Reflex Fillcontrol Auto Operating Manual

Hide thumbs

Also See for Fillcontrol Auto:

- Operating instructions manual (50 pages) ,

- Original operating manual (348 pages)

Summary of Contents for Reflex Fillcontrol Auto

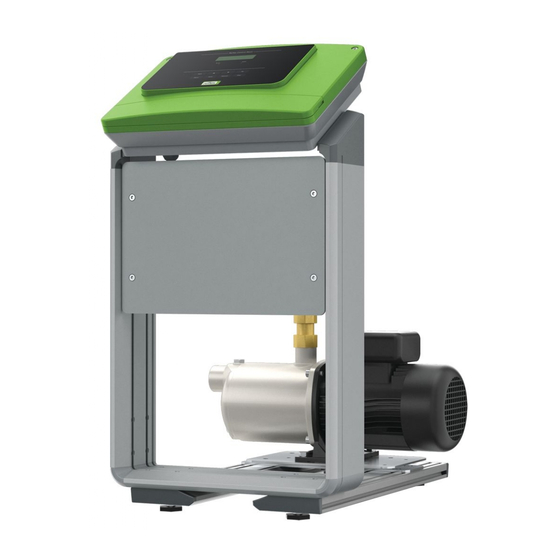

- Page 1 Fillcontrol Auto 22.09.2020 - Rev. C Operating manual Original operating manual...

-

Page 2: Table Of Contents

12.1 Reflex Customer Service ................16 6.5.1 Terminal diagram ..............8 12.2 Conformity and standards ................. 16 6.5.2 RS-485 interface..............9 12.3 Guarantee ....................16 6.6 Installation and commissioning certificate ..........9 2 — English Fillcontrol Auto — 22.09.2020 - Rev. C... -

Page 3: Notes On The Operating Manual

Reflex Winkelmann GmbH accepts no liability for any damage resulting from vicinity can occur. failure to observe the information in this operating manual. In addition to the requirements set out in this operating manual, national statutory regulations ... -

Page 4: Description Of The Device

Note! An application without system separator tank is possible. – For customised design and adjustment, see chapter 12.1 "Reflex Customer Service" on page 16 . Note! In a solar circuit, you must have installed a system separator tank to ensure a water/glycol mixture for the circuit. -

Page 5: Type Code

When the filling level falls below the minimum level, the pressurisation unit sends a signal to the device controller. The controller activates the pump. mains water is added to the system circuit from the system separator vessel. Fillcontrol Auto — 22.09.2020 - Rev. C English — 5... -

Page 6: Installation

The device is installed sufficiently close to the diaphragm expansion vessel. prerequisite for the making of warranty claims. You ensure so that the "PIS" pressure sensor is able to measure the filling – Have the Reflex Customer Service carry out commissioning and pressure. the annual maintenance. •... -

Page 7: Hydraulic Connection

At make-up temperatures > 70 °C and the use in system circuits without system separator tanks, you must plan according to the local Pump "PU" "BT" system separator vessel conditions, see chapter 12.1 "Reflex Customer Service" on page 16 . "PIS" pressure transducer "ST" dirt trap Switching and make-up variants... -

Page 8: Electrical Connection

Make-up (230 V) • Before you remove the covers, completely isolate the device controller (Set the controller to from the power supply. "Levelcontrol") • Verify that the main circuit board is voltage-free. 8 — English Fillcontrol Auto — 22.09.2020 - Rev. C... -

Page 9: Rs-485 Interface

All entries in the fault memory. • Communication with control centres. • Communication with other equipment. Note! If required, please request the RS-485 interface protocol from the Reflex Customer Service. • Connection details. • Accessory information and data. •... -

Page 10: Modifying The Controller's Start Routine

9.2.1 "Customer menu" on page 13 . Note! Plug in the mains plug to provide power (230 V) to the controller. 10 — English Fillcontrol Auto — 22.09.2020 - Rev. C... -

Page 11: Use The Device To Fill The Facility System With Water

Do not shut down the device when the automatic operation. pressurisation of the heating and cooling systems are in operation. Note! The commissioning process is now concluded. Fillcontrol Auto — 22.09.2020 - Rev. C English — 11... -

Page 12: Restarting

If the set number of make-up cycles is exceeded within • Call up the Customer menu cycles two hours, the system interrupts the make-up and Quit returns the "Make-up cycles" fault message. 003 / 2 h • Acknowledge messages 12 — English Fillcontrol Auto — 22.09.2020 - Rev. C... -

Page 13: Customer Menu

For the output of messages to the floating contact, see contact chapter 9.3 "Messages" on page 14 . • YES: Output of all messages. • NO: Output of all messages identified with "xxx" ("01", for example). Fillcontrol Auto — 22.09.2020 - Rev. C English — 13... -

Page 14: Service Menu

The display provides alarms in plain text and the ER codes shown in the list. Use to access this menu, see chapter 12.1 "Reflex Customer Service" on page 16 . the arrow buttons to scroll through multiple alarms displayed at the same time. -

Page 15: Maintenance

Seal any leaks at the connections or replace the connections, if Arrange for maintenance tasks must be carried out only by specialist required. personnel or Reflex Customer Service. • Seal leaking screw connections or replace, if required. Fillcontrol Auto — 22.09.2020 - Rev. C English — 15... -

Page 16: Cleaning The Dirt Trap

12.2 Conformity and standards • Repeat the steps described above to clean the dirt trap. Device conformity declarations are available on the Reflex homepage. www.reflex-winkelmann.com/konformitaetserklaerungen Disassembly Alternatively, scan the QR code: DANGER Risk of serious injury or death due to electric shock. - Page 17 Installation and commissioning certificate - This device has been installed and commissioned in accordance with the instructions provided in the operating manual. The settings in the controller match the local conditions. Typ / Type: Fabr. Nr. / Serial-No. Fillcontrol Auto — 22.09.2020 - Rev. C English — 17...

- Page 18 Reflex Winkelmann GmbH Gersteinstraße 19 59227 Ahlen, Germany +49 (0)2382 7069-0 +49 (0)2382 7069-9546 www.reflex-winkelmann.com...

Need help?

Do you have a question about the Fillcontrol Auto and is the answer not in the manual?

Questions and answers