SKF LINCOLN ATEX PSG1 Series Operating Instructions Manual

Hide thumbs

Also See for LINCOLN ATEX PSG1 Series:

- Operating instructions manual (114 pages) ,

- Operating instructions manual (30 pages)

Summary of Contents for SKF LINCOLN ATEX PSG1 Series

- Page 1 Oferating instructions ATEX frogressive metering devices according to ATEX Directive 2014/34/EU of the series PSG1, PSG2, PSG3 Version 01 951-180-085-EN...

- Page 2 EU Declaration of Conformity fursuant to ATEX Directive 2014/34/EU, Annex X The manufacturer, SKF Lubrication Systems Germany GmbH, Hockenheim Plant, 2. Industriestr. 4, DE - 68766 Hockenheim hereby declares the conformity of the device: Designation: Progressive metering devices, Series: PSG1; PSG2 and PSG3...

-

Page 3: Masthead

Masthead Manufacturer Training Disclaimer of liability SKF Lubrication Systems Germany GmbH SKF conducts detailed training in order to The manufacturer shall not be held liable for Address of manufacturer flants enable the maximum safety and efficiency. damage resulting from: Headquarters SKF recommends taking advantage of this ○... -

Page 4: Table Of Contents

Table of contents Table of contents Masthead ..................3 Exflanation of symbols and signs ............7 Safety instructions ..............9 1.22 Special safety instructions regarding explosion protection .....18 General safety instructions ..............9 1.23 Nullification of ATEX approval ..............20 General behavior when handling the product ........9 1.24 Operation in potentially explosive atmospheres .......20 Intended use ..................10... - Page 5 Table of contents 3.8.1 Functional description of a general progressive system ....35 Assembly ................54 Overview of PSG1 progressive metering device series ....36 General information ................54 3.10 Overview of PSG2 progressive metering device series ....37 Assembly location .................54 3.11 Overview of PSG3 progressive metering device series ....38 Mechanical connection .................55 6.3.1 Minimum mounting dimensions ...........55...

- Page 6 Table of contents Installing a PSG modular metering device .........70 Maintenance ............... 86 Consolidation of outlets ................71 Malfunctions, causes, and remedies ........87 Changing a PSG module ..............72 11.1 Prior to beginning troubleshooting ............87 6.10 Connecting the lubricant lines .............73 11.2 Metering device and system malfunctions.........88 6.10.1...

-

Page 7: Exflanation Of Symbols And Signs

Explanation of symbols, signs, and abbreviations Exflanation of symbols and signs General warning Risk of electrical shock Risk of slipping Hot surfaces Being drawn into machinery Crushing hazard Pressure injection Suspended load Electrostatic sensitive Potentially explosive Reserve Reserve components atmosphere Wear personal protective gear Wear personal protective Wear personal protective gear... - Page 8 Explanation of symbols, signs, and abbreviations Abbreviations and conversion factors regarding °C degrees Celsius °F degrees Fahrenheit approx. approximately Kelvin ounce i.e. that is Newton fl. oz. Fluid ounce etc. et cetera hour inch poss. possibly second pound per square inch if necessary if necessary sq.in.

-

Page 9: Safety Instructions

1. Safety instructions 1. Safety instructions ○ Wear personal protective equipment. 1.1 General safety instructions and environmental protection must be observed. ○ The operator must ensure that the in- ○ All safety regulations and in-house structions are read by all persons tasked instructions relevant to the particular with working on the product or who activity must be observed. -

Page 10: Intended Use

Modular metering devices (progressive Only ATEX attachments and monitoring metering devices) of the series PSG are equipment approved by SKF for the PSG1, designed for positively driven distribution of PSG2 and PSG3 series metering devices lubricants (oils/greases) in centralized lubri- may be installed. -

Page 11: Foreseeable Misuse

1. Safety instructions 1.5 Foreseeable misuse ○ Use in potentially explosive gases and Any usage of the product other than as 1910.1200 that are marked with hazard specified in this manual is strictly prohibited. pictograms GHS01-GHS06 and GHS08 vapors whose ignition temperature is Particularly prohibited are: less than 125% of the maximum surface ○... -

Page 12: Prohibition Of Certain Activities

1. Safety instructions 1.6 Prohibition of certain activities 1.8 Inspections prior to delivery The following activities must be performed The following tests were performed prior to If applicable: only by employees of the manufacturer or delivery: ○ Project planning documents persons authorized by the manufacturer ○... -

Page 13: Markings On The Product

1. Safety instructions 1.10 Markings on the product 1.11 Notes on the type plate 1.12 Note on CE marking The rating plate provides important data The CE marking is based on the require- such as the type designation, order number, ments of the applied Directives: Equipotential bonding connec- etc. -

Page 14: Directive 2014/34/Eu

1. Safety instructions 1.13 Explosion protection marking in 1.14 Persons authorized to use the product accordance with Directive 2014/34/EU Note on Pressure Equipment Directive 1.14.1 Operator 2014/68/EU The ignition hazard analysis conducted in accordance with EN 80079-36 / -37 A person competent due to training, knowl- Due to its performance characteristics, the found that the progressive metering devices edge, and experience to execute the func-... -

Page 15: Qualified Electrician

1. Safety instructions 1.14.3 Qualified electrician 1.15 Instruction of outside fitters 1.17 Operation A person with appropriate technical training, knowledge, and experience who can recog- Before commencing work, the operator The following must be observed during first nize and avoid hazards that may result from must inform outside fitters of the opera- start-up and operation: electricity. -

Page 16: Transport, Assembly, Maintenance, Malfunction, Repair, Shutdown, Disposal

1. Safety instructions 1.19 Transport, assembly, maintenance, malfunction, repair, shutdown, disposal ○ Prior to the start of this work, all relevant ○ Establish the electrical connection only in limbs can be pinched by unintended persons must be notified of it. Precau- movements. -

Page 17: First Start-Up, Daily Start-Up

1. Safety instructions 1.20 First start-up, daily start-up ○ All components used must be designed ○ Use suitable hoisting equipment when Ensure that: for: working with heavy parts. ○ All safety mechanisms are fully present - The maximum operating pressure ○... -

Page 18: Cleaning

1. Safety instructions 1.21 Cleaning 1.22 Special safety instructions regarding explosion protection ○ There is a fire hazard from the use of ○ Always behave so as to avoid explosion ○ Depending on the operating conditions, flammable cleaning agents. Use only hazards. - Page 19 1. Safety instructions gas and dust groups and temperature containing the following information: slipping, rubbing, or striking. If necessary, classes. Light metal dusts, as a poten- - Date cover materials by appropriate means. tially explosive ambient medium, are - Executing company ○...

-

Page 20: Nullification Of Atex Approval

○ Unauthorized alterations ○ All information within this manual and ○ Junction boxes must be securely closed the information within the referenced ○ Use of non-original SKF spare/replace- and the cable glands properly sealed. documents ment components ○ Any additional electrical monitoring ○... -

Page 21: Explosion Protection Marking

1. Safety instructions 1.25 Explosion protection marking 1.26.2 Exflosion frotection measures ○ Selects suitable employees The explosion protection marking is located Based on a comprehensive assessment of ○ Provides the employees with adequate on the Declaration of Conformity and on the the work area, the operator ensures that the rating plate. -

Page 22: Duty To Provide Instruction And Training

1. Safety instructions 1.26.3 Provision of necessary 1.26.4 Duty to frovide instruction and information training ○ Handling operating materials and clean- The operator must the relevant required The operator clearly defines the respon- instructions available to all persons assigned sibilities of the personnel for operation, ing agents with operation, repair, and maintenance. -

Page 23: Residual Risks

1. Safety instructions 1.27 Residual risks Possible in Residual risk Avoidance / Remedy lifecycle Personal injury / property damage due Unauthorized persons must be kept away; nobody is allowed to be present below hoisted A, B, C, G, H, K to falling of hoisted parts parts. -

Page 24: Residual Atex Risks

1. Safety instructions 1.28 Residual ATEX risks Possible in Residual risk Avoidance / Remedy lifecycle Use in a potentially explosive atmo- Check the equipotential bonding for continuity before first start-up, after every repair, and ad- sphere without checking equipotential C, D, G ditionally at regular intervals defined by the operator bonding for electrical continuity Operation with a finish or paint coat that... - Page 25 1. Safety instructions Possible in Residual risk Avoidance / Remedy lifecycle Generation of electrostatic charges or sparks by C, D, E, F, G Secure parts against falling. If necessary, cover parts to avoid sparking. dropping of parts Introduction of catalytic, unstable, or pyro- Ensure that none of these substances enter the potentially explosive atmosphere;...

-

Page 26: Lubricants

2. Lubricants 2.1 General information 2.2 Selection of lubricants Lubricants are used specially for specific SKF Lubrication Systems considers lubri- This will spare you potentially costly down- applications. To fulfill the task, lubricants cants to be an element of system design. -

Page 27: Aging Of Lubricants

See the ards on the packaging when han- "Technical data" chapter for the required Please contact SKF if you have further ques- dling lubricants. viscosities. tions regarding lubricants. -

Page 28: Solid Lubricants

2. Lubricants 2.5.1 Solid lubricants Solid lubricants may only be used Coffer after prior consultation with SKF Chisel pastes containing copper are known Lubrications Systems. to lead to coatings forming on pistons, bore holes, and mating surfaces. This can result... -

Page 29: Overview, Functional Descriftion

PSG are accordance with EN 80079-36 / -37 found cm³/min designed for positively driven distribution of that SKF basic metering devices of series 6 000 lubricants (oils/greases) in centralized lubri- PSG1, PSG2 and PSG3 without electrical cation systems. -

Page 30: Information On Volume Data

3. Overview, functional description 3.3 Information on volume data See Figure 2 Fig. 2 Maximum stro- The maximum stroke and thus the piston ke and comfulsory stroke In centralized lubrication systems, the nomi- capacity/metered quantity can reduce due to Maximum nal volume is indicated per stroke. -

Page 31: Functioning Of A Psg Progressive Metering Device

3. Overview, functional description 3.4 Functioning of a PSG progressive metering device See Figure 3 Observation of the movements beginning corresponding metering volume into the Fig. 3 PSG sectional view with the moment that all three pistons (A, duct to outlet 3. This movement of piston B, C) on the left end stop shows that the C opens, among others, the reversing duct lubricant and operating pressure reach from... -

Page 32: Information On The Design Of A Psg Progressive Metering Device

3. Overview, functional description 3.5 Information on the design of a PSG progressive metering device The general criteria for the design of pro- The outlet in the baseplate that is no longer (PSG1=50 mm /stroke, PSG2 =60 mm gressive metering devices also apply without needed is to be closed using a washer and a stroke, PSG3 =800 mm /stroke). -

Page 33: Dummy Module

3. Overview, functional description 3.6 Dummy module 3.7 Consolidation of outlets Dummy and functional modules can be See Figure 4 Fig. 4 Consolidation of outlets varied as desired within the frame size. A minimum of three functional modules per The volumetric flow of an outlet can be metering device is required. -

Page 34: Overview Of A General Progressive System

3.8 Overview of a general progressive system Fig. 5 Examfle of frogressive system with fumf unit Legend to Fig. 5 PSG3-3-05557 SKF Lubrication Systems Germany AG bade in Germany KW/JJ Progressive system with function PSG3-3-05557 SKF Lubrication Systems Germany AG... -

Page 35: Functional Description Of A General Progressive System

3. Overview, functional description 3.8.1 Functional description of a general progressive system See Figure 5 ○ Connectivity of a proximity switch for the lubricant coming from the pump unit A general progressive metering device sys- is delivered to the main metering device. monitoring the metering device function tem consists of the following components: The main metering device distributes the... -

Page 36: Overview Of Psg1 Progressive Metering Device Series

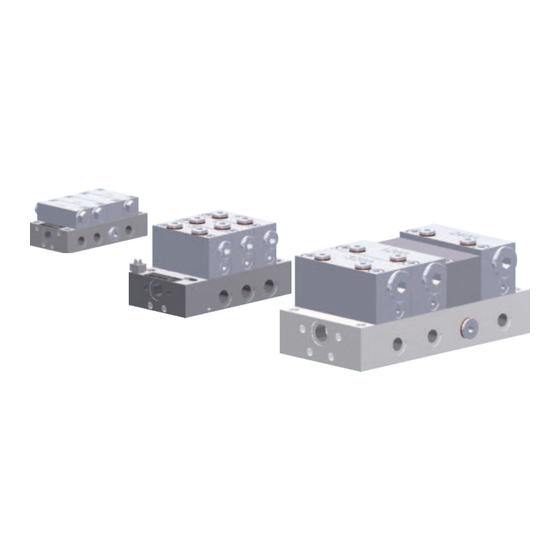

3. Overview, functional description 3.9 Overview of PSG1 progressive metering device series Fig. 6 ATEX PSG1 frogressive metering device series Legend to Fig. 6 PSG1 basic design for oil and grease, without attachments, without monitoring PSG1 basic design with cycle indicator for oil or grease, mon- itoring type ZY (visual monitoring) -

Page 37: Overview Of Psg2 Progressive Metering Device Series

3. Overview, functional description 3.10 Overview of PSG2 progressive metering device series Fig. 7 ATEX PSG2 frogressive metering device series Legend to Fig. 7 PSG2 basic design for oil and grease, without attachments, without monitoring PSG2 basic design with cycle indicator for oil or grease, monitoring type ZY (visual monitoring) -

Page 38: Overview Of Psg3 Progressive Metering Device Series

3. Overview, functional description 3.11 Overview of PSG3 progressive metering device series Fig. 8 ATEX PSG3 frogressive metering device series Legend to Fig. 8 PSG3 basic design for oil and grease, without attachments, without monitoring PSG3 basic design with cycle in- dicator for oil or grease, monitor- ing type ZY (visual monitoring) PSG3 with inductive proximity... -

Page 39: Technical Data

4. Technical data 4. Technical data 4.1 PSG1-ATEX General technical data 4.1.1 PSG1 - Basic metering device Technical data PSG1, Table 1 (1/2) Type hydraulically controlled In case of attachments on moving machine parts or in case of strong vibrations (e.g., Mounting position on pressing machines), the piston position of the metering device must not match the direction of movement of the machine part. - Page 40 4. Technical data Technical data PSG1, Table 1 (2/2) Piston stroke rate max. 200/min Dividing ratio of delivery volumes 1:1 to 1:10 Larger dividing ratios are possible when consolidated! (up to 1:10) Required starting pressure with oil Min. 2 bar Pressure loss See pressure-loss diagrams on the following page Lubricant...

-

Page 41: Psg1 Pressure-Loss Diagram

4. Technical data 4.1.2 PSG1 pressure-loss diagram Fig. 9 PSG1, Technical data, Pressure loss diagram Measurement frerequisites Measurement frerequisites Oil viscosity: 150 cSt Oil viscosity: 357 cSt Test medium: ISO VG 150 Test medium: ISO VG 150 (viscosity index 92) (viscosity index 92) Oil temperature: + 40°C Oil temperature: + 26°C... -

Page 42: Psg1 With Inductive Proximity Switch

4. Technical data 4.1.3 PSG1 with inductive proximity switch PSG1 with inductive froximity switch, Table 2 PSG1 progressive metering device with inductive proximity switch For further technical data, see PSG1 basic design Inductive proximity switch Order number: 24-1884-2288 Connection to switching amplifier: Yes Internal thread M12x1 Design... -

Page 43: Psg2-Atex General Technical Data

4. Technical data 4.2 PSG2-ATEX General technical data 4.2.1 PSG2 - Basic metering device Technical data PSG2, Table 3 (1/2) Type hydraulically controlled In case of attachments on moving machine parts or in case of strong vibrations (e.g., Mounting position on pressing machines), the piston position of the metering device must not match the direction of movement of the machine part. - Page 44 4. Technical data Technical data PSG2, Table 3 (2/2) Piston stroke rate max. 200/min Dividing ratio of delivery volumes 1:1 to 1:28 AM Larger dividing ratios are possible when consolidated! Pressure differential (with oil) 5 to 15 bar Depending on volume index and viscosity or penetration and volumetric flow Starting pressure required with oil Min.

-

Page 45: Psg2 With 2/2 Directional Solenoid Valve

4. Technical data 4.2.2 PSG2 with 2/2 directional solenoid valve PSG2 with directional solenoid valve, Table 4 2/2 directional solenoid valve Order number: 24-1254-2212 Type Seat valve, double-sided blocking Operating media Oils ISO VG 10 to 68 greases NLGI grades 000 to 2 How it works De-energized closed (NC) Media temperature... -

Page 46: Psg2 With Inductive Proximity Switch 24-1884-2292

4. Technical data 4.2.3 PSG2 with inductive proximity switch 24-1884-2292 PSG2 with inductive froximity switch, Table 5 PSG2 progressive metering device with inductive proximity switch For further technical data, see PSG1 basic design Inductive proximity switch Order number: 24-1884-2292 (Proximity switch 24-1884-2292) Connection to switching amplifier: Yes Internal thread M18x1... -

Page 47: Psg2 With Inductive Proximity Switch 24-1884-2613

4. Technical data 4.2.4 PSG2 with inductive proximity switch 24-1884-2613 PSG2 with inductive froximity switch, Table 6 EN 60947-5-6:2000 Type Inductive/NAMUR (Proximity switch 24-1884-2613) IEC 60947-5-6:1999 Certification UL and CSA Inductive proximity switch Order number: 24-1884-2613 Internal thread M18x1 Nominal sensing distance Sn 1,5mm, flush mountable Secured sensing distance Sa 0 to 1.22 mm... -

Page 48: Psg3-Atex General Technical Data

4. Technical data 4.3 PSG3-ATEX General technical data 4.3.1 PSG3 - Basic metering device Technical data PSG3, Table 7 (1/2) Type hydraulically controlled In case of attachments on moving machine parts or in case of strong vibrations (e.g., Mounting position on pressing machines), the piston position of the metering device must not match the direction of movement of the machine part. - Page 49 4. Technical data Technical data PSG3, Table 7 (2/2) Dividing ratio of delivery volumes 1:1 to 1:14 AM Larger dividing ratios are possible when consolidated! Pressure differential (with oil) 5 to 15 bar Depending on volume index and viscosity or penetration and volumetric flow Starting pressure required with oil Min.

-

Page 50: Psg3 With Inductive Proximity Switch 24-1884-2292

4. Technical data 4.3.2 PSG3 with inductive proximity switch 24-1884-2292 Technical data PSG3, Table 8 PSG3 progressive metering device with inductive proximity switch For further technical data, see PSG1 basic design Inductive proximity switch Order number: 24-1884-2292 (Proximity switch Connection to switching amplifier: Yes 24-1884-2292) Internal thread M18x1... -

Page 51: Delivery, Returns, Storage

5. Delivery, returns, storage 5. Delivery, returns, storage 5.1 Delivery 5.2 Return shipment 5.3 Storage After receipt of the delivery, it must be in- Before return shipment, all contaminated The following conditions apply to storage: spected for any shipping damage and for parts must be cleaned and properly packed ○... -

Page 52: Storage Temperature Range

5. Delivery, returns, storage 5.4 Storage temperature range 5.5 Storage conditions for parts filled with lubricant ○ In cases of parts not filled with lubricant, Before usage, check products for damage that may have occurred the permitted storage temperature The conditions listed below must be main- during storage. -

Page 53: Storage Period Between 6 And 18 Months

5. Delivery, returns, storage 5.5.2 Storage feriod between 6 and 18 months 5.5.3 Storage feriod more than 18 months Pumf • Allow pump to run until fresh lubricant • Connect pump electrically is discharged at the metering device To prevent faults, the manufacturer should manifold be consulted before start-up. -

Page 54: Assembly

6. Assembly 6. Assembly 6.1 General information ○ The mounting position of the product is Modular metering devices (progressive vice contacts are clean and free of metal metering devices) of the series PSG can be chips. as shown in the assembly drawing. used in the context of the technical specifi- ○... -

Page 55: Mechanical Connection

ATEX rules and Only attachments and monitoring other hazards such as moving com- certificates must be present and equipment approved by SKF for the ponents. maintained. It must be ensured ATEX progressive metering devices Maintain safety clearances and (checked) that no potentially explo- may be installed. -

Page 56: Installing The Psg1

6. Assembly 6.4 Installing the PSG1 6.4.1 Basic design PSG1-ATEX Fig. 10 PSG1-ATEX in basic design Metering device module Dummy module Equipotential bonding terminal (1) for cable clamp Ø 4.3 mm G1/8 Baseplate 19.5 Outlet G1/8 4x Ø6.5 Inlet Minimum mounting dimensions BM = Width: 100 mm... -

Page 57: Psg1 Tightening Torques

6. Assembly 6.4.2 PSG1 tightening torques PSG1 dimensions The specified torques must be observed dur- IMPORTANT NOTE ing assembly and repair. Quantity Dim. Dim. Dim. Weight of the The inlet and the outlet screw unions are Tightening torques [kg] modules [mm] not included in the basic design (see Acces- Number of... -

Page 58: Psg1-Atex With Visual Cycle Indicator (Zy)

6. Assembly 6.4.3 PSG1-ATEX with visual cycle indicator (ZY) Fig. 11 PSG1-ATEX with visual cycle indicator (ZY) Note! The cycle indicator ZY can be attached to either the left or right side of a 200 or 250 mm metering device module. -

Page 59: Psg1-Atex With Visual Cycle Indicator, Housing, And Inductive Proximity Switch (Zs)

6. Assembly 6.4.4 PSG1-ATEX with visual cycle indicator, housing, and inductive proximity switch (ZS) Fig. 12 PSG1 with visual cycle indicator, housing, and inductive froximity switch (ZS) Note! The proximity switch can be at- Connection only via a tached to either the left or right NAMUR amplifier side of the 200 mm and 250 mm... -

Page 60: Assembly Psg2-Atex

6. Assembly 6.5 Assembly PSG2-ATEX 6.5.1 Basic design PSG2-ATEX Fig. 13 PSG2-ATEX in basic design Metering device module Dummy module Baseplate G1/4 G1/4 Outlet Equipotential bonding terminal (1) Measurement connector or for attaching a blockage indicator G 1/8 for cable clamp Ø 4.3 mm Ø7.1 Inlet G1/4 Minimum mounting dimensions... -

Page 61: Psg2 Tightening Torques

6. Assembly 6.5.2 PSG2 tightening torques PSG2 dimensions The specified torques must be observed dur- IMPORTANT NOTE ing assembly and repair. Quantity Dim. Dim. Dim. Weight The inlet and the outlet screw unions are of the Tightening torques [kg] modules [mm] not included in the basic design (see Acces- Number of... -

Page 62: Psg2-Atex With Visual Cycle Indicator (Zy)

6. Assembly 6.5.3 PSG2-ATEX with visual cycle indicator (ZY) Fig. 14 PSG2 with visual cycle indicator (ZY) Note! The cycle indicator can be attached to either the left or right side of the metering device modules (not on the 60 module). -

Page 63: Psg2-Atex With Pressure-Resistant Inductive Proximity Switch 24-1884-2292

6. Assembly 6.5.4 PSG2-ATEX with fressure-resistant inductive froximity switch 24-1884-2292 Fig. 15 ATEX metering device with inductive froximity switch Note! The proximity switch can be at- tached to either the left or right side of the modules on design ZY. It is attached to the right side at the factory. -

Page 64: Psg2-Atex With Pressure-Resistant Inductive Proximity Switch 24-1884-2613

6. Assembly 6.5.5 PSG2-ATEX with fressure-resistant inductive froximity switch 24-1884-2613 Fig. 16 ATEX metering device with inductive froximity switch Note! The proximity switch can be at- tached to either the left or right side of the modules on design ZY. It is attached to the right side at the factory. -

Page 65: Psg2-Atex With 2/2 Directional Solenoid Valve 24-1884-2292

6. Assembly 6.5.6 PSG2-ATEX with 2/2 directional solenoid valve 24-1884-2292 Fig. 17 PSG2 with 2/2 directional solenoid valve Note! Use 2/2 directional solenoid PE 1 valve only for oil applications. G1/4 3x G1/4 3x G1/4 Sfare fart no. Inlet 2/2 directional solenoid valve 24-1884-2292 Minimum mounting dimensions BM =... -

Page 66: Assembly Psg3-Atex

6. Assembly 6.6 Assembly PSG3-ATEX 6.6.1 Basic design PSG3 Fig. 18 PSG3 in basic design Dummy module Metering device module Equipotential bonding terminal (1) 27.5 for cable clamp Ø 4.3 mm G3/8 G1/4 Outlet G 1/8" (e.g. for overpressure indication) 4x Ø9 Inlet G 3/8"... -

Page 67: Psg3 Tightening Torques

6. Assembly 6.6.2 PSG3 tightening torques The specified torques must be observed dur- PSG3 dimensions IMPORTANT NOTE ing assembly and repair. Quantity Dim. Dim. Dim. Weight of the Tightening torques The inlet and the outlet screw unions are [kg] modules [mm] not included in the basic design (see Acces- Number of... -

Page 68: Psg3-Atex With Visual Cycle Indicator (Zy)

6. Assembly 6.6.3 PSG3-ATEX with visual cycle indicator (ZY) Fig. 19 PSG3 with visual cycle indicator Note! The cycle indicator can be attached to either the left or right side of the metering device modules (not on the 60 mm module). -

Page 69: Psg3 With Cycle Indicator, Housing, And Inductive Proximity Switch 24-1884-2292

6. Assembly 6.6.4 PSG3 with cycle indicator, housing, and inductive proximity switch 24-1884-2292 Fig. 20 PSG3 with visual cycle indicator, housing, and froximity switch (ZS) Note! Depiction of optional attachment of the cycle switch at the 2nd module, right side The proximity switch can be attached to either the left or right side on design ZY. -

Page 70: Installing A Psg Modular Metering Device

6. Assembly 6.7 Installing a PSG modular metering device See: PSG1 - see Chapter 6.4. • Cylinder hexagon socket screws diagonal The product and its equipotential PSG2 - see Chapter 6.5 with a tightening torque of: bonding connection must be connected PSG3 - see Chapter 6.6. -

Page 71: Consolidation Of Outlets

6. Assembly 6.8 Consolidation of outlets See Figure 21 and Fig. 4 • If fitted, screw in the right or left outlet Designation Order Number The volumetric flow of an outlet can be screw union Setscrew "G" 915-AM5x8-45H doubled by internal consolidation of two G 1/8”... -

Page 72: Changing A Psg Module

6. Assembly 6.9 Changing a PSG module See Figure 22 Prior to beginning installation of the new module, ensure that each of the O- IMPORTANT NOTE rings is properly seated in its respective For the purpose of self-venting, the groove. Fig. -

Page 73: Connecting The Lubricant Lines

6. Assembly 6.10 Connecting the lubricant lines IMPORTANT NOTE Exflosion hazard Observe the following assembly information The customer must take appropriate for safe and trouble-free operation. Outlets of a progressive metering device precautions to ensure that no con- ○ Use only clean components and prefilled that are not needed must not be closed tamination enters the lubricant and because this will cause the metering device... -

Page 74: Installing The Lubrication Piping

• Insert the lubrication line (1) into the union nut (2) and cutting sleeve (3) ○ For higher operating pressures up to 250 bar, SKF compression fittings conforming • Insert the lubrication line (1), union to DIN 2353 can be used. If using fittings... -

Page 75: Attachment Of Bridges (Crossporting)

6. Assembly 6.11 Attachment of bridges (crossporting) See Figures 24 to 25 Fig. 24 PSG1-Crossforting The technical data for each bridge can 3-bridge, with one outlet, be found in Chapter 14, page 99. with check valve, (G1/8) • If fitted, unscrew and remove outlet Order No. - Page 76 6. Assembly Fig. 25 PSG2-Crossforting Designation 4-bridge, with one outlet, with check valves Order No. G 1/4" 24-2151-3739 Designation 24-2151-3754 3-bridge, with one outlet Order No. Designation G 1/4" 24-2151-3733 3-bridge, with one outlet, with check valves Order No. Designation G 1/4"...

- Page 77 6. Assembly Fig. 26 PSG3-Crossforting Designation 4-bridge, with one outlet, with check valves Designation Order No. 3-bridge, with one outlet on request Order No. Designation G 1/4" 24-2151-3737 3-bridge, with one outlet, with check valves Order No. Designation G 1/4" 24-2151-3338 2-bridge, with one outlet 24-2151-4143...

-

Page 78: Establishing Equipotential Bonding

6. Assembly 6.12 Establishing equipotential bonding -See Figure 27 Fig. 27 Equifotential bonding Equipotential bonding connection (screw M4) The product has an equipotential bonding • Loosen the clamping screw (2) on the connection (screw M4). ground terminal (1) The product and its equipotential bonding •... -

Page 79: Electrical Connection

II 1D Ex ia IIIC T90°C Da / -20...+70°C II 1D Ex ia IIIC T90°C Da / -20...+70°C Only attachments and monitoring equip- Sfare farts Sfare farts ment approved by SKF for the metering Designation Order number Designation Order number devices may be installed. -

Page 80: Inductive Proximity Switch 24-1884-2613

6. Assembly 6.13.3 Inductive froximity switch 24-1884-2613 6.13.4 Connecting directional solenoid valve 24-1254-2212 -See Figure 30 -See Figure 31 • Connect inductive proximity switch ac- See electrical data of the directional so- cording to terminal diagram in Figure lenoid valves, Chapter 4 •... -

Page 81: First Start-Uf

7. First start-up 7. First start-uf • Connect the hand lever grease gun or CAUTION lubricating device to the metering device Fig. 32 Examfle of frogressive sys- tem with KFGS/KFGL fumf unit Exflosion hazard inlet (1) or, if present, to the emergency The product and its equipotential lubricant nipple attached to the metering bonding connection must be con-... -

Page 82: Venting An Oil Progressive System

6. Assembly 7.2 Venting an oil progressive system -See Figure 33 A requirement for venting an oil progressive • Slightly loosen the main lubrication lines • Actuate the pump/pump unit until bub- system is that the system has already been of the main metering device at the out- ble-free oil discharges at the plug screws fully assembled. -

Page 83: Inspections Before First Start-Up

7. First start-up Checklist for first start-uf To ensure safety and functionality, the per- 7.4 Inspections before first start-up son specified by the operator is required YES NO to perform the following inspections. Any Electrical connection (inductive proximity switch) established correctly detected deficiencies must be resolved im- Mechanical connection established correctly mediately. -

Page 84: Oferation

8. Operation 8. Oferation SKF products operate automatically. The activities required during normal op- eration are limited primarily to checking the connections and cleaning of the exterior of the product if contaminated. - 84 - 951-180-085-EN Version 01... -

Page 85: Cleaning

• Unauthorized persons must be kept away tion 2.3 for materials). • Thoroughly clean all external surfaces Please contact SKF Customer Service. with a moist cloth Always completely remove residue of the cleaning agent on the prod- 9.4 Cleaning sensors uct and rinse with clear water. -

Page 86: Maintenance

10. Maintenance Maintenance Careful and regular maintenance is required in order to detect and remedy possible faults in time. The specific intervals must always be determined by the operator according to the operating conditions and regularly reviewed and adapted where necessary. If necessary, copy the table for regular maintenance activities. Maintenance checklist Activity to be performed Electrical connection of the inductive proximity switch / directional solenoid valve established correctly... -

Page 87: Malfunctions, Causes, And Remedies

11. Malfunctions Malfunctions, causes, and remedies 11.1 Prior to beginning troubleshooting The only condition that can cause a properly WARNING configured progressive metering device to System pressure jam/clog is the entry of contaminants into Lubrication systems are pressur- the lubricant lines or an insufficient quantity ized during operation. -

Page 88: Metering Device And System Malfunctions

11. Malfunctions 11.2 Metering device and system malfunctions Malfunctions table Malfunction Cause Remedy o Insufficient system pressure • Check the system pressure at the metering device inlet, increase system pressure if at metering device inlet necessary • Trigger interim lubrication and release the outlet screw unions in sequence as seen from the metering device inlet. - Page 89 Damaged lubricant line, detect- • Replace the lubricant line able only by visual inspection and • For grease progressive systems, use only original SKF replacement lines significant lubricant discharge. that have already been completely filled. Perform start-up and functional...

- Page 90 Pressure relief valve does • Clean or replace the pressure relief valve not close • Only use original SKF spare parts No pressure o Unsuitable lubricant (see • Remove lubricant from entire system and dispose of lubricant in the proper manner;...

-

Page 91: Refairs

Only attachments and monitoring ○ Unauthorized persons must be ent and maintained. It must be en- equipment approved by SKF for the kept away sured (checked) that no potentially ATEX progressive metering devices explosive atmosphere is present. -

Page 92: Replace Inductive Proximity Switch

12. Repairs 12.2 Replace inductive proximity switch -see Figure 34 • Check that the new inductive proximity • Turn on customer's power supply then switch (2) matches the documentation screw the proximity switch (2) into the Fig. 34 Reflace inductive froximity switch and the intended use sensor holder (4) until a sensor pulse is present on the customer's control unit... -

Page 93: Shutdown, Disfosal

13. Shutdown, disposal Shutdown, disposal 13.1 Temporary shutdown 13.3 Disposal Temporary shutdown is performed by: Countries within the Eurofean Union Dispose of or recycle electrical Waste should be avoided or minimized to components in accordance with Switching off the main machine the extent possible. -

Page 94: Sfare Farts

14. Spare parts Spare parts Progressive metering device spare parts, Fig. 40 - 94 - 951-180-085-EN Version 01... - Page 95 14. Spare parts Sfare farts table 1 Baseplate PSG1 PSG2 PSG3 Corrosion- Corrosion- resistant resistant Inlet Inlet Inlet Outlet Outlet Order No. Order No. Order No. Order No. Order No. ItemDesignation Outlet 99-0014-0908 99-0014-0908 Plug screw for 466-419-001 DIN908-R1-4-5.8 DIN908-R1-4-5.8 baseplate outlet (incl.

- Page 96 14. Spare parts Sfare farts table 2 PSG1 PSG2 PSG3 Metering module Item Designation [mm³] Order No. [mm³] Order No. [mm³] Order No. Metering device module (metering 24-2151-4664 24-2151-4230 24-2151-4250 module) complete with plunger rod on 24-2151-4665 24-2151-4231 1200 24-2151-4258 right 24-2151-4232 1600...

- Page 97 14. Spare parts Sfare farts table 3 Monitoring PSG1 PSG2 PSG3 Item Designation Order No. Order No. Order No. 24-1884-2292 9 Proximity switch 24-1884-2288 24-1884-2292 24-1884-2613 Housing for proximity switch 24-1884-2288 VPKM.13 Housing for proximity switch 24-1884-2292 44-0711-2592 44-0711-2593 11 Setscrew for housing DIN914-M4×6-45H –...

- Page 98 14. Spare parts Sfare farts table 4 Inlet screw union PSG1 PSG2 PSG3 Item Designation Inlet Order No. Inlet Order No. Inlet Order No. G 1 /8 G 1 /4 G 3 /8 Pipe ø6 mm 406-403W 96-0204-0058-EO – G 1 /8 G 1 /4 G 3 /8 Pipe ø8 mm...

- Page 99 14. Spare parts Sfare farts table 5 Bridges (crossforting) PSG1 PSG2 PSG3 Item Designation Outlet Order No. Outlet Order No. Outlet Order No. without outlet and without check valve 2-bridge 24-2151-3760 24-2151-3730 24-2151-3734 3-bridge 24-2151-3761 24-2151-3731 24-2151-3735 with outlet and without check valve 2-bridge 24-2151-3762 24-2151-3732...

-

Page 100: Accessories

15. Accessories Accessories PSG acces- sories Designation Weight BN = conductor coloring brown Order No. BU = conductor coloring blue Cable sockets M12x1, 2-fin design, NAMUR V1-G-N-M-PUR Circular connector, straight, with 5-m integrally extruded 24-1882-5005 cable, NAMUR V1-G-N-5M-PUR Circular connector, straight, with 10-m integrally 24-1882-5010 extruded cable, NAMUR V1-G-N-10M-PUR... - Page 101 15. Accessories PSG2/PSG3 accessories 24-1207-2158 95-5080-3901 Pressure gauge and screw union PSG2 / PSG3 Designation Order No. Pressure gauge 160 bar 24-1207-2158 96-0308-0060 Straight threaded socket 95-5080-3901 Pressure gauge 96-0308-0060 Reduction fitting for PSG3 96-3120-0058 14.5 PSG2/PSG3 accessories 24-2105-2405 24-2151-4115, 24-2151-4116 Measurement connection and screw union M16×2 PSG2 / PSG3...

-

Page 102: Declarations Of Conformity

16. Declarations of Conformity Declarations of Conformity 16.1 Inductive proximity switch 24-1884-2288 - 102 - 951-180-085-EN Version 01... -

Page 103: Inductive Proximity Switch 24-1884-2292

16. Declarations of Conformity 16.2 Inductive proximity switch 24-1884-2292 - 103 - 951-180-085-EN Version 01... -

Page 104: Inductive Proximity Switch 24-1884-2613

16. Declarations of Conformity 16.3 Inductive proximity switch 24-1884-2613 - 104 - 951-180-085-EN Version 01... -

Page 105: Directional Solenoid Valve 24-1254-2212

16. Declarations of Conformity 16.4 Directional solenoid valve 24-1254-2212 - 105 - 951-180-085-EN Version 01... - Page 106 The Power of Knowledge Engineering Over the course of more than a century, SKF has specialized in five fields of competence and ac- Bearings Lubrication Seals and Bearing quired a wide range of application expertise. We utilize this experience to provide innovative solu-...

Need help?

Do you have a question about the LINCOLN ATEX PSG1 Series and is the answer not in the manual?

Questions and answers