Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Voxelab Aries

- Page 1 Each printer must be tested before leaving factory. If there are some WARNING residues in extruder or some tiny scratches on the build plate, it is normal and won’t affect the printing quality. This manual is only applicable to Voxelab Aries 3D printer...

- Page 2 Thank you for choosing and using the products of Voxelab Technology. For your conve- nience, please read this manual carefully before use and follow the manual strictly. The Voxelab team is always ready to provide you with the perfect service. Please contact us by email listed, if you have any problems.

- Page 3 USB flash disk and the platform. Lift the printer and put it on the desk, then Remove the top foam, there should be a take Aries out of the plastic bag. power cable included. Hold the platform and lift it carefully to Take out the foam under nozzle as remove the foam below it.

- Page 4 Double check the foam, it should contain: 8. Cut the three black cable ties: one for filament, material rack, nozzle, remove fixing X-axis synchronous belt, two for tool, needle, wrenches and screwdrivers. fixing Y-axis synchronous belts on both sides. Cut four white cable ties that used to hold Discard the blue protective tapes all the rods in place.

- Page 5 Notes Do not make any modifications to the printer. To avoid personal injury or property damage please ensure your operation followed by the Manual. Dress properly. Do not wear loose clothing or jewelry. Keeping your hair, clothing and gloves away from moving parts. Do not directly touch the nozzle and build plate to avoid high-temperature burn.

-

Page 6: Kit Contents

Each device must be tested before leaving factory. If there are some residues in extruder or some tiny scratches on the build plate, it is normal and won’t affect the printing quality. This guide is only applicable to Voxelab Aries 3D printer 3D Printer Power Cable... -

Page 7: Equipment Parameters

Equipment Parameters Model Voxelab Aries Print size 200*200*200 mm Forming technology Number of nozzle Layer thickness 0.05 mm - 0.4 mm Nozzle diameter Standard 0.4 mm XY axis precision ±0.2 mm Filament φ1.75 mm PLA / ABS / PETG File format... -

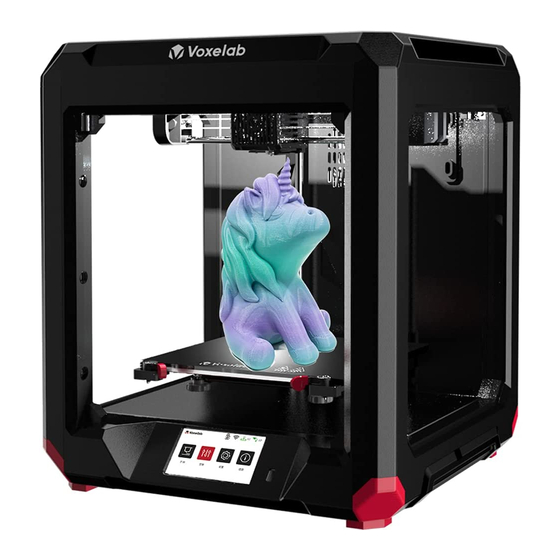

Page 8: Product Introduction

Product Introduction Y-axis Guide Rod X-axis Guide Rod Z-axis Guide Rod Build Plate Clip Limit position assembly Touch Screen USB Stick Input Power Voltage Switch LED Light Nozzle Turbofan Baffle Power Switch Power Input Spool installation port Drive assembly... -

Page 9: Hardware Assembly

Hardware Assembly Glass Build Plate Put the glass build plate on the heating platform and insert it into the limit position assembly, then locked by clips. The four edges of glass build plate need to be aligned with the platform. Unlocked Locked Rotate 180°... - Page 10 Power On Plug in the power cord and toggle the switch to turn on the power. Do not disconnect the cables when Aries is powered on. Attention · Damage might occur if voltage setting is incorrect. Make sure the current input voltage matches to your local power supply (115/230V).

-

Page 11: Leveling Build Plate

Leveling Build Plate Before leveling, let's learn the function of nuts. How to use the nuts Build plate goes up Build plate goes down Rotate the nuts Anticlockwise Rotate the nuts clockwise Raise the build plate to reduce the distance Lower the build plate to increase the distance between the nozzle and build plate. - Page 12 When the extruder move to the second point, pull the A4 paper to feel the friction resistance. If the friction is too big to move, rotate nut anticlockwise to increase the distance of nozzle and build plate; if the friction is too small, rotate nut clockwise to reduce the distance of nozzle and build plate.

-

Page 13: Loading Filament

Loading Filament 1. Tap [Control]. 2. Tap [Load]. 3. The extruder is heating to the targeted temperature automatically. The auto-load is start to load the filament when 5. Tap [OK] to back to the homepage. the targeted temperature reached. Do not stop loading when the nozzle extrudes the filament. -

Page 14: First Print

First Print Suggestions 1. Ensure that the build plate has been leveled before printing. 2. Ensure that the filament has been loaded in an appropriate approach. 3. Please clean extruder before printing (Load the filament for a while to extrude all the melted filament you printed last time out of the extruder). -

Page 15: Unloading Filament

Unloading Filament Please follow steps below if you need to unload filament in daily use. 1. Tap [Control]. 2. Tap [Unload]. 3. When the filament unload out of the filament feeding port, the unload operation is finished. Note: After unload completed then load again, it can finish the filament replacement. - Page 16 WIFI Connection 1. Tap [Settings] - [WIFI], open the WIFI function. 2. Choose the Internet and save the password.

- Page 17 Connect Printer by WIFI 1. After the WIFI connected successfully, tap [Info] and check the IP Address. 2. Open the VoxelMaker, click [Print] - [Connect Machine], input the IP address and click the connect. 3. There is a connect icon when it connected successfully.

-

Page 18: Firmware Upgrade

Firmware Upgrade Get the firmware files: Enter the official website <www.voxelab3dp.com> and download them at <Download Center>. Method 1: 1. Copy the firmware into the blank USB flash disk. 2. Plug in the USB flash disk into the USB port of printer and reboot the printer, waiting for the upgrade process finished. -

Page 19: Slicing Software

Slicing Software Load the STL file. Move the STL file in the X or Y axis directly, Enter the support setting mode. it can be moved in Z -axis directly by long Enter the slicing setting mode. pressing shift and the mouse. Observe the STL file in different views Rotate the STL file. -

Page 20: Wiring Connection

Wiring connection... - Page 21 Printing Notice The adhesion of glass build plate may decrease after long time using. Please apply proper amount of glue to keep and improve the adhesion. Warping issues may occur when print ABS filament in cold environment, you may use glue to enhance the adhesion.

- Page 22 Q: How to get the firmwares? A: Enter the official website <www.voxelab3dp.com> and download them at the <Download Center>. Q: What if the model warps or is unable to stick to the build plate? A: 1. The temperature of the build plate was too low; please increase its temperature; 2.

- Page 23 Q:What if the files are garbled and cannot be read? A: 1. The format of files after slicing is not compatible; 2. Repair the model before slicing. Q:What if knock and noise occur when nozzle returning to zero point? A: 1. Check whether the zero sensor is knocked and broken; 2.

-

Page 26: After Sales Support

This equipment should be installed and operated with minimum distance 20cm between the radiator & your body. Voxelab Voxelab voxelabofficial Voxelab 3D Printing After-Sales Service: support@voxelab3dp.com Tel: +86 579 82238626 Web: www.voxelab3dp.com Add: 2/F, No.518, Xianyuan Road, Jinhua, Zhejiang, China...

Need help?

Do you have a question about the Aries and is the answer not in the manual?

Questions and answers