Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Wenglor OPT2151

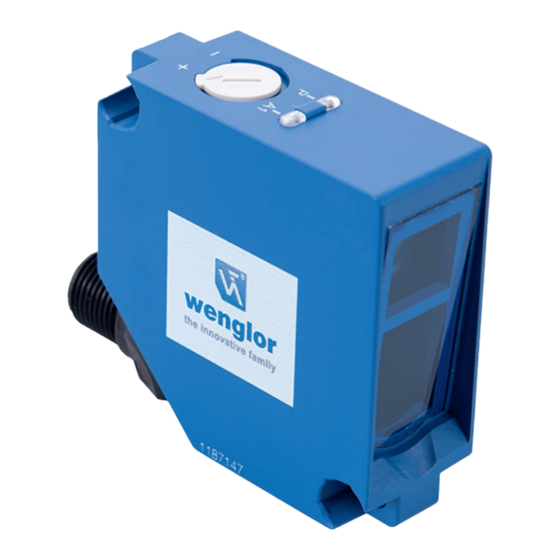

- Page 1 OPT2151 OPT2152 Reflex Sensors with Background Suppression Operating Instructions Translation of the Original Operating Instruction Subject to change without notice Available as PDF version only Version: 1.0.0 Status: 01.02.2021 www.wenglor.com...

-

Page 2: Table Of Contents

Table of Contents 1. General ...........................3 1.1 Information Concerning these Instructions ..................... 3 1.2 Explanations of Symbols ......................... 3 1.3 Limitation of Liability ..........................4 1.4 Copyrights ..............................4 2. For Your Safety ........................5 2.1 Use for Intended Purpose ........................5 2.2 Use for Other than the Intended Purpose.................... -

Page 3: General

1. General 1.1 Information Concerning these Instructions • These instructions apply to the products with ID codes OPT2151 and OPT252. • They make it possible to use the product safely and efficiently. • These instructions are an integral part of the product and must be kept on hand for the entire duration of its service life. -

Page 4: Limitation Of Liability

• wenglor assumes no liability for printing errors or other inaccuracies contained in these operating instructions, unless wenglor was verifiably aware of such errors at the point in time at which the operating instructions were prepared. -

Page 5: For Your Safety

• The product is not suitable for use in potentially explosive atmospheres. • The product may only be used with accessories supplied or approved by wenglor, or combined with approved products. A list of approved accessories and combination products can be accessed at www.automationdirect.com on the product detail page. -

Page 6: Personnel Qualifications

2.3 Personnel Qualifications • Suitable technical training is a prerequisite. • In-house electronics training is required. • Trained personnel must have uninterrupted access to the operating instructions. DANGER! Risk of personal injury or property damage in case of incorrect initial start-up and maintenance! Personal injury and damage to equipment may occur. -

Page 7: Technical Data

Protection class Mechanical Data Setting method Potentiometer Housing material Plastic Degree of protection IP67 / IP68 Lens cover PMMA Order Number OPT2151 OPT2152 Technical Data Principle Electronic background suppression Range 400 mm Adjustable Range 50...400 mm Switching hysteresis < 3 % Temperature range –40…60 °C... -

Page 8: Spot Diameter

11 mm 13 mm 14 mm Table 1 3.2 Switching Distance Deviation Typical characteristic curve based on Kodak white (90 % remission). OPT2151, OPT2152: P1PH Sr/mm Sr = Switching Distance dSr = Switching Distance Change Black 6 % remission Grey 18 % remission... -

Page 9: Layout

3.3 Layout OPT2151, OPT2152 = Emitter diode = Receiving diode Screw M4 = 0,5 Nm Potentiometer = 40 Nmm Dimensions specified in mm (1 mm = 0,03937 Inch) 3.4 Control Panel 05 = switching distance adjuster 30 = switching status indicator / contamination warning... -

Page 10: Scope Of Delivery

3.5 Scope of Delivery • Sensor • Safety precautions • Mounting Set 14 • Spacer sleeves Z1PE002 4. Transport and Storage 4.1 Transport Upon receipt of shipment, the goods must be inspected for damage in transit. In the case of damage, con- ditionally accept the package and notify the manufacturer of the damage. -

Page 11: Installation And Electrical Connection

5. Installation and Electrical Connection 5.1 Installation • Protect the product from contamination during installation. • Observe all applicable electrical and mechanical regulations, standards, and safety rules. • Protect the product against mechanical influences. • Make sure that the sensor is mounted in a mechanically secure fashion. •... -

Page 12: Electrical Connection

5.2 Electrical Connection Legend Encoder A/A (TTL) Platinum measuring resistor Encoder B/B (TTL) Supply Voltage + not connected Encoder A Supply Voltage 0 V Test Input Encoder B Supply Voltage (AC Voltage) Test Input inverted Digital output MIN Switching Output (NO) Trigger Input Switching Output... -

Page 13: Diagnostics

5.3 Diagnostics Causes for Triggering the Contamination Warning (blinking LED): Display LED Diagnosis/Cause Elimination Contamination Carefully clean the optic cover with a cloth. Continuous blinking Aged emitter diode Replace the sensor. at approx. 2.5 Hz • Increase the sensor’s switching distance. Unreliable working range •... -

Page 14: Settings

Required action in case of fault: NOTE! • Shut down the machine. • Analyze and eliminate the cause of error with the help of the diagnostics information. • If the error cannot be eliminated, please contact AutomationDirect’s support department. • Do not operate in case of indeterminate malfunctioning. •... -

Page 15: Maintenance Instructions

• Do not clean the sensor with solvents or cleansers which could damage the product. • The product must be protected against contamination during initial start-up. 9. Proper Disposal wenglor sensoric GmbH does not accept the return of unusable or irreparable products. Respectively valid national waste disposal regulations apply to product disposal. 10. Appendix 10.1 List of Abbreviations...

Need help?

Do you have a question about the OPT2151 and is the answer not in the manual?

Questions and answers