Table of Contents

Advertisement

English

Operating and Assembly Instructions

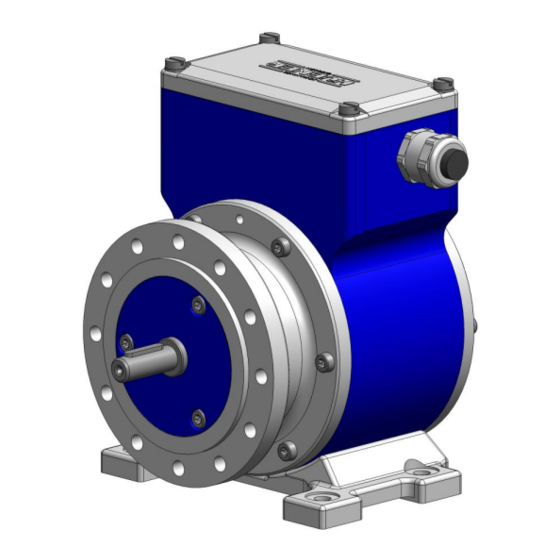

Incremental Encoder FG 40

Read the Operating and Assembly Instructions prior to

assembly, starting installation and handling!

Keep for future reference!

Translation of the original Operating and Assembly Instructions

FG40_MANUAL-en_R12(2018-10-31)ID74490.doc

ID 74490

Advertisement

Table of Contents

Summary of Contents for Hubner FG 40 Series

- Page 1 English Operating and Assembly Instructions Incremental Encoder FG 40 Read the Operating and Assembly Instructions prior to assembly, starting installation and handling! Keep for future reference! Translation of the original Operating and Assembly Instructions FG40_MANUAL-en_R12(2018-10-31)ID74490.doc ID 74490...

- Page 2 It is strictly forbidden to reproduce this publication or parts of this publication in any form or by any means without the prior written permission of Johannes Hubner Fabrik elektrischer Maschinen GmbH. Subject to errors and changes due to technical improvements.

-

Page 3: Table Of Contents

Incremental Encoder FG 40 Directory 1 General ..........................5 1.1 Information about the Operating and Assembly instructions ........5 1.2 Scope of delivery ....................... 5 1.3 Explanation of symbols ....................5 1.4 Disclaimer ........................6 1.5 Copyright ........................6 1.6 Guarantee terms ......................6 1.7 Customer service ....................... - Page 4 Incremental Encoder FG 40 5.7 Mounting tolerances for construction type B5 and B35 ..........21 5.8 Attaching additional devices ..................22 5.9 Electrical connection and start up ................24 5.9.1 Preparing cables ....................24 5.9.2 Electrical connection .....................24 6 Dismantling ........................26 6.1 Safety instructions .....................26 6.2 Dismantling the encoder ...................26 7 Faults ..........................27 7.1 Faults table .......................27...

-

Page 5: General

Incremental Encoder FG 40 1 General 1.1 Information about the Operating and Assembly instructions These Operating and Assembly Instructions provide important instructions for working with the device. They must be carefully read prior to starting all tasks, and the instructions contained herein must be followed. -

Page 6: Disclaimer

Incremental Encoder FG 40 1.4 Disclaimer All information and instructions in these Operating and Assembly Instructions have been provided under due consideration of applicable guidelines, as well as our many years of experience. The manufacturer assumes no liability for damages due to: ... -

Page 7: Improper Use

Incremental Encoder FG 40 2.3 Improper use Do not use the device in potentially explosive areas. The device must not be subjected to mechanical loads in addition to its own weight and unavoidable vibration and shock loads that arise during normal operations. Examples for non-permitted mechanical loads (incomplete list): Fastening transport or lifting tackle to the device, for example a crane hook to lift a motor. -

Page 8: Technical Data

Incremental Encoder FG 40 3 Technical Data 3.1 Type plates Nameplates for different device variations are shown below Encoder with one terminal box Encoder with 2 terminal boxes (redundant version) Encoder with 2 sinusoidal signals The type plate is located on the outside of the housing and contains the following information: ... -

Page 9: Electrical And Mechanical Data

Incremental Encoder FG 40 3.2 Electrical and mechanical data 3.2.1 For pulse rates (square wave pulses) Pulse rates Value Standard pulse rates 500, 600, 1000, 1024, 1200, 2000, 2048, 2400, 2500 4000, 4096, 4800, 5000, 8192, 10000, 12000, 16000, 16384, 20000, 25000, 40000, 50000 Special pulse rates (further pulse rates according to customers specification) -

Page 10: Output Signals Sine / Cosine

Incremental Encoder FG 40 3.2.2 Output signals Sine / Cosine Pulse rates Value Standard pulse rates 500, 600, 1000, 1024, 1200, 2000, 2048, 2400, 2500 Connection data 5 V … 30 V DC Supply voltage No load-current Approx. 120 mA at 5 V, approx. 50 mA at 24 V Max. - Page 11 Incremental Encoder FG 40 Protection class Sealing Permissible Rotor moment of Breakaway torque acc. to inertia speed DIN EN 60529 ≤ 6000 min IP65 Standard 510 gcm² 6 Ncm ≤ 6000 min IP66 with labyrinth seal 580 gcm² 6 Ncm 510 gcm²...

- Page 12 Incremental Encoder FG 40 Signal outputs Basic version Basic channel 0° (A) and pulse channel 90° (B) Internal system diagnostics with error output (ERROR) Each with inverted signals Option N Reference pulse (N) mechanically defined; one square-wave pulse per revolution; with inverted signal Option 2F Twice as many pulses as basic channel by...

- Page 13 Incremental Encoder FG 40 Signal outputs for output signals sine / cosine Basic channel 0° (A) and pulse channel 90° (B). Reference pulse (N) mechanically defined; one square-wave pulse per revolution; with inverted signal Each with inverted signal. Internal system diagnostics with error output (ERROR).

-

Page 14: Type Code

Incremental Encoder FG 40 3.3 Type code 3.3.1 For pulse rates (square wave pulses) 1024 Incremental encoder Series connections, radial design Terminal box ® Burndy -plug Connection cable Fiber optic connection 15-pole EMC industrial plug 2 terminal boxes, i.e. redundant version or with option S further combined connections available connections, axial design... -

Page 15: For Output Signals Sine / Cosine

Incremental Encoder FG 40 3.3.2 For output signals Sine / Cosine 1024 Incremental encoder Series connections, radial design Terminal box ® Burndy -plug Connection cable Fiber optic connection 15-pole EMC industrial plug 2 terminal boxes, i.e. redundant version Resolution 1024 signal periods per revolution Output signals 2 sinusoidal signals A and B each with inverted signals Option reference pulse with inverted signal... -

Page 16: Transport, Packaging And Storage

Incremental Encoder FG 40 4 Transport, packaging and storage 4.1 Safety instructions for transport CAUTION! Material damage caused by improper transport! Observe the symbols and information on the packaging: Do not throw - risk of breakage Keep dry ... -

Page 17: Mounting And Commissioning

Incremental Encoder FG 40 5 Mounting and commissioning 5.1 Safety instructions Personnel Installation and commissioning must be carried out by skilled technical staff only. NOTES! Observe the safety instructions contained in Chapter 2 when installing or working on the device! 5.2 Technical information NOTES! Do not use a hammer or similar tool when installing the device due to the risk of damage... -

Page 18: Mounting Preparations

Incremental Encoder FG 40 5.4 Mounting preparations 1. Ensure all accessories are available (please refer to Chapter 11 Dimension drawings). NOTES! Fastening screws and earth cable are not included in the range of supply. 2. Preparing the place of attachment: Clean the (motor) shaft, centering, bolting surfaces and fastening threads;... - Page 19 Incremental Encoder FG 40 1. Lightly grease the (motor) shaft (1) and centering (9). 2. Fit coupling (2) onto (motor) shaft. NOTES! You must be able to mount the coupling without force. Ream out the bores of used couplings, if necessary! 3.

-

Page 20: Mounting B35 Type (Flange And Foot) Incremental Encoders

Incremental Encoder FG 40 5.6 Mounting B35 type (flange and foot) incremental encoders NOTES! B35 type encoders can be attached by means of a flange (B5, please refer to Chapter 5.5) or foot (B3): For a mounting example please refer to dimension drawing HM 09 M 102 240a (Chapter 11.2). Figure 2: FG 40 construction type B35 1. -

Page 21: Mounting Tolerances For Construction Type B5 And B35

Incremental Encoder FG 40 4. Align the encoder shaft (5) to the (motor) shaft and insert into the coupling hub. NOTES! Use shims (19) to achieve the correct vertical alignment to the base plate (20). Observe information in Chapter 5.7about mounting errors and max. permissible mounting tolerances! 5. -

Page 22: Attaching Additional Devices

Incremental Encoder FG 40 5.8 Attaching additional devices NOTES! Encoders in construction type B5/B14 have a second shaft end with integrated coupling half (1) and a B 14 flange (2) on the non-drive end onto which it is possible to fit an additional device with a B5 flange, for example an incremental encoder, absolute shaft encoder or an overspeed switch. - Page 23 Incremental Encoder FG 40 WARNING! If no second device is added ensure the cover plate is fitted to protect and cover the second shaft end. Figure 4: 3. Slide on the coupling half (5) with elastomer ring up to the collar of the shaft of the additional device (7), and secure by tightening the grub screw (6).

-

Page 24: Electrical Connection And Start Up

Incremental Encoder FG 40 Electrical connection and start up NOTES! You must observe applicable EMC guidelines when routing cables! 5.9.1 Preparing cables 1. Strip cable insulation. 2. Crimp wire-end ferrules. 5.9.2 Electrical connection 1. Open the terminal box cover (16, Fig.1). CAUTION! Do not allow moisture to enter the terminal box when the cover is open! 2. - Page 25 Incremental Encoder FG 40 NOTES! Prevent lateral pulling forces acting on the cable and plugs so as not to impair the degree of protection of the cable gland. 6. Connect the supply voltage and signal cable (please refer to the connection diagrams, Chapter 11).

-

Page 26: Dismantling

Incremental Encoder FG 40 6 Dismantling 6.1 Safety instructions Personnel Dismantling must be carried out by skilled technical staff only. WARNING! Observe the safety instructions contained in Chapter 2 when inspecting or working on the device! NOTES! Do not use a hammer or similar tool when installing the device due to the risk of damage occurring to the bearings or coupling! 6.2 Dismantling the encoder Remove all electrical cables from the device before dismantling. -

Page 27: Faults

Signal end stage overloaded Check pin assignment; observe connection diagram Do not assign unused outputs Signal interruptions Outputs short-circuited Do not connect outputs with supply voltage or GND Contact Hubner-Service (page 2) if none of the remedies listed above provides a solution)! FG40_MANUAL-en_R12(2018-10-31)ID74490.doc... -

Page 28: Inspections

Incremental Encoder FG 40 8 Inspections 8.1 Safety instructions WARNING! Skilled technical staff only are permitted to inspect the device and its installation. Observe the safety instructions contained in Chapter 2 when inspecting or working on the device! 8.2 Maintenance information The device is maintenance-free. -

Page 29: Dimension Drawings

Incremental Encoder FG 40 11 Dimension drawings Further dimension drawings on our website or on request. 11.1 Construction type B5 (flange) FG 40 K With radial terminal box HM 08 M 57 221a FG 40 AK With axial terminal box HM 08 M 57 024a FG40_MANUAL-en_R12(2018-10-31)ID74490.doc... - Page 30 Incremental Encoder FG 40 FG 40 KK Redundant version HM 08 M 57 223a Mounting example for construction type B5 FG 40 K HM 09 M 57 263a with flange and coupling HK 522 FG40_MANUAL-en_R12(2018-10-31)ID74490.doc...

-

Page 31: Construction Type B35 (Flange And Foot)

Incremental Encoder FG 40 11.2 Construction type B35 (flange and foot) FG 40 K With radial terminal box HM 08 M 57 222a FG 40 KK Redundant version HM 08 M 57 224a FG40_MANUAL-en_R12(2018-10-31)ID74490.doc... - Page 32 Incremental Encoder FG 40 Mounting example for construction type B35 FG 40 K HM 09 M 102 240a With coupling HKD 522 FG40_MANUAL-en_R12(2018-10-31)ID74490.doc...

-

Page 33: Construction Type B5/B14 (Flange With 2 Shaft Ends)

Incremental Encoder FG 40 11.3 Construction type B5/B14 (flange with 2 shaft ends) Construction type B5/B14 FG 40 K HM 09 M 102 541 (flange with 2 shaft ends) FG40_MANUAL-en_R12(2018-10-31)ID74490.doc... - Page 34 Incremental Encoder FG 40 FG 40 KK redundant version HM 09 M 102 549 FG40_MANUAL-en_R12(2018-10-31)ID74490.doc...

-

Page 35: Construction Type B35/B14 (Flange And Foot With 2 Shaft Ends)

Incremental Encoder FG 40 11.4 construction type B35/B14 (flange and foot with 2 shaft ends) construction type B35/B14 FG 40 K HM 09 M 102 280 (flange and foot with 2 shaft ends) FG40_MANUAL-en_R12(2018-10-31)ID74490.doc... - Page 36 Incremental Encoder FG 40 FG 40 KK redundant version HM 09 M 101 548 FG40_MANUAL-en_R12(2018-10-31)ID74490.doc...

-

Page 37: Mounting Options

Incremental Encoder FG 40 11.5 Mounting options FG 40 K FG 40 K with coupled unit HM 09 M 102 245 FG40_MANUAL-en_R12(2018-10-31)ID74490.doc... - Page 38 Incremental Encoder FG 40 FG 40 KK FG 40 KK with coupled unit HM 09 M 102 627 FG40_MANUAL-en_R12(2018-10-31)ID74490.doc...

-

Page 39: Additional Dimension Drawings - Electrical Socket Design

Incremental Encoder FG 40 11.6 Additional dimension drawings – electrical socket design additional dimension drawing FG 40 R/RR HM 09 M 102 270 electrical socket design FG 40 R/RR FG40_MANUAL-en_R12(2018-10-31)ID74490.doc... -

Page 40: Incremental Encoder Fg

Incremental Encoder FG 40 additional dimension drawing FG 40 L/LL HM 09 M 103063 electrical socket design FG 40 L/LL FG40_MANUAL-en_R12(2018-10-31)ID74490.doc... - Page 41 Incremental Encoder FG 40 FG 40 S/SS additional dimension drawing electric connection implementation FG 40 S/SS HM 12 M 105755 15 pole EMC FG40_MANUAL-en_R12(2018-10-31)ID74490.doc...

-

Page 42: Connection Diagrams

Incremental Encoder FG 40 12 Connection diagrams Shielding: The shield of the signal cable can be connected directly to the housing of the encoder by the cable gland. Alternatively the shield of the signal cable can be connected to K11 via a capacitor(10nF / 500V) to the housing of the encoder FG 40... - Page 43 Incremental Encoder FG 40 Socket insert view Crimp contacts for cross-sectional data of wire from 0,52 up to 1,5 mm² Shield: The shield of the signal cable is directly to be connected with the socket housing. ® Crimping tool: Burndy No.

- Page 44 Incremental Encoder FG 40 12 pole printed circuit spring terminal block type Phoenix ZFKDS Connection data: Wire section 0,2-1,5 [ mm² ] Shielding: The shield of the signal cable can be connected directly to the housing of the encoder by the cable gland.

- Page 45 Incremental Encoder FG 40 12 pole printed circuit spring terminal block type Phoenix ZFKDS Connection data: Wire section 0,2-1,5 [ mm² ] Shielding: The shield of the signal cable can be connected directly to the housing of the encoder by the cable gland.

- Page 46 Incremental Encoder FG 40 FG 40 connection sheme PN 109-470 terminal box FG40_MANUAL-en_R12(2018-10-31)ID74490.doc...

- Page 47 Incremental Encoder FG 40 FG 40 connection sheme PN 109-415 EMC industrial plug FG 40 connection sheme 649 Option S Burndy plug FG40_MANUAL-en_R12(2018-10-31)ID74490.doc...

- Page 48 Incremental Encoder FG 40 FG 40 connection sheme 148 400b Sine /cosine output FG40_MANUAL-en_R12(2018-10-31)ID74490.doc...

Need help?

Do you have a question about the FG 40 Series and is the answer not in the manual?

Questions and answers