Table of Contents

Advertisement

Quick Links

3648 Series

Operator's Manual

This

PRE

CAU

WA

mater

Do

comb

not

is

ustibl

heate

a

CION

RN

ING

to

placin

fill

ial

be

clean

e,

water

such

or

conta

parts

-base

d

clean

/ ADV

ERT

an

g inside

extrem

ed

as

gasol

minat

of

clean

e

d

er.

Use

ISSE

Este

mente

es

hazar

ely

any

et.

cabin

comb

ine,

alcoh

ol,

ing

with

any

comp

ounds

only

nonfla

MEN

T

inflam

mater

ables

en

limpia

esta

un

dous

Failur

condi

ustibl

e to

miner

flamm

e

or

obser

able

spirits

al

in

mmab

le,

this

CA

mater

etc.

ial

Drene

y no

inflam

comb

máqu

ina

dor

de

partes

tion.

ve

flamm

able

this

, etc.

or

mach

comb

ine.

non-

CUID

ADO

UT

ION

descu

nes

extrem

ial

ida

inflam

partes

las

able

como

ustibl

comp

es.

onent

que

mater

warni

ial

Drain

ng

parts

before

ustibl

e

HO

/ ATT

Ce

obser

adam

able

estas

var

a ser

antes

limpia

, gasol

ina,

No

llenar

de

es

se

calien

limpie

ta.

will

create

seco

Befo

re

T WA

ENT

ION

inflam

seule

nettoy

ment

eur

ente

peligr

preca

das

de

ucion

introd

de

alcoh

ol,

esenc

cualq

o conta

minar

za

base

Utilice

arm/

nds

open

ing

to

TE

R

PRE

comb

des

ustibl

mable

de

des

s.

pièce

nettoy

osas.

ucir

es,

puede

en

uier

comb

ias

agua,

miner

con

sola-

no

algún

turnt

spinn

able

lid,

allow

spray

wait

CAU

WA

RN

à l'intér

créer

ieur

matér

tels:

es

iaux

pas

Ne

est

à base

y ajoute

eurs

s

chauf

el

n crears

ustibl

gabin

ales,

e o

ing.

to

stop

5

•

Mach

CION

/ ADV

ING

des

du

situat

cabin

ustibl

comb

gasol

ine,

r ou

alcoo

d'eau

fé.

Utilise

e condi

ete.

Si

cio-

CA

AG

UA

•

•

Insta

locka

ine

ble

must

ERT

OPE

risqué

ions

Ne

et.

es

ou

inflam

pas

conta

l, etc.

, non

comb

miner

Vider

r dans

cet

espe

Ante

s de

LIE

NT

•

For

at

supp

llatio

least

n must

disco

nnec

be

conn

ISSE

MEN

compl

IMPO

RAT

ING

es.

obser

ver

mable

s avant

les

ustibl

pièce

avec

des

es

et

eil

appar

que

la

re

5 segu

abrir

barra

la

tapa,

E

Do

not

ly

conn

90

degr

comp

ectio

t.

ected

to

T

instruc

manua

etely

RTAN

T:

Before

familia

INS

TRU

ces

ssem

averti

s conte

de

les

matér

iaux

non

EA

deten

rotat

ndos

oria

para

•

La

eléct

máqu

use

below

ees

n,

C.

ly

with

use

NEC

a prop

erly

Before

tain

l provid

ted

loadin

ed.

individ

rize

yourse

ting

opera

CTI

ents

nant

place

peut

r

atten

Avan

U

t d'ouv

CH

ga.

se

•

•

La

rico

insta

de

ina

debe

grad

e floor

wires

code

acce

sized

solutio

1.

the

pump

ns

g parts

uals

Only

should

author

lf with

this

machi

ONS

teur/p

perm

ettre

dez

5 seco

rir

AU

DE

do

Para

para

las

lació

segu

ridad

n debe

estar

grad

or

ptab

.

le

Check

Water

tank

Fill

are

at

with

is

onto

off

and

opera

turnta

not

ized

opera

and

instruc

prope

te

ne,

tion

INS

laque

au

couv

le

bras

ndes

ert,

No

utilic

meno

cone

al

xione

cump

.

cone

ctada

e level

for

2.

opera

Progra

daily.

should

level

water

and

runnin

tempe

ting

ble/

g and

baske

this

machi

rly

IMPO

TRU

CCI

tourn

de

tourn

ante

pour

risa-

vapo

•

L'app

e por

s 90

deba

s de

grad

alime

lir

con

a un

ench

.

3.

solutio

tion.

Open

heater

n.

Allow

m

timer

below

2"

cleani

be

ng

rature

.

the

solutio

wash

t, be

ne.

cer-

person

pletam

RTAN

ente

TE:

ONE

er.

d'arrê

ter

•

•

L'ins

verro

uillab

areil

doit

jo

del

os

nivel

el

centí

ntaci

códig

ón,

ufe

baske

throug

door/li

t/turnt

time

for

for

desire

the

acces

n.

carga

éste

esté

al

autoriz

equipo

ado

con

Antes

el

de

manua

opara

SDE

OPE

Pour

fils

tallat

le

le

ion

de

être

conn

del

piso.

grad

os.

o NEC

use

cable

.

baske

height

h the

bottom

able.

d and

t/turnt

place

Be

unit

d period

prehe

to

s doors.

1.

estén

a tempe

apaga

sobre

la

. Antes

tornam

da

de

abrir

y debida

l de

equipo

opera

r el

RAC

Ne

pouv

pas

racco

ant

taille

doit

rdem

appr

se

ecté

à un

a-

4.

Close

set

or

weigh

able.

door/li

Do

article

certain

or

beyon

s to

no

at

of

cleani

ng

Llene

nivel

el

depós

ratura

y sin

funcio

esa/ca

nasta,

mente

la

puerta

ción

capac

que

, familia

ION

utilis

pter

er

acce

de

ent

confo

oprié

rmer

e.

secti

5.

has

expire

cleani

to

time.

ng

wash,

d and

turn

t limit

latch

for

excee

not

this

parts

d the

d the

sides

protru

clean

be

onto

Progra

2.

ceso.

del

Verifiq

agua

de

con

ito

debe

funcio

nar,

asegú

y que

rta

/cubie

itado

debe

incluy

se

e.

rícese

com-

INS

un

calib

au

moin

l'alim

re

entat

au

code

onne

ur

Before

off

and

d.

openin

Pump

"wash

secure

cycle"

ly.

spray

specifi

wash

of

the

de

3.

precal

opera

me

ción

el

Tempo

ue

desea

nivel

el

estar

2"

agua

soluci

namie

y la

nto.

rese

las

soluci

de

o las

ones

opara

piezas

que

r

Solo

IMPO

TRU

ou

grad

s 90

un

degr

ion,

utilis

NEC

.

ning.

This

and

exces

wait

5 secon

will

g the

door/li

start

will

and

timer

to

machi

With

cabine

ed

t.

Abra

names

brepa

iente

la

la

puerta

soluci

do.

rizado

diariam

r del

Deje

por

ente.

debajo

ón

para

la

de

limpie

bomba

de

RTAN

compl

machi

vous

T:

CTI

ONS

e infér

Cels

és

des

er

MAI

s water

allow

for

steam

ds

turn

d,

machi

run

the

until

desire

ne

time

d

lavado

los

a/cana

se

limites

sta,

fondo

el

/tapa

y coloqu

ón

para

pasar

calent

limpie

un

ador

de

las

limpie

za.

puerta

za

autoris

ou

du

devrai

ne

èteme

é et

nt

Avant

avec

d'utilis

D'O

PÉR

ieur.

ius.

NTE

to

drain

to

from

escap

wash

ne

stop

to

cycle

en

Cierre

4.

.

la

espec

el

asegú

ni

ificado

perím

rese

e las

tiempo

za.

para

para

el

períod

El

ac-

de

pas

et

s'assu

fonctio

rer

que

formé

charge

t être

. Avant

ment

utilisé

le

cette

er

manue

machi

ATIO

nance

The

Highe

r usage

followi

ng

NAN

CE

your

parts.

e the

timer

cabine

spin-

lavado

duran

posici

" al

de

ón

puerta

/tapa

s de

que

etro

de

peso

de

piezas

ningun

a lavar

la

que

o de

unidad

Remp

1.

nneme

que

les

la

des

solutio

pompe

l'ouve

pièces

e seulem

rture

ent

l d'instr

ne,

familia

uction

N

fore

IMPO

.

RTAN

may

schedu

le is

INS

TRU

t

5.

Antes

ciclo

te

de

tiempo

el

tiempo

lavar,

desea

y asegu

ajuste

re

tornam

y altura

la

esa.

a pieza

en

la

tor-

2.

portes

niveau

Le

lir

le

réserv

nt.

de

ns

est

sur

lavage

en

positio

la

de

table

porte/

par

du

la

fourni.

person

risez-

servic

DAILY

e this

drainin

Be

g sump.

T:

requir

based

e more

averag

on

CTIO

deje

el

de

exces

de

abrir

lavado

girar.

puerta

selecc

la

ionado

do.

La

tempo

el

el

bomba

canda

para

do.

gabine

so-

No

el

exced

périod

la

Progra

mmer

d'accè

d'eau

doit

s. Vérifie

d'eau

oir

sont

n arrêt

tourna

et

à tempé

nte/le

couve

du

Cette

nel

•

:

Check

machi

sure

ne.

Only

electri

freque

nt

e use.

NS

INS

Esto

o de

agua

y espere

permi

/cubie

5 segun

.

rta,

rizado

arranc

r de

Con

la

"ciclo

máqui

a

de

te

Ouvrir

pour

3.

l'appa

que

e de

le

fonctio

minute

se

r quotid

d'une

trouve

et

solutio

r à

fonctio

ne

rature

panier

rcle

,

off

the

heater

water

water

qualifi

ed

supply

cal

person

is

mainte

-

TRU

drene

tirá

de

que

dos

para

e el

apagu

ará

de

y funcio

na

du

aucun

sur

le

panier

la

porte/

couve

reil

rie

nneme

précha

iennem

de

chauff

5 cm

ent.

(2

po)

n de

nettoy

de

nne

•

•

Remo

Visual

ve

eleme

nt.

daily

level

will

the

in

nel

should

be-

OFF

El

basad

plan

de

CCI

ONE

el

las

piezas

vapor

que

tempo

salga

la

rizado

nará

La

Ferme

4.

painer

/plaqu

e pièce

dépas

/plaqu

rt et

e tourna

uffe

nt

placez

solutio

la

itée.

age

souha

de

l'appa

sous

age.

les

nal

and

and

ly

clean

check

clean

preven

sump

t damag

daily.

severo

IMPO

puede

o en

mante

un

uso

nimien

S DE

.

gabine

del

máqui

r del

na

cycle"

jusqu'

machi

z la

ne

au

porte/

couve

e tourna

sant

nte.

le

painer

Assur

les

article

Prévo

n de

ir du

reil

nettoy

pour

WEEK

•

LY:

positio

n.

if neede

for

debris

plugge

screen

Toppin

g

e to

debe

APAG

RTAN

ADO

requer

TE:

ir un

prome

dio

que

to

se

MAN

presen

TEN

te

y

Avant

5.

cycle

temps

à ce

d'ouvr

que

de

prête

rt et

pour

verrou

nte.

le

ou

dans

s à

ez-vou

s qu'il

être

age.

temps

•

MONT

HLY:

Greas

e/oil

Reins

d.

d nozzle

tall

s.

.

the

•

DIARI

repara

AMEN

antes

r esta

Asegú

de

vaciar

mante

rese

del

nimien

equipo

. Un

a contin

ta

IMIE

l'appa

s'écha

lavage

de

reil

ir la

porte/

temps

la

lavage

sélect

désiré

lavage

, tourne

illez

de

le

fond

lavé

n'y

au-de

est

•

Perfor

Drain

m

visual

hinges

door

in

exact

Remo

the

ve

eleme

Mante

Comp

ruebe

TE:

máqui

na.

el

de

cárter

el

que

sistem

uso

más

to

más

frecue

uación

NTO

, está

pièces

pper

s'arrêt

.

cabine

du

e de

à l'arrêt

le

et

couve

ionné

. La

soit

façon

z le

pompe

minute

sécuri

là

from

grit

taken

wash

bottom

check

solutio

.

origi-

•

•

Retire

ner

el

nto

del

el

nivel

nivel

del

person

. Sólo

a eléctri

nte.

frecue

nte

o

DIR

t et

tourne

à l'excès

attend

r. Cela

re

penda

rcle,

mettre

écoulé

.

fonctio

"wash

taire.

ur

•

When

ment

during

to

avoid

of

bendin

turntab

n from

the

of

le

sump,

drive

Comp

correc

y limpie

ruebe

los

adecu

calent

agua

ado

ador.

del

en

el

co

esté

al

califica

tablea

Le

Une

ECT

IVE

perme

d'eau

la

ttra

nt

5 secon

minute

rie

nnera

NOTE

water,

gent

sump

add

the

cleani

has

g or

sump.

Care

damag

remov

chain.

•

SEMA

posici

NALM

la

tamen

ón

visual

te.

Retire

os

mente

residu

de

evitará

agua

cárter

diariam

do

fréque

IMPO

utilisa

u suivan

nt.

tion

plus

t est

S D'E

de

à la

vapeu

s'écou

du

des

r de

que

amoun

before

adding

: Dissol

for

your

machi

recom

the

been

ng

cleane

proces

should

ing

heater

s.

be

e sand/

•

MENS

UALM

Lubriq

las

ue

origina

ENTE:

l exacta

y limpie

las

la

que

criba.

dañar

ente.

parer

RTAN

avant

vider

de

T :

tante

fondé

impor

sur

NTR

ETIE

ler

vos

de

t to

the

the

ve

cleani

manuf

ng

ne.

mende

d quanti

d and

refilled

ele-

•

Realic

de

e una

ENTE:

bisagr

as

si

.

boquil

neces

es

las

están

el

QUOT

•

cet

IDIEN

appar

le

eil.

S'assu

réserv

rer

que

peut

une

utilisa

exiger

tion

N

tank.

powde

acture

r into

r's

ty

of

with

deter-

cárter

Drene

la

tornam

la

verific

esa.

ación

de

la

puerta

ario.

instala

Reins

das

Vérifie

ervoir.

r quotid

NEME

NT:

oir.

Seul

systèm

le

le

un

entret

moyen

ne.

recom

mende

warm

water

•

limpie

dañar

soluci

el

sedim

los

de

ón

visual

.

en

tale

•

•

d'endo

Démo

mmag

Le

iennem

rempli

ent

person

nel

e électri

que

ien

plus

d

vez

Una

agreg

za.

eleme

entos.

nto

Debe

del

limpie

za

del

de

la

caden

struée

Vérifie

r visuel

nter

nettoy

er

et

l'élém

ssage

quotid

niveau

le

ent

qualifi

est

é doit

à l'arrêt

NOTA

lo

máqui

: Disuel

que

ue

la

na.

cantid

el

cárter

calent

tener

ador

cuidad

cárter

, retire

a de

propu

lsión

dans

HEBD

•

la

s.

OMAD

positio

lemen

Démo

nter

t si

er

filtre

le

chauff

ien

d'eau

ant.

d'eau

dans

ré-

al

tanque

va

en

el

ad

recom

está

limpio

duran

te

o de

el

fondo

no

del

•

MENS

Graiss

er/huil

UELL

AIREM

n initiale

et

buses

nettoy

des

à débris

.

perme

le

t d'évite

rés-

la

cantid

deterg

ente

ad

endad

a de

y relleno

proces

doblar

de

o

o de

•

de

Procé

der

er

EMEN

pentur

les

ENT:

exacte

er,

.

cas

le

sont

bouch

échéa

r

recom

en

agua

endad

calient

deterg

de

agua,

ente

sable/

Asséc

her

la

table

contrô

à un

tourna

T:

es/cha

rnière

nt.

Réins

ées/ob

-

a por

e antes

el

fabrica

para

de

la

•

être

ou

gravie

prises

de

solutio

la

r se

le

n de

nte.

visuel

de

s de

la

taller

nte.

agrega

r-

quanti

Lorsqu

NOTE

l'endo

e le

pour

mmag

éviter

trouva

nt

au

lavage

la

chaîne

porte.

d'ajou

té

: Bien

ter

déterg

dissou

de

réserv

au

oir

er

a été

plier/c

cours

de

du

réserv

fond.

Des

ourbe

oir,

d'entra

îneme

dans

le

réserv

dre

la

ent

recom

nettoy

é et

proces

du

précau

r l'élém

et

enleve

tions

r tout

nt

oir.

e dans

poudr

mandé

rempli

e pour

sus

ent

de

d'eau,

doiven

chauff

nettoy

ant

t

chaud

l'eau

votre

ajoute

appar

age.

e avant

r la

eil.

8.922-

402.0

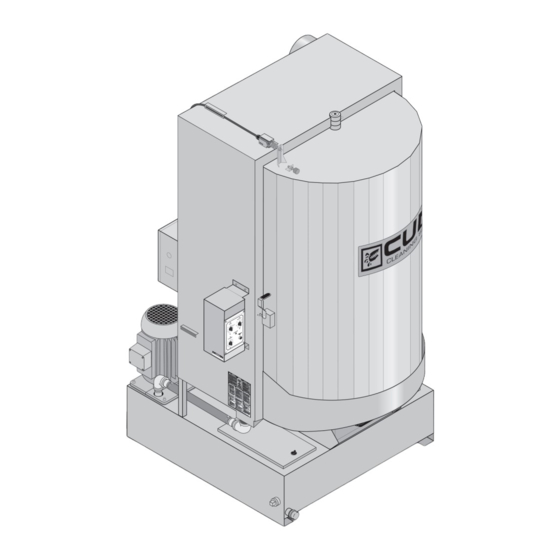

CLEANING SYSTEMS

Automatic Parts Washer

MODELS:

For the Cuda Dealer nearest

you, consult our web page at

www.CudaUSA.com

9.801-627.0-AM

9.801-627.0-AM

Front-Load

1.043-477.0

1.043-478.0

1.043-479.0

1.043-505.0

1.043-506.0

1.043-507.0

07/19/19

08/01/20

Advertisement

Table of Contents

Summary of Contents for CUDA 3648 Series

- Page 1 8.922- 402.0 For the Cuda Dealer nearest you, consult our web page at www.CudaUSA.com 9.801-627.0-AM 07/19/19 9.801-627.0-AM 08/01/20...

-

Page 2: Machine Data Label

Machine Data Label Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 3: Table Of Contents

Wash Cycle Control ......12 Cuda 3648 Front ......36 Heater Control. -

Page 4: How To Use This Manual

KIT INSTRUCTIONS which came with the kit. It contains replacement parts numbers needed for ordering future parts. NOTE: The manual part number is located on the lower right corner of the front cover. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 5: Safety

When ordering parts, please specify model and serial number. Use only identical replacement parts. This machine is to be used only by trained operators. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 6: General Safety Information

8. Use caution when lifting items in and out of parts pourraient survenir. basket to prevent back injuries. KEEP WATER SPRAY AWAY FROM 2.All installations must comply ELECTRICAL WIRING. with local codes. Contact your Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 7 16. After the machine stops, wait 10 seconds before opening the lid or door. This automatic parts washer is designed to operate safely and efficiently. Before you begin to install and use the machine, please familiarize yourself with the major components. Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 8: Operations

, ajout yage appa avan reil. 8.92 2-40 Lock Retaining Washer Debris Screen Bearing Parts Tree Sump Cover Bearing Oil Seal Spindle Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 9: Component Identification - Rear

Diss tank befo Fresh Water In Drive Pivot Motor °F °C) °F °F °C) °C) Compression Spring Assy. °F °C) Sump Cover °F °F °C) °C) Pump Heating Element & Thermostat Enclosure Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 10: Installation

Step 3: Connect A Water Line This step is required for machines equipped with the optional automatic water fill system. If your machine does not have this option, skip this step. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 11: Step 4: Fill The Machine With Water And Add Detergent

3. When the water level indicator indicates that the sump is full, shut off the water. If your machine is equipped with the automatic water fill system the water will shut off automatically when the sump is full. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 12: Main Operating Components

Increase/Decrease add or remove parts. Temperature To adjust the thermostat, rotate the control knob clockwise to increase the temperature, or counterclock- wise to decrease the temperature. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 13: Door Safety Switch

5. Replace the cover. When properly adjusted, you should hear a slight “click” as the door latch engages and compresses the door seal and the door closure safety switch. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 14: Oil Skimmer System

The power brush is located on the right front corner of the machine. Refer to for detailed installation informa- tion. To Air Supply Power Brush Throttle Lever Lock Position 2: Detail Brush Holding Bracket Throttle Lever To Air Supply Outlet To Detail Brush Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 15: Using The Oil Skimmer System

To remove oil from the cleaning solution, perform the following procedure: 1. Allow the machine to sit idle for at least 30 minutes to allow the oil to float to the surface of the wash solution. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 16: Detail Brush And Flow Regulator (Optional)

The flow regulator controls the flow of cleaning solution protection oculaire approuvée lors du chargement et through the detail brush. du déchargement de la machine. Air Flow Valve Flow Regulator Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 17: Water Level

It is not necessary to add Cover detergent each time you add water. Only add detergent after you clean the sump chamber each month, or if you notice specific low-detergent indicators (See Detergent Concentration). Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 18: Automatic Water Fill (Optional)

When the outlet pressure drops to 30 psi or less, stop the operation of the automatic water fill system. the machine and clean or replace the filter bag(s) (See Cleaning the Filters). Check filters daily. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 19: Detergent Concentration

Heat the water to operating temperature (recommend 160° to 180°F) • Add detergent if necessary (see Detergent Concentration); • Verify that none of the spray nozzles are clogged; and • Clean the debris screen. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 20: Washing Parts

4. When the machine automatically stops (or after you manually stop the wash cycle), open the door and wait a few moments to allow the parts to cool and dry before removing them. Most parts will flash-dry in seconds. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 21: Maintaining The Machine

Lubricate the door spindle using high-quality automotive grease. Add grease until it begins to flow out of the joint beneath the grease fitting, then wipe excess grease from the fitting and the joint. Door Spindle Grease Fitting Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 22: Cleaning And Aligning The Spray Nozzles

The use of any other detergent during the warranty period will void the warranty. Manual Sump Clean Out To manually clean out the sump, perform the following procedure: Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 23 A buildup of debris around the element will decrease heating performance and may cause the element to overheat and fail. 6. Refill the sump with fresh clean water.. Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 24: Cleaning The Filters

When you install a new heating element, use are using a polyester felt filter bag, you must sealing tape or compound on the threads to deter replace it. Contact your distributor or call customer corrosion. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 25: Thermostat

Replacement Procedure 1. Disconnect power to the machine. 2. Disengage the drive chain from the turntable. 3. Taking care not to kink or tangle the chain, place it on the turntable. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 26: Timers And Switches On The Control Panel

11. Install the new motor. Installation is the reverse of 7. Attach the power leads to the new timer. removal. 8. Install the new timer. Installation is the reverse of 12. Reconnect the drive chain to the turntable. removal. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 27: Oil Skimmer Motor

5. Remove the two screws from the center of the Slide Cover skimmer disk to detach the disk from the skimmer Toward Rear to Remove assembly. To remove the disk, disengage it from the center pin, then slide it down. Screws Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 28: Troubleshooting

Avoid contact with power leads, terminals, and on the machine. Assembly is the reverse of fuses when power is connected. removal. • Disconnect power to machine before removing fuses or other electrical components. Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 29 Blown; Replace the Blown Fuse of Each approximately 0 Ohms E l e c t r i c a l Pa n e l i s OK. Refer to Testing Individual Components Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 30: Testing Individual Components

If there is continuity, the switch is no longer func- Cover tional; replace the switch. 4. With the switch fully closed (depressed), test for continuity. If there is not continuity, the switch is no longer functional; replace the switch. Screws Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 31 4. If the start capacitor has not visibly failed, remove it from the motor bracket, disconnect the wires, and test it for shorts using an ohm meter. If the ohm meter reads infinity, the start capacitor is no longer functional; replace it. Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

- Page 32 WHITE POWDER ON (totally dissolved residue) more frequently. PARTS Large parts can dry before solution runs off, leaving Monitor soap concentration, and correct as-needed. powdery residue WASH SOLUTION Failed thermostat Replace the thermostat. TOO HOT Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

- Page 33 (See Detergent Concentration). Condensation collecting on door Leave door open if wash solution is cold and and inside of cabinet unit is not in use. during long idle times. Add rust inhibitor solution. Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

- Page 34 Test the skimmer timer; replace if necessary Failed skimmer timer (See Wash Cycle, Heater and Skimmer Timers). Contact a licensed electrician to test the motor; Failed skimmer motors replace if necessary (See Oil Skimmer Motor). Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 35: Parts

Parts Parts 1.043-477.0, 1.043-478.0, 1.043-479.0, 1.043-505.0, 1.043-506.0, 1.043-507.0 CUDA 3648 Cuda 3648 Operator’s Manual 9.801-627.0 - AM... -

Page 36: Cuda 3648 Front

Cuda 3648 Front For Detail See Door Latch Assy Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 37 NUT, 1/2", HEX, NC, SS 8.718-794.0 SCREW, 10-32 X 3/4" HEX, SL 8.754-306.0 SCREW,10-32 X 3/4", HEX WASHER HEAD, SS 8.922-094.0 WELDMENT, HUB MOUNT 8.922-608.0 WLMT, HUB MOUNT, SS 8.712-951.0 16.5" FOAM STRIP-1/8" X 1" ADHESIVE BACK Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

- Page 38 NUT, NYLOC 1"-14 8.754-660.0 NUT, NYLOC 1"-14, S/S 8.713-038.0 WHEEL, TRACK 8.753-682.0 WHEEL, TRACK, SS 8.753-731.0 PIN, COTTER, 1/16" X 3/4" SS 8.731-254.0 PARTS BASKET - SMALL 8 X 8 X 4 NOT SHOWN Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

- Page 39 PARTS TREE, 4 HOOK, 34" X 30" NOT SHOWN 8.753-767.0 CONTAINMENT RING, 36", MARKED YELLOW NOT SHOWN 8.718-988.0 WASHER, 7/16" FLAT SAE, ZINC 8.751-823.0 WASHER, 7/16" FLAT SAE, SS 8.924-491.0 COVER, EXPANDED CUTOUT 8.925-504.0 COVER, EXPANDED CUTOUT, SS Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 40: Cuda 3648 Rear

’s reco • r, add your ning ufac turer wate gent olve clea addi Diss tank befo 180° (82° 120° 150° F (66° (49° °F °C) °F °F °C) °C) Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 41 WELDMENT, GEAR MOTOR SWING RRM 4860 8.916-406.0 WASHER, GEARMOTOR 8.714-009.0 TORQUE LIMITER, LARGE SIZE 8.754-200.0 TORQUE LIMITER, LARGE SIZE, SS 8.753-738.0 BOLT, 3/8" X 8" FULL THREAD 9.802-811.0 WASHER, 3/8" X 1-1/2", FENDER, SAE Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

- Page 42 CONDUIT, WATER TIGHT, FLEX 1/2" 8.716-547.0 CONNECTOR, 1/2" L/T, STR, BLK 8.922-402.0 LABEL, OPERATOR INSTALL 8.753-709.0 SWITCH, LIMIT PLASTIC, NC/NO 8.922-117.0 ASSY, CONTROL BOX 8.718-980.0 WASHER, 5/16", FLAT, SAE 9.802-776.0 NUT, 5/16", ESNA, NC Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

- Page 43 8.754-663.0 PLUG, HEX, 2" NPT, 304 S/S 1 8.921-982.0 COVER, SUMP W/O GAUGE, SS 8.713-761.0 72" SEAL-BULB TYPE (7 GA) EPDM, SIDE PROFILE 8.921-274.0 SPACER, BRAKE LINK, 800 8.755-014.0 GASKET, 1/8" THK, R426 Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 44: Spray Arm

Spray Arm Side View View Rotate Each Nozzle Approx. 3° Align Notch In Each From Center Spray Nozzle With Line Of Pipe The Center Of The Turntabl Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 45 UNION, 1.5', 304 SS 8.724-258.0 ELBOW, STREET, 1-1/2" GALV 8.753-719.0 ELBOW, STREET, 1-1/2" NPT, 90, STREET, S40 S/S 8.706-328.0 PIPE PLUG 1/4, GALV 8.753-897.0 PLUG, PIPE, 1/4, 304SS 8.708-075.0 NOZZLE, 1x65 1/4' VEE JET SS Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 46: Latch And Door

Latch and Door Stainless Only Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 47 U-BOLT, 1/4" X 3/8" PIPE, SS NUT, 1/4-20, WHIZ LOC FLANGE, SS STAINLESS 8.718-817.0 UNITS ONLY 8.718-603.0 BOLT, 1/4" X 3/4", NC HH SS 9.802-807.0 WASHER, 3/8", SAE, FLAT ZINC 9.802-779.0 NUT, 3/8", ESNA, NC Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 48: Control Panel

Control Panel Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 49 LABEL, CONTROL PANEL, CUDA 9.802-784.0 NUT, 6-32 KEPS 8.716-377.0 TERMINAL, RING TONGUE, 14 AB-10 8.749-434.0 CONTACT, CART. TURNTABLE JOG 9.800-016.0 LABEL, DISCONNECT POWER SUPPLY 9.802-802.0 WASHER, 1/4" FLAT 8.756-586.0 KNOB, TIMER, SPRING WOUND Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 50: Oil Skimmer

Oil Skimmer 8, 9 Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 51 SCREW, 6-22 X 1/2" 9.802-802.0 WASHER, 1/4" FLAT 8.913-732.0 OIL SKIMMER, SMALL 8.922-839.0 OIL SKIMMER, SMALL, SS 9.804-374.0 LABEL, KEEP DRY 9.804-567.0 NUT, 10/32 ESNA 9.804-137.0 GASKET, SKIMMER, SMALL, 8.718-968.0 WASHER, #10 FLAT ZINC PLT Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 52: Electrical Box

230V Electrical Box Auto Fill Option Timer Option Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 53 END COVER 8.753-064.0 TERMINAL BLOCK, IDC 8.749-977.0 JUMPER 8.749-976.0 TERMINAL BLOCK, IDC X 2 8.724-284.0 CONTACTOR, 60 AMPS 8.716-375.0 TERMINAL, RING TONGUE, RC10-516 8.718-980.0 WASHER, 5/16", FLAT 8.715-980.0 26" WIRE, MTW, 12 GA. GREEN Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 54: Electrical Box

460V Electrical Box Auto Fill Option Timer Option Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 55 END, COVER 8.753-064.0 TERMINAL BLOCK, IDC 8.749-977.0 JUMPER 8.749-976.0 TERMINAL BLOCK, IDC X 2 8.724-272.0 CONTACTOR, 30 AMPS 8.716-375.0 TERMINAL, RING TONGUE, RC10-516 8.718-980.0 WASHER, 5/16", FLAT 8.715-980.0 26" WIRE, MTW 12 GA. GREEN Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

-

Page 56: Electrical Box

575V Electrical Box Auto Fill Option Timer Option Cuda 3648 Operator’s Manual 9.801-627.0 - AM... - Page 57 END COVER 8.753-064.0 TERMINAL BLOCK, IDC 8.749-977.0 JUMPER 8.749-976.0 TERMINAL BLOCK, IDC X 2 8.724-272.0 CONTACTOR, 30 AMPS 8.716-375.0 TERMINAL, RING TONGUE, RC10-516 8.718-980.0 WASHER, 5/16", FLAT 8.715-980.0 26" WIRE, MTW 12 GA. GREEN Cuda 3648 Operator’s Manual 9.801-627.0 - AM...

- Page 58 CLEANING SYSTEMS 9.801-627.0 • Printed in U.S.A.

Need help?

Do you have a question about the 3648 Series and is the answer not in the manual?

Questions and answers