Subscribe to Our Youtube Channel

Summary of Contents for Reflex Servitec 35-120

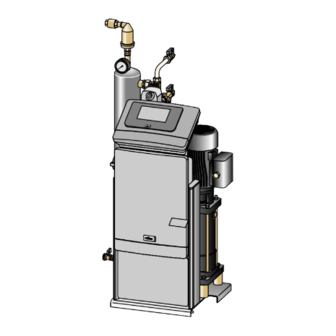

- Page 1 06.07.2016 - Rev. B Servitec 35-120 with Touch controller Vacuum spray degassing Operating manual Original operating manual...

-

Page 3: Table Of Contents

Filling the device with water and venting ............................39 Vacuum test ......................................41 Hydraulic equalisation ..................................42 Use the device to fill the facility system with water ........................45 Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 3... - Page 4 Conformity and standards ................................. 75 12.3 Certificate No. of the CE type test ..............................76 12.4 Guarantee ......................................76 Servitec 35-120 with Touch controller 06.07.2016 - Rev. B 4 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B...

-

Page 5: Notes On The Operating Manual

Reflex Winkelmann GmbH accepts no liability for any damage resulting from failure to observe the information in this operating manual. In addition to the requirements set out in this operating manual, national statutory regulations and provisions in the country of installation must also be complied with (concerning accident prevention, environment protection, safe and professional work practices, etc.). -

Page 6: Safety

The sign, in combination with the signal word 'Attention', indicates a situation where damage to the product itself or objects within its vicinity can occur. Note! This symbol, in combination with the signal word 'Note', indicates useful tips and recommendations for efficient handling of the product. 6 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 7: Personnel Requirements

For use with flammable media. • For use with distilled water. Note! It is not permitted to make any modifications to the hydraulic system or the circuitry. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 7... -

Page 8: Residual Risks

Contact with glycol containing water in plant systems for cooling circuits can result in irritation of the skin and eyes. • Use personal protective equipment (safety clothing, gloves and goggles, for example). 8 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 9: Description Of The Device

Reduction of corrosion damage by removal of oxygen from the water. Note! The device can only be operated at water temperatures up to a maximum of 90 °C. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 9... -

Page 10: Overview

"CD" 2-ways motor ball valve downstream of "PU" pump "VT" vacuum spray tube Connection for degassing "FD" feed and drain cock • Gas-rich water inlet Connection for degassing • Degassed water outlet 10 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... - Page 11 "CD" 3-ways motor control valve upstream of vacuum Degassed water pump connection spray tube Make-up to degassing connection Feed and drain cock Connection for degassing • Gas-rich water inlet Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 11...

- Page 12 For gas-rich water from the system "VT" vacuum spray tube "CD " pressure-reducing valve of the "WC“ make-up line "VT" vacuum spray tube "GV" solenoid valve of the "DC" degassing line 12 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B...

-

Page 13: Identification

Set opening pressure of the safety valve 4.3.2 Type code Type code (example) Device name Pump head height Servitec 35 Touch Controller type Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 13... -

Page 14: Function

Idling time – When the gas has been discharged, the device will remain in idle until the next cycle is started. Post-degassing occurs during the idling time. 14 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... - Page 15 For optional equipment and accessories see chapter 4.6 "Magcontrol" make-up variant "Optional equipment and accessories" on page 17 "DC" degassing line (degassed water) Control Touch controller "DC" degassing line (gas-rich water) Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 15...

- Page 16 "DC" degassing line (degassed water) For optional accessories, see chapter 4.6 "Optional equipment and accessories" on page 17 "DC" degassing line (gas-rich water) Control Touch controller "WC" make-up line 16 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B...

-

Page 17: Scope Of Delivery

Ethernet. • I/O module for standard communication. • Modbus RTU • Gas discharge measurement for an optimised degassing operation. Note! Separate operating instructions are supplied with accessories. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 17... -

Page 18: Technical Data

IG ½ " 1 " 1215 IG ½ " Internal thread IG ½ " 1 " 120 GL 1215 IG ½ " Internal thread IG ½ " 1 " 18 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 19: Operation

Approximate values for the maximal "Va" system volume to be degassed under extreme conditions during commissioning at a nitrogen reduction from 18 mg/l to 10 mg/l. Continuous degassing "t" System volume "Va" [m Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 19... -

Page 20: Installation

Confirm that installation and start-up have been carried out correctly using the installation, start-up and maintenance certificate. This action is a prerequisite for the making of warranty claims. – Have the Reflex Customer Service carry out commissioning and the annual maintenance. 20 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 21: Installation Conditions

For the Fillset, see chapter 4.6 "Optional equipment and accessories" on page 17 . Note! Install the device in the return flow side of the plant system. – This ensures stable pressure conditions for the device. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 21... -

Page 22: Execution

Install the "DV" degassing valve (2) with the check valve (1) on the "VT" vacuum spray tube. Check all screw fittings of the device for proper seating. 22 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 23: Floor Mounting

"G" weight of the device. Note! Consider a potential height difference "h “ between the pressure expansion tank and the device when calculating the "P “ minimum operating pressure. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 23... -

Page 24: Hydraulic Connection

Ensure the integration in the "V" main flow volume when using switching variants with hydraulic switching points and return admixtures. – For switching and make-up variants, see chapter 6.4 "Switching and make-up variants" on page 27 . 24 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... - Page 25 Ensure that the water temperature does not exceed the range 0 °C – 70 °C (special types up to 90 °C). The return line side should be • preferred for heating systems. This ensures the permissible temperature range for degassing. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 25...

- Page 26 For a water make-up via a "BT" system water tank, its bottom edge must be at least 100 mm over the "PU" degassing pump. Various Reflex make-up variants, see chapter 6.4 "Switching and make-up variants" on page 27 . For water make-up, note the following conditions: •...

-

Page 27: Switching And Make-Up Variants

Connect the degassing lines at the return side of the system upstream of the hydraulic switching point. The permissible temperature range of 0 °C – 70 °C (special types up to 90 °C) can thus be met. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 27... -

Page 28: Level Dependent "Levelcontrol" Make-Up Mode

Make-up with water is realised by regulating the motor ball valve in the "WC" make-up line. The device controller regulates the motor actuator of the motor ball valve. This ensures a controlled make-up with water and monitoring of the make-up time and cycles. 28 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... - Page 29 Make-up with water is realised by the solenoid valve in the "WC" make-up line. The device controller opens or closes the solenoid valve. This ensures a controlled make-up with water and monitoring of the make-up time and cycles. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 29...

-

Page 30: Electrical Connection

Covers of the connection unit (folding) • Supply and fusing • Floating contacts • Aggregate connection Connection unit Covers of the operating unit (folding) • RS-485 interfaces • Pressure output Cable bushings 30 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... - Page 31 Operating component, see chapter 6.5.2 "Terminal plan, operating unit" on page 34 . – Note the connection ratings of the device for the user-supplied fusing, see chapter 5 "Technical data" on page 18 . Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 31...

-

Page 32: Terminal Plan, Connection Component

Dry-running protection message (floating). Not assigned FB2a External make-up request. – With Levelcontrol setting. User, optional FB2b Input 230 V signal via L+N. Group message (floating). User, optional 32 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... - Page 33 +24 V (supply) "CD" 2-ways motor ball valve in the pump line (Servitec 35-95, 70°C). Pre-wired 0–10V (correcting – For regulating the hydraulic adjustment of degassing. variable) 0–10V (feedback) Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 33...

-

Page 34: Terminal Plan, Operating Unit

GND IO1 +5 V R × D I/O interface: Interface to the main circuit board. Factory T × D GND IO2 10 V~ 10 V supply. Factory 34 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 35: Rs-485 Interface

Modbus RTU. Note! If required, please contact the Reflex Customer Service for the protocol of the RS-485 interface, details of the connections and information about the accessories offered, see chapter 12.1 "Reflex Customer Service" on page 74 . Installation and commissioning certificate... -

Page 36: Commissioning

This action is a prerequisite for the making of warranty claims. – Have the Reflex Customer Service carry out commissioning and the annual maintenance. Checking the requirements for commissioning The device will be ready for commissioning when the tasks described in the "Installation" chapter have been completed. -

Page 37: Setting The Minimum Operating Pressure For Magcontrol

> 5.0 bar) valve "OPEN") Safety valve actuation + 1.2 bar (for p ≤ 5.0 bar) pressure = 1.1 x p + 0.8 bar (for p > 5.0 bar) Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 37... - Page 38 The actuation pressure must not fall below the minimum value of the actuation pressure of the safety valve. Note! Avoid dropping below the minimum operating pressure. Vacuum, vaporisation and the formation of vapour bubbles are thus excluded. 38 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B...

-

Page 39: Modifying The Controller's Start Routine

(1). 1 "PI" vacuum gauge "PU" pump 2 "DV" degassing valve Make-up line 3 "FD" feed and drain cock Degassing lines 4 "AV" vent screw Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 39... - Page 40 The "PU" pump must not be switched on when the device is filled with water. Note! Do not fully unscrew the vent screw. Wait until air-free water appears. Repeat the venting process until the "PU" pump is fully vented. 40 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B...

-

Page 41: Vacuum Test

The obtainable vacuum corresponds to the saturation pressure at the existing water temperature. – At 10 °C, a vacuum of approximately. -1 bar can be obtained. Note! Repeat steps 2 to 4 until no further pressure rise is observed. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 41... -

Page 42: Hydraulic Equalisation

(2) during the adjustment. Flow noise from the valves indicate that volume flows. The relevant pressure gauges indicate the actual pressure. Note! Hydraulic equalisation is not required for Servitec 35-95 devices with motor ball valve. 42 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... - Page 43 Counter-clockwise turning decreases the pressure. Set the overflow valve (1) to the setpoint. • Take the setpoint for the setting from the "Technical Data" chapter (overflow valve setpoint (bar)). Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 43...

- Page 44 Hydraulic equalisation is completed. Note! Read the flow pressure at the corresponding manometers when regulating the valves. After the regulation, re-check all setting values at the manometers. 44 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B...

-

Page 45: Use The Device To Fill The Facility System With Water

For adjusting the default settings, see chapter 7.9 "Parametrising the controller in the Customer menu" on page 45 . – For information about controller operation, see chapter 9.1 "Operator panel" on page 51 . Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 45... -

Page 46: Starting Automatic Mode

The "ST" dirt trap in the "DC" degassing line must be cleaned after the expiry of the continuous degassing time at the latest, see chapter 10.2.1 "Cleaning the dirt trap" on page 69 . Note! The commissioning process is now concluded. 46 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 47: Operation

For selecting the degassing programmes, see chapter 7.8 "Setting the degassing programme in the Customer menu" on page 45 . The controller displays the selected degassing programme in the message line. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 47... -

Page 48: Manual Mode

2-ways motor ball valve in the overflow line Note! Manual operation can not be performed if safety-relevant parameters are exceeded. – Switching is blocked if safety-relevant settings are exceeded. 48 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 49: Stop Mode

Continuous degassing Note! For a detailed description of the selection of degassing programmes, see chapter 7.8 "Setting the degassing programme in the Customer menu" on page 45 . Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 49... -

Page 50: Restarting

Note! Jamming of the pump is prevented during continuous device operation by a forced starting action (after 24 hours). 50 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 51: Controller

"Scroll back" button "Info menu" button • Cancel. • Displays general information. • Move backward up to the main menu. "Display help texts" button • Opens help texts. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 51... -

Page 52: Calibrating The Touch Screen

Touch the displayed crosses on the touch screen after each other. Switch the device off and on again at the main switch. The touch screen is fully calibrated. Please touch the red cross … … 52 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 53: Modifying The Controller's Start Routine

Start routine Step 2 "OK". – For calculation of the make-up variant, see chapter 6.4 Levelcontrol "Switching and make-up variants" on page 27 . Magcontrol 2.2 bar Continuous degassing Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 53... - Page 54 Use the "Left" and "Right" buttons to select the display value. 09:30 – Use the "Up" and "Down" buttons to change the display value. – Confirm your entries with "OK". 2.2 bar Continuous degassing 54 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B...

- Page 55 Press "OK" to conclude the start routine. Terminate start routine? 2.2bar Continuous degassing Note! After successful conclusion of the start routine, you are in Stop mode. Do not yet switch to Automatic mode. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 55...

-

Page 56: Configuring Settings In The Controller

If "Yes", reset to "0". • Maximum make-up quantity ... l • With softening "Yes/'No". – If "Yes", continue with 031. – If "No", continue with 007. 56 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... - Page 57 Display settings > Brightness, screen saver Information > • Position of the "CD" 2-ways motor ball valve at the pressure side of the pump. – Position in % • Software version Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 57...

- Page 58 The controller switches to the selected area. – Use the scroll bar to navigate through the list. (001) Language (002) Time 11:21 01/07/201 (003) Date (004) System type Magcontrol 2.2 bar Continuous degassing 58 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B...

- Page 59 Press "i“ to display a help text for the selected area. – Press "X“ to cancel your input without saving the new settings. The controller automatically opens again the list. 2.2 bar Continuous degassing Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 59...

-

Page 60: Service Menu

Service menu This menu is protected with a password. It can be accessed only by the Reflex Customer Service. A partial summary of the settings stored in the Service menu is proved in the Chapter Default settings, see chapter 9.4.3 "Default settings" on page 60 . -

Page 61: Degassing Programmes - Overview

The make-up water is degassed for as long as it is supplied, see chapter 9.4.1 "Customer menu" on page 56 . Note! Manual activation of the degassing program takes place in the customer menu. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 61... -

Page 62: Setting Degassing Programmes

Settings > Customer > Degassing – The controller opens the list of degassing programmes. (010) Degassing programme Continuous degassing (011) Time, continuous degassing 24.0 h 2.2 bar Continuous degassing 62 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... - Page 63 Press "i“ to display a help text for the selected area. – Press "X“ to cancel your input without saving the new settings. The controller automatically opens again the list. 2.2 bar Continuous degassing Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 63...

-

Page 64: Messages

The controller displays the messages with a help text. By selecting the fault memory in the Customer menu, you display the last 24 messages. Message causes can be eliminated by the operator or a specialist workshop. If required, please contact the Reflex Customer Service. - Page 65 Set value for the discharge period has Discharge period • Open the degassing pipe. "OK" been exceeded. • Clean the dirt trap. • Degassing pipe closed. • Dirt trap clogged. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 65...

- Page 66 Check the wiring at the analogue inputs – voltage faulty (pressure/level). Check the wiring at the 2-ways motor ball Input voltage missing Short-circuit of input voltage. – valve in the overflow line. 66 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B...

-

Page 67: Maintenance

Perform servicing, if the intervals have been exceeded. Note! Maintenance/service work must be carried out and acknowledged by specialist personnel or the Reflex Customer Service. Note! The annual maintenance is displayed upon expiry of the set operating time. • Press "OK" to acknowledge the "Service recommended"... -

Page 68: Exterior Leak Test

Degassing valves Proceed as follows: • Seal any leaks at the connections or replace the connections, if required. • Seal leaking screw connections or replace, if required. 68 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 69: Cleaning

Clean all other installed dirt traps (in the Fillset, for example). Note! Perform a fine adjustment of the hydraulic compensator, if the dirt traps are heavily soiled. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 69... -

Page 70: Function Test

Press "AUTO" to deactivate Manual mode. – Automatic mode is activated. The inspection of the degassing is concluded. Note! The "Insufficient water" message must not be displayed at the controller. 70 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 71: Maintenance Certificate

Maintenance 10.4 Maintenance certificate All maintenance tasks have been completed according to the Reflex Installation, Operating and Maintenance Manual. Date Service organisation Signature Remarks Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 71... -

Page 72: Inspection

The actual intervals must be determined by the user on the basis of a safety-technical assessment taking into account the real operational conditions, the experience with the operation and the charging material, and the national regulations for the operation of pressure equipment. 72 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 73: Disassembly

5. Open the "FD" drain cock at the "VT" spray tube of the device until the spray tube no longer contains any water. 6. If necessary, physically remove the device from the system. The dismantling process is completed. Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 73... -

Page 74: Annex

Customer Service extension: +49 (0)2382 7069 - 9505 Fax: +49 (0)2382 7069 - 9588 E-mail: service@reflex.de Technical Hotline For questions about our products Telephone number: +49 (0)2382 7069-9546 Monday to Friday 8:00 to 16:30 74 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... -

Page 75: Conformity And Standards

Gersteinstraße 19 59227 Ahlen - Germany Telephone: +49 2382 7069 -0 Norbert Hülsmann Volker Mauel Fax: +49 2382 7069 -9588 Members of the Board of Directors E-mail: info@reflex.de Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English — 75... -

Page 76: Certificate No. Of The Ce Type Test

DN 80 / 100 / 150 / 250 16 bar – 120 °C 07 202 1403 Z 0475 /2/ D0045 12.4 Guarantee The respective statutory guarantee regulations apply. 76 — English Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B... - Page 78 Reflex Winkelmann GmbH Gersteinstraße 19 59227 Ahlen, Germany Telefon: +49 (0)2382 7069-0 Telefax: +49 (0)2382 7069-9588 www.reflex.de...

Need help?

Do you have a question about the Servitec 35-120 and is the answer not in the manual?

Questions and answers