Summary of Contents for SMC Networks CE1 Series

- Page 1 Doc.No. CE*-OMD0004-H PRODUCT NAME MONOSASHI-KUN (Stroke Reading Cylinder) MODEL / Series / Product Number CE1* Series...

-

Page 2: Table Of Contents

Contents 1. Safety Instructions ·····································································2~6 2. Product Summary 2-1. System Configuration ···························································· 7 2-2. How to Order ····································································7~8 2-2-1. MONOSASHI-KUN ··················································· 7 2-2-2. Applicable Auto-Switch Models ···································· 8 2-2-3. Options ··································································· 8 2-3. Precautions on Selection ······················································· 9 3. Specifications 3-1. -

Page 3: Safety Instructions

1.Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC) , and other safety regulations. - Page 4 1.Safety Instructions Caution We develop, design, and manufacture our products to be used for automatic control equipment, and provide them for peaceful use in manufacturing industries. Use in non-manufacturing industries is not covered. Products we manufacture and sell cannot be used for the purpose of transactions or certification specified in the Measurement Act.

- Page 5 may cause the risk of human injury, design a Operating and Storage Environments structure to avoid contact with human body. Warning ! 3. Securely tighten all stationary parts and connected parts of cylinders so that they will 1. Envionments to avoid not become loose.

- Page 6 damage and malfunction. Selection When hardware and nuts are screwed into the piston rod end, the piston rod should be fully Warning ! retracted. 1. Confirm the specifications. double nuts work since The product in this manual is designed to be used MONOSASHI-KUN (Stroke Reading Cylinder) only industrial compressed air system.

- Page 7 initial lubricant flows out causing malfunction. Wiring Sensor Unit Warning ! Caution ! 1. Preparation for wiring Shut off the power before wiring (including 1. Do not remove the sensor unit. insertion and removal of connectors). Mount a The position and sensitivity of the sensor is protective cover on the terminal block after wiring.

-

Page 8: Product Summary

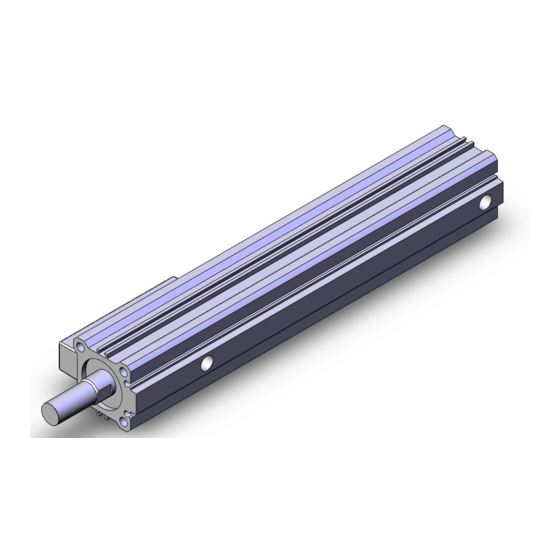

2. Product Summary MONOSASHI-KUN is a cylinder that has a built-in linear encoder. The scale of the magnetic rod and magnetic sensor detects change in piston position, and pulse signal is outputted with A/B quadrature pulse (90 ゚ nominal phase relationship). Position detection in 0.1 mm resolution is possible by inputting this signal to CEU5. -

Page 9: Applicable Auto-Switch Models

2-2-2 Applicable Auto-Switch Models Mark Auto-Switch Model Mark Auto-Switch Model Mark Auto-Switch Model D-A90 D-M9N M9NW D-M9NW D-A93 D-M9P M9PW D-M9PW D-A96 D-M9B M9BW D-M9BW A90V D-A90V M9NV D-M9NV M9NWV D-M9NWV 2-color A93V D-A93V M9PV D-M9PV M9PWV D-M9PWV Indication A96V D-A96V M9BV D-M9BV... -

Page 10: Precautions On Selection

2-3 Precautions on Selection ● Use MONOSASHI-KUN CE1 with Multi-Counter CEU5. ● For SMC CE1 series and SMC CEU5 series, operation check was performed with SMC extension cable CE1-R※※ for the maximum wire length of 23m. Since operation check was not performed with other counters and cables, a system designer who selects equipment should check the operation. -

Page 11: Specifications

3. Specifications 3-1 Cylinder Specifications Action Double acting, single rod (Non-rotating piston rod) Fluid Proof pressure 1.5MPa Max. operating pressure 1.0MPa φ20~φ63 φ12 Min. operating pressure 0.07MPa 0.05MPa 70~500mm/s Operating piston speed 0~60゜(No freezing) Ambient & fluid temperature 25~85%RH(No dew condensation) Humidity Lubrication Non-lube. -

Page 12: Allowable Kinetic Energy

3-3 Allowable Kinetic Energy 3-3-1 Allowable Kinetic Energy φ12 φ20 φ32 φ40 φ50 φ63 Bore size(mm) Allowable Kinetic Energy:E 0.022 0.055 0.15 0.26 0.46 0.77 3-3-2 Mass of Cylinder Movable Parts Cylinder stroke (mm) Bore size(mm) φ12 φ20 φ32 φ40 1054 φ50 1015... -

Page 13: Wiring

4. Wiring 4-1 Connector Wiring Table The table below shows combinations of contact mark and wire core color. The connector pin layout shows the layout of CE1 with connector. 4-2 Wiring for Counter CEU5 sensor input part The wiring for CEU5 and MONOSASHI-KUN Monosashi-kun series uses three twisted-pair cables. -

Page 14: Structure And Measuring Principle

5. Structure and Measuring Principle 5-1 Structure Cylinder body Sensor head Piston rod ・A part of the piston rod has scale (magnetic scale). In order to maintain the relative position of the scale and the sensor head, piston rod is used to have a structure of non-rotating cylinder. !... -

Page 15: Measuring Principle

5-2 Measuring Principle MONOSASHI-KUN is an air cylinder that has a function to output piston stroke movement as pulse signal in 0.1 mm resolution. Measuring Principle is as follows. ① Amplification ② Counter & Interpolation Circuit Movement Magnetic resistive element Magnet A-phase Piston rod... -

Page 16: Troubleshooting

6. Troubleshooting 6-1 Troubleshooting for Measuring Function Page of Failure Cause Countermeasure reference Isn’t the wiring removed, or is it 12 Does not Check the wiring and connector count. correct? loosening. 12 Is 12VDC or 24VDC supplied to the Supply the rated power (12VDC- sensor? 24VDC) to the sensor. -

Page 17: Troubleshooting For Cylinder Operation

Page of Failure Cause Countermeasure reference 10 Isn’t cylinder speed out of the Measured Cylinder speed should be in the range value does not specified range? of 70 mm/s to 500 mm/s. In addition, have repro- When cylinder speed is too fast, prevent knocking and bounding. -

Page 18: Outside Dimensions Of Ce1B12

Outside dimensions of CE1B12... -

Page 19: Outside Dimensions Of Ce1B20

Outside dimensions of CE1B20... -

Page 20: Outside Dimensions Of Ce1B32

Outside dimensions of CE1B32... -

Page 21: Outside Dimensions Of Ce1B40

Outside dimensions of CE1B40... -

Page 22: Outside Dimensions Of Ce1B50

Outside dimensions of CE1B50... -

Page 23: Outside Dimensions Of Ce1B63

Outside dimensions of CE1B63... - Page 24 Revision history A:Revised in July 2000 B:Revised in January 2001 C:Revised in July 2011 D:Revised in May 2013 E:Revised in August 2017 F:Revised in October 2017 G:Revised in March 2023 H:Revised in February 2024 Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362 https://www.smcworld.com Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

Need help?

Do you have a question about the CE1 Series and is the answer not in the manual?

Questions and answers