Summary of Contents for Waters Otto SPEcialist PPM

- Page 1 Otto SPEcialist Positive Pressure Manifold Overview and Maintenance Guide 715006867 Copyright © Waters Corporation 2021 Version 01 All rights reserved...

-

Page 2: General Information

This document is believed to be complete and accurate at the time of publication. In no event shall Waters Corporation be liable for incidental or consequential damages in connection with, or arising from, its use. For the most recent revision of this document, consult the Waters website (www.waters.com). -

Page 3: Contacting Waters

Contacting Waters Contact Waters with enhancement requests or technical questions regarding the use, transportation, removal, or disposal of any Waters product. You can reach us via the Internet, telephone, fax, or conventional mail. Contact method Information www.waters.com The Waters website includes contact information for Waters locations worldwide. -

Page 4: Specific Considerations To The Otto Specialist Positive Pressure Manifold

• Use SVT-type power cords in the United States and HAR-type power cords, or better, in Europe. For requirements elsewhere, contact your local Waters distributor. • Do not replace power cords with inadequately rated power cords. -

Page 5: Electrical Power Safety Notice

interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. Electrical power safety notice Do not position the device so that it is difficult to disconnect the power cord. Equipment misuse notice If equipment is used in a manner not specified by its manufacturer, the protection provided by the equipment may be impaired. - Page 6 For compliance with the Waste Electrical and Electronic Equipment Directive (WEEE) 2012/19/EU, contact Waters Corporation for the correct disposal and recycling instructions For indoor use only No pushing...

-

Page 7: Audience And Purpose

Pressure Manifold (PPM). It gives an overview of the technology and operation of this device. Intended use of the Otto SPEcialist Positive Pressure Manifold Waters designed the Otto SPEcialist PPM for use in solid-phase extraction (SPE) applications. This device is not intended for use in diagnostic applications. -

Page 8: Canada Spectrum Management Emissions Notice

Canada spectrum management emissions notice This class A digital product apparatus complies with Canadian ICES-001. Cet appareil numérique de la classe A est conforme à la norme NMB-001. July 1, 2021, 715006867 Ver. 01 Page viii... -

Page 9: Table Of Contents

Table of contents General information......................ii Copyright notice............................ii Trademarks.............................ii Customer comments..........................ii Contacting Waters..........................iii Safety considerations..........................iii Safety hazard symbol notice......................iii Specific considerations to the Otto SPEcialist Positive Pressure Manifold........iv FCC radiation emissions notice.......................iv Electrical power safety notice......................v Equipment misuse notice......................... v Safety advisories..........................v... - Page 10 3.1 96-port pressure manifold......................16 3.2 Manifold elevator mechanism......................16 3.3 Plate slider............................17 3.4 Safety features..........................17 3.4.1 Active safety shield....................... 18 3.4.2 Manifold processing height....................18 3.4.3 Virtual safety bars......................... 19 3.4.4 Full Open Manifold touchscreen functionality............... 19 3.4.5 Plate slider emergency stop....................19 4 User interface and control..................

- Page 11 A.3 Bottles Prohibited symbol......................41 A.4 Required protection........................41 A.5 Warnings that apply to all Waters instruments and devices............41 A.6 Warnings that address the replacement of fuses................45 A.7 Electrical symbols.......................... 47 A.8 Handling symbols...........................48 B Specifications......................49 B.1 Physical specifications........................49 B.2 Electrical specifications........................49 B.3 Environmental and performance specifications................

-

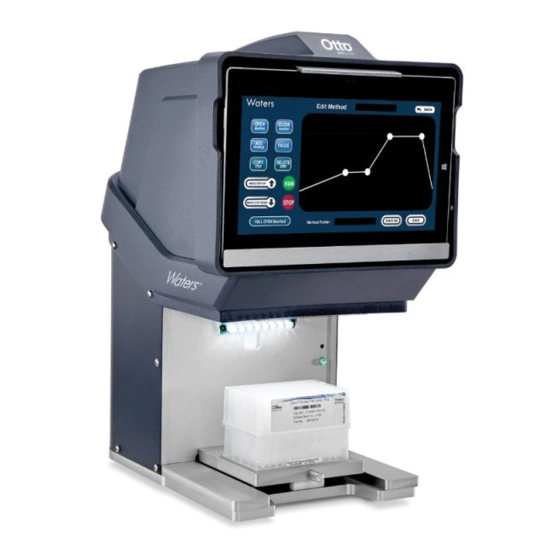

Page 12: Overview

1 Overview 1.1 Features The Waters Otto SPEcialist Positive Pressure Manifold (PPM) offers advanced positive-pressure processing of 96-well solid phase extraction (SPE) plates and individual SPE columns in a small footprint that conserves bench space and fits easily into suitably sized hoods. -

Page 13: Preparation And Setup

2 Preparation and setup 2.1 Safety advisories The Otto SPEcialist PPM is designed and engineered to meet or exceed all safety standards. Careless or abusive handling of this device, however, may still lead to possible hazardous situations. Exercise caution and comply with the following guidelines:... -

Page 14: Installing The Device

(approximately 84 mm) to 6.8 inches (approximately 173 mm). You can accommodate consumable stacks lower than 3.3 inches by adding a spacer under the consumable stack to raise it to a height within the standard processing range of 3.3 to 6.8 inches. Contact Waters for further information (see section Contacting Waters (Page iii)). -

Page 15: Operating Conditions

7. Ensure that the tablet and stylus are secured properly in the front panel's holder. 2.3 Operating conditions The Otto SPEcialist PPM is designed to perform optimally and safely under normal laboratory settings. Operate this device under the conditions outlined in section... -

Page 16: Operation

Otto SPEcialist's manifold during movement. Notice: The elevator mechanism in the Otto SPEcialist PPM is capable of exerting considerable force when pressing the manifold onto the consumables below. July 1, 2021, 715006867 Ver. 01... -

Page 17: Plate Slider

Notice: The plate slider in the Otto SPEcialist PPM has a recess in the base to aid in locating the consumable stack correctly in the slider tray. Ensure that any consumable stack in use is properly positioned within this recess or damage to the consumables may result from the pressure manifold. -

Page 18: Active Safety Shield

Otto SPEcialist's manifold during movement. Notice: The elevator mechanism in the Otto SPEcialist PPM is capable of exerting considerable force when pressing the manifold onto the consumables below. Positive pressure processing of SPE consumables using a system gas requires gas-tight sealing of a manifold over the column/plate consumables to be processed. -

Page 19: Virtual Safety Bars

between the safety shield and the top of the consumables. This safety feature helps prevent accidental insertion of anything in the space below the manifold. 3.4.3 Virtual safety bars When the manifold is in the Fully Open position and you want to close it for a processing step, the control screen displays a warning to keep fingers, hands, and objects out from underneath the manifold. -

Page 20: User Interface And Control

4 User interface and control 4.1 Device startup The Otto SPEcialist PPM is operated via a Microsoft Surface Pro tablet (with a user-friendly touchscreen interface), running Waters-proprietary control software (Otto-trademarked) on a Windows 10 or above operating system (OS). The control tablet is removable and may be coupled to the unit via a connective cable, giving you multiple options when working with the unit situated in a safety hood. -

Page 21: Device Functions

Control Mode when you tap Initialization on the software's main screen. 4.2 Device functions Although the Otto SPEcialist PPM is capable of executing sophisticated and complex methods, its basic usage derives from sequences composed of the following functions: •... -

Page 22: Control Screens

position over a consumable stack, the pressure forces liquids within the stack to flow through the columns or plate wells. The range of selectable pressures is 0.1 to 0.5 psi, in approximately 0.1 psi increments. • Creating pressure profiles. A pressure profile consists of a sequence of pressure settings executed over a user-specified time. -

Page 23: Load/Run Method Screen

Figure 4–4: Otto software main screen On the control tablet, tap to select the various functions as follows: • Load/Run Method – Opens the Load/Run Method screen. • Create Method – Opens the Create Method screen. • Pressure Profile – Opens the Pressure Profiles screen. •... -

Page 24: Create Method And Edit Method Screens

Figure 4–5: Load/Run Method screen Function details: • Method Folder – Field in which to type a unique name for a new folder. • Create Folder – Creates a folder for you to save profiles to. Note: To create a new folder, type a unique name in the Method Folder field, and then tap Create Folder. - Page 25 Figure 4–6: Edit Method screen Function details of the Edit Method screen: • Open Manifold – Adds an Open Manifold step into a method. • Close Manifold – Adds a Close Manifold step into a method. • Add Profile – Opens the Pressure Profiles screen, where you can select a pressure profile to add a method.

-

Page 26: Pressure Profiles And New/Edit Profile Screens

4.3.4 Pressure Profiles and New/Edit Profile screens Use the Pressure Profiles screen to select existing pressure profiles to add to a method and access additional screens for creating and editing new pressure profiles. Figure 4–7: Pressure Profiles screen Figure 4–8: Pressure Profiles screen, with folder created On the control tablet touchscreen, single-tapping a profile image selects and highlights it. - Page 27 Figure 4–9: New/Edit Profile screen Function details of the Pressure Profiles screen: • Drawing Mode – Opens the profile in Drawing Mode on the New/Edit Profile screen, where you can create new pressure profiles by drawing the desired profile on the screen. •...

- Page 28 Figure 4–10: New/Edit Profile screen, Drawing Mode Use the "+ Point" function to add inflection points to the profile, or remove them using the “- Point” function by tapping on the profile line. You can change the location of inflection points by first tapping on the point, and then tapping on the desired new location.

- Page 29 • Save and Save As – Saves the current profile with the existing name or a new name, respectively. • Open Manifold – Raises the manifold to the Current Consumable Height. • Close Manifold – Lowers the manifold to seal on top of the consumable stack. •...

- Page 30 • To edit a step, highlight it and select the field to edit within it, make the edit, and then tap Add/Edit Step on the control tablet when done. • To add a step, specify the new time (in seconds) and a pressure point, and then tap Add/ Edit Step on the control tablet when done.

-

Page 31: System Settings Dialog Box

• Up Single Arrow and Down Single Arrow – Increases or decreases the gas pressure in 0.1 psi increments, respectively. • Up Double Arrows and Down Double Arrows – Increases or decreases the gas pressure in 2.0 psi increments, respectively. •... - Page 32 • Open Steps – Determines the number of stepper motor steps that the manifold raises above the sealed position to allow plate or rack clearance to slide out from underneath the manifold, and determines the safety clearance height. • Change Password – Allows users to change their password. •...

-

Page 33: Building An Spe Method

5 Building an SPE method 5.1 Typical components of an SPE workflow To establish a context for the use of the Otto SPEcialist PPM, it is helpful to review the typical SPE method building process. Most SPE methods consist of multiple steps in which a liquid (solvent, buffer, or sample) is added to the SPE column or SPE plate well, and is then pushed through the sorbent bed by a positive gas pressure exerted on top of the consumable. -

Page 34: Developing An Spe Method

method development is largely dependent on testing flow rates for different protocol solvents, using the SPE consumables desired, and observing the flows visually. You can execute the SPE method building process from the Otto SPEcialist's Manual Profile control screen. 5.2 Developing an SPE method Most SPE methods contain a common sequence of steps, similar to the following: 1. -

Page 35: Executing The Pressure Profile

9. Save the profile, which is the “draft” profile to be executed for that step in the method. Waters recommends that you save the profile with a descriptive name that corresponds to the step in the method (for example, “Vitamin D Conditioning Step”). - Page 36 As a guide for a typical method, you can reference the sample method stored in the Otto SPEcialist library. To build an SPE method: 1. On the tablet touchscreen, tap Create Method. Alternative: Tap Load/Edit Method, select an existing method from the library, and then tap Edit Method.

-

Page 37: Care And Maintenance

The recommended daily maintenance routine includes the following tasks: Note: Waters also recommends yearly maintenance. Proper maintenance helps ensure device accuracy and performance. • Wipe down the device's surfaces using a clean cloth moistened with a mild solvent or cleanser. -

Page 38: A Safety Advisories

Heed all warnings when you install, repair, or operate any Waters instrument or device. Waters accepts no liability in cases of injury or property damage resulting from the failure of individuals to comply with any safety precaution when installing, repairing, or operating any of its instruments or devices. -

Page 39: Specific Warnings

(Risk of high-pressure gas release.) A.1.1 Specific warnings A.1.1.1 Burst warning This warning applies to Waters instruments and devices fitted with nonmetallic tubing. Warning: To avoid injury from bursting, nonmetallic tubing, heed these precautions when working in the vicinity of such tubing when it is pressurized: •... -

Page 40: Notices

A.1.1.2 Biohazard warning The following warning applies to Waters instruments and devices that can process biologically hazardous materials. Biologically hazardous materials are substances that contain biological agents capable of producing harmful effects in humans. Warning: To avoid infection from blood-borne pathogens, inactivated microorganisms, and other biological materials, assume that all biological fluids that you handle are infectious. -

Page 41: Bottles Prohibited Symbol

Use eye protection when performing this procedure. Requirement: Wear clean, chemical-resistant, powder-free gloves when performing this procedure. A.5 Warnings that apply to all Waters instruments and devices When operating this device, follow standard quality-control procedures and the equipment guidelines in this section. - Page 42 Advertencia: cualquier cambio o modificación efectuado en esta unidad que no haya sido expresamente aprobado por la parte responsable del cumplimiento puede anular la autorización del usuario para utilizar el equipo. 警告: 未经有关法规认证部门明确允许对本设备进行的改变或改装,可能会使使用者 丧失操作该设备的合法性。 警告: 未經有關法規認證部門允許對本設備進行的改變或修改,可能會使使用者喪失操 作該設備的權利。 경고 규정 준수를 책임지는 당사자의 명백한 승인 없이 이 장치를 개조 또는 변경할 경 우, 이...

- Page 43 Warnung: Bei der Arbeit mit Polymerschläuchen unter Druck ist besondere Vorsicht angebracht: • In der Nähe von unter Druck stehenden Polymerschläuchen stets Schutzbrille tragen. • Alle offenen Flammen in der Nähe löschen. • Keine Schläuche verwenden, die stark geknickt oder überbeansprucht sind. •...

- Page 44 튜브를 부풀려 튜브의 파열 압력을 크게 감소시킬 수 있으므로 유의하십시오. 警告 圧力のかかったポリマーチューブを扱うときは、注意してください。 • 加圧されたポリマーチューブの付近では、必ず保護メガネを着用してください。 • 近くにある火を消してください。 • 著しく変形した、または折れ曲がったチューブは使用しないでください。 • 非金属チューブには、テトラヒドロフラン(THF)や高濃度の硝酸または硫酸などを 流さないでください。 • 塩化メチレンやジメチルスルホキシドは、非金属チューブの膨張を引き起こす場合 があり、その場合、チューブは極めて低い圧力で破裂します。 This warning applies to Waters instruments fitted with nonmetallic tubing or operated with flammable solvents. July 1, 2021, 715006867 Ver. 01 Page 44...

-

Page 45: Warnings That Address The Replacement Of Fuses

Warning: The user shall be made aware that if the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. Avertissement : L’utilisateur doit être informé que si le matériel est utilisé d’une façon non spécifiée par le fabricant, la protection assurée par le matériel risque d’être défectueuses. - Page 46 Avertissement : pour éviter tout risque d'incendie, remplacez toujours les fusibles par d'autres du type et de la puissance indiqués sur le panneau à proximité du couvercle de la boite à fusible de l'instrument. Warnung: Zum Schutz gegen Feuer die Sicherungen nur mit Sicherungen ersetzen, deren Typ und Nennwert auf den Tafeln neben den Sicherungsabdeckungen des Geräts gedruckt sind.

-

Page 47: Electrical Symbols

警告: 为了避免火灾,应更换“维护步骤”一章的“更换保险丝”一节中介绍的相同类型和 规格的保险丝。 警告: 為了避免火災,更換保險絲時,應使用「維護步驟」章節中「更換保險絲」所 指定之相同類型與規格的保險絲。 화재의 위험을 막으려면 유지관리 절차 단원의 “퓨즈 교체” 절에 설명된 것과 동일 경고 한 타입 및 정격의 제품으로 퓨즈를 교체하십시오. 警告 火災予防のために、ヒューズ交換ではメンテナンス項目の「ヒューズの交換」 に記載されているタイプおよび定格のヒューズをご使用ください。 A.7 Electrical symbols The following electrical symbols and their associated statements can appear in instrument manuals and on an instrument’s front or rear panels. -

Page 48: Handling Symbols

A.8 Handling symbols The following handling symbols and their associated statements can appear on labels affixed to the packaging in which instruments, devices, and component parts are shipped. Symbol Description Keep upright! Keep dry! Fragile! Use no hooks! Upper limit of temperature Lower limit of temperature Temperature limitation July 1, 2021, 715006867 Ver. -

Page 49: B Specifications

B Specifications This section lists groups of individual specifications for the Otto SPEcialist PPM, as follows: • Physical specifications (Page 49) • Electrical specifications (Page 49) • Environmental and performance specifications (Page 50) The reproducibility of the operating specifications presented in this document depends on the conditions in individual laboratories. -

Page 50: Environmental And Performance Specifications

B.3 Environmental and performance specifications Table B–3: Otto SPEcialist PPM environmental and performance specifications Attribute Specification Sound pressure level ≤64 dBa Optimal environment Indoor, temperature regulated, non-dusty Operating pressure 0.5 to 40.0 psi (0.03 to 2.76 bar), settable in 0.1 psi increments Operating temperature 50 to 100 °F (10 to approximately 38 °C)

Need help?

Do you have a question about the Otto SPEcialist PPM and is the answer not in the manual?

Questions and answers