Table of Contents

Advertisement

Quick Links

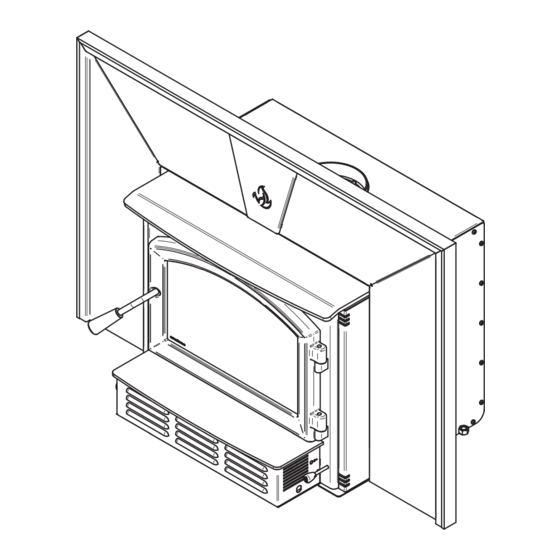

SOLUTION 1.7-I

(EB00057 model)

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION REQUIREMENTS

IN THE AREA.

READ THIS ENTIRE MANUAL BEFORE INSTALLATION AND USE OF THIS WOOD INSERT. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH.

READ AND KEEP THIS MANUAL FOR REFERENCE

Printed in Canada

Wood Insert

Owner's Manual

Part 2 of 2

INSTALLATION AND

OPERATION REQUIREMENTS

Safety tested according to

CAN/ULC 628, UL 1482 and

UL 737 by an accredited

US Environmental Protection

Agency phase II certified

wood insert compliant with

2020 cord wood standard.

laboratory.

EPA

< ≤

2.5

g/h

45983_IA

Advertisement

Table of Contents

Summary of Contents for Enerzone SOLUTION 1.7-I

- Page 1 Wood Insert Owner's Manual Part 2 of 2 INSTALLATION AND OPERATION REQUIREMENTS SOLUTION 1.7-I (EB00057 model) Safety tested according to CAN/ULC 628, UL 1482 and UL 737 by an accredited laboratory. US Environmental Protection Agency phase II certified wood insert compliant with 2020 cord wood standard.

- Page 2 It is also highly recommended to register the warranty online at https://www.enerzone-intl.com/en/warranty/warranty-registration/ Registering the warranty will help to quickly find the information needed on the unit.

-

Page 3: Table Of Contents

Optional Fresh Air Intake Kit Installation...............26 Optional Fire Screen Installation ..................27 Log Retainers Installation ...................29 Air Tubes and Baffle Installation ..................29 Removal Instructions ....................32 Exploded Diagram and Parts List ................33 ENERZONE LIMITED LIFETIME WARRANTY ................36 Product Specification Manual - Solution 1.7-I Page 3... -

Page 4: Certification Plate

1. CERTIFICATION PLATE Page 4 Product Specification Manual - Solution 1.7-I... -

Page 5: General Information

This appliance is officially tested and certified by an independent agency. Tested and certified in compliance with CFR 40 part 60, subpart AAA, section 60.534(a)(1(ii) and ASTM E3053-17. Based on EPA letter dated November 1, 2022. Carbon monoxide. Product Specification Manual - Solution 1.7-I Page 5... -

Page 6: Specifications

CAN/CSAZ240 MH standard. Tested and certified in compliance with CFR 40 part 60, subpart AAA, section 60.534(a)(1(ii) and ASTM E3053-17. Based on EPA letter dated November 1, 2022. Page 6 Product Specification Manual - Solution 1.7-I... -

Page 7: Dimensions

251mm 15 7/8" 403mm 24 1/4" 6 5/8" 616mm 169mm 16 1/2" 419mm 18" 457mm 22 3/8" 570mm Figure 3 : Front View Figure 4 : Side View - Maximum Insert Projection Product Specification Manual - Solution 1.7-I Page 7... - Page 8 Figure 5 : Door Opening 3/8" 3/16" 10mm 19 5/8" 11 7/8" 498mm 301mm 13 1/2" 343mm Figure 6 : Front View - Combustion Chamber Figure 7 : Side View - Combustion Chamber Page 8 Product Specification Manual - Solution 1.7-I...

- Page 9 The front (3rd) piece should stand off on the steel andirons by approximately 1-2 inches. The 2 other pieces should be added on top of the first Product Specification Manual - Solution 1.7-I Page 9...

- Page 10 4 inches cross section dimensions approximately) on top. To make sure combustion is equal, put the smallest piece on top of the first three, at the back of the firebox (see Figure 16 for an example of low burn load). Page 10 Product Specification Manual - Solution 1.7-I...

- Page 11 For optimal medium fire load, use medium to large size fuel pieces (between 4- and 5.5-inches cross section dimensions approximately) on the bottom and use small to medium size fuel pieces (2.5 to 4 inches cross section dimensions approximately) on top. To make sure combustion is Product Specification Manual - Solution 1.7-I Page 11...

- Page 12 4 and 15 minutes after the loading period. Before closing further, make sure the flame intensity is increasing or stable. Turn ON the blower at maximum speed. Page 12 Product Specification Manual - Solution 1.7-I...

-

Page 13: Clearances To Combustible Material

27 ½" (700 mm) 12 ¾" (324 mm) If a fresh air intake is required, it is recommended to add at least 4" to the width of the minimum opening of the hearth. Product Specification Manual - Solution 1.7-I Page 13... -

Page 14: Floor Protection

(406 mm USA) and at least 18" (457 mm Canada) without an R value. If the hearth elevation is lower than 5" (127 mm), the non-combustible (B) floor protection in front of the insert should have an R value equal or greater than 1.00 and shall extend 23" (584 mm) in front of the unit. Page 14 Product Specification Manual - Solution 1.7-I... -

Page 15: R Value

0.51 Hardibacker® 500 0.44 Wonderboard® 3.23 0.31 Cement mortar 5.00 Common brick 5.00 Face brick 9.00 0.11 Marble 14.3 – 20.00 0.07 – 0.05 Information as reported by manufacturers and other resources. Product Specification Manual - Solution 1.7-I Page 15... - Page 16 K value = 0.75 Thickness = 1 R value = Thickness/K = 1/0.75 = 1.33 Horizontal still air can’t be «stack» to accumulate R-values; each layer must be separated with another non-combustible material. Page 16 Product Specification Manual - Solution 1.7-I...

-

Page 17: Installing Options On Your Product And Replacing Parts

Remove the split pin by pulling and turning it using pliers. Turn the handle one counterclockwise turn to increase pressure. Reinstall the split pin with a small hammer. Figure 20 : Removing the split pin Figure 21 : Installing the split pin Product Specification Manual - Solution 1.7-I Page 17... - Page 18 Using a flat screwdriver, turn the adjustable hinge rods in the direction shown to adjust the doors. Tighten all door hinge pressure screws when they are at the desired positions. Configurations 1-2-3-4-5-6, show in which direction these act on the adjustment of the door. Page 18 Product Specification Manual - Solution 1.7-I...

- Page 19 WARNING : DO NOT USE SUBSTITUTE MATERIALS WHEN REPLACING THE GLASS. Product Specification Manual - Solution 1.7-I Page 19...

- Page 20 Cut the gasket to the required length. Pinch the gasket onto the glass in a U shape, all around the glass. By following these instructions, the edge clearances are maintain. Page 20 Product Specification Manual - Solution 1.7-I...

-

Page 21: Blower And Ash Lip Installation

Blower and Ash Lip Installation Install the ash lip (A) on the insert with Center the blower on the ash lip and push three screws (B). it against the firebox. Then push it until it clips. Product Specification Manual - Solution 1.7-I Page 21... -

Page 22: Faceplate Installation

Lay the panels on a flat and non abrasive surface. Align the top panel holes (L) with the left (N) and right (M) panels. Secure together using the four bolts (O) and nuts (P) provided. Page 22 Product Specification Manual - Solution 1.7-I... - Page 23 Secure the trim to the faceplate by squeezing edge of the faceplate and slowly slide it down the eight trim retainers (W) between the over the faceplate. inner edge of the trim and the front of the faceplate. Product Specification Manual - Solution 1.7-I Page 23...

- Page 24 Align the holes of the faceplate extension (X) with the holes in the faceplate panels. Screw them using bolts (Z) and nuts (Y) provided. Page 24 Product Specification Manual - Solution 1.7-I...

- Page 25 (BB). Then push towards the fireplace. 11. Once the faceplate is in place, secure the assembly by tightening nuts (AA) using a 7/16" (11 mm) open end wrench. Product Specification Manual - Solution 1.7-I Page 25...

-

Page 26: Optional Fresh Air Intake Kit Installation

Install the plate (K) with four screws (L) on the unused side of the insert. he pipe must be HVAC type, insulated, and must comply with ULC S110 and/or UL 181, Class 0 or Class 1. Page 26 Product Specification Manual - Solution 1.7-I... -

Page 27: Optional Fire Screen Installation

In the United States or in provinces with a particulate emissions limit (e.g.: US EPA), the use of open- door wood stoves with a rigid firescreen is prohibited. Open the door. Hold the fire screen by the two handles and bring it close to the door opening. Product Specification Manual - Solution 1.7-I Page 27... - Page 28 Lift the fire screen upwards and push the bottom part towards the insert then let the fire screen rest on the bottom of the door opening. Warning: Never leave the insert unattended while in use with the fire screen. Page 28 Product Specification Manual - Solution 1.7-I...

-

Page 29: Log Retainers Installation

Log Retainers Installation Air Tubes and Baffle Installation Product Specification Manual - Solution 1.7-I Page 29... - Page 30 « Vise grip » hold the tube and lock it in place by turning the tube as shown. Make sure the notch reaches the end of the key way. Install the baffle. Repeat steps 1 and 2 for the three other tubes. To remove the tubes use the above steps in reverse order. Page 30 Product Specification Manual - Solution 1.7-I...

- Page 31 Note that secondary air tubes (A) can be replaced without removing the baffle board (B) and that all tubes are not necessarely identical (look at the part number on the tube). Product Specification Manual - Solution 1.7-I Page 31...

-

Page 32: Removal Instructions

Remove faceplate (C) by pulling on it. Remove the blower assembly (D). Remove the three screws securing the pipe connector (A). 5. Unscrew the bolts securing the insert to the floor on each side of the unit (E). Page 32 Product Specification Manual - Solution 1.7-I... -

Page 33: Exploded Diagram And Parts List

Exploded Diagram and Parts List DETAIL A DETAIL B DETAIL C 23 24 Product Specification Manual - Solution 1.7-I Page 33... - Page 34 3 5/8" X 9'' X 1 1/4'' REFRACTORY BRICK PL70516 SECONDARY AIR TUBE 21521 1 1/4" x 18 7/8" x 9 1/2" C-CAST BAFFLE OA10128 BLACK LARGE FACEPLATE TRIMS (32" X 50") OA10122 BLACK FACEPLATE TRIMS (29" X 44") Page 34 Product Specification Manual - Solution 1.7-I...

- Page 35 RHEOSTAT WITHOUT NUT (MODEL KBMS-13BV) 44087 RHEOSTAT NUT 44085 RHEOSTAT KNOB AC05959 METALLIC BLACK STOVE PAINT - 342 g (12oz) AEROSOL SE45983 SOLUTION 1.7 INSERT INSTRUCTIONS MANUAL KIT PL75747 1.7 SERIES SECONDARY AIR TUBE Product Specification Manual - Solution 1.7-I Page 35...

-

Page 36: Enerzone Limited Lifetime Warranty

Labour cost and repair work to the account of the manufacturer are based on a predetermined rate schedule and must not exceed the wholesale price of the replacement part. Shall your unit or a components be defective, contact immediately your ENERZONE dealer. To accelerate processing of your warranty claim, make sure to have on hand the following information when calling:... - Page 38 Resale is strictly prohibited. The manufacturer may update St-Augustin-de-Desmaures (Québec) Canada this document from time to time and cannot be responsible G3A 2H3 for problems, injuries, or damages arising out of the use 1-877-356-6663 of information contained in any document obtained from www.enerzone-intl.com/en/ unauthorized sources. tech@sbi-international.com...

Need help?

Do you have a question about the SOLUTION 1.7-I and is the answer not in the manual?

Questions and answers