Table of Contents

Advertisement

Quick Links

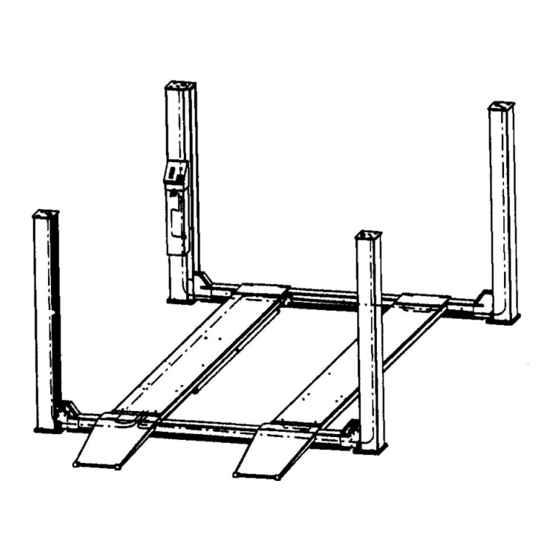

4.45 HN/ 4.45 HN Plus

Automotive-Lift date: 01/2007

Manual date: 01.08.2012

Operating Instruction and Documentation

Serial-number:............................................

Retailer address / phone

Otto Nußbaum GmbH & Co.KG//Korker Straße 24//D-77694 Kehl-Bodersweier

Tel: +49(0)7853/8990 Fax: +49(0)7853/8787

E-mail: info@nussbaum-lifts.de// http://www.nussbaum-lifts.de

Advertisement

Table of Contents

Summary of Contents for Nussbaum 4.45 HN

- Page 1 4.45 HN/ 4.45 HN Plus Automotive-Lift date: 01/2007 Manual date: 01.08.2012 Operating Instruction and Documentation Serial-number:..........Retailer address / phone Otto Nußbaum GmbH & Co.KG//Korker Straße 24//D-77694 Kehl-Bodersweier Tel: +49(0)7853/8990 Fax: +49(0)7853/8787 E-mail: info@nussbaum-lifts.de// http://www.nussbaum-lifts.de...

- Page 2 Operating Instruction and Documentation 4.45 HN Attention! Important information for the installation! After the general adjustment of the automotive lift all ropes must be locked at the rope-terminal and on the top of all 4 columns as followed: 1. move the locking plate on the ropes to the block (position as shown in picture 1) 2.

-

Page 3: Table Of Contents

Operating Instruction and Documentation 4.45 HN Table of content Foreword .............................. 4 Record of installation ........................... 6 Record of handing over ........................7 1 General Information ........................... 8 1.1 Installation and service checks of the automotive lift ..............8 1.2 Warning Symbols ........................... 8 2 Master document of the automotive lift ................... -

Page 4: Foreword

Operating Instruction and Documentation 4.45 HN Foreword Nussbaum lifting systems are the result of over 25 years experience in the automotive lifting industry. The high quality and the superior concept ensure reliability, a long lift lifetime and above all and economic business solution. - Page 5 Operating Instruction and Documentation 4.45 HN The lift must only be operated : For its appropriate use In faultless condition concerning technical security. Organisational Requirements The instructions for use are to be kept at the place of operation being easily accessible at any time.

-

Page 6: Record Of Installation

Operating Instruction and Documentation 4.45 HN After completely filling out this sheet including signatures, copy and return the original to the manufacturer. The copy must remain in the manual. Otto Nußbaum GmbH & Co. KG Korker Straße 24 D-77694 Kehl-Bodersweier... -

Page 7: Record Of Handing Over

Operating Instruction and Documentation 4.45 HN Record of handing over The automotive lift with the serial number:..........was installed on:..........at the firm:..........at:..............the safety was checked and the lift was started. The persons below were introduced after the installation of the automotive lift. The introduction was carried out by either the erector from the lift-manufacturer or from a franchised dealer (competent person). -

Page 8: General Information

Operating Instruction and Documentation 4.45 HN 1 General Information The document “Operating Instructions and Documentation” contains important information about installation, operation and maintenance of the automotive lift. Conformation of installation of the automotive lift is recorded on the ”Record of •... -

Page 9: Master Document Of The Automotive Lift

Operating Instruction and Documentation 4.45 HN 2 Master document of the automotive lift 2.1 Lift–manufacturer Otto Nußbaum GmbH & Co. KG Korker Straße 24 D-77694 Kehl-Bodersweier 2.2 Application The automotive lift is a lifting mechanism for lifting motor vehicles with a laden weight of up to 4500 kg . The max. load distribution is 2:1 either in or against the drive- on direction. -

Page 10: Declaration Of Conformity

Operating Instruction and Documentation 4.45 HN 2.5 Declaration of Conformity - 10 -... -

Page 11: Technical Information

Operating Instruction and Documentation 4.45 HN 3 Technical Information 3.1 Technical ratings Capacity: 4500 kg Load distribution: max. 2:1 in or against the drive on direction Lifting time: approx. 50 sec. with 2670 kg Load Lowering time: approx. 30 sec. + CE-Stop with 2670 kg Load Lifting height: max. -

Page 12: Data Sheet

Operating Instruction and Documentation 4.45 HN 3.3 Data sheet - 12 -... - Page 13 Operating Instruction and Documentation 4.45 HN - 13 -...

- Page 14 Operating Instruction and Documentation 4.45 HN Data sheet with RFH - 14 -...

-

Page 15: Manufacturing Reference

Operating Instruction and Documentation 4.45 HN 3.4 Manufacturing reference Each platform becomes with a curvature upward manufactured by approx. + 8 mm. (initial tension) Dependent on the vehicle weight and wheel base can the initial tension reduce. With tests determined results of measurement were registered into the following table. -

Page 16: Hydraulic Diagram

Operating Instruction and Documentation 4.45 HN 4 Hydraulic diagram Hydraulic diagram without wheel free lift Hydraulic parts list Oil tank Oil level gauge Hydraulic block sub oil motor 2,2 kW gear pump 4,2 cm /rotation Oil filter pressure relief valve... - Page 17 Operating Instruction and Documentation 4.45 HN Hydraulic diagram with wheel free lift - 17 -...

- Page 18 Operating Instruction and Documentation 4.45 HN Hydraulic parts list part # description oil tank motor 990910 gear pump 980486 filter 980201 screw 9VSTIR1/4ED hydraulic block complete 232POW22037 ball valve (main lift / wheel free lift) 980513 holding valve 980480 emergency lowering screw 9232TTL42038 0.10...

-

Page 19: Electrical Diagram Drawing Without Wheel Free Lift

Operating Instruction and Documentation 4.45 HN 5 Electrical diagram drawing without wheel free lift - 19 -... - Page 20 Operating Instruction and Documentation 4.45 HN - 20 -...

- Page 21 Operating Instruction and Documentation 4.45 HN - 21 -...

- Page 22 Operating Instruction and Documentation 4.45 HN - 22 -...

- Page 23 Operating Instruction and Documentation 4.45 HN - 23 -...

- Page 24 Operating Instruction and Documentation 4.45 HN - 24 -...

- Page 25 Operating Instruction and Documentation 4.45 HN - 25 -...

-

Page 26: Electrical Diagram Drawing With Wheel Free Lift

Operating Instruction and Documentation 4.45 HN 6 Electrical diagram drawing with wheel free lift - 26 -... - Page 27 Operating Instruction and Documentation 4.45 HN - 27 -...

- Page 28 Operating Instruction and Documentation 4.45 HN - 28 -...

- Page 29 Operating Instruction and Documentation 4.45 HN - 29 -...

- Page 30 Operating Instruction and Documentation 4.45 HN - 30 -...

- Page 31 Operating Instruction and Documentation 4.45 HN - 31 -...

- Page 32 Operating Instruction and Documentation 4.45 HN - 32 -...

-

Page 33: Connection-Command (Picture)

Operating Instruction and Documentation 4.45 HN 6.1 Connection-Command (picture) Electrical wiring has to be executed by qualified personal only! Oben-Aus-Schalter / top-off switch Anschluss/contact 11oder/or 21 Anschluss/contact 12 oder/or 22 - 33 -... -

Page 34: Safety Regulations

Operating Instruction and Documentation 4.45 HN 7 Safety regulations If you use the automotive lift, the German following regulations are to be considered: BGG945: Examine of automotive-lifts; BGR500 Using automotive-lifts; (VBG14). Especially the following regulations are very important: • The laden weight of the lifted vehicle must not exceed 4500 kg for the automotive lift. -

Page 35: Lowering The Vehicle

Operating Instruction and Documentation 4.45 HN 8.2 Lowering the vehicle • Check all danger points of the lift and be sure that there are no objects or people in the working area (danger area) around the lift or on the lift. -

Page 36: Adjusting The Platform

Operating Instruction and Documentation 4.45 HN 8.4 Adjusting the platform • It is possible to adjust the rail of the different wheelbase. That is necessary to reach the different wheelbases of the vehicles. One platform is only movable without load. (See the measure at the data sheet) •... -

Page 37: Lowering Onto An Obstacle

Operating Instruction and Documentation 4.45 HN Problem: the lift does not lower! Potential causes: solution: An obstacle is restricting the lift from being lowered (see chapter 6.1) Fuse is defective Check the fuse The ratchets are locked of defective Phone the technical service Button “unlocking the ratchets”... -

Page 38: Inspection And Maintenance

Operating Instruction and Documentation 4.45 HN Pic 4: Double seat valve with lowering device • Check all danger points of the lift and be sure that there are no objects or people in the working area (danger area) around the lift or on the lift. - Page 39 Operating Instruction and Documentation 4.45 HN • Clean the piston-rod using compressed air. • Examine the energy chain. Clean it and examine the supply lines and the chain for damages. • Check the condition of ropes. If torn wires are discovered, the complete rope set must be changed.

-

Page 40: How Often Must The Lift Be Cleaned

Operating Instruction and Documentation 4.45 HN Pic. 5: 10.2 How often must the lift be cleaned? A regular and appropriate maintenance practice will aid the preservation of the lift. No guarantees can be given when damage (egg rust or fading colour) is the direct result of poor maintenance and cleaning practice. -

Page 41: Security Check

Operating Instruction and Documentation 4.45 HN 11 Security check The security check is necessary to guarantee the safety of the lift during use. It has to be performed in the following cases: 1. Before the initial operation, after the first installation. -

Page 42: Erection And Doweling Of The Lift

Operating Instruction and Documentation 4.45 HN 12.2 Erection and doweling of the lift It is necessary to dowel the columns at 4 points. For this a concrete floor without reinforcement, thickness of 140 mm and quality C20/25 is needed. In case of doubt a test drill is necessary and a dowel is to put in. - Page 43 Operating Instruction and Documentation 4.45 HN Pic 6: Hang up the spring into the ratchet-strip • Raise the lift into the ratchet. (press the button „B“ and the button “C”). • Adjust the columns again with a water bubble. •...

-

Page 44: Change Of Lift Location

Operating Instruction and Documentation 4.45 HN 12.3 Change of lift location If the place of installation is to be changed, the new place has to be prepared in according to the regulations of the first installation. The change should be performed in accordance with the following points: •... - Page 45 Operating Instruction and Documentation 4.45 HN Picture 8: choice of the dowel length without floor pavement or tile surface BM10-15 Liebig-dowels Dowel type BM10-/70/40 Drilling depth Min. anchorage depth Thickness of concrete min. 140 Diameter of bore Thickness of the lift-pieces...

- Page 46 Operating Instruction and Documentation 4.45 HN Picture 9: choice of the dowel length with floor pavement or tile surface Liebig-dowels Dowel type BM10-15/70/65 BM10-15/0/100 BM10-15/70/140 Drilling depth Min. anchorage depth Thickness of concrete min.140(*) min.140(*) min.140(*) Diameter of bore Thickness of the lift-pieces...

- Page 47 Operating Instruction and Documentation 4.45 HN Änderungen vorbehalten! subject to alterations! sous réserve des modifications! Jumbo , Sprinter HDL5000 , HDL6500 , 2.50 SL 2.30 SL , 2.40 SL fischer-Dübel SPL3000 , SPL4000 UNI-LIFT 3500 NT/CLT Dübel typ of dowel...

- Page 48 Operating Instruction and Documentation 4.45 HN HILTI - Dübel 4.45 HN Bodenbelag (Estrich, ohne ohne ohne Fliesen) Bodenbelag Bodenbelag Bodenbelag Bodenbelag Bodenbelag Dübel HSL-3-G typ of dowel HSL-3-G M10/40 HSL-3-G M12/50 HSL-3-G M12/100 HSL-3-G M16/50 M16/100 type de cheville Art.Nr.: 371797 Art.Nr.: 371800...

-

Page 49: First Security Check Before Installation

Operating Instruction and Documentation 4.45 HN First security check before installation Fill out and leave in this manual Serial-number:__________________________ defect veri- kind of check right missing fication remark ---------------------------------------------------------------------------------------------------------------------------------------- Type plate......................Short operating instruction................... Sticker max. capacity.................. -

Page 50: Regular Security Check And Maintenance

Operating Instruction and Documentation 4.45 HN Regular security check and Maintenance Fill out and leave in this manual Serial-number:__________________________ defect veri- kind of check right missing fication remark ---------------------------------------------------------------------------------------------------------------------------------------- Type plate......................Short operating instruction................... Sticker max. capacity.................. - Page 51 Operating Instruction and Documentation 4.45 HN Regular security check and maintenance Fill out and leave in this manual Serial-number:__________________________ defect veri- kind of check right missing fication remark ---------------------------------------------------------------------------------------------------------------------------------------- Type plate......................Short operating instruction................... Sticker max. capacity..................

- Page 52 Operating Instruction and Documentation 4.45 HN Regular security check and maintenance Fill out and leave in this manual Serial-number:__________________________ defect veri- kind of check right missing fication remark ---------------------------------------------------------------------------------------------------------------------------------------- Type plate......................Short operating instruction................... Sticker max. capacity..................

- Page 53 Operating Instruction and Documentation 4.45 HN Regular security check and maintenance Fill out and leave in this manual Serial-number:__________________________ defect veri- kind of check right missing fication remark ---------------------------------------------------------------------------------------------------------------------------------------- Type plate......................Short operating instruction................... Sticker max. capacity..................

- Page 54 Operating Instruction and Documentation 4.45 HN Regular security check and maintenance Fill out and leave in this manual Serial-number:__________________________ defect veri- kind of check right missing fication remark ---------------------------------------------------------------------------------------------------------------------------------------- Type plate......................Short operating instruction................... Sticker max. capacity..................

- Page 55 Operating Instruction and Documentation 4.45 HN Regular security check and maintenance Fill out and leave in this manual Serial-number:__________________________ defect veri- kind of check right missing fication remark ---------------------------------------------------------------------------------------------------------------------------------------- Type plate......................Short operating instruction................... Sticker max. capacity..................

- Page 56 Operating Instruction and Documentation 4.45 HN Regular security check and maintenance Fill out and leave in this manual Serial-number:__________________________ defect veri- kind of check right missing fication remark ---------------------------------------------------------------------------------------------------------------------------------------- Type plate......................Short operating instruction................... Sticker max. capacity..................

-

Page 57: Extraordinary Security Check

Operating Instruction and Documentation 4.45 HN Extraordinary security check Fill out and leave in this manual Serial-number:__________________________ defect veri- kind of check right missing fication remark ---------------------------------------------------------------------------------------------------------------------------------------- Type plate......................Short operating instruction................... Sticker max. capacity..................Designation lifting/lowering......

Need help?

Do you have a question about the 4.45 HN and is the answer not in the manual?

Questions and answers