Table of Contents

Advertisement

Quick Links

English

Operating and Assembly Instructions

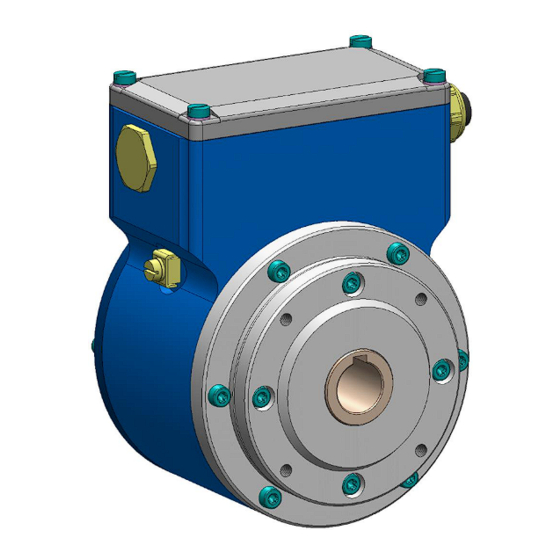

Hollow Shaft Absolute Encoder

AMSH 40 K-1312

ASSH 40 K-13

Read the Operating and Assembly Instructions prior to

assembly, starting installation and handling!

Keep for future reference!

Translation of the original

Operating and Assembly Instructions

AMSH_ASSH_MANUAL-en_R2(2022-01-19)ID78121.docx

ID 78121

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Hubner AMSH 40 K-1312

- Page 1 English Operating and Assembly Instructions Hollow Shaft Absolute Encoder AMSH 40 K-1312 ASSH 40 K-13 Read the Operating and Assembly Instructions prior to assembly, starting installation and handling! Keep for future reference! Translation of the original Operating and Assembly Instructions AMSH_ASSH_MANUAL-en_R2(2022-01-19)ID78121.docx...

- Page 2 Protected trademarks bearing a ™ or ® symbol are not always depicted as such in the manual. However, the statutory rights of the respective owners remain unaffected. Manufacturer / publisher Johannes Hubner Fabrik elektrischer Maschinen GmbH Siemensstr. 7 35394 Giessen...

-

Page 3: Table Of Contents

Hollow Shaft Absolute Encoder AMSH40 ASSH40 Directory 1 General ..........................5 1.1 Information about the Operating and Assembly Instructions ........5 1.2 Scope of delivery ....................... 5 1.3 Explanation of symbols ....................5 1.4 Disclaimer ........................6 1.5 Copyright ........................6 1.6 Guarantee terms ...................... - Page 4 Hollow Shaft Absolute Encoder AMSH40 ASSH40 6.3 Connecting the encoder (electrically) ................19 6.3.1 Connections ......................19 7 Connection diagram ......................20 8 Faults ..........................22 8.1 Fault table .........................22 9 Inspections ........................22 9.1 Safety instructions .....................22 10 Data transmission ......................23 10.1 Maintenance information ...................24 10.2 Inspection schedule ....................24 11 Disposal ..........................24 11.1 Disposal procedure ....................24...

-

Page 5: General

Hollow Shaft Absolute Encoder AMSH40 ASSH40 1 General 1.1 Information about the Operating and Assembly Instructions These Operating and Assembly Instructions provide important instructions for working with the device. They must be carefully read prior to starting all tasks, and the instructions contained herein must be followed. -

Page 6: Disclaimer

Hollow Shaft Absolute Encoder AMSH40 ASSH40 1.4 Disclaimer All information and instructions in these Operating and Assembly Instructions have been provided under due consideration of applicable guidelines, as well as our many years of experience. The manufacturer assumes no liability for damages due to: ... -

Page 7: Improper Use

Hollow Shaft Absolute Encoder AMSH40 ASSH40 2.3 Improper use Do not use the device in potentially explosive areas. The device must not be subjected to mechanical loads in addition to its own weight and unavoidable vibration and shock loads that arise during normal operations. Examples for non-permitted mechanical loads (incomplete list): Fastening transport or lifting tackle to the device, for example a crane hook to lift a motor. -

Page 8: Technical Data

Hollow Shaft Absolute Encoder AMSH40 ASSH40 3 Technical Data 3.1 Type plate Example type plate: The type plate is located on the outside of the housing and contains the following information: Manufacturer, Address Type, Year of construction CE marking ... -

Page 9: Electrical And Mechanical Data

Hollow Shaft Absolute Encoder AMSH40 ASSH40 3.2 Electrical and mechanical data Connection data 12…30 V DC Supply voltage For UL und CSA Class 2 supplied No-load power consumption approx. 1 W Resolution singleturn Max. 13 bit (8192 steps per revolution) see type plate Resolution multiturn Max. -

Page 10: Type Code

Hollow Shaft Absolute Encoder AMSH40 ASSH40 3.3 Type code 1312 Absolute encoder M = multiturn S = singleturn SSI Interface Hollow shaft design With isolated bearings – hybrid bearings – Series Connections K = Terminal box S = 15 pole EMC industrial plug T = 12-pole plug M 23 Resolution (see type plate) Singleturn 13 bit... -

Page 11: Transport, Packaging And Storage

Hollow Shaft Absolute Encoder AMSH40 ASSH40 4 Transport, packaging and storage 4.1 Safety instructions for transport CAUTION! Material damage caused by improper transport! Observe the symbols and information on the packaging: Do not throw - risk of breakage Keep dry ... -

Page 12: Installation And Commissioning

Hollow Shaft Absolute Encoder AMSH40 ASSH40 5 Installation and commissioning 5.1 Safety instructions NOTES! Observe the safety instructions contained in Chapter 2 when installing or working on the device! Personnel Installation and commissioning must be carried out by skilled technical staff only. 5.2 Technical information NOTES! Do not use a hammer or similar tool when installing the device due to the risk of damage... -

Page 13: Mounting Preparations

Hollow Shaft Absolute Encoder AMSH40 ASSH40 5.4 Mounting preparations 1. Ensure all accessories are available (please refer to chapter 13 dimension drawings). NOTES! Fastening screws and earth cable are not included in the range of supply. 2. Preparing the place of attachment: Clean the (motor) shaft, centering, bolting surfaces and fastening threads;... - Page 14 Hollow Shaft Absolute Encoder AMSH40 ASSH40 Grease lightly the adapter shaft (1). Secure the torque bracket (3) to the hollow-shaft device (12) with 4 tensilock screws (2). NOTES! When fitting to the device is possible to align the torque bracket in four different directions. If possible fit the device in a manner that ensures the cable gland points downwards! Exchange the position of the cable gland (11) and the blanking plug on the opposite side, if necessary.

-

Page 15: Mounting Hollow Shaft Type Absolute Encoder With Locking Element

Hollow Shaft Absolute Encoder AMSH40 ASSH40 5.6 Mounting hollow shaft type absolute encoder with locking element Figure.2 1. Mount adapter shaft (1) and align using dial gauge. NOTES! The maximum radial run-out of the adapter shaft is 0.05 mm. If necessary, use the ball thrust adjustment screw to align the adapter shaft. Secure ball ®... - Page 16 Hollow Shaft Absolute Encoder AMSH40 ASSH40 2. Grease lightly the adapter shaft (1). 3. Slide the locking element (14) onto the adapter shaft until it stops. 4. Secure the torque bracket (3) to the hollow-shaft device (12) with 4 tensilock screws (2). NOTES! When fitting to the device is possible to align the torque bracket in four different directions.

-

Page 17: Electrical Connection And Start Up

Hollow Shaft Absolute Encoder AMSH40 ASSH40 5.7 Electrical connection and start up NOTES! You must observe applicable EMC guidelines when routing cables! NOTES for UL and CSA! Do only use copper cables 5.7.1 Preparing cables 1. Strip cable insulation. 2. Crimp wire-end ferrules. 5.7.2 Electrical connection 1. - Page 18 Hollow Shaft Absolute Encoder AMSH40 ASSH40 6. Connect the supply voltage and signal cable (please refer to the connection diagrams, chapter 7). CAUTION! Do not apply supply voltage to the signal outputs, as this will destroy the device! 7. Applicable to alternative shield connection only: fit cable lug to cable shield and connect to the shield terminal (please refer to the connection diagrams, chapter 12).

-

Page 19: Dismantling

Hollow Shaft Absolute Encoder AMSH40 ASSH40 6 Dismantling 6.1 Safety instructions Personnel Dismantling must be carried out by skilled technical staff only. WARNING! Observe the safety instructions contained in Chapter 2 when dismantling the device! NOTES! Do not use a hammer or similar tool when installing the device due to the risk of damage occurring to the bearings or coupling! Dismantling the absolute encoder To dismantling the absolute encoder follow the instructions given in chapters 5.5, and 5.7 in the... -

Page 20: Connection Diagram

Hollow Shaft Absolute Encoder AMSH40 ASSH40 7 Connection diagram AMSH / ASSH 40 Standard Terminal box AMSH / ASSH 40 PN178-440 EMC industrial plug AMSH_ASSH_MANUAL-en_R2(2022-01-19)ID78121.docx... - Page 21 Hollow Shaft Absolute Encoder AMSH40 ASSH40 AMSH 40 12-pole plug M 23 ASSH 40 AMSH_ASSH_MANUAL-en_R2(2022-01-19)ID78121.docx...

-

Page 22: Faults

Hollow Shaft Absolute Encoder AMSH40 ASSH40 8 Faults 8.1 Fault table Faults Possible cause Remedy Soiled gasket or seal surfaces of Clean gasket of terminal box terminal box cover cover and seal surfaces Damaged gasket of terminal box Replace gasket of terminal box cover cover Moisture in the terminal box... -

Page 23: Data Transmission

Hollow Shaft Absolute Encoder AMSH40 ASSH40 10 Data transmission Data transmission: Data transmission is effected acc. to SSI processing (Serial Synchronous Interface). This means the encoder input „CLCK“ and CLCKG“ (inverted) will be supplied with sets of 25 clockpulses (AMSH) or 13 clockpulses (ASSH) through an opto coupler input for electrical isolation. Synchroneously 25 data bits (AMSH) or 13 data bits (ASSH) will be available at the output „DATA“... -

Page 24: Maintenance Information

Hollow Shaft Absolute Encoder AMSH40 ASSH40 Status-output A signal indicating operation of the encoder will be generated on the output „Status“ as follows: While operating accurately a high level will be generated on „Status“. Low on signal „Status“ indicates non-correct operating of the SSI encoder. Control input V/R Position values when the shaft rotates clockwise. -

Page 25: Spare Parts

Hollow Shaft Absolute Encoder AMSH40 ASSH40 12 Spare Parts The in the following listed spare parts can be covered when required about the service address on the page 2. Spare part Remark Cover Cover of the hollow- shaft bore (non drive end) Cable gland M20 x 1,5 Terminal box cover... -

Page 26: Dimension Drawings

Hollow Shaft Absolute Encoder AMSH40 ASSH40 13 Dimension drawings Further dimension drawings on our website or on request. 13.1 Construction type hollow shaft design AMSH(J) 40K / 20P HM 13 M 106280 With radial terminal box ASSH(J) 40 K / 20 P HM 15 M 108973 AMSH_ASSH_MANUAL-en_R2(2022-01-19)ID78121.docx... - Page 27 Hollow Shaft Absolute Encoder AMSH40 ASSH40 AMSH(J)40K / 16K HM 12 M 105299 With lateral terminal box ASSH(J)40K / 16K HM 15 M 109066 AMSH_ASSH_MANUAL-en_R2(2022-01-19)ID78121.docx...

- Page 28 Hollow Shaft Absolute Encoder AMSH40 ASSH40 Additional dimension drawing AMS 40 T / ASS 40 T HM 15 M 109157 12-pole plug M 23 (not for UL/CSA) AMSH_ASSH_MANUAL-en_R2(2022-01-19)ID78121.docx...

Need help?

Do you have a question about the AMSH 40 K-1312 and is the answer not in the manual?

Questions and answers