Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Wenglor OPT2203

- Page 1 OPT2203, OPT2204, OPT2206, OPT2207, OPT2208 Ultrasonic Distance Sensor / Ultrasonic Through-Beam Sensor IO-Link Operating Instructions Translation of the original operating instructions Subject to change without notice Available as PDF file only Version 1.0.0 Status: 17.11.2022 www.wenglor.com...

-

Page 2: Table Of Contents

Table of Contents General .............................4 1.1 Information Concerning these Instructions .....................4 1.2 Explanations of Symbols ........................4 1.3 Limitation of Liability ..........................5 1.4 Copyrights ...............................5 For Your Safety........................6 2.1 Use for Intended Purpose ........................6 2.2 Use for Other than the Intended Purpose ....................7 2.3 Personnel Qualifications .........................7 2.4 Modification of Products .........................7 2.5 General Safety Precautions ........................7... - Page 3 8.2 Condition Monitoring/Process Data ..................... 33 8.2.1 Process Data In ........................33 8.2.2 Process Data Out ........................33 8.3 Events ..............................34 NFC ............................34 10. Maintenance Instructions .....................35 11. Proper Disposal ........................35 12. Appendix ..........................35 12.1 Index of Changes for the Operating Instructions ................35 12.2 EU/UKCA Declaration of Conformity ....................

-

Page 4: General

1. General 1.1 Information Concerning these Instructions • These instructions apply to products OPT2203, OPT2204, OPT2206, OPT2207 and OPT2208. • They make it possible to use the product safely and efficiently. • These instructions are an integral part of the product and must be kept on hand for the entire duration of its service life. -

Page 5: Limitation Of Liability

• wenglor assumes no liability for printing errors or other inaccuracies contained in these operating instruc- tions unless wenglor was verifiably aware of such errors at the point in time at which the operating instruc- tions were prepared. -

Page 6: For Your Safety

2. For Your Safety 2.1 Use for Intended Purpose This sensor is used for object detection and distance determination. Ultrasonic sensors emit pulsed ultrasonic waves at a certain frequency using air as a transmitting medium. The sensors evaluate the transit time of the ultrasound reflected from the object. Parameters can be taught into the sensors using the teach-in key, via an input or via IO-Link. -

Page 7: Use For Other Than The Intended Purpose

• The product is not suitable for use in potentially explosive atmospheres. • The product may be used only with accessories supplied or approved by wenglor, or in combination with approved products. A list of approved accessories and combination products can be found at www.automationdirect.com on the product detail page. -

Page 8: Approvals And Protection Class

2.6 Approvals and Protection Class For Your Safety... -

Page 9: Technical Data

3. Technical Data 3.1 General Data Order number OPT2203/2207 OPT2204/2208 OPT2206 Technical Data Ultrasound Data Working range, Reflex Sensor 100…1,200 mm Working range, Through-Beam Sensor 1…2,000 mm 1...2,000 mm Setting range 100…1,200 mm Reproducibility 5 mm Linearity deviation 2 mm... -

Page 10: Warm-Up Phase

Order number OPT2203/2207 OPT2204/2208 OPT2206 Technical Data Functions Reflex sensor mode Yes (Only emitter Through-Beam Sensor (receiver possible) in default) PNP NO (default setting) NPN NO (default setting) Error output IO-Link 3.2 Warm-Up Phase The warm-up phase lasts roughly 30 minutes. At the beginning of the warm-up phase, linearity deviation and reproducibility may deviate from the specified values. -

Page 11: Mode-Dependent Data

3.3 Mode-Dependent Data Some technical data depend on the filter set. Depending on the setting, the following data are obtained: Reflex and Through-beam Mode Filter value Switching frequency in Hz Response time in ms 2,000 * The specified switching frequency and response time correspond to the maximum duration including interfer- ence filter. -

Page 12: Sonic Cone Diagrams For Reflex Sensor Mode

3.4 Sonic Cone Diagrams for Reflex Sensor Mode Measurement of sonic cone on plate 100×100 mm Ob = object Sc = sonic cone width Standard Narrow Extra Narrow Measurement of the sonic cone on a rod with a diameter of 25 mm Technical Data... -

Page 13: Housing Dimensions

3.5 Housing Dimensions Dimensions in mm M3 screw = 0.5 Nm Ultrasonic Sensors... -

Page 14: Complementary Products

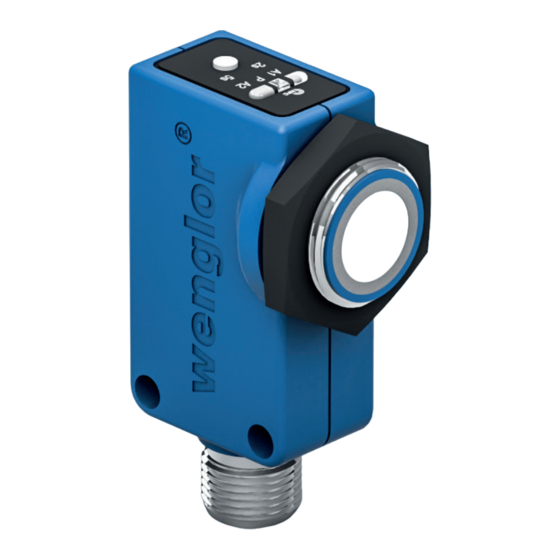

3.6 Complementary Products Suitable connection equipment no. IO-Link masters Baffle plate 3.7 Layout 1 = sensing face 2 = connector plug 3 = mounting holes 4 = teach-in key 5 = indicator LEDs Technical Data... -

Page 15: Control Panel

3.8 Control Panel A 49 06 = teach-in key 5a = switching status indicator O1 68 = supply voltage 6a = switching status display, O2 3.9 Scope of Delivery • 1 ultrasonic distance sensor OPT22xx • 1 plastic nut (NUT-M18-E012) •... -

Page 16: Transport And Storage

4. Transport and Storage 4.1 Transport Upon receipt of shipment, inspect the goods for damage in transit. In the case of damage, conditionally accept the package and notify the manufacturer of the damage. Then return the device, making reference to damage in transit. -

Page 17: Installation And Electrical Connection

5. Installation and Electrical Connection 5.1 Installation • Protect the product from contamination during installation. • Observe all applicable electrical and mechanical regulations, standards, and safety rules. • Protect the product against mechanical influences. • Make sure that the sensor is mounted in a mechanically secure fashion. •... -

Page 18: Electrical Connection

5.2 Electrical Connection • Wire the sensor in accordance with the connection diagram. • Switch on the supply voltage (see “3. Technical Data” on page • The blue supply voltage indicator lights up. • Please consider the different product variants mentioned in chapter “3. -

Page 19: Diagnosis

5.3 Diagnosis 5.3.1 LED Indicators Indicator Status Meaning Sensor ready for operation Supply voltage indicator P No voltage supply Switching output active Warning Switching status 2.5 Hz indicator O1, O2 Error 5 Hz Switching output inactive Not lit up Flashing Permanently lit up 5.3.2 Troubleshooting Error... -

Page 20: Default Settings

• Shut down the machine. • Analyze and eliminate the cause of error with the aid of the diagnostics information. • If the error cannot be eliminated, please contact wenglor’s support department. • Do not operate in case of indeterminate malfunctioning. -

Page 21: Sensor Settings

7. Sensor Settings This section describes the settings that can be made directly on the sensor via the control panel. Teach-In for sensors in refllex sensor mode or receiver mode. The three different teach-in modes foreground teach-in, background teach-in and window teach-in are avail- able. -

Page 22: Setup Via Io-Link

8. Setup via IO-Link The sensors can exchange parameters and process data via IO-Link. The parameters can be used to make many additional settings on the device. The process data transmit cyclical data and condition monitoring. To this end, the sensor is connected to a suitable IO-Link master (see product detail page/complementary products). - Page 23 Function Possible Settings Default NOTE! • Sensors in synchronous mode should have the same sonic cone settings for optimal measurement results. • The response time of the sensors in synchronous mode increases to 1.43 × the response time in normal mode (e.g.

- Page 24 Function Possible Settings Default Filter Filters are available for sensors in reflex sensor mode or receiver mode. The selected filter has an influence on the response time (see response time in section “3. Technical Data” on page 9) and the number of distance values to be evaluated.

- Page 25 Function Possible Settings Default Filter Median filter of 24 measured values and bridging from 15 missing measured values (420 ms) Median filter of 27 measured values and bridging from 31 missing measured values (868 ms) Median filter of 36 measured values and bridging from 62 missing measured values (1.7 s) NOTE! The technical data resulting from the various modes are...

- Page 26 Function Possible Settings Default Temperature The sensor has internal temperature compensation. Alternatively, the Internal mode temperature can be measured externally and sent to the sensor as a process or parameter. Internal Sensor operates with internal temperature compensation External Sensor works with external temperature compensation and uses the transmitted process or parameters (see section “8.2 Condition Monitor- ing/Process...

-

Page 27: Input/Output Functions (I/O)

8.1.2 Input/Output Functions (I/O) 8.1.2.1 Pin Functions for sensors in reflex sensor mode or receiver mode The pin function is used to define the function of pins I/O1, I/O2, and I3, as these can be used for different functions. Possible Settings Default I/O1 Switching Output... -

Page 28: Output Functions For Sensors In Reflex Sensor Mode Or Receiver Mode

Transmit Signal Off Input Transmit signal The sensor’s transmit signal is deactivated as long as the input is activat- off input ed. The sensor does not send a measured value and sets the status to "No signal". Teach-In Input Teach-in The outputs (switching outputs) can be set using the same procedure as with the teach-in key (see section 6). -

Page 29: Input Functions

8.1.2.3 Input Functions The input functions are used to set the physical inputs. Function Possible Settings Default Input mode Operating Voltage Active Operating volt- The function is triggered as soon as operating voltage is applied to the age active input. Operating Voltage Inactive The function is triggered as soon as 0 V is applied to the input or the input is not occupied. - Page 30 Function Possible Settings Default Window Teach-In Sensor Near switching point Window size Object Far switching point NOTE! The far switching point must be greater than the near switching point. 100…1200 mm Switching point 1200 mm 100…1200 mm Near switching 100 mm point window 100…1200 mm Far switching...

-

Page 31: Condition Monitoring Functions

8.1.4 Condition Monitoring Functions 8.1.4.1 Status Message Function The sensor provides various status messages. Due to the process data structure, four status messages can be transmitted as individual process data. These parameters can be used to set the status messages that are transmitted via the process data. Function Possible Settings Default... -

Page 32: Simulation Functions

Error Short circuit A short circuit has occurred on at least one pin. Device error A hardware error has occurred. 8.1.5 Simulation Functions This function simulates the behavior of the sensor regardless of the current status and measured value. This can be used to check whether a plant in which the sensor is integrated reacts correctly to the data supplied by the sensor and processes them accordingly. - Page 33 8.2 Condition Monitoring/Process Data The data described in the following section can be read or written cyclically via IO-Link/process data. 8.2.1 Process Data In Data Meaning Measured Measured distance in mm or 1/10 inch value As the sensor cannot determine a measured value in the following error cases, substitute values are read out: No signal: 0x7FFC / –...

- Page 34 "weCon" app. Process data cannot be read out via NFC but they’re available via IO-Link. The wenglor app can be downloaded free of charge from the Google Play Store or from App Store. Download the app and follow the installation instructions.

- Page 35 • Do not clean the sensor with solvents or cleaning agents that could damage the product. • The product must be protected against contamination during initial start-up. 11. Proper Disposal wenglor sensoric GmbH does not accept the return of unusable or irreparable products. Respectively valid national waste disposal regulations apply to product disposal. 12. Appendix 12.1 Index of Changes for the Operating Instructions...

Need help?

Do you have a question about the OPT2203 and is the answer not in the manual?

Questions and answers