Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for FAAC E124S

- Page 1 E124S Translation of the original instructions...

- Page 2 Die Kunden dürfen nur für den Eigengebrauch Kopien anfertigen. Dieses Handbuch wurde 2023 veröffentlicht. © Copyright FAAC S.p.A. del 2023. Todos los derechos están reservados. No puede reproducirse, archivarse, distribuirse a terceros ni copiarse de ningún modo, ninguna parte de este manual, con medios mecánicos o mediante fotocopia, sin el permiso previo por escrito de FAAC S.p.A.

-

Page 3: Table Of Contents

Board E124S ........ -

Page 4: Introduction To The Instruction Manual

E124S will be installed, prior to commissioning the machine. These activities include the analysis of all the risks associated with the machine and subsequent E124S 532434 - Rev.A... -

Page 5: Meaning Of The Symbols Used

SPENT BATTERY HAZARD Risk to the environment and health posed by batteries at the end of their lives due to WIRE STRIPPERS fluid escaping. EXPLOSION HAZARD Risk of explosion due to gas pro- duced by lead batteries building up inside the container (OPTIONAL). E124S 532434 - Rev.A... -

Page 6: Safety Recommendations

The required level of workplace lighting must be equal to at least 200 lux. Operate CE marked machinery and equipment in compli- ance with the manufacturer's instructions. Use work instruments in good conditions. E124S 532434 - Rev.A... -

Page 7: E124S

- It is prohibited to use and/or install accessories which have not been specifically authorised by FAAC S.p.A. 3 E124S - It is prohibited to use the E124S in the presence of 1Y 11 03 19 identification code faults which could compromise safety. -

Page 8: Technical Characteristics

BASIC and ADVANCED. In addition, remote programming from Simply Connect The E124S can control one or two 24 V " brushed mo- provides a larger number of options, including upload- tors, each having a maximum power of 70 W. -

Page 9: Installation Requirements

This is man- datory in the case of hold-to-run controls. The hold-to-run controls in the dead-man mode of operation, must comply with standard EN 60947-5-1. 2 E124S 532434 - Rev.A... -

Page 10: Installation

Prepare the cable routing holes PREPARE THE CABLE ROUTING HOLES ( 4 ) Open the cable routing holes to a diameter suitable for the diameter if the conduits. Install suit- able cable glands. Ø16/20/25 (open to a suitable diameter) 4 E124S 532434 - Rev.A... -

Page 11: Fasten The Enclosure

INSTALL THE COVER ( 6) Insert the hinges for opening towards the left or right. Reinstall the cover OPENING TO THE RIGHT enclosure cover OPENING TO THE LEFT cover enclosure 6 5 E124S 532434 - Rev.A... -

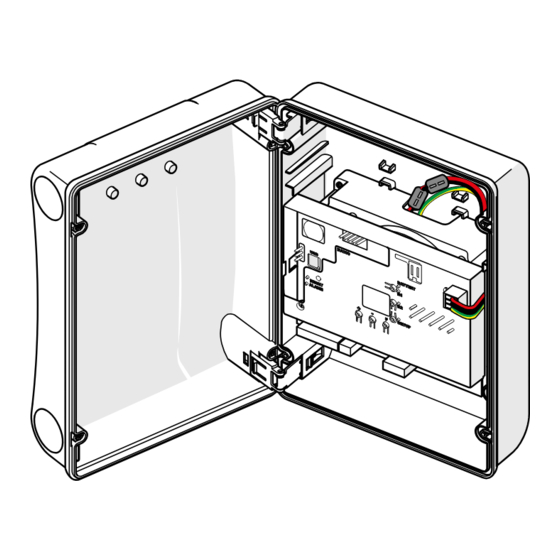

Page 12: Components

1. ( 7 ) Disconnect the POWER connector and remove the cover of the board. 2. Remove the E124S board. 3. Remove the cover from the power supply. 4. (8) Place the selector switch to 120 V. 5. Put back the parts and insert the POWER connector. -

Page 13: Board E124S

Removable terminal board for BUS 2easy MOT2 accessories Removable terminal board for Leaf2 motor Removable terminal board for control device Connector (3 pin) for XF FAAC radio module inputs (IN1 ... IN5) and accessories power RADIO Connec tor (5 pin) for RP/DECODER supply... -

Page 14: Connections

NO type inputs (normally open) Devices with a NO contact must be connected to NO inputs: the com- mand is activated when the contact closes. Multiple NO contacts on same input must be connected in parallel. E124S 532434 - Rev.A... -

Page 15: Gatecoder (Enc)

- further 8 s of pre-flashing). 17 18 19 20 ELECTRIC LOCK (LOCK/ OUT1, OUT2) E124S controls an electric lock to block the leaf in the closed position. Connect the FAAC electric lock to the LOCK terminal Gatecoder 2 board. -

Page 16: Xf Or Xf Fds Module

5-pin quick insertion connector. Insert it as shown in the figure. If a FAAC RP receiver is used, it is recommended to install the appropriate external antenna in order to obtain a sufficient range (see the device instructions). -

Page 17: Start-Up

- the display reverts to the automation status view. (SETUP required). If the SETUP has already been carried out , appears on the display and then the automation status (e.g. For LED and display signals see § Diagnostics. E124S 532434 - Rev.A... -

Page 18: Basic Programming Menu

(CH 2), (CH 3), (CH 4) TYPE OF AUTOMATION Select the type of actuator installed (board loads the relative default configuration). no FAAC actuator S450H The letters indicate a "mixed" automation: 2 leaves with 2 412, 413, 415, 770, 390, 770N S800H ENC different actuators (from Simply Connect). - Page 19 PAUSE VERIFYING BUS 2easy EMERGENCY CLOSE OPEN OPENING PRE-FLASHING and then OPENS Hold Position . (point flashing) SLEEP STATIONARY THEN OPENS CLOSING PRE-FLASHING and then CLOSES STATIONARY THEN CLOSES FAIL- SAFE in progress EMERGENCY OPEN E124S 532434 - Rev.A...

-

Page 20: Advanced Programming Menu

CLOSING PHOTOCELLS Specifies the operation of the closing photocells. reopen when the photocells disengage reopen immediately ADMAP FUNCTION Enables/disables operation in accordance with French standard NFP 25/362. enabled, disabled E124S 532434 - Rev.A... - Page 21 TIMER programming (from Simply Connect, not modifiable from the board). TIMING OUT2 Displayed if . Sets the duration of output OUT2, if a timed function is programmed. … Adjustment step: 1 min if , 1 s if E124S 532434 - Rev.A...

- Page 22 PRE-FLASHING and then CLOSING in EMERGENCY OPENS OPEN CLOSING Hold Position PRE-FLASHING and then SLEEP mode (point STATIONARY THEN OPENS FAIL- SAFE in progress CLOSES flashing) STATIONARY THEN CLOSES VERIFYING BUS 2easy OPENING in EMERGENCY in PAUSE E124S 532434 - Rev.A...

-

Page 23: Setup

If the SETUP procedure doesn’t start or stops before it has been completed, the board exits from program- ming mode and flashes on the display: check the ERRORS that are present (Chapter § Diagnostics). E124S 532434 - Rev.A... -

Page 24: Configuring Movements And Timing

(when the obstacle is removed, the original length of travel is restored automatically). The functions used for adjusting the anti-crushing sys- tem are listed below. Some allow the static force or the E124S 532434 - Rev.A... -

Page 25: Final Checks

Refer to the actuator instructions for any additional tests that may be required. 6.7 CLOSE THE ENCLOSURE Close the enclosure using the screws on the cover. 10 E124S 532434 - Rev.A... -

Page 26: Radio System

7. RADIO SYSTEM The E124S is fitted with an integrated two-channel INSTALLING THE XF FDS OR XF RADIO decoding system that requires either a XF FDS or XF MODULE radio module to be installed, to allow various types of 1. The module should only be inserted into the con- FAAC radio controls to be memorised. -

Page 27: Memorising The First Radio Control (Master)

2 on another radio control). The procedure ends after 20 s if no further radio 1. Press the - - button and DO NOT release it until the controls are memorised and the RADIO LED switches E124S 532434 - Rev.A... - Page 28 - after 5 s, both the RADIO1 RADIO2 LEDs start to flash quickly (deletion in progress) - after 7 s, both LEDs come on steadily (deletion complete) 2. Release the button, both LEDs switch off. E124S 532434 - Rev.A...

-

Page 29: Bus 2Easy Devices

DIP switch 5 enables the device for 1 (OFF )command or 2 (ON) commands. commands BUS 2easy control devices require E124S firmware ver- sion FW 3.2 or later. 1. Configure the DIP switches on the device to assign 1 2 3 4 5 1 2 3 4 5 1 o 2 commands. -

Page 30: Bus 2Easy Photocells, Sensitive Edges

- note: BUS 2easy registration is also carried out via the SETUP. 2EASY BUS 2easy BUS 2easy BUS 2easy Do not exceed the maximum load of 500 mA. The overall length of the BUS 2easy cables must not exceed 100 m. 13 E124S 532434 - Rev.A... -

Page 31: Bus 2Easy Encoder

Correct connections registered, after disconnecting them, repeat the regis- tration (or alternatively the SETUP) procedure. MOT2 MOT1 MOT1 MOT2 DL2 on = encoder connected to MOT1 DL2 off = encoder connected to MOT2 15 E124S 532434 - Rev.A... -

Page 32: Relay Photocells

Connecting 2 pairs of closing or opening photocells Connecting 1 pair of closing photocells and 1 pair of opening and closing photocells IN4 o IN5 IN4 IN5 +24V +24V +24V +24V +24V +24V +24V +24V 16 E124S 532434 - Rev.A... -

Page 33: Simply Connect

RADIO / DECODER carried out remotely (activations, SETUP and/or modi- fications to operating parameters). DL14 Simply Connect requires E124S firmware version FW CLOCK BATTERY 4.0 or later. When programming is taking place via Simply Connect, PRGRM programming via the board is inhibited. -

Page 34: Emergency Batteries

Use rechargeable lead batteries that can supply: Volt- age 20…28 V " , Current 16 A max. To install, use the BATTERY SUPPORT KIT (see FAAC cata- logue - includes the connection cables). 1. Remove the cover and set up the enclosure: To prevent the risk of explosion due to the build up of gas generated by lead batteries, drill a ∅... -

Page 35: Diagnostics

ENC2 Gatecoder Leaf2 moving warning in progress (DL11) no warnings condition with the board powered, the gate at the halfway position and no connected devices active. 19 E124S 532434 - Rev.A... -

Page 36: Firmware Version (Fw)

(OUT1, OUT2) (see advanced program- ming, functions Closing photocells Encoder 2 Photocells for OPEN A Closing sensitive edge E.g.: 1 or more OPEN A control devices and closing photocells are registered: OPEN A BUS 2easy Closing photocells 20 E124S 532434 - Rev.A... -

Page 37: Error Codes, Alarms/Info

E124S. Restore the previous settings or carry out Board thermal pro- Thermal overload protection active. SETUP procedure. tection Wait for the E124S to cool down. SETUP incorrect or Perform SETUP. Check for overloads. missing Encoder 2 fault Make sure that the encoder is connected... -

Page 38: Reset

Programming in Programming in progress, e.g. mainte- nance (via Simply Connect). progress Control board data All data on the E124S has been deleted. deletion RESET Press the RESET button lightly with a thin screwdriver. - The RESET LED lights up and the board is restarted. -

Page 39: Maintenance

The table lists the operations that should be per- Check that the earth connections are intact and that the formed on a regular basis on the E124S board in order circuit breaker and differential switch are working correctly. to keep the automation working reliably and safely;... -

Page 40: Cycle Counter

- After approximately 10 s, appears on the dis- play and LEDS R1 and R2 light up. 3. Release the buttons. - LEDs R1 and R2 switch off. - After approximately 10 s, flashes on the display (SETUP required). E124S 532434 - Rev.A... -

Page 41: Fw - Board Firmware

- The display shows the percentage of progress tem (the board does not recognise other file systems). ) and lastly, shows 2 alternating dashes Firmware (FW) The E124S FW is supplied by FAAC in a compressed file. 3. To exit the procedure:... -

Page 42: Operation

The automation closes automatically after the If an obstacle is detected during opening or closing, pause time has elapsed. the leaf reverses for 2 s and then the automation stops. E124S 532434 - Rev.A... - Page 43 The triggering of the closing photocells reverses the di- pause time has elapsed. rection of movement, the triggering of the opening OPEN during the pause, resets the pause time. photocells stops the movement OPEN during opening, is ignored. E124S 532434 - Rev.A...

- Page 44 (CLOSE) to close. Partial motion is not available. A maintained command must be activated intentionally and the automation must be visible. Maintained OPEN opens the automation. Maintained CLOSE closes the automation. If the photocells are triggered, movement is stopped. E124S 532434 - Rev.A...

- Page 45 Cet appareil se recycle FAAC S.p.A. Soc. Unipersonale À DÉPOSER À DÉPOSER EN MAGASIN EN DÉCHÈTERIE Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY Tel. +39 051 61724 - Fax +39 051 09 57 820 Points de collecte sur www.quefairedemesdechets.fr www.faac.it - www.faactechnologies.com...

Need help?

Do you have a question about the E124S and is the answer not in the manual?

Questions and answers