Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for GEZE Slimdrive SL NT

- Page 1 Slimdrive SL NT EN Installation and service instructions Product family 192351-02...

-

Page 2: Table Of Contents

Replace brushes on the roller carriage ..............................31 Electrical faults........................................ 32 Drive identification plate ........................... 33 Inspection of the installed door system ....................... 34 10.1 Protective measures to prevent and protect from hazardous areas ..................34 10.2 Installation checklist Slimdrive SL NT ..............................34... -

Page 3: Introduction

If there are several actions to be taken, keep to the given order. Revisions and validity Version 02: valid for Slimdrive SL NT product family from model year 2021. Product liability In compliance with the liability of the manufacturer for his products as defined in the German “Product Liability Act”, compliance with the information contained in this brochure (product information and intended use, misuse,... -

Page 4: Fundamental Safety Precautions

à The country-specific laws and regulations are to be observed during safety-related tests. à If unauthorised changes are made to the system, GEZE cannot be held liable in any way whatsoever for any resulting damage, and the statement of approval for use in escape and rescue routes is no longer valid. -

Page 5: Safety-Conscious Working

Slimdrive SL NT product family Fundamental safety precautions The product should be installed or incorporated in such a way that effortless access to the product is guaranteed during any repairs and/or maintenance, and that any removal costs do not stand out of economic proportion to the value of the product. -

Page 6: About This Document

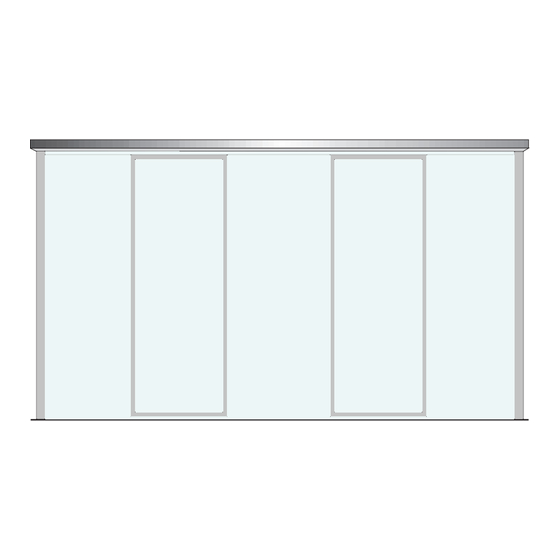

3. 1 Overview These instructions describe the installation of the automatic sliding door drives of the Slimdrive SL NT product family. The installation of the fixed panels and the girder section is described in the installation instructions “Girder section with fixed panel”. -

Page 7: Overview

Slimdrive SL NT with protective leaf 70511-ep08 Installation diagram Slimdrive SL NT/-FR, wooden leaf 70511-ep13 Installation diagram Slimdrive SL NT /-FR, ISO-glass fitting + hook lock 70511-ep16 Installation diagram Slimdrive SL NT & Lock A, 2-leaf 70511-ep17 Installation diagram Slimdrive SL NT & Lock A, 1-leaf... -

Page 8: Tools And Aids

Installation Slimdrive SL NT product family Tools and aids Tool Size Tape measure Marking pen Torque spanner Allen key 2 mm, 2.5 mm, 3 mm, 4 mm, 5 mm, 6 mm Open-ended spanner 8 mm, 10 mm, 13 mm, 15 mm... -

Page 9: Mounting The Track

Slimdrive SL NT product family Installation Mounting the track Protect the running surface from damage. 5.3. 1 Mounting the intermediate plates Clip the intermediate plates (1) onto the rear of the track. à Upper row of drill holes for wall installation à... -

Page 10: Mounting The Floor Guide

Installation Slimdrive SL NT product family Mounting the floor guide à The selection of floor guide depends on the on-site conditions. One of the following floor guide options must be used. à For further information see the respective installation drawing, Chapter 4.1. -

Page 11: Installing The Moving Leaf

Slimdrive SL NT product family Installation Installing the moving leaf 5.5. 1 Fit the connecting arm WARNING! Danger of injury due to glass breakage. Always install the moving leaves together with another person. WARNING! Danger of crushing! The moving leaves are still unsecured and move easily. - Page 12 Installation Slimdrive SL NT product family 5.5.2 Inserting roller carriage into the track Insert roller carriage (2) into the track (1) as shown below. Insert the moving leaf mounting aid (3) as shown below to secure the roller carriage in the track.

- Page 13 Slimdrive SL NT product family Installation Slide the track-supporting rollers (4) upwards and tighten slightly using screws (5). 5.5.3 Install the supporting brackets on the moving leaf The supporting brackets are installed during glazing of the moving leaves. In case of subsequent installation of the supporting brackets, the frames of the moving leaves must be dismantled (see installation instructions...

- Page 14 Installation Slimdrive SL NT product family 5.5.5 Adjusting the moving leaves WARNING! Danger of injury caused by crushing! The moving leaves are still unsecured and move easily. Make sure that the moving leaves are not moved accidentally or by unauthorised persons.

- Page 15 Slimdrive SL NT product family Installation Adjusting the counter-roller The counter-roller (4) must have an upper clearance of 0.5 mm to the track (corresponds approximately to the thickness of 4 sheets of copy paper). Loosen the screw (5) on the rear of the counter-roller.

- Page 16 Installation Slimdrive SL NT product family 5.5.6 Mounting the short driver à Drivers must not touch any obstacle over the entire travel path. à See the drive drawing for the precise position of the driver. 1-leaf: Mount the short driver (2) to the clamping plate (3) using 2 screws (1).

-

Page 17: Installing The Drive Components

Slimdrive SL NT product family Installation Installing the drive components 5.6. 1 Mounting the module mounts on the left and right WARNING! Unsecured components may fall when under load. When mounting the module mount, ensure that its entire length is suspended in the track. - Page 18 Installation Slimdrive SL NT product family 5.6.3 Fitting the tooth belt to the driver 1-leaf 2-leaf Screw the toothed belt locking (1) to the short driver (2). Do not tighten the screws yet. 5.6.4 Tensioning the tooth belt The tooth belt must be pre-tensioned with 300 N ±35 N (see drive drawing).

- Page 19 Slimdrive SL NT product family Installation 5.6.5 Setting the closing position Setting the closing position With 2-leaf systems: Slide the moving leaf to the closed position. Fit second belt lock on the long driver, do not tighten the screws (2) yet.

- Page 20 Installation Slimdrive SL NT product family 5.6.7 Position the tooth belt locking mechanism (optional) Close the moving leaves. Loosen the screws (1) at the tooth belt locking mechanism (optional). Align the locking device. Following installation, the locking pin (2) must be positioned in the hole in the cover in such a way that the lock- ing mechanism can be locked and unlocked.

- Page 21 Slimdrive SL NT product family Installation 5.6.8 Mounting cable guides Cables can be cut! Lay cables in such a way that there are no cables near the moving parts. Fix the cable guide (2) to the module mount (1) or track (3). Cable guide spacing approx. 200 mm.

-

Page 22: Connecting Earthing

Installation Slimdrive SL NT product family 5.6. 1 0 Connecting the tooth belt locking mechanism (optional) and control unit Route the cable tooth belt locking mechanism (optional) (1) to the control unit (2) and plug it in. Connecting earthing Connect the earthing cable (1) from the trans-... -

Page 23: Production Test And Commissioning

Slimdrive SL NT product family Production test and commissioning Production test and commissioning 6. 1 Connecting the drive WARNING! Risk of fatal injury due to electric shock! The electrical system (230 V) may only be connected and disconnected by a qualified electrician or a qualified electrician for specified tasks. -

Page 24: Mounting The Cover

Production test and commissioning Slimdrive SL NT product family Mounting the cover WARNING! Danger of injury! People can be injured when handling the cover. Always make sure two people handle the cover. WARNING! Danger of injury from falling cover! Make sure that the cover is attached along the entire length of the track. - Page 25 Slimdrive SL NT product family Production test and commissioning Push the cords (rubber cables) (3) onto the mounted suspension pieces (1) of the cover. 6.2.2 Mounting the side panel suspension piece Screw the side panel suspension piece (2) using the oval head screw (3) into side panels (1) left and right (tightening torque 1.5 Nm).

- Page 26 Production test and commissioning Slimdrive SL NT product family 6.2.4 Hook the cover catch rope in place Hook the cover catch rope (2) on the cover suspension piece (3) in the cover (4). Hook the cover catch rope (2) on the suspension piece (1) of the side panels.

-

Page 27: Mounting The Safety Devices

Slimdrive SL NT product family Production test and commissioning 6.2.6 Sliding the cover in place Slide the cover (1) onto the side panels (3) until it latches in and ensure that it is also seated correctly in the area of the module mounts and cable guides. -

Page 28: Dismantling

Production test and commissioning Slimdrive SL NT product family Dismantling WARNING! Risk of fatal injury due to electric shock! The electrical system (230 V) may only be disconnected by a qualified electrician or a qualified electrician for specified tasks. WARNING! Danger of injury! People can be injured when handling the cover. -

Page 29: Service And Maintenance

Slimdrive SL NT product family Service and maintenance Service and maintenance 7. 1 Mechanical service 7. 1 . 1 Checking tooth belt tension The tooth belt must not lift up from the motor gear or skip when braking and accelerating. -

Page 30: Troubleshooting

Troubleshooting Slimdrive SL NT product family Test spot Action Comments Track Check for cracks Replace the track Check for cleanliness Clean the track Roller carriage Check the abrasion of the track rollers Remove the abrasion Check brushes Remove the roller carriage (see Chapter 8.2) Replace the brushes if necessary (see Chapter 8.3) -

Page 31: Replacing Roller Carriage

Slimdrive SL NT product family Troubleshooting 8. 1 . 1 Check moving leaf Disconnect the moving leaf from the tooth belt using the toothed belt locking. Move the moving leaf and check for ease of movement. If moving leaves move easily: Check the motor gear unit and deflection pulley and replace if necessary. -

Page 32: Electrical Faults

Troubleshooting Slimdrive SL NT product family Electrical faults For read-out instructions and a list of fault messages, see wiring diagram. 8.4. 1 Replacing fuse in transformer DANGER! Risk of fatal injury due to electric shock! If the main switch on the transformer is activated, the fuse is still energised since it is upstream of the main switch. -

Page 33: Drive Identification Plate

Slimdrive SL NT product family Drive identification plate Drive identification plate Only relevant in Germany and in the scope of validity of DIN 18650-1:2010-06. Supplement classification code on the identification plate. Sliding door drive Slimdrive SL NT 50 °C Input 230 V 50 Hz 0.65 A... -

Page 34: Inspection Of The Installed Door System

10.2 Installation checklist Slimdrive SL NT Test in On page Com- pleted All cables laid correctly for the installation of the Slimdrive SL NT? – – Track mounted? Angled floor guide/continuous floor guide installed? Moving leaf installed? Drive components installed? 5.6.1... - Page 35 Slimdrive SL NT product family...

- Page 36 E-Mail: leonberg.de@geze.com Baltic States – Iberia Scandinavia – Norway Lithuania / Latvia / Estonia GEZE Iberia S.R.L. GEZE Scandinavia AB avd. Norge GEZE GmbH E-Mail: norge.se@geze.com E-Mail: baltic-states@geze.com E-Mail: info.es@geze.com Niederlassung Süd-Ost www.geze.no www.geze.es Tel. +49 (0) 7152 203 6440 E-Mail: muenchen.de@geze.com...

Need help?

Do you have a question about the Slimdrive SL NT and is the answer not in the manual?

Questions and answers