Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Norton clipper TT 251

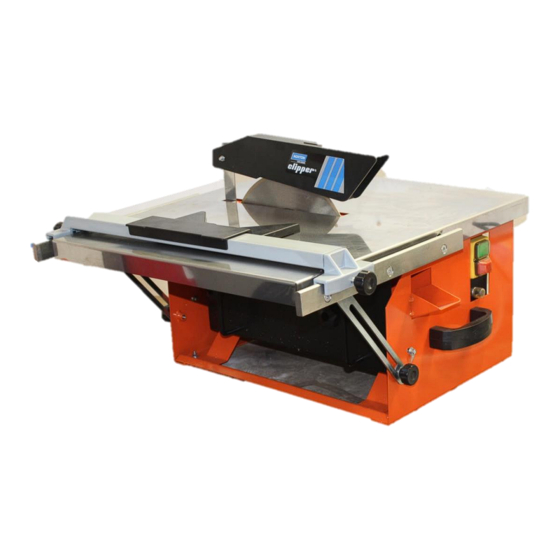

- Page 1 TT 251 OPERATING INSTRUCTIONS Translation of the original instructions...

- Page 2 VERS.2017.12.04 TT251_MAN_EN...

- Page 3 VERS.2017.12.04 TT251_MAN_EN Declaration of conformity The undersigned manufacturer: SAINT - GOBAIN ABRASIVES S.A. 190, BD J.F. KENNEDY L- 4930 BASCHARAGE Declares that this product: Tile saw (Code) TT251230V 70184602662 TT 251 230 V UK 70184602667 TT 251 115V 70184602663 is in conformity with the following Directives: ...

- Page 4 VERS.2017.12.04 TT251_MAN_EN...

-

Page 5: Table Of Contents

VERS.2017.12.04 TT251_MAN_EN TT 251 : OPERATING INSTRUCTIONS TABLE OF CONTENTS 1. Basic Safety Instructions 1.1 Symbols 1.2 Machine plate 1.3 Safety instructions for particular operating phases 2. Machine description 2.1 Short description 2.2 Purpose of use 2.3 Layout 2.4 Technical Data 2.5 Statement regarding the vibration emission 2.6 Statement regarding noise emission 3. -

Page 6: Basic Safety Instructions

VERS.2017.12.04 TT251_MAN_EN 1. Basic Safety Instructions The TT251 is exclusively designed for the cutting of tiles mainly on construction sites. Uses other than the manufacturer's instructions shall be considered as contravening the regulations. The manufacturer shall not be held responsible for any resulting damage. Any risk shall be borne entirely by the user. -

Page 7: Machine Plate

Always cut with the blade guard in position. Only fit NORTON CLIPPER diamond blades with continuous rim to the machine! The use of other tools can damage the machine! Read the blades’ specifications carefully to choose the correct tool for your application. -

Page 8: Machine Description

VERS.2017.12.04 TT251_MAN_EN Electrical powered machine Always turn off the machine and separate it from the main source of electricity before any work on the machine is done. Make all electrical connections securely to eliminate contact of live wires with spray water or dampness ... -

Page 9: Layout

VERS.2017.12.04 TT251_MAN_EN 2.3 Layout Frame (1) The frame is made of a jig-welded reinforced steel construction to ensure perfect rigidity. It supports the motor, the cutting table and the switch. Cutting table (2) Stainless steel top for an excellent resistance to corrosion with engraved measurements for precise guide-a-cut alignment. -

Page 10: Technical Data

VERS.2017.12.04 TT251_MAN_EN 2.4 Technical Data Electric motor 1000W 220V Voltage 110V Protection rating IP 54 Max. blade diameter 250 mm Bore 25,4 mm Rotation speed of the blade 2990 Tr. min Flange diameter 70 mm Cutting depth mm 55 mm Sound pressure level 71 dB (A) (ISO EN 11201) Sound energy level... -

Page 11: Statement Regarding The Vibration Emission

VERS.2017.12.04 TT251_MAN_EN 2.5 Statement regarding the vibration emission Declared value of vibration emission following EN 12096. Machine Measured value of vibration Uncertainty K Tool used Model / code emission at m/s Model / code TT 251 <2.5 Clipper Classic Ceram ... -

Page 12: Statement Regarding Noise Emission

VERS.2017.12.04 TT251_MAN_EN 2.6 Statement regarding noise emission Declared value of noise emission following EN ISO 11201 and NF EN ISO 3744. Machine Sound Uncertainty K Sound power Uncertainty K Model / code Pressure level (Sound level (Sound power level Pressure level EN ISO 11201 NF EN ISO 3744 NF EN ISO 3744) -

Page 13: Assembly And Commissioning

3.1 Tool assembly Only NORTON CLIPPER continuous rim blades with a maximum diameter of 250 mm can be used with the TT251. All tools used must be selected with regard to their maximum permitted cutting speed for the machine’s maximum permitted rotation speed. -

Page 14: Starting The Machine

VERS.2017.12.04 TT251_MAN_EN 3.4 Starting the machine Press the green button to start the machine. To start again the machine press on the red button. 3.5 Water cooling system Fill the water pan with clean water to the small hole drilled into the plastic water tray. ... -

Page 15: Operating The Machine

VERS.2017.12.04 TT251_MAN_EN 5. Operating the machine 5.1 Site of work 5.1.1 Siting the machine Remove from the site anything, which might hinder the working procedure! Make sure the site is sufficiently well lit! Observe manufacturer's conditions for connecting to power supplies! ... -

Page 16: Maintenance And Servicing

VERS.2017.12.04 TT251_MAN_EN 6. Maintenance and servicing To ensure a long-term quality from the cutting with the TT251, please follow the maintenance plan below: Whole machine Visual control (general aspect, watertightness) Clean Flange and blade fixing devices Clean Motor cooling fans Clean Water pan Clean... -

Page 17: Faults: Causes And Cures

VERS.2017.12.04 TT251_MAN_EN 7. Faults: causes and cures 7.1 Fault-finding procedures Should any fault occur during the use of the machine, turn it off, and isolate it from the electrical supply. Any works dealing with the electrical system or supply of the machine can only be carried out by a qualified electrician. -

Page 18: Circuit Diagram

VERS.2017.12.04 TT251_MAN_EN Circuit diagram... -

Page 19: Customer Service

Spare parts for the motor can be ordered with the manufacturer of the motor or with their dealer, which is often quicker and cheaper. This machine has been manufactured by Saint-Gobain Abrasives S.A. 190, Bd J.F.Kennedy L- 4930 BASCHARAGE Grand-duché de Luxembourg. Tel. : 00352-50401-1 Fax : 00352- 50 16 33 http://www.construction.norton.eu e-mail: sales.nlx@saint-gobain.com... - Page 20 VERS.2017.12.04 TT251_MAN_EN Guarantee can be claimed and technical support obtained from your local distributor where machines, spare parts and consumables can be ordered as well...

Need help?

Do you have a question about the clipper TT 251 and is the answer not in the manual?

Questions and answers