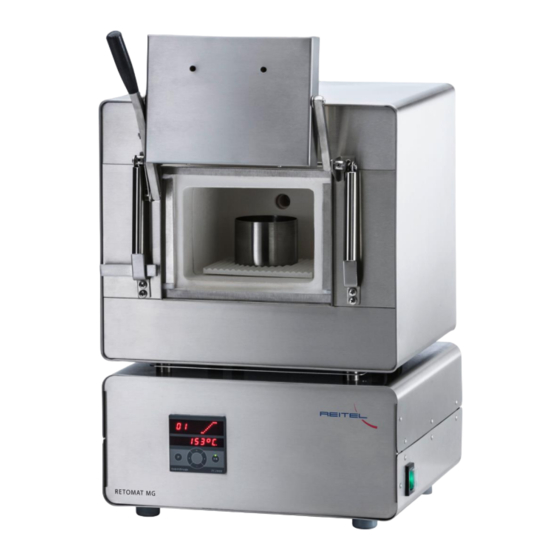

REITEL RETOMAT Series Operating Instructions Manual

Laboratory equipment in stainless steel

Hide thumbs

Also See for RETOMAT Series:

- Operating instructions manual (20 pages) ,

- Operating instructions manual (24 pages)

Summary of Contents for REITEL RETOMAT Series

- Page 1 Operating Instructions RETOMAT-Series with COMFORT-controller REITEL Feinwerktechnik GmbH Senfdamm 20 | 49152 Bad Essen Phone: +49(0)5472-9432-0 | Fax: +49(0)5472-9432-40 www.reitel.com | info@reitel.com...

- Page 2 Dear Customer! The laboratory furnaces of the RETOMAT series are especially designed for precious and non-precious alloys and partial frameworks. The COMFORT-control offers you 10 programming spaces with up to 30 heating ramps and a speed program for speed investment. Temperature is distributed and stays even in the chamber due to the four-sided heating element and optimal chamber insulation.

-

Page 3: Table Of Contents

INDEX TECHNICAL DESCRIPTION ..................4 ....................... 4 ASIC QUIPMENT ....................4 PECIAL CCESSORIES ....................4 PERATING LEMENTS ......................5 ECHNICAL DATA SAFETY NOTES ......................6 .................... 6 ENERAL AFETY OTES ................. 7 PECIFIC AFETY NSTRUCTIONS INSTALLATION ......................8 ......................8 NSTALLATION .............. -

Page 4: Technical Description

Technical Description Basic Equipment • RETOMAT laboratory furnace with COMFORT-controller Special Accessories • Order-No.: 27301000 Catalyst • Order-No.: 27302000 Steam ventilator • Order-No.: 27303000 Casting ring drawer Operating Elements Power switch Oven door Handle (furnace door) Control panel (COMFORT control) Rubber feet Socket (for optional steam ventilator or catalyst) Circuit breaker... -

Page 5: Technical Data

Fig.: rear side Fig.: furnace chamber Technical data RETOMAT MINI RETOMAT RETOMAT MG Line voltage 230 V/50-60 Hz Current consumption 2.500 W 2.600 W 3.000 W W x H x D in cm 39 x 53/61 x 45 42 x 55/66 x 43 45 x 57/71 x 52 Heating room 16,5 x 11,5 x 15... -

Page 6: Safety Notes

Safety Notes General Safety Notes • All equipment undergoes final inspection and testing before leaving our factory. However, if equipment is damaged during shipping or through any other circumstances, it must not be used in service. Please check the device regularly for damages. Damaged parts should be replaced immediately. -

Page 7: Specific Safety Instructions

When using the optional drawer, place the casting rings on the fireproof plate. • The RETOMAT series is not intended for use with flammable, explosive and chemically aggressive substances without special protective or auxiliary equipment. • Do not use substances / liquids with harmful vapor formation. Use melting substances with protective vessel. -

Page 8: Installation

Installation The electric equipment is being delivered fully installed. The sealed plug can be connected directly to the mains supply 230 V/16 A. For installation please refer to chapter 2. Installation 1. Place the RETOMAT on a stable fireproof workstation of suitable height and on a horizontal surface (minimum width 450 mm). -

Page 9: Control Panel And Basic Settings

Control panel and basic settings Control panel After switching on the main switch (1), a self-test is performed . The version number appears on the lower display (as shown in the illustration on the control panel). upper display lower display program button Start / stop button (Alarm off) -

Page 10: Set Time And Date

Set time and date Press P and keep it pressed for a few seconds. After displaying "Config", the upper display shows S91, the lower display shows the time. Adjust the time with the + and - buttons. If you keep the button pressed for a longer time, the setting will run faster. -

Page 11: Programming And Operation

Programming and operation Program for speed investment materials After switching on and self-test performance, the current time is shown in the display. Use P to select the program slot and start programming with the right arrow button. In the upper display, 01 stands for the first ramp in the program slot. -

Page 12: Programming Heating Ramps

Programming heating ramps After switching on and self-test performance, the current time is shown in the display. Use P to select the program slot and start programming with the right arrow key. In the upper display, 01 stands for the first ramp in the program slot. -

Page 13: Continuous Heating After Program Completion

At the end of the ramp setting, terminate programming with the arrow key "minus" until "End" appears. Another touch of the button on the right confirms the programming. The program is started with the Start / Stop button, which then lights up green. After the warm-up time has elapsed, the alarm sounds, which is acknowledged with the Start / Stop key (press once) -

Page 14: Troubleshooting

Regularly check the device for visible damage to the casing or power cord. • Clean the housing at regular intervals with a damp cloth or with the REITEL spray. Note Clean and maintain your device at regular intervals with the REITEL spray (Order No.: 90405000) against contamination and corrosion. -

Page 15: Warranty

Warranty We, REITEL Feinwerktechnik GmbH, offer a 1 year’s warranty beginning from the proven date of purchase. This warranty covers all defects traceable to materials, design or workmanship. The following warranty regulations are applicable: Within the warranty period Reitel Feinwerktechnik GmbH or an authorized distributor agrees at its sole option, to perform repair or replace this product at no charge covering all defects traceable to materials, design or workmanship. - Page 16 REITEL Feinwerktechnik GmbH; − The warranty does not cover the cost of removal and replacement of parts and accessories, unless supplied as original equipment by REITEL Feinwerktechnik GmbH − All kind of damages occurred not directly at the device as well as consequential damages (e.g.

- Page 17 Should you need to borrow a device while your device is being repaired, please contact Messrs. REITEL or your distributor. These loans are a service for which availability cannot necessarily be guaranteed. After the warranty period, a free may be charged for loan...

-

Page 18: Disposal Regulations

Notes: The thermocouple is excluded from the warranty. For insurance reasons we recommend to change this every six months. Please do not overfill the chamber as damage resulting from cracking or overheating will not be covered by the warranty. The use of ceramic sintering in this oven will void the warranty. -

Page 19: Eu Directive

EU DIRECTIVE... - Page 20 We manufacture in compliance with Quality Management ISO 13485:2016 incorporating established standards. REITEL Feinwerktechnik GmbH Senfdamm 20 | 49152 Bad Essen Phone: +49-(0)5472-9432-0 | Fax: +49-(0)5472-9432-40 www.reitel.com | info@reitel.com...

Need help?

Do you have a question about the RETOMAT Series and is the answer not in the manual?

Questions and answers