Subscribe to Our Youtube Channel

Summary of Contents for Belanger Signature Series

- Page 1 Low Side Washer Signature Series Low Side Washer Signature® Series 1MANUL860 Rev 02...

- Page 3 Do not make additional copies of this manual or electronically transmit it in any form whatsoever, ® in whole or in part, without the prior written permission of Belanger, Inc. The registered trademarks used in this document are the property of their respective owners. The use of such trademarks is for ®...

- Page 5 Changed 108716 (Electric Model)/108650 (Hydraulic Model) to See Following Page for Arm Weldment Part Numbers. Part # 108716 is incorrect it is a FSW-SL DS/PS Arm Weld PC Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

- Page 6 Material to contain set assembly numbers instead of 1 piece part numbers Back Updated Back Cover to the new layout Cover Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

-

Page 7: Table Of Contents

Neo-Tex™ Cleaning Material (1/4” Thick) – C Channeled Hubs ..................45 Wave Hub Assembly (Overview) ............................46 Wave Hub Assembly (Parts) ..............................47 Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... - Page 8 Misc. Wave Hub Components ............................... 49 Welted Cloth Cleaning Material – Only Used on C-Channel Hubs ..................50 Waves & Fins™ Cloth Cleaning Material ..........................50 Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

-

Page 9: Belanger Incorporated® Limited Warranty

PURPOSE CONTAINED IN THE UNIFORM COMMERCIAL CODE – SALES ARE EXPRESSLY DISCLAIMED. Copyright ©2020 by Belanger, Inc. All rights reserved. No part of this work may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, or by any information storage or retrieval system, except as may be expressly permitted by the 1976 Copyright Act. -

Page 10: Operational Warning

During the installation process, the installer is responsible for re-tightening ALL lugs, set screws, and terminals located in the electrical panels. Components may vibrate loose during shipping. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 11: Introduction

IT IS IMPERATIVE THAT WHEELS ARE SPINNING DURING ANY PERIOD THAT THE CONVEYOR IS ACTIVATED HYDRAULIC DRIVE MODEL ELECTRIC DRIVE MODEL Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 12: Before You Get Started

Notify your local distributor or Belanger, Inc.® immediately if the shipment is determined damaged or incomplete. ELECTRIC DRIVE MODEL HYDRAULIC DRIVE MODEL Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 13: Important Safety Information - Must Read

Read, understand and follow this manual and any other labels or related materials supplied with this equipment. If you do not understand the procedure, call a Belanger, Inc.® representative at 248-349-7010. It is imperative for your safety and the safety of others to understand the procedures before beginning work. -

Page 14: Safety Warnings

Doing so will prevent unexpected energization, startup, or release of hazardous energy while maintenance and servicing activities are being performed. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... - Page 15 BE SURE TO SAVE THESE INSTRUCTIONS. It is imperative to your safety and the safety of others to always follow safe work procedures. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

-

Page 16: Specifications

A compressed Air System should be set correctly to support the 90 PSI necessary to operate equipment, but should never be set to deliver more than 120 PSI air pressure to the Belanger® specified equipment. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 17: General Dimensions

LOW SIDE WASHER ® Specifications General Dimensions Equipment Envelope 68” Top View 152-1/2” Entrance View 51” 13” Conveyor: 52-1/2” 14-1/2” Conveyor: Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 18: Identify Conveyor

1-1/2" to the dimensions to position the driver side Low Side Washer assembly. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 19: Tunnel Placement Overview

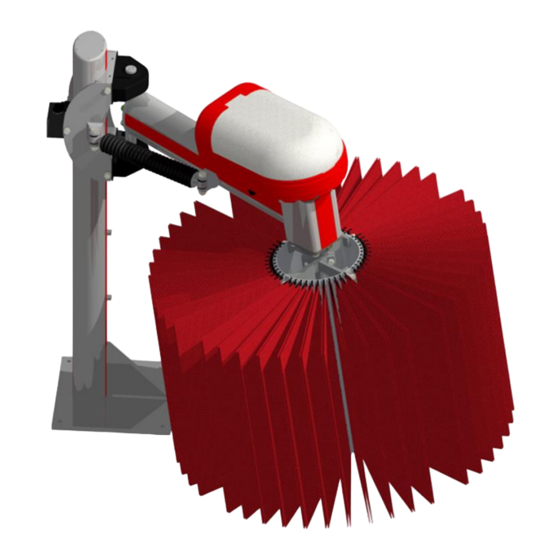

The above image shows the Low Side Washers with the wash material installed to indicate the operating envelope required for proper function. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 20: Tunnel Placement - Optional, Staggered With Quickfire® Wraps

The above image shows the Low Side Washers with the wash material installed to indicate the operating envelope required for proper function. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 21: Utilities

Confirm that the wheels are rotating in the proper direction. If they are not, reverse two leads to the electric motors on the overload located in the Control Panel. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... - Page 22 Feed from hydraulic supply Return to hydraulic supply Using field supplied lines, supply hydraulic feeds to the manifolds shown below. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

- Page 23 Feed (IN) passenger side. Locate the supplied hose clamps and secure them into place at the approximate mid-point as shown below. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

- Page 24 Locate the supplied 1/2” ear clamps from the accessory box. Using field supplied water hose feed both legs assemblies to the valve shown below. Tighten the clamps into place. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

-

Page 25: Neo-Tex™ Cleaning Material

On the passenger side, mount the 12” diameter x 28-1/4” tall hub at 36” from the floor (see the image above) while the hub is 60” from the inside Guide Rail. See the image below. 60” Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... - Page 26 16” x 10” When folded in half, this piece is 16” x 8” When folded in half, this piece is 16” x 10” Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

-

Page 27: Welted Cloth Cleaning Material

2” angle cut This piece is 16” x 10” NO” angle cut This piece is 20” x 8” 4” angle cut Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 28: Waves And Fins™ Hubs And Cleaning Material

5/32” Allen wrench DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE SERVICING ANY EQUIPMENT! CAUTION Always wear safety glasses when performing maintenance on any equipment Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... - Page 29 Certain machine configurations require the driver side wheel to use 22” Fins. Otherwise, Note: all Fins will be 24”. If you have received 22” Fins™ with your order, load wash material accordingly. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

- Page 30 Press down on the top of the Wave stack to seat the wash material and verify the bottom Wave is on the drive plate. See the image below. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

- Page 31 Top Wave cap section Adjust the wheel speed to between 110 and 120 RPM while under vehicle load at 900 to 1100 PSI. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

-

Page 32: Maintenance

Monthly • Wash the component frame. Refer to Powder Coating Maintenance. • Check the cleaning material for wear. Replace as necessary. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 33: Troubleshooting

Replace the motor on the unit Brush is turning too slow • Check motor starter Electric drive: Wheels not turning • Check gearbox • Check motor Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 34: Powder Coating Maintenance

If you have any questions or concerns regarding how to clean powder coat equipment please call Belanger® Technical Support / Aftermarket Group for additional assistance. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 35: Powder Coating Repair

Continue rubbing down and applying light coats, until the edges of the damaged paint have disappeared. Applied properly, at this stage all physical signs of repair can be lost. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... - Page 36 The result is that it will peel off. It is always a good practice to mechanically abrade a key by using rubbing down paper or at least use a non-scratch scrub sponge. A small discrete area should be tested first. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

-

Page 37: Torque Plate And Electric Motor Replacement

The terminal block may need to be removed from the side of the motor for additional access. Use a Phillips screwdriver. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... - Page 38 Once the cover mount and cover are removed, you will be able to access the bottom of the gearbox / torque plate assembly. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

- Page 39 6) Repeat steps 3 and 5 on the remaining fasteners. Before tightening fasteners to the proper torque, verify that the torque plate orientation is correct on the gearbox. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

- Page 40 Once the key and keyway are aligned, lower the gearbox onto the torque bolts to its resting position. 3) To secure the gearbox, locate and install the washers and new zinc cotter pins. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

- Page 41 7) Once the motor gearbox unit is properly secured into position, power can be turned back ON. 8) Verify wheel rotation prior to running any test vehicle through the system. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

-

Page 42: Exploded Parts View

1FSTNR-HH540 (6) 1WASHR-LC498 (6) 1ELBOW-BR360 (2) 1NOZZL-FJ696 (2) 7920 108657 1MCONC-SS015 (2) 1WASHR-LC456 (5) 1FSTNR-HH589 (5) Electric Drive Hydraulic Drive 110298 7921 Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 43: Water Intake Components

(Same for DS & PS) Arm Weldment Only Driver Side: 108650 7178 Passenger Side: 108651 1FSTNR-PH290 (2) 108649 1PLSTC- CV038 1FSTNR-HH540 (4) 1WASHR-LC456 (4) Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 44: Arm Components

7934 1FSTNR-HH811 (2) 108647 101576 1TUBE798 7932 1TIE790 (2) 7931 1NUT-LC220 (2) Electrical Feed Components 1ELECT-FS215 1ELECT-FS220 (Sleeve) 1FSTNR-SH030 (4) 7923 Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 45: Electric Drive Head Assembly

1FSTNR-HH714 (2) Blue: 1PLSTC-CV082 1WASHR-LC581 (4) Green: 1PLSTC-CV088 Gray: 1PLSTC-CV092 1BERNG849 Orange: 1PLSTC-CV086 Red: 1PLSTC-CV084 Yellow: 1PLSTC-CV090 1BERNG849 1WASHR-LC581 (4) 1FSTNR-HH714 (4) Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 46: Hydraulic Drive Head Assembly

PASSENGER SIDE: 110306 (49”) 1FSTNR-HH045 DRIVER SIDE: 110303 (37”) PASSENGER SIDE: 110305 (47”) 1CLAMP462 (2) 1ELBOW -ST539 (4) 1WASHR-FL332 (2) 1NUT-LC210 Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 47: Filler Strips For Electric Drive System

Section A is a wider filler strip than sections B thru K. The wider filler strip is no longer available in Green, Orange, and Yellow therefore section A for these colors has been changed to black. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 48: Filler Strips For Hydraulic Drive System

Section A is a wider filler strip than sections B thru K. The wider filler strip is no longer available in Green, Orange, and Yellow therefore section A for these colors has been changed to black. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 49: Aluminum Hub Assembly (Overview)

Signature Series LOW SIDE WASHER ® Maintenance Exploded Parts View Aluminum Hub Assembly (Overview) Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 50: Aluminum Hub Assembly: 106026

101118: 6” x 42-1/4” Skin Assembly (4 per Hub) Lower Hub Assembly 106026 is used on the driver & passenger side LSW assemblies. Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 51: Neo-Tex™ Cleaning Material (1/8" Thick) - C Channeled Hubs

Complete fill replacement set BLACK BLUE GREEN ORANGE YELLOW for both DS & PS Hubs Neo-Tex Fill Only (1/4” Thick) 105904 105901 105902 ™ Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 52: Wave Hub Assembly (Overview)

Signature Series LOW SIDE WASHER ® Maintenance Exploded Parts View Wave Hub Assembly (Overview) 102126: Hub Assembly Complete (includes all fasteners) Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 53: Wave Hub Assembly (Parts)

3648: Clamp Half 1NUT-RG436 (2) 1WASHR-FL498 (2) 1FSTNR-HH441 (2) 1WASHR-LC291 (2) 1WASHR-LC456 (4) 1NUT-LC219 (4) 1FSTNR-HH562 (4) 3708: Clamp 101907: Drive Plate Weldment Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 54: Exploded Parts View (Continued)

Exploded Parts View Wave Hub Assembly (Plastic Waves) 1PLSTC-SW400: Top Cap Half (2) Lower Hub Assembly 1PLSTC-SW100 (9) 1PLSTC-SW300: Bottom Cap Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 55: Misc. Wave Hub Components

LOW SIDE WASHER ® Maintenance Exploded Parts View Misc. Wave Hub Components 102024: Drive Plate Assembly 101907: Drive Plate Weldment 101064 Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860... -

Page 56: Welted Cloth Cleaning Material - Only Used On C-Channel Hubs

24” (61 cm) HH Cloth (20 pieces), 4 sets to fill both DS & PS 105593 DS = Driver Side PS = Passenger Side Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL860...

Need help?

Do you have a question about the Signature Series and is the answer not in the manual?

Questions and answers