Summary of Contents for TapFlo PT CIP

- Page 1 IOM manual PT High Pressure Hose Pumps Original Instruction 2021 | 2 Read this instruction manual carefully, before you install and operate the pump Pump models:...

-

Page 2: Table Of Contents

Instruments ........................... 12 1.10.1. Electric power ........................12 1.10.2. Optional instruments ....................... 12 1.10.3. Thermometer ........................12 1.10.4. Pressure safety device ..................... 12 1.11. Motor connection ........................ 13 1.12. Gear-motor standard ......................13 OPERATION ..........................14 IOM manual Tapflo Hose Pumps... - Page 3 Spare parts list PT25 – PT40 ....................36 4.5. Exploded view PTX40 – PT65 ....................38 4.6. Spare parts list PTX40 – PT65 ....................38 4.7. Exploded view PTX80 – PT80 ....................40 4.8. Spare parts list PTX80 – PT80 ....................40 IOM manual Tapflo Hose Pumps...

- Page 4 5.4.2. PT25 – PT80 .......................... 49 5.5. Tightening torques ........................50 5.6. Permitted loads on manifolds ....................51 WARRANTY ..........................52 6.1. Warranty form .......................... 52 6.2. Returning parts ........................53 6.3. Warranty ........................... 53 IOM manual Tapflo Hose Pumps...

-

Page 5: Ec Declaration Of Conformity 02/Ec/Pt/2021

Text with EEA relevance Mr Michał Śmigiel is authorized to compile the technical file. Tapflo Sp. z o.o. ul. Czatkowska 4b 83-110 Tczew Signed for and on behalf of Tapflo AB Håkan Ekstrand Managing director Tapflo AB, 14.05.2021 r. -

Page 6: General

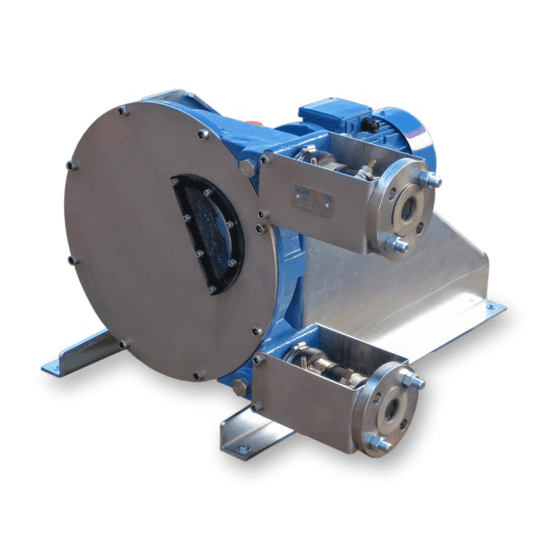

0.1. Introduction The Tapflo Hose Pump range is a series of pumps for industrial and hygienic applications. The pumps are designed to be safe, simple and easy to use and maintain. The pumps are suitable for almost all different liquids used by the industry today. -

Page 7: Nameplate

0.4. Nameplate The nameplate is made in the below design. It is made of AISI 304 stainless steel and placed on the pump stand or discharge flange bracket. Nameplate dimensions are 38 x 48 mm. IOM manual Tapflo Hose pumps... -

Page 8: Installation

1.1. Operation principle The Tapflo hose pump is driven by a gear-motor. The rotor is installed directly on the shaft. It is equipped with shoes or has a special shape itself. The shoes compress the hose creating vacuum on the suction side of the pump and pressure on the discharge to transfer the liquid. -

Page 9: Storage

The way the piping is arranged and the positioning of the components has a great influence on the operation and the lifetime of the pump. The pump cannot be used as a support for the components connected to it. IOM manual Tapflo Hose pumps... -

Page 10: Connection Of Suction Pipe

The pumps are tested with water. If the pumped product can come into reaction with water, please make sure the pump is dry before putting it into operation. IOM manual Tapflo Hose pumps... -

Page 11: Protection

(please contact Tapflo for interval proposals). Ambient temperature limits are form -20ºC to +40ºC. NOTE! If ambient temperature is below 0 ºC, add antifreeze to the lubricant inside the pump. -

Page 12: Rotating Parts

During pump installation provide enough space to be able to perform hose replacement procedure. Please follow the guidline below: PUMP L [mm] PUMP L[mm] PT40 1000 PT10 PTX40 1200 PT15 PT50 1400 PT20 PT65 1400 PT25 PTX80 1600 PT32 1000 PT80 2000 IOM manual Tapflo Hose pumps... -

Page 13: Instruments

IOM manual Tapflo Hose pumps... -

Page 14: Motor Connection

1.12. Gear-motor standard As a standard Tapflo Hose pump are equipped with gear-motors of the following parameters: ➢ International Mounting Arrangement – B5 ➢ Number of poles / Rotation speed [rpm] – 4 / ~1400 ➢... -

Page 15: Operation

The performance of the pump can be adjusted by means of a frequency inverter. The pump operation does not depend upon the direction of rotation and can achieve full capacity in both directions of rotation. IOM manual Tapflo Hose pumps... -

Page 16: Dry Running

The pump should be stopped by cutting of electrical power to the motor or frequency inverter (if used – at 50 Hz cool down should be set to 5 seconds). NOTE! Never stop the pump by completely closing the discharge valve without motor shut down. IOM manual Tapflo Hose pumps... -

Page 17: Cleaning And Disinfection

In addition, the currently handled fluid and the corresponding safety data sheet must be taken into account. When fluid leakage occurs, the power supply has to be closed and the pressure released. During spillage of an aggressive liquid, local and national safety rules must be followed. IOM manual Tapflo Hose pumps... -

Page 18: Maintenance

The intervals for a complete inspection depend upon the operation conditions of the pump. The characteris of the liquid, temperature, materials used in the pump and running time decide how often a complete inspect is necessary. Nevertheless, Tapflo recommends to inspect the pump at least once a year. IOM manual Tapflo Hose pumps... -

Page 19: Location Of Faults

If a problem has occurred, or if the pump is in need of a complete inspection, refer to chapters 3.5 "Locatio faults" and 3.6 "Disassembly of the pump". You are of course warmly welcome to consult Tapflo for further h Parts that are subject to wear should be kept in stock, see our recommendations in chapter 4.7 “... -

Page 20: Disassembly Of The Pump

3.6.1. Before the disassembly procedure Be sure to drain all liquid from the pump. Cleanse or neutralize the pump thoroughly. Disconnect the electrical connection, air supply and then the suction and discharge connections. IOM manual Tapflo Hose pumps... -

Page 21: Disassembly Procedure

/ insert [70] with he flange rings [71/73]. Fig. 3.6.5 Fig. 3.6.6 Loosen the big clamp band [271] and remove all Remove the boot covers [270]. clamp bands form the pump. IOM manual Tapflo Hose pumps... - Page 22 Remove the front cover [12] with its seal [18]. Unscrew the clamping set bolts and remove the NOTE! In big pump sizes, the front cover is very complete clamping set [16]. heavy and requires special removing procedure. IOM manual Tapflo Hose pumps...

- Page 23 Remove the gearmotor along with the seal ring [162]. Fig. 3.6.17 Fig. 3.6.18 Remove the shaft seal [161]. Unscrew the gearmotor mounting stud bolts [111]. Unscrew the casing mounting bolts [174] and remove them with their washers [175]. IOM manual Tapflo Hose pumps...

-

Page 24: Test Run

We recommend you to conduct a test run of the pump before installing it in the system, so no liquid gets wasted if the pump leaks or perhaps does not start accordingly to wrong assembly of the pump. After two weeks of operation retighten the nuts with appropriate torque. IOM manual Tapflo Hose pumps... -

Page 25: Lubricant Emptying And Filling Procedure

In order to fill the pump with lubricant, remove the [11]. Use PTFE tape to seal the connection. sight glass [41] and its gasket [42] by unscrewing the sight glass mounting screws [411] and washers [412]. IOM manual Tapflo Hose pumps... - Page 26 Fill the pump casing [11] with appropriate amount of lubricant (see chapter 5.2. Technical data for more information). The appropriate level of the lubricant inside the pump is: ➢ Below the shaft for PT5 – PT20; ➢ Below the bottom edge of the sight glass for PT25 – PT80. IOM manual Tapflo Hose pumps...

-

Page 27: Hose Cleaning

Remove the insert [70] and, if applicable, the flange Follow steps 3.9.1a and 3.9.2 on the discharge side of ring [71/73]. the pump. Additionally, unscrew the bracket bolts [171] and remove the brackets [170]. Remove the clamp bands [272] and [273]. IOM manual Tapflo Hose pumps... - Page 28 Fig. 3.9.5a PT25 – PT80 Fig. 3.9.5b PT5 – PT20 Pre-assemble the flange ring [71/73] using two bolts Pre-assemble the bracket [170] on the discharge side on the discharge side of the pump. of the pump. IOM manual Tapflo Hose pumps...

- Page 29 [71/73] into the hose and tighten Disassemble the flange ring and brackets on the the clamp bans [272] and [273]. discharge side. NOTE! Tapflo lubricant may be used to ease assembly of the insert into the hose. IOM manual Tapflo Hose pumps...

- Page 30 Fix the bracket [170] with the mounting bolts [171] and block the insert with the circlip [274]. Tighten the clamp bands. NOTE! Tapflo lubricant may be used to ease assembly of the insert into the hose. 71 73 Fig. 3.9.13a PT25 – PT80 Fig.

-

Page 31: Pump Casing Cleaning Procedure

NOTE! PT80 – PT125 pumps are equipped with a dedicated lifting lug on top of the front cover. IOM manual Tapflo Hose pumps... - Page 32 Check condition of the shaft seal [161] and seal ring Wash the casing with water and remove any debris left [162] and replace if necessary. inside the casing. Fig. 3.10.7 Dry the pump casing thoroughly and reassemble the pump cover. IOM manual Tapflo Hose pumps...

-

Page 33: Shoe Shimming - Pt25 - Pt80

Fig. 3.11.4 Unscrew the sight glass bolts [411] and remove the Slightly unscrew the shoe mounting bolt [901]. sight glass [41] with its gasket [42]. NOTE! Check condition of the gasket and replace if necessary. IOM manual Tapflo Hose pumps... - Page 34 NOTE! There should always be the same amount of shims on both shoes. Fig. 3.11.9 Re-connect the power to the motor and jog run until the other shoe comes in front of the sight glass. IOM manual Tapflo Hose pumps...

-

Page 35: Spare Parts

15 – PT high pressure hose pump xxx – pump size 18 – part position NOTE! Use only Original Tapflo spare parts. Using counterfeit parts creates a risk of improper operation, increases possibility of breakdown and voids warranty terms. 4.1. - Page 36 Breather plug PA/NBR/AISI304 Breather plug elbow AISI 316L Insert AISI 316L, PP-H Rotor Nodular cast iron / Aluminum 4 for PT5-PT10 / 8 for PT15-PT20 Only for PT15-PT20 2 for PT5-10 / 1 for PT15-20 IOM manual Tapflo Hose pumps...

-

Page 37: Exploded View Pt25 - Pt40

Casing mounting bolt A4-70 Casing mounting washer A4-70 Casing seal EPDM, NBR Boot cover EPDM, NBR Clamp band big – casing AISI 304 Clamp band small – hose AISI 316 2-piece hose clamp Zinc plated steel IOM manual Tapflo Hose pumps... - Page 38 AISI 316L Rotor Nodular cast iron Shim AISI 304L Shoe Nodular cast iron Shoe centering pin Shoe mounting bolt A4-70 Shoe mounting spring washer A4-80 Shoe mounting washer A4-70 6 for PT25 / 7 for PT32-PT40 IOM manual Tapflo Hose pumps...

-

Page 39: Exploded View Ptx40 - Pt65

Connection bracket Galvanized steel, AISI 304L Connection bracket bolt A4-70 Connection bracket washer A4-70 Casing mounting bolt A4-70 Casing mounting washer A4-70 Eye bolt Zinck plated steel Casing seal EPDM, NBR Boot cover EPDM, NBR IOM manual Tapflo Hose pumps... - Page 40 Shoe centering pin Shoe mounting bolt A4-70 Shoe mounting spring washer A4-80 Shoe mounting washer A4-70 10 for PTX40 / 15 for PT50-PT65 4 PTX40 / 10 for PT50-PT65 10 for PTX40 / 14 for PT50-PT65 IOM manual Tapflo Hose pumps...

-

Page 41: Exploded View Ptx80 - Pt80

1.7035 steel Spacer ring 1.7035 steel Taper bush flange Cast iron 1641 Taper bush flange mounting bolts Zinc plated steel Taper bush flange mounting nuts 1642 Seal flange Steel 1651 Seal flange mounting screw M10x16 A4-70 IOM manual Tapflo Hose pumps... - Page 42 Nodular cast iron Shoe centering pin Shoe mounting bolt M20x75 A4-70 Shoe mounting spring washer M20 Shoe mounting washer M20 Zinc plated steel 2 for PTX80 / 4 for PT80 Only for PT80 Only for PTX80 IOM manual Tapflo Hose pumps...

-

Page 43: Stocking Recommendation

4.10. How to order parts When ordering spare parts for Tapflo pumps, please let us know what is the model number and serial number from the pump centre body or housing. Then just indicate the part numbers from the spare parts list and quantity of each item. -

Page 44: Pump Code

VI. Special executions VII. Motor power VIII. Output rpm IX. Motor options A R- 1S3X -05 PT = Tapflo Hose pump = Optional connection type A = ANSI/ASME B16.5 Class 150 Flange II. Pump series: B = BSP male thread... -

Page 45: Data

See below how the capacity will change at different viscosities and suction lifts. Intermittent duty = 1 hour stop for every 2 hours of operation. Occasional duty = not more than 1 hour per day. IOM manual Tapflo Hose pumps... - Page 46 DATA IOM manual Tapflo Hose pumps...

-

Page 47: Technical Data

Weight with biggest gearmotor [kg] / [lb] 650 / 1433 930 / 2050 Lubricant volume [l] / [US Gallon] 27 / 40 / 10.6 * Max temperature can depend on hose material utilized in the pump. IOM manual Tapflo Hose pumps... -

Page 48: Shimming Tables

20-27 ΔP = differential pressure 5.4. Dimensions Dimensions in mm (where other is not indicated) Dimensions in inch (where other is not indicated) General dimensions only, ask us for detailed drawings. Changes reserved without notice. IOM manual Tapflo Hose pumps... -

Page 49: 5.4.1. Pt5 - Pt20

18.78 18.78 4 x Ø9 4 x Ø9 4 x Ø13 4 x Ø13 ØQ 4 x 0.35 4 x 0.35 4 x 0.51 4 x 0.51 14.96 14.96 17.13 17.13 10.28 10.28 12.80 12.80 IOM manual Tapflo Hose pumps... -

Page 50: 5.4.2. Pt25 - Pt80

4 x Ø27 ØQ 4 x 0.51 4 x 0.51 4 x 0.51 4 x 0.75 4 x 0.77 4 x 0.77 4 x 0.77 4 x 1.06 DN25 DN32 DN40 DN40 DN50 DN65 DN80 DN80 EN1092-1 IOM manual Tapflo Hose pumps... -

Page 51: Tightening Torques

What is more, for proper operation and safety the torque values should be checked frequently as part of preventive maintenance (please contact Tapflo for interval proposals). Although pump applications vary, a general guideline is to re-torque the pump every two weeks. -

Page 52: Permitted Loads On Manifolds

We recommend not to exceed the following loads and forces reacting on the manifolds. Load Force Load Force Pump size Direction Pump size Direction [Nm] [Nm] [Nm] [Nm] PT5 – PT10 PTX40 PT15 – PT20 PT50 PT25 PT65 PT32 PTX80 1640 PT40 PT80 1110 IOM manual Tapflo Hose pumps... -

Page 53: Warranty

%, of max size [mm]: Flow [l/min]: Duty [h/day]: No of starts per day: Discharge head [bar]: Suction head / lift [m]: Air pressure [bar]: Quality of the air (filter, micron, lubrication): Other: Place for sketch of installation: IOM manual Tapflo TE series... -

Page 54: Returning Parts

6.3. Warranty Tapflo warrants products under conditions as stated below for a period of not more than 5 years from installation and not more than 6 years from date of manufacturing. 1. The following terms and conditions apply to the sale of machinery, components and related services and products, of Tapflo (hereinafter “the products”). - Page 55 9. Tapflo will not be liable on any claim, whether in contact, tort, or otherwise, for any indirect, special, incidental, or consequential damages, caused to the customer or to third parties, including loss of profits, arising by any possible infringement of par.

Need help?

Do you have a question about the PT CIP and is the answer not in the manual?

Questions and answers