Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Kemppi HiArc M 400A

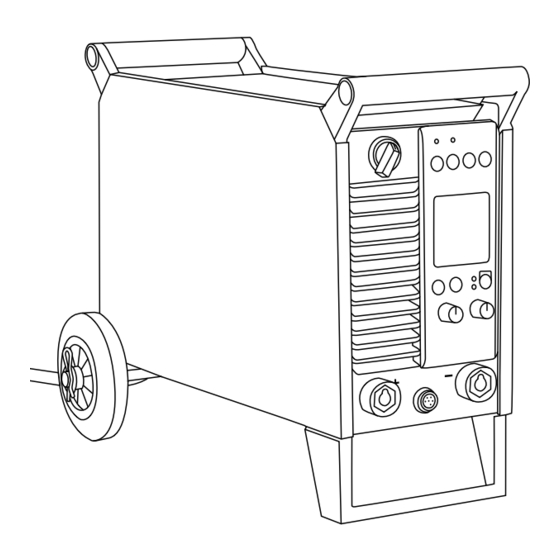

- Page 1 HiArc M 400A, M 500A Operating manual...

- Page 3 Operating manual english...

-

Page 4: Table Of Contents

....................... . . HiArc M 400A, M 500A... -

Page 5: Introduction

This operating manual contains important information on the use, maintenance and safety of your Kemppi product. The technical specifications of the device can be found at the end of the manual. Please read the operating manual and the safety instructions booklet carefully before using the equipment for the first time. -

Page 6: About Hiarc Product Series

Hiarc product series Kemppi’s HiArc M 400A/M 500A products are inverter MIG/MAG welding power sources to be used in a 3-phase mains power supply. HiArc welding machines are designed for industrial and professional use. These MIG/MAG power sources can be used with various wire feeders. However, it is recommended to use Kemppi’s HiArc F wire feeder units, which have been designed especially... -

Page 7: Installation

Power source fuse, 8A Fan grill Shielding gas heater fuse, 6.3 A Wire feeder cable connector ( + ) 10. Connector for shielding gas heater Control cable connection Earth return cable connector ( – ) © Kemppi Oy / 1244... -

Page 8: Positioning Of The Machine

The machine is not allowed to be operated in the rain as the protection class of the machine, IP23S, allows preserving and storing outside only. Never aim the spray of sparks from a grinding machine toward the equipment. NOTE! HiArc M 400A, M 500A... -

Page 9: Distribution Network

Check also that the mains cable complies with the local electrical regulations, and replace the cable if necessary. See ’Technical data’ . The mains cable or wall plug may be installed or replaced only by an electrical contractor or NOTE! installer authorised to perform such operations. © Kemppi Oy / 1244... -

Page 10: Wire Feeder Connection

Connect the shielding gas hose to the gas bottle or to the shielding gas distribution system. Please read carefully the wire feeder installation and operation instructions in the Kemppi NOTE! HiArc F operating manual. Normally the wire feeder should be connected to the plus pole. However, with some filler... -

Page 11: Earth Return Cable Connection

HiArc power source. Please see the plug-in delivery package for usage and fitting instructions. • Castor wheel kit replaces the static front support leg of the machine and allows the machine to be free wheeled. © Kemppi Oy / 1244... -

Page 12: Using The Machine

10. Selection for display of amperes/wire feed speed (automatic mode) 11. Selection of 2T/4T gun operating mode 12. Control knob for wire feed speed or power (Crater fill only) 13. Control knob for voltage or arc length (Crater fill only) HiArc M 400A, M 500A... -

Page 13: Starting The Machine

In Automatic mode you can use the pre-set Automatic values also when making the Tail Arc settings. There are welding programs available only for Fe wires. NOTE! CRATER FILL © Kemppi Oy / 1244... -

Page 14: Using Manual Operating Mode

With the wire feeder's arc length control knob (V) you can make fine-adjustments to the arc lenght. The optimal Automatic values are calculated automatically also when you select the Tail Arc settings with the power source controls. HiArc M 400A, M 500A... -

Page 15: Selection For Filler Wire, Diameter And Gas

Select CO₂ if you are using carbon dioxide. Select Ar + CO₂ (MAG) if you are using mixed gas. HiArc M 400A and M 500A have a factory set pre-gas time of 0.2 s and a Post-gas time of NOTE! between 2 –... -

Page 16: Gas Test

3.4.5 selection for display of amperes/wire feed speed (automatic mode) A long press (5 secs) of button 11 also switches the display from m/min to amperes. 3.4.6 lCd display Automatic settings Welding parameters Crater fill parameters HiArc M 400A, M 500A... -

Page 17: Material Thickness And Weld Shape Display

This control knob increases and reduces the available output voltage of the machine to the welding arc. The scale is regulated in volts. In automatic mode this control knob offers minor arc voltage adjustment for fine tuning the welding arc at crater fill phase. © Kemppi Oy / 1244... -

Page 18: Trigger Logic Function

• Push the trigger – welding starts after preset pre-gas time. • Release the trigger – values drop to preset crater fill level and welding ends after preset time. Post-gas flows for preset time. Pre-gas time Crater fill time Post-gas time HiArc M 400A, M 500A... - Page 19 • Trigger released – welding starts. • Trigger pushed down – welding values change to crater fill level. • Trigger released – welding ends. Post-gas time flows for preset time. Pre-gas time Crater fill time Post-gas time © Kemppi Oy / 1244...

-

Page 20: Calibrating Wire Feed Speed

Press WIRE INCH button at the wire feeder. • Wire feed starts and continues for 12 seconds When wire feed stops, cut the wire at the contact tip and measure the length of the fed wire in mm. HiArc M 400A, M 500A... - Page 21 • If the device is left idle for 5 minutes, it automatically exits the calibration mode. • If the device is turned off before the step 10, it automatically exits the calibration mode, and the old calibration values remain. © Kemppi Oy / 1244...

-

Page 22: Troubleshooting

• Check the mains fuses • Check the mains cable and the wall plug * Contact Kemppi service in case of Err 2 and Err 3 without mains voltage cause. maintenanCe regular maintenance Check regularly the electrical connections of the machine. Clean any oxidised connections, and tighten the loosened cable connections. -

Page 23: Technical Data

647 x 385 x 485 mm 716 x 385 x 485 mm Weight 36 kg 41 kg EMC class Degree of protection IP23S IP23S Gas heater connection 110 V/150 W 110 V/150 W Standards IEC 60974-1 IEC 60974-10 © Kemppi Oy / 1244... -

Page 24: Ordering Codes

HiArc 10-50-G 50 mm2, 10 m 6310510 HiArc 15-50-G 50 mm2, 15 m 6310515 Earth return cables Earth return cable, HiArc M 400A 50 mm², 5 m 6184511H Earth return cable, HiArc M 500A 70 mm², 5 m 6184711H Accessories... - Page 26 78681 EPONE CEDEX myynti.fi@kemppi.com info.ru@kemppi.com FRANCE Tel +33 1 30 90 04 40 KEMPPI SVERIGE AB KEMPPI, TRADING (BEIJING) COMPANY, Telefax +33 1 30 90 04 45 LIMITED Box 717 sales.fr@kemppi.com Room 420, 3 Zone, Building B, S-194 27 UPPLANDS VÄSBY No.12 Hongda North Street,...

Need help?

Do you have a question about the HiArc M 400A and is the answer not in the manual?

Questions and answers