENDIX 2 : PEDESTAL INSTALLATION Remove the door, the firebricks, the spacers and the ash plug from the stove. DETAIL A Put the stove on its back. Remove and dispose of the two freight supports (D). Keep the nuts (C) and washers (B) for step 3. Page 50 Installation and Operation Manual - Solution 2.3... - Page 51 Install the pedestal (E) on the stove and screw it in place using the 4 the nuts (G) and washers (F) kept from step 2. Put the stove on its pedestal and install the fresh air panel (L) with the screws (M), the molding (K) with the screws (J) and install the ash drawer (H).

-

Page 52: Appendix 3: Door Overlay Installation

APPENDIX 3: DOOR OVERLAY INSTALLATION Position the overlay (A) on the door frame and secure it in place from behind using the screws (B). To ease the installation, do not tighten the screws until they are all installed. Note: It is not necessary to remove the glass to install the overlay. Page 52 Installation and Operation Manual - Solution 2.3... -

Page 53: Appendix 4: Decorative Accent Installation

APPENDIX 4: DECORATIVE ACCENT INSTALLATION Remove both decorative panels (A) and (B) and also the heat deflector (C). Remove the protective film and install the decorative accents (D) found in the user manual kit. Reinstall the decorative panels (A) and (B) first. Then the heat deflector (C). Installation and Operation Manual - Solution 2.3 Page 53... -

Page 54: Appendix 5 : Optional Air Mate Installation

APPENDIX 5 : OPTIONAL AIR MATE INSTALLATION This wood stove can be equippel with an optional air mate. It accumulates heat and increase the air flow. Remove the heat deflector (A), keep the screws (B). Install the air mate (C) and fix it in place using the 3 screws (B) removed previously Page 54 Installation and Operation Manual - Solution 2.3... -

Page 55: Appendix 6: Optional Fresh Air Intake Kit Installation

APPENDIX 6: OPTIONAL FRESH AIR INTAKE KIT INSTALLATION This mobile home approved stove requires installation of a fresh air intake kit (A) and an insulated fresh air intake pipe (HVAC type, must meet ULC S110 or UL 181 class 0 or class 1) (B), sold separately. -

Page 56: Appendix 7: Optional Fire Screen Installation

APPENDIX 7: OPTIONAL FIRE SCREEN INSTALLATION Open the door. Hold the fire screen by the two handles and bring it close to the door opening. DETAIL A Lean the upper part of the fire screen against the top door opening making sure to stove the top fire screen brackets behind the primary air deflector. -

Page 57: Appendix 8: Optional Blower And Thermodisc Installation

APPENDIX 8: OPTIONAL BLOWER AND THERMODISC INSTALLATION A blower and a thermodisc, sold separately, can be installed on the stove. The installation of the blower is identical for a stove on legs or pedestal. Thermodisc allows the blower to operate only when the stove is hot enough. -

Page 58: Appendix 9: Air Tubes And Baffle Installation

APPENDIX 9: AIR TUBES AND BAFFLE INSTALLATION Starting with the rear tube, lean and stove the right end of the secondary air tube into the rear right channel hole. Then lift and stove the left end of the tube into the rear left channel. DETAIL A Align the notch in the left end of the tube with the key of the left air channel hole. - Page 59 Note that secondary air tubes (B) can be replaced without removing the baffle board (A) and that all tubes are identical. Installation and Operation Manual - Solution 2.3 Page 59...

-

Page 60: Appendix 10: Exploded Diagram And Parts List

APPENDIX 10: EXPLODED DIAGRAM AND PARTS LIST DETAIL A 10 11 Page 60 Installation and Operation Manual - Solution 2.3... - Page 61 THREAD-CUTTING SCREW 1/4-20 X 1/2" F HEX STEEL SLOT WASHER C102 ZINC PL65620 ASH LIP SUPPORT SE65959 ASH LIP 30441 ENERZONE LOGO 30076 SEALING STEEL "POP" RIVET 1/8" X 3/8" 30187 STAINLESS WASHER ID 17/64" X OD 1/2" 30206 ZINC WASHER 5/16"ID X 3/4"OD...

- Page 62 Description AC01206 BLACK CAST IRON LEG WITH ASH PAN KIT AC01208 BRUSH NICKEL PLATED CAST IRON LEG AND ASH PAN KIT 24012PN BRUSH NICKEL PLATED CAST IRON LEG ENERZONE 24012 CAST IRON LEG WITH LEVELING BOLT PL65531 LEG SUPPORT AC01293...

-

Page 63: Enerzone Limited Lifetime Warranty

Labour cost and repair work to the account of the manufacturer are based on a predetermined rate schedule and must not exceed the wholesale price of the replacement part. Shall your unit or a components be defective, contact immediately your ENERZONE dealer. To accelerate processing of your warranty claim, make sure to have on hand the following information when calling: •... - Page 64 Resale is strictly prohibited. The manufacturer may update St-Augustin-de-Desmaures (Québec) Canada this document from time to time and cannot be responsible G3A 2H3 for problems, injuries, or damages arising out of the use 418-908-8002 of information contained in any document obtained from https://www.enerzone-intl.com/en/ unauthorized sources. tech@sbi-international.com...

Need help?

Do you have a question about the EB00041 and is the answer not in the manual?

Questions and answers