Table of Contents

Advertisement

Quick Links

Fluidcontrol

External level switches

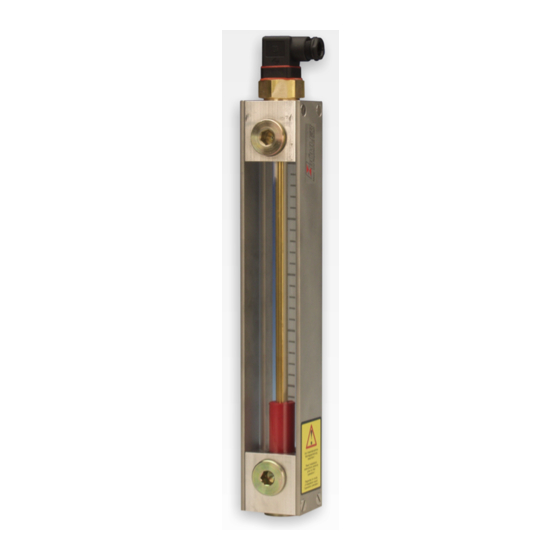

NS 1-G1/2-AM

Installation and Operation Instructions

Original instructions

BE200006

Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen

01/2022

Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20

E-Mail: fluidcontrol@buehler-technologies.com

Internet: www.buehler-technologies.com

Advertisement

Table of Contents

Summary of Contents for Bühler technologies NS 1-G1-AM

- Page 1 Fluidcontrol External level switches NS 1-G1/2-AM Installation and Operation Instructions Original instructions BE200006 Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen 01/2022 Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20 E-Mail: fluidcontrol@buehler-technologies.com Internet: www.buehler-technologies.com...

- Page 2 Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20 Internet: www.buehler-technologies.com E-Mail: fluidcontrol@buehler-technologies.com Read this instruction carefully prior to installation and/or use. Pay at- tention particularly to all advises and safety instructions to prevent in- juries.

-

Page 3: Table Of Contents

NS 1-G1/2-AM Contents Introduction............................................. 2 Intended Use......................................... 2 Functionality......................................... 2 Model key.......................................... 2 Scope of Delivery........................................ 2 Safety instructions......................................... 3 Important advice ......................................... 3 General hazard warnings .................................... 4 Transport and storage ........................................ 5 4 Installation and connection ...................................... 6 Mechanical installation..................................... 6 Electrical connections ...................................... -

Page 4: Introduction

NS 1-G1/2-AM 1 Introduction 1.1 Intended Use The NS1 level switch series serves liquid level monitoring in tanks in fluid systems. They are installed on the tank and have a visual display. Up to four switching contacts provide an electronic signal for fill level monitoring. A medium temperature between -20 °C and 80 °C (-4 °F and 176 °C) must be maintained. -

Page 5: Safety Instructions

NS 1-G1/2-AM 2 Safety instructions 2.1 Important advice Operation of the device is only permitted if: – the product is used under the conditions described in the installation- and operation instruction, the intended application according to the type plate and the intended use. In case of unauthorized modifications done by the user Bühler Technolo- gies GmbH can not be held responsible for any damage, –... -

Page 6: General Hazard Warnings

NS 1-G1/2-AM 2.2 General hazard warnings The equipment must be installed by a professional familiar with the safety requirements and risks. Be sure to observe the safety regulations and generally applicable rules of technology relevant for the installation site. Prevent malfunctions and avoid personal injuries and property damage. -

Page 7: Transport And Storage

NS 1-G1/2-AM 3 Transport and storage Only transport the product inside the original packaging or a suitable alternative. The equipment must be protected from moisture and heat when not in use. It must be stored in a covered, dry, dust-free room at room temperature. -

Page 8: Installation And Connection

NS 1-G1/2-AM 4 Installation and connection 4.1 Mechanical installation CAUTION Oil leak Damaged sight glass Ensure the bypass tank, particularly the sight glass, is not damaged by external forces. NOTICE The level switch must be mounted vertically to the tank to allow the float to move freely. The mounting surface on the tank must have a minimum surface quality of R = 6.3. -

Page 9: Electrical Connections

NS 1-G1/2-AM CAUTION Oil leak Removing the level switch When removing the level switch, ensure there is no fluid left in the tank or could leak from the tank. Note: After removing the float, be sure the magnet inside the float is above the fluid level. This can easily be verified with a piece of iron to determine the magnet position inside the float. - Page 10 NS 1-G1/2-AM – Carefully slide the contacts to the desired position on the bent rail. Use a small screwdriver or similar tool to do so. Use a drop of oil if the contacts are very tight. Please note the minimum spacing! If the contacts are configured as NO contact (NO) or NC contact (NC), the contact function can be reversed by turning the con- tacts 180°.

-

Page 11: Information On The Correct Operation Of Reed Contacts In Bühler Level Switches

NS 1-G1/2-AM 4.4 Information on the correct operation of reed contacts in Bühler level switches Based on their construction, reed contacts are very long lasting and reliable components. Yet the following should be considered when using them: Life of reed switches The life of reed switches can be up to 10 cycles. -

Page 12: Operation And Control

NS 1-G1/2-AM 5 Operation and control NOTICE The device must not be operated beyond its specifications. Bühler Technologies GmbH BE200006 ◦ 01/2022... -

Page 13: Cleaning And Maintenance

NS 1-G1/2-AM 6 Cleaning and Maintenance DANGER Toxic, corrosive gases or liquids Gasses or liquids can be harmful to the health. a) If necessary, ensure a safe gas/liquid discharge. b) Always disconnect the gas supply when performing maintenance or repairs. c) Protect yourself from toxic/corrosive gasses/liquids when performing maintenance. -

Page 14: Service And Repair

NS 1-G1/2-AM 7 Service and repair This chapter contains information on troubleshooting and correction should an error occur during operation. Repairs to the unit must be performed by Bühler authorised personnel. Please contact our Service Department with any questions: Tel.: +49-(0)2102-498955 or your agent If the equipment is not functioning properly after correcting any malfunctions and switching on the power, it must be inspected by the manufacturer. -

Page 15: Disposal

NS 1-G1/2-AM 8 Disposal Dispose of parts so as not to endanger the health or environment. Follow the laws in the country of use for disposing of elec- tronic components and devices during disposal. BE200006 ◦ 01/2022 Bühler Technologies GmbH... -

Page 16: Appendices

NS 1-G1/2-AM 9 Appendices 9.1 Technical Data Basic Unit Dimensions Operating pressure: max. 1 bar Operating temperature: -20 °C to +80 °C Plug SW 36 G3/4 Min. fluid density: 0.80 kg/dm³ SW12 Lengths: 280, 370, 500 mm (standard) variable to max. 800 mm Weight at L = 280 mm: approx. -

Page 17: Standard Pin Assignment

NS 1-G1/2-AM 9.2 Standard pin assignment Connector: M3 valve connector M12 plug A-coded C7 HAN 3 A Dimensions: 8 (PE) Connection schematic: Number of poles: 3-pin + PE 4-pin 7-pin + PE DIN EN 175301-803 61076-2-101 175301-801 Max. voltage: 230 V AC/DC* 30 V DC 230 V AC/DC* IP rating:... -

Page 18: Attached Documents

NS 1-G1/2-AM 10 Attached documents – Declaration of Conformity KX100008 – RMA - Decontamination Statement Bühler Technologies GmbH BE200006 ◦ 01/2022... - Page 20 RMA-Formular und Erklärung über Dekontaminierung RMA-Form and explanation for decontamination RMA-Nr./ RMA-No. Die RMA-Nummer bekommen Sie von Ihrem Ansprechpartner im Vertrieb oder Service./ You may obtain the RMA number from your sales or service representative. Zu diesem Rücksendeschein gehört eine Dekontaminierungserklärung. Die gesetzlichen Vorschriften schreiben vor, dass Sie uns diese Dekontaminierungserklärung ausgefüllt und unterschrieben zurücksenden müssen.

- Page 21 Dekontaminierungserklärung DE000011 Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen 01/2019 Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20 E-Mail: service@buehler-technologies.com Internet: www.buehler-technologies.com...

Need help?

Do you have a question about the NS 1-G1-AM and is the answer not in the manual?

Questions and answers