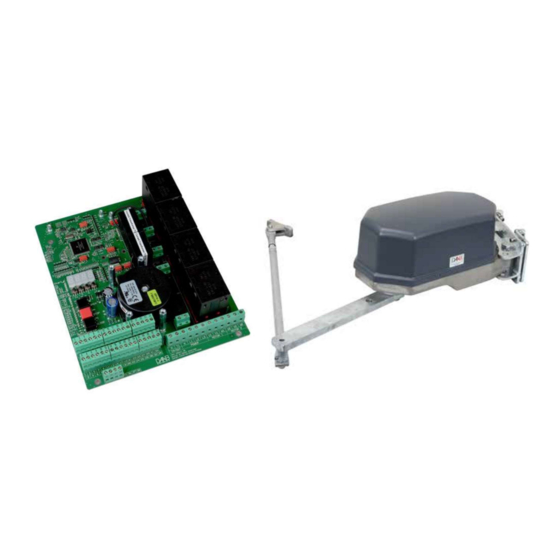

FAAC DAAB EP104 Instruction Manual

Control board

Hide thumbs

Also See for DAAB EP104:

- Quick start manual (12 pages) ,

- Installation manual (60 pages) ,

- Quick manual (4 pages)

Summary of Contents for FAAC DAAB EP104

- Page 1 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Instruction manual version 1 for software version 4.04 FAAC Nordic AB BOX 125, SE-284 22 PERSTORP SWEDEN TEL. +46 435 77 95 00 FAX +46 435 77 95 29 www.faac.se...

-

Page 2: Table Of Contents

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Contents Manufacturer's declaration ..........................6 Manufacturer ...............................6 Person authorised to compile the technical documentation .................6 Type designation ............................6 Declaration of performance ..........................6 Intended use of the construction product ....................6 System for assessment and continuous verification of the performance of the construction product ..6 Performance ..............................6... - Page 3 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Safety edge ..............................19 Sliding doors/sliding gates ..........................19 Load guard ..............................19 Safety edge ..............................19 Up-and-over doors ............................19 Load guard ..............................19 Safety edge ..............................19 Hinged gates ..............................19 Load guard ..............................19 Safety edge ..............................19 Barriers ................................19...

- Page 4 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Stop function ...............................27 Automatic closing after stop ........................27 Automatic closing after photocell activation ....................28 Automatic closing after vehicle loop activation ...................28 Direction sensing for internal closing pulse ....................28 Closing from PHOTO input ...........................28 Control functions ............................28...

- Page 5 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable output 2 ..........................51 Programmable output 3 ..........................54 Programmable output 4 ..........................57 Programmable inputs, P channels ........................60 Programmable input 1 ..........................60 Programmable input 2 ..........................61 Programmable input 3 ..........................62 Programmable input 4 ..........................63 Programmable input 5 ..........................64...

-

Page 6: Manufacturer's Declaration

Nor does it relate to third-party equipment or to interfaces between third-party equipment and the equipment specified below and supplied by FAAC Nordic AB. The machinery is, where applicable, compliant with the following standardised norms: •... -

Page 7: Description Of The Ep104

FAAC Nordic AB will not charge to process used electronic products supplied by us, provided they are returned to us. • Instruction manual The installed control unit must be accompanied by this instruction manual or by an instruction manual that in every respect meets the requirements in the applicable Machine Directive and Low Voltage Directive and the relevant standardised norms, and must be provided to the installer and the end user. -

Page 8: Safety

Follow the safety instructions of the equipment to be controlled by the control unit. • Safety classification FAAC Nordic AB has validated the safety circuits in the EP104 to performance level PL = c and Category 2 as defined by SS- EN ISO 13849-2:2008. -

Page 9: Operation

• Resetting/replacing tripped fuses If the fuse protecting the power supply to the automatic control unit trips, FAAC Nordic AB recommends following these steps to reset/replace it. • Switch off the main switch to the automatic control unit. -

Page 10: Technical Specification

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Technical specification Dimensions (WxHxD) 190x224x60 mm. Power supply 3-phase or single-phase. Power supply 3x400V+N+PE, 3x230V+PE, 1x230V+N+PE, 3x400V+PE (requires external transformer) Permitted voltage variation ±10% Frequency 50 Hz. Motor in 3-phase operation 3-phase asynchronous motor 0.18-1.5 kW. -

Page 11: Installing The Ep104 Pcb

If you are installing the PCB in a dedicated enclosure, you must follow the instructions below – otherwise the requirements of the applicable EU directive will not be met, FAAC Nordic's declaration of conformity will not be valid and the product will not be authorised for use. -

Page 12: Connections

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Connections • Safety The electrical connections may only be made by a qualified electrician, who accepts responsibility for ensuring that the electric connections are in accordance with the applicable standards and this instruction manual. - Page 13 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD For information about connecting to the frequency converter, see the instructions for add-in card DB406. If a symmetrical single-phase motor is used (as Supply 1x230V w/o neutral (symmetrical) shown on the left) make the following changes.

-

Page 14: Connecting A Safety Edge

See the wiring diagram below. The resistor can be between 1.0-8.2 kΩ with 1% tolerance and a power capability of at least ½ W. FAAC Nordic AB recommends an impedance of 8.2 kΩ. A safety edge can only be connected in series. -

Page 15: Connecting Communication

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Connecting communication To optimise communication between two EP104s, it is important to choose suitable cable and to lay it correctly. FKAR-PG, E 01 721 20 is a suitable cable. -

Page 16: Configuring The Ep104

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Configuring the EP104 This section provides general instructions on how to change settings in the EP104. It is a good idea to discharge any static charge in your body by always touching an earthed connection before starting installation. -

Page 17: Signal Reference

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Signal reference Safety edge 1, closing movement (S.E1) Safety edge 2, closing movement (S.E2) Safety edge, opening movement (S.E3) 24VDC Stop input 1 Stop input 2 Stop input 3... -

Page 18: Indicators

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Indicators To simplify commissioning and troubleshooting, LEDs are provided to indicate faults and the status of input signals, as shown in the table below. Colour Indication Active when Constant when control signal received, flashing when counting down for automatic... -

Page 19: Applications

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Applications This section describes the settings required for various types of application. • Folding doors Load guard When a folding door is commissioned, the load guard must be configured for personal protection. This means that it provides protection during the opening movement according to the applicable standards (obstacles while opening and also inside the folds). - Page 20 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Commissioning The process is the same for EP104-1 for one motor winder and EP104-2 for two motor winders. The settings are changed as described in the section "Changing settings in the EP104". An E on the far left of the display indicates an error message, see "Error messages". Note that the start-up values "EP-1" and "EP-2"...

- Page 21 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Set the value as the closed position in channel L113 for motor 1 and L123 for motor 2. • Run the motor (hold-to-run) to the fully open position. •...

- Page 22 • Check whether the external unit has an internal resistor at the output. If not, fit a 8.2kohm 0.5W resistor to the output. FAAC recommends that this output is short circuited when the protection is activated. • Check the active and inactive levels of the test input on the unit. Set C102 to the right polarity.

- Page 23 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Load guard The load guard can be used in two different ways. • With certified personal protection – fixed upper and lower limits and adjustable normal power • Without certified personal protection – adjustable upper and lower limits only The automatic control unit is initially configured for certified personal protection.

- Page 24 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Safety edge Safety edge monitor The integrated safety edge monitor in the automatic control unit performs a self test before the start of every movement. If any of the safety edge devices is faulty, the EP104 is stopped and an error is indicated. Make sure that S.E1 is connected to motor 1 and S.E2 is connected to motor 2.

- Page 25 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Function check of safety edge Check that the automatic control unit reacts as configured above when the safety edge is activated. Check that the LEDs indicate the affected safety edge S.E1, S.E2 and S.E3. And check that the safety edge flashes when it is no longer activated.

- Page 26 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • PHOTO input The EP104 has a PHOTO input for use with a photocell or a vehicle loop via an external control unit, see "Signal reference". To connect both devices to the same input, connect them in series via voltage-free contacts.

-

Page 27: Stop Function

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Programmable inputs, P channels There are six programmable inputs available in the EP104. The instructions are identical for all six programmable inputs, apart from the channel number – input 1 has channel number P1nn, input 2 has channel number P2nn, etc. -

Page 28: Automatic Closing After Photocell Activation

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD disable automatic closing. Automatic closing after photocell activation This function enables automatic closing after a photocell is activated. Use channel C351 to activate the function. Select channel C351, set the value to 1 to activate or 0 to deactivate. -

Page 29: Run-On Time For Closing

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Run-on time for closing Stopping with a run-on time means that when the limit switch is activated in the closing direction, the door continues for a specified time. Select channel C422 for motor 1 and channel C432 for motor 2, and set the run-on time in seconds. -

Page 30: Interlock

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Interlock Two EP104s can communicate with each other, sending interlocks and start signals between doors. Each of the doors must first be commissioned and tested locally in accordance with the "Commissioning" section. The text below mentions the local door and the remote door. -

Page 31: Functions Using Add-In Cards

Add-in cards can be installed in the EP104 for access to extra functions. The add-in cards are DB401 for programmable outputs, DB402 for a vehicle detector, DB403 (DBR1 system) for four programmable wireless inputs, DB404 (FAAC SLH system) for one programmable input and DB406 for motor control using a frequency converter. -

Page 32: Programmable Wireless Inputs, R Channels

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Programmable wireless inputs, r channels You can use the DB403 add-in card to access four programmable wireless inputs in the EP104. The instructions are identical for all four wireless inputs, apart from the channel number – input 1 has channel number r1nn, input 2 has channel number r2nn, etc. -

Page 33: Vehicle Detector, D Channels

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Vehicle detector, d channels Two vehicle loops can be connected to the EP104 via DB402 add-in cards – to activate the inputs set d100 and/or d200 to 1. When the unit is delivered and following a reset, channels d000, d100 and d200 are set to 0, disabled. The settings below apply to vehicle loop 1, using channel numbers d101 –... -

Page 34: Loop Safety Functions

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Loop safety functions You can use the following channels to select and configure these safety functions. d140, Safety when closing Used to configure the safety setting in the closing movement. The value 0 means the function is disabled – note that the door will close even if there is a vehicle over the loop. -

Page 35: Channel Reference

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Channel reference There are six channel categories, each with its own letter and each handling different functions in the card. • C channels: General readout and configuration channels. • d channels: Channels relating to the DB402 vehicle detector. -

Page 36: General Configuration Channels

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD General configuration channels Name Range Factory Setting Ref. page C033 Pulse/hold-to-run 0 - 4 Open and close with hold-to-run and load guard inactive Open with pulse and close with hold-to-run and load guard active... -

Page 37: Safety Edge

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Safety edge Name Range Factory Setting Ref. page C101 Safety edge acknowledgement S.E1 (CPC) 0 – 1 Disabled Enabled C102 Function of output for external protection 0 – 4 Check disables, open output. -

Page 38: Load Guard And Motor Settings

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Load guard and motor settings Name Range Factory Setting Ref. page C200 Load guard function 0 – 4 <?> Disabled Service and troubleshooting only Reversal when closing, stop when opening Stop when closing and reversal when opening... -

Page 39: Photocell

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Name Range Factory Setting Ref. page 0.00-0.99 cos φ C281 Power factor readout motor 2 Photocell Name Range Factory Setting Ref. page C340 Safety function in closing movement 0 – 3 <?>... -

Page 40: General Time Channels

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD General time channels Name Range Factory Setting Ref. page C401 Running time readout motor 1 000-999 sec C402 Running time readout motor 2 000-999 sec C403 Set limited running time 001-999 sec C411 Time readout, opened to closed position motor 1, 00.0-99.9 sec... -

Page 41: Automatic Closing

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Automatic closing Name Range Factory Setting Ref. page C500 Automatic closing time 0.00-9.59min 0.00 C501 Short automatic closing time 0.0-9.9 sec C510 Time for PHOTO closing when a vehicle passes 0.0-9.9 sec... -

Page 42: Interlock Block

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Interlock block Name Range Factory Setting Ref. page C664 Block of the other door 0 – 3 No block Opening blocked until the other door is closed Opening blocked until the other door is open... -

Page 43: Vehicle Detector, D Channels

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Vehicle detector, d channels Vehicle loop 1 Name Range Factory Setting Ref. page d100 Use loop 1 0 – 1 Input disabled Input enabled d101 Loop reading x1 000-999... - Page 44 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Name Range Factory Setting Ref. page d161 Type of control signal when activated 0 - 1 Pulse Constant signal when loop is activated d162 Half operation 1 - 3 Half 1 Half 2...

-

Page 45: Vehicle Loop 2

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Vehicle loop 2 Name Range Factory Setting Ref. page d200 Use loop 2 0 - 1 Input disabled Input enabled d201 Loop reading x1 000-999 d202 Loop reading x1000 00-99... - Page 46 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Name Range Factory Setting Ref. page d261 Type of control signal when activated 0 - 1 Pulse Signal when loop is activated d262 Half operation 1 - 3 Half 1 Half 2 Halves 1 and 2...

-

Page 47: Limit Switch, L Channels

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Limit switch, L channels Name Range Factory Setting Ref. page L001 Choice of limit switch type for motor 1 Disabled Encoder Limit switch Time L002 Choice of limit switch type for motor 2... -

Page 48: Programmable Outputs, O Channels

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Programmable outputs, o channels Programmable output 1 Name Range Factory Setting Ref. page o100 Function of output 1 0 - 4 Disabled Position indicator/Movement/Warning Signal as configured in o110 – o122 Presence detection/Direction sensing Signal as configured in o191 Lock Alarm output Signal as configured in o130 –... - Page 49 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Name Range Factory Setting Ref. page o132 Alarm for error message in display 0 - 1 Disabled Constant signal o133 Alarm if stop circuit interrupted 0 - 1 Disabled Constant signal...

- Page 50 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD o191 Function when LOOP2, LOOP2 or PHOTO 01 - 14 activated Presence detection Signal when LOOP1 is activated, remains until LOOP1 is clear. Presence detection Signal when LOOP2 is activated, remains until LOOP2 is clear.

-

Page 51: Programmable Output 2

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable output 2 Name Range Factory Setting Ref. page o200 Function of output 2 0 - 4 Disabled Position indicator/Movement/Warning Signal as configured in o210 – o222 Presence detection/Direction sensing Signal as configured in o291 Lock Alarm output Signal as configured in o230 –... - Page 52 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Name Range Factory Setting Ref. page o233 Alarm if stop circuit interrupted 0 - 1 Disabled Constant signal o234 Alarm if door open 0 - 1 Disabled Constant signal o235 Alarm if door is in mid position...

- Page 53 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD o291 Function when SL.1, SL.2 or photocell/loop 01 - 14 activated Presence detection Signal when LOOP1 is activated, remains until LOOP1 is clear. Presence detection Signal when LOOP2 is activated, remains until LOOP2 is clear.

-

Page 54: Programmable Output 3

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable output 3 Name Range Factory Setting Ref. page o300 Function of output 3 0 - 4 Disabled Position indicator/Movement/Warning Signal as configured in o310 – o322 Presence detection/Direction sensing Signal as configured in o391 Lock Alarm output Signal as configured in o330 –... - Page 55 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Name Range Factory Setting Ref. page o333 Alarm if stop circuit interrupted 0 - 1 Disabled Constant signal o334 Alarm if door open 0 - 1 Disabled Constant signal o335...

- Page 56 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD o391 Function when SL.1, SL.2 or photocell/loop 01 - 14 activated Presence detection Signal when LOOP1 is activated, remains until LOOP1 is clear. Presence detection Signal when LOOP2 is activated, remains until LOOP2 is clear.

-

Page 57: Programmable Output 4

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable output 4 Name Range Factory Setting Ref. page o400 Function of output 4 0 - 4 Disabled Position indicator/Movement/Warning Signal as configured in o410 – o422 Presence detection/Direction sensing Signal as configured in o491 Lock Alarm output Signal as configured in o430 –... - Page 58 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Name Range Factory Setting Ref. page o422 Function during warning time 1 - 2 Output signal deactivated during warning Output signal as configured in o410-o413 o423 Flashing frequency 0.1-2.0 sec o430 Alarm if there is an error as configured in 0.00-9.59min...

- Page 59 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD o491 Function when LOOP2, LOOP2 or PHOTO 01 - 14 activated Presence detection Signal when LOOP1 is activated, remains until LOOP1 is clear. Presence detection Signal when LOOP2 is activated, remains until LOOP2 is clear.

-

Page 60: Programmable Inputs, P Channels

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Programmable inputs, P channels Programmable input 1 Name Range Factory Setting Ref. page P100 Channels in programmable input 1 0 - 1 Disabled Enabled P160 Control function Disabled Open Close Stop Open/close... -

Page 61: Programmable Input 2

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable input 2 Name Range Factory Setting Ref. page P200 Channels in programmable input 2 0 - 1 Disabled Enabled P260 Control function Disabled Open Close Stop Open/close Open/stop/close P261... -

Page 62: Programmable Input 3

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable input 3 Name Range Factory Setting Ref. page P300 Channels in programmable input 3 0 - 1 Disabled Enabled P360 Control function Disabled Open Close Stop Open/close Open/stop/close P361 Type of control signal when activated... -

Page 63: Programmable Input 4

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable input 4 Name Range Factory Setting Ref. page P400 Channels in programmable input 4 0 - 1 Disabled Enabled P460 Control function Disabled Open Close Stop Open/close Open/stop/close P461... -

Page 64: Programmable Input 5

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable input 5 Name Range Factory Setting Ref. page P500 Channels in programmable input 5 0 - 1 Disabled Enabled P560 Control function Disabled Open Close Stop Open/close Open/stop/close P561 Type of control signal when activated... -

Page 65: Programmable Input 6

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable input 6 Name Range Factory Setting Ref. page P600 Channels in programmable input 6 0 - 1 Disabled Enabled P660 Control function Disabled Open Close Stop Open/close Open/stop/close P661... -

Page 66: Programmable Wireless Inputs, R Channels

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD • Programmable wireless inputs, r channels Programmable wireless input 1 Name Range Factory Setting Ref. page r001 Readout of received wireless input 0 - 4 No wireless reception Wireless input 1 is receiving a wireless signal... -

Page 67: Programmable Wireless Input 2

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable wireless input 2 Name Range Factory Setting Ref. page r001 Readout of received wireless input 0 - 4 No wireless reception Wireless input 1 is receiving a wireless signal... -

Page 68: Programmable Wireless Input 3

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable wireless input 3 Name Range Factory Setting Ref. page r001 Readout of received wireless input 0 - 4 No wireless reception Wireless input 1 is receiving a wireless signal Wireless input 2 is receiving a wireless signal... -

Page 69: Programmable Wireless Input 4

DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Programmable wireless input 4 Name Range Factory Setting Ref. page r001 Readout of received wireless input 0 - 4 No wireless reception Wireless input 1 is receiving a wireless signal... -

Page 70: Error Messages

INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Error messages E-code Meaning Possible cause Not an error code – indicates the type of EP104 EP-1 in use Not an error code – indicates the type of EP104 EP-2 in use No error, shown to acknowledge a change in the E000 service channel. - Page 71 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD E224 Normal power too low, motor 2 Check C240. E318 Error in loop 1 Are the loop and connectors electrically continuous? For more troubleshooting tips, see the instruction manual for...

-

Page 72: Troubleshooting

• Resetting/replacing tripped fuses If the fuse protecting the power supply to the automatic control unit trips, FAAC Nordic AB recommends following these steps to reset/replace it. • Switch off the main switch to the automatic control unit. - Page 73 DAAB STYRAUTOMATIK EP104 INSTRUCTION MANUAL FOR DAAB EP104 CONTROL BOARD Instruction manual version 1 for software version 4.04...

Need help?

Do you have a question about the DAAB EP104 and is the answer not in the manual?

Questions and answers