Veeder-Root TLS-300 Operator's Quick Manual

Hide thumbs

Also See for TLS-300:

- System setup manual (227 pages) ,

- Troubleshooting manual (160 pages) ,

- Site prep and installation manual (91 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Veeder-Root TLS-300

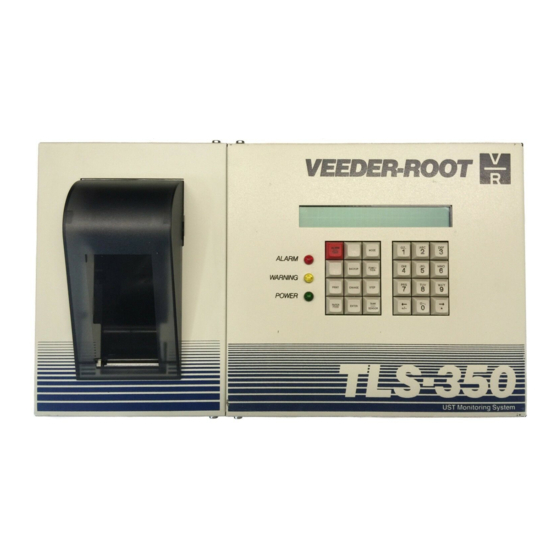

- Page 1 Operator's Quick Help Manual 576013-939, Rev D TLS-300 TLS-350 TLS-350R...

- Page 2 Notice Veeder-Root makes no warranty of any kind with regard to this This publication contains proprietary information which is protected by publication, including, but not limited to, the implied warranties copyright. All rights reserved. No part of this publication may be of merchantability and fitness for a particular purpose.

-

Page 3: Table Of Contents

Table of Contents Page i Console Operating Features ........1 System Status Messages .......... 17 Key Functions ............2 To Start An In-Tank Leak Test ........18 Automatic Reports ............. 3 To Stop In-Tank Leak Testing ........19 Business Inventory Reconciliation (BIR Option) ..4 In-Tank Leak Test Reports ........ -

Page 4: Console Operating Features

Console Operating Features Page 1 MMM DD, YYYY HH:MM XM ALL FUNCTIONS NORMAL Liquid Crystal Display (showing normal operating display) ALARM MODE TEST ALARM Alarm Indicator Light FUNCT- BACKUP TION WARNING Warning Indicator Light PRINT CHANGE STEP POWER Power Indicator Light PAPER TANK ENTER... -

Page 5: Key Functions

Key Functions Page 2 Press to change to a Select a character by successive Press to silence the alarm. A B C ALARM different option than presses of the key. Press once for "A". CHANGE This will not reset the display TEST currently displayed. -

Page 6: Automatic Reports

Automatic Reports Page 3 INVENTORY INCREASE REPORT ADJUSTED DELIVERY REPORT (BIR Option) This report is generated after each delivery. It During the delivery the TLS-350R is continu- shows the volume of the tank contents before ously monitoring any sales from the tank being T 1:REGULAR UNLEADED T 1:PRODUCT 1 INVENTORY INCREASE... -

Page 7: Business Inventory Reconciliation (Bir Option)

Business Inventory Reconciliation (BIR Option) Page 4 MMM DD, YYYY HH:MM XM The TLS-350R, in addition to accurately measuring the con- TO PRINT A RECONCILIATION REPORT SHIFT RECONCILIATION - - - - - - - - - - - tents of each tank, also monitors the amount of fuel dis- T 1:REGULAR UNLEADED Press until the display shows:... -

Page 8: Variance Reports

Variance Reports Page 5 If enabled in Setup Mode, you can generate daily, weekly, and/or periodic Delivery Variance Reports, Book Variance PROD 1: UNLEADED GASOLIN Reports, and Variance Analysis Reports. Also, you can display and print enabled Variance Reports for all products, or for a specific product. - Page 9 Page 6 TO PRINT BOOK VARIANCE REPORTS PROD 1: UNLEADED GASOLIN BOOK VARIANCE DAILY Press until the display shows: MMM DD, YYYY HH:MM XM RECONCILIATION MODE VOLUMES ARE STANDARD PRESS <FUNCTION> TO CONT OPENING DATE & TIME: MMM DD, YYYY HH:MM XM Press until the display shows: CLOSING DATE &...

- Page 10 Page 7 TO PRINT VARIANCE ANALYSIS REPORTS PROD 1: UNLEADED GASOLIN CORRECTIVE ACTIONS Press until the display shows: VARIANCE ANALYSIS INSPECT METERS DAILY RECONCILIATION MODE MMM DD, YYYY HH:MM XM LEAK TEST RESULTS PRESS <FUNCTION> TO CONT VOLUMES ARE STANDARD T 1: UNLEADED GASOLINE OPENING DATE &...

-

Page 11: Warnings And Alarms

Warnings And Alarms Page 8 The TLS Console is constantly monitoring its probes and sensors for warning and Do not ignore alarms!!! alarm conditions, such as fuel leaks, excessively high or low fuel levels, and equipment problems. Be sure you are familiar with the alarm response procedures for the site. To Switch Off All Warnings and Alarms If there is no warning or alarm condition active the system displays the “ALL Press the red ALARM/TEST key to silence the alarm. -

Page 12: In-Tank Warning And Alarm Levels

In-Tank Warning And Alarm Levels Page 9 Single-Wall Double-Wall Full Volume Full Volume Tanks Tanks Max (Label) Volume Max (Label) Volume Limit Limit High Level Limit High Level Limit Overfill Limit Overfill Limit Delivery Limit Delivery Limit Low Level Limit Low Level Limit High Water Limit Water Warning Limit... -

Page 13: In-Tank Warnings

In-Tank Warnings Page 10 CAUSE: CAUSE: MMM DD, YYYY HH:MM XM MMM DD, YYYY HH:MM XM Water collecting in the tank shown has exceed- Fuel level in the tank shown is below the Deliv- T1 : HIGH WATER WARNING T1 : DELIVERY NEEDED ed the Water Warning level. -

Page 14: In-Tank Alarms

In-Tank Alarms Page 11 CAUSE: CAUSE: MMM DD, YYYY HH:MM XM MMM DD, YYYY HH:MM XM Fuel loss has exceeded the pre-programmed Fuel level in the tank shown has exceeded the T1 : LEAK ALARM T1 : OVERFILL ALARM limit during a leak test in the tank shown. Overfill Level during a delivery. - Page 15 Page 12 CAUSE: CAUSE: MMM DD, YYYY HH:MM XM MMM DD, YYYY HH:MM XM Fuel loss in the tank shown has exceeded a Fuel level in the tank shown has exceeded T1 : MAX PRODUCT ALARM T1 : SUDDEN LOSS ALARM pre-set limit during a Leak Test.

-

Page 16: Liquid Sensor Alarms

Liquid Sensor Alarms Page 13 CAUSE: CAUSE: MMM DD, YYYY HH:MM XM 14-09-97 19:25:47 The sensor shown has detected liquid in the The Interstitial Monitor for the tank shown L1 : FUEL ALARM T1 : INTERSTITIAL ALARM sump being monitored. has detected a change in the interstitial fluid LIQUID STATUS ACTION:... -

Page 17: Dual-Float Discriminating Sensor Alarms

Dual-Float Discriminating Sensor Alarms Page 14 CAUSE: CAUSE: MMM DD, YYYY HH:MM XM 14-09-97 19:25:47 The sensor at the location shown has detected The sensor at the location shown has L1 : FUEL ALARM L1 : LIQUID ALARM fuel vapor or liquid. detected at least 1 inch of non-hydrocarbon ACTION: liquid. -

Page 18: Vapor Sensor Alarms

Vapor Sensor Alarms Page 15 CAUSE: CAUSE: MMM DD, YYYY HH:MM XM MMM DD, YYYY HH:MM XM The vapor sensor at the location shown has The vapor sensor at the location shown is V1 : FUEL ALARM V1 : WATER ALARM detected fuel vapor in the monitoring well. -

Page 19: Groundwater Sensor Alarms

Groundwater Sensor Alarms Page 16 CAUSE: CAUSE: MMM DD, YYYY HH:MM XM MMM DD, YYYY HH:MM XM The Groundwater sensor at the location shown The water level in the monitoring well shown G1 : FUEL ALARM G1 : WATER ALARM has detected fuel. -

Page 20: System Status Messages

System Status Messages Page 17 CAUSE: CAUSE: MMM DD, YYYY HH:MM XM MMM DD, YYYY HH:MM XM The paper roll is empty. The system backup battery has failed. PAPER OUT BATTERY OFF ACTION: ACTION: consoles\qh\US\40.eps consoles\qh\US\42.eps Silence the alarm by pressing the red ALARM/ Do not switch off power to the system. -

Page 21: To Start An In-Tank Leak Test

To Start An In-Tank Leak Test Page 18 START IN-TANK LEAK TEST Press until the display shows: PRESS <STEP> TO CONTINUE consoles\qh\44.eps TEST CONTROL: ALL TANKS To test individual tanks press . To test all tanks press the display will show TIMED DURATION consoles\qh\45.eps To end the test manually press... -

Page 22: To Stop In-Tank Leak Testing

To Stop In-Tank Leak Testing Page 19 STOP IN-TANK LEAK TEST Press until the display shows: The system confirms the ending of the test by displaying: PRESS <STEP> TO CONTINUE consoles\qh\48.eps To stop single tank testing: LEAK TEST NOT ACTIVE PRESS <FUNCTION>... -

Page 23: In-Tank Leak Test Reports

In-Tank Leak Test Reports Page 20 Press until the display shows: MMM DD, YYYY HH:MM XM LEAK TEST REPORT IN-TANK TEST RESULTS T 1:REGULAR UNLEADED PRESS <STEP> TO CONTINUE PROBE SERIAL NUM 012345 consoles\qh\52.eps TEST STARTING TIME: Press to generate a report for all tanks. MMM DD, YYYY HH:MM XM TEST LENGTH = 4.3 HRS... -

Page 24: Last Shift Inventory Report

Inventory Report Last Shift Inventory Report Page 21 MMM DD, YYYY HH:MM XM Press until the display shows: ALL FUNCTIONS NORMAL MMM DD,YYYY HH:MM XM SHIFT STARTING INV #1 consoles\qh\US\56.eps - - - - - - - - - - LAST SHIFT INVENTORY INVENTORY REPORT Press... -

Page 25: Inventory Increase Report

Inventory Increase Report Page 22 MMM DD, YYYY HH:MM XM ALL FUNCTIONS NORMAL MMM DD, YYYY HH:MM XM T1:REGULAR UNLEADED consoles\qh\US\56.eps INVENTORY INCREASE Press once and until you see the Delivery INCREASE START MMM DD, YYYY HH:MM XM message (the last delivery amount): VOLUME = 5146 GALS HEIGHT = 44 INCHES T 1: REGULAR UNLEADED... -

Page 26: Entering A Ticketed Delivery Volume

Entering A Ticketed Delivery Volume (BIR Option) Page 23 The Delivery Maintenance function, if enabled in Setup Mode, lets you edit, view, and print information about ticketed deliveries (refer to the Delivery Maintenance section of the Operator’s Manual for complete instructions and printing options). -

Page 27: Pressurized Line Leak Detection Tests

Pressurized Line Leak Detection Tests (PLLD Option) Page 24 You can run a PLLD test on all lines or on a single line. This step lets you select 3.0, 0.2, or 0.1 gph line leak tests to run on the selected line(s). If your system does not have 0.2 or 0.1 gph test TO START A PLLD TEST options, you will not see these selections. - Page 28 Press to begin the test. The system displays: and the system displays the message: Page 25 STOP LINE TEST: LINE (#) Q# : RUNNING PUMP PRESS <ENTER> PRESS <STEP> TO CONTINUE consoles\qh\US\plld9.eps consoles\qh\US\plld6.eps To exit this function, press Press to stop the test on the line shown,or press until you see the line you want to select, then press .

-

Page 29: Wireless Pressurized Line Leak Detection Tests

Wireless Pressurized Line Leak Detection Tests (WPLLD Option) Page 26 You can run a WPLLD test on all lines or on a single line. This step lets you select 3.0, 0.2, or 0.1 gph line leak tests to run on the selected line(s). - Page 30 Press to begin the test. the system displays: and the system displays the message: Page 27 W # : TEST PENDING SELECT LINE PRESS <STEP> TO CONTINUE W#: WPLLD NUMBER # consoles\qh\US\wplld6.eps consoles\qh\US\wplld10.eps To exit this function, press Press to stop the test on the line shown,or press until you see the line you want to select, then press .

-

Page 31: To Set The System Date

To Set The System Date Page 28 SETUP MODE Press until the display shows: PRESS <FUNCTION> TO CONT consoles\qh\63.eps SETUP MODE Press . If the system has a security passcode you will be asked to enter a six digit code: ENTER PASSCODE>_ _ _ _ _ _ _<... -

Page 32: To Set The System Time

To Set The System Time Page 29 If the date is correct press SET TIME The display will show: TIME: 12:34 PM consoles\qh\68.eps If the time is correct press to return to the Operating mode. To change the time press and enter the correct time. -

Page 33: Changing The Printer Paper

Changing The Printer Paper Page 30 The paper roll should be changed Separate the two halves of the take-up when a red stripe appears on the spool by pulling them apart (4) and printouts. remove the printed reports. Roll Shaft A 3-roll pack of printer paper (Part Do not discard any reports as they may Number 514100-328) is available from... - Page 34 Page 31 Push the roll into the lower slots in Push the Take-up Spool into the the printer with the paper tail down upper slots. Rotate the spool and from the back. counterclockwise until you remove all slack in the paper. Feed the paper tail through behind the paper feed roller (3).

- Page 36 Manual 576013-939, Rev D...

Need help?

Do you have a question about the TLS-300 and is the answer not in the manual?

Questions and answers

Hello, my name Is Johnny learning the system can't find out why or how to fix when it says Low Product Alarm, not sure if just need to reset the system because we've already filled our tanks if someone could reach out let me know what I can do to fix this would be greatly appreciated Thank You