Table of Contents

Advertisement

Quick Links

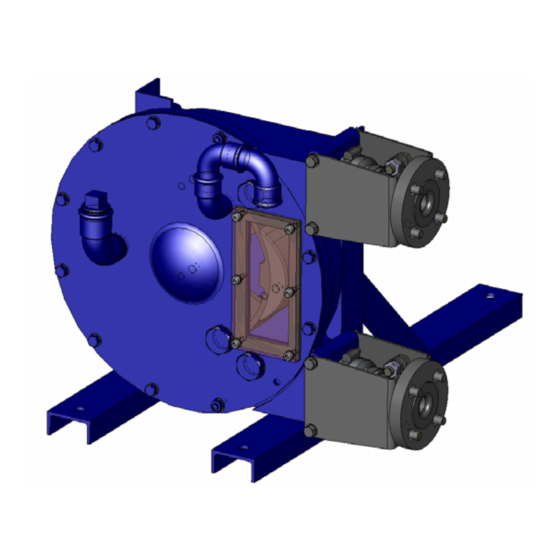

PUMPS A25 - AS25

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

contact@mouvex.com - www.mouvex.com

INSTRUCTIONS 1101-D00 e

Section

Effective

Replaces

Original instructions

INSTALLATION

OPERATION

MAINTENANCE

Your distributor :

3, Poruchik Nedelcho Bonchev Str., . 5

1528 So a, Bulgaria

tel: +359 2 973 27 67

e-mail: o ce@daisglobal.eu

1101

August 2010

July 2010

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Mouvex AS25

- Page 1 Section 1101 Effective August 2010 Replaces July 2010 Original instructions PUMPS A25 - AS25 INSTALLATION OPERATION MAINTENANCE Your distributor : 3, Poruchik Nedelcho Bonchev Str., . 5 1528 So a, Bulgaria Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE tel: +359 2 973 27 67 Tel.

-

Page 2: Table Of Contents

• 160 tr/mn (rpm) 1.2 AS25 model ........4 •... -

Page 3: Overall Dimensions

1. OVERALL DIMENSIONS 1.1 A25 model NT 1101-D00 08.10 A25 - AS25 e 3/19... -

Page 4: As25 Model

1. OVERALL DIMENSIONS (continued) 1.2 AS25 model NT 1101-D00 08.10 A25 - AS25 e 4/19... -

Page 5: Installation

15 % of the internal diameter of the hose). the same diameter as the pipes and, by preference, be a full bore model. You can contact our Technical Services at any time to ask for the information you require. NT 1101-D00 08.10 A25 - AS25 e 5/19... -

Page 6: Direction Of Rotation

• A25 .........108 kg (238 lb) • AS25 ......56 kg (123 lb) The MOUVEX pump is reversible, this allows it to always circulate the liquid in the desired direction by choosing the corresponding direction of rotation. -

Page 7: Anchoring The Pump Units

Three phase motor : switch any two wires of the current supply. Two phase motor : switch the two wires of the same phase. Single phase motor : comply with the instructions of the manual supplied with the motor. NT 1101-D00 08.10 A25 - AS25 e 7/19... -

Page 8: Use

With products including particles that settle at shutdown, it is necessary to ensure that the consistency of the deposi- ted products will not affect the start-up of the pump. NT 1101-D00 08.10 A25 - AS25 e 8/19... -

Page 9: Maintenance Operations

1. Provide sufficient clearance as described in § PUMP LOCATION. 2. Drain the lubricant by unscrewing the level plug 57 and collect the lubricant in a tub. 3. Put the lubricant level plug 57 back in place. NT 1101-D00 08.10 A25 - AS25 e 9/19... - Page 10 4. Wash the inside of the pump body 1 and the cover 2 with water or a cleaning product that is compatible with the pump materials. Also wash the wheel (front + back). NT 1101-D00 08.10 A25 - AS25 e 10/19...

- Page 11 6. 13. Tighten the hose clamp 9 (the screw should be tigh- tened to the stop) onto the hose 16. TOP PORT Repeat the previous steps from 1 to 13. NT 1101-D00 08.10 A25 - AS25 e 11/19...

-

Page 12: Re-Assembling And Disassembling The Wheel

3. Insert the parts of the hub 19 in the wheel center. NOTE Screws 19a must not be tightened so the wheel assembly can freely slide along the axis. 4. Slide wheel 3 with its hub 19 on the axis. NT 1101-D00 08.10 A25 - AS25 e 12/19... -

Page 13: Setting Of Pump At Service Pressure Needed

3. Drain the pump of his lubricant following the instruc- Repeat the previous steps from 1 to 13. tions of the § DISASSEMBLING THE HOSE. NOTE There must be the same number of shims under each shoe. NT 1101-D00 08.10 A25 - AS25 e 13/19... - Page 14 ANY SPILLS MUST BE CLEANED UP. 3. Screw the plug 124. Slippery lubricant. Spills should be cleaned up. NOTES Handle the lubricant with care. Wear suitable clothes and protect yourself from pump lubricant spatters. NT 1101-D00 08.10 A25 - AS25 e 14/19...

-

Page 15: Technical Specifications

10000 Max service @70°C Max service @80°C 5000 Continuous service Intermittent service Rotation speed (rpm) ATEX certified Abaque pumps have specific limits for use. Refer to corresponding Instructions Manual for more informations. NT 1101-D00 08.10 A25 - AS25 e 15/19... -

Page 16: Characteristics

< 60°C (140°F) > 60°C (140°F) < < 7,5 (108,75) 5 (72,5) < < 10 (145) 7,5 (108,75) < < 15 (217,5) 10 (145) NT 1101-D00 08.10 A25 - AS25 e 16/19... -

Page 17: Maintenance

6. MAINTENANCE 6.1 Lubrication 6.3 Seals The hose is lubricated with a special mixture. MOUVEX 6.3.1 SHAFT SEAL 26 lubricant is recommended to lengthen the service life of The shaft seal 26 must be replaced if lubricant leakage the hose. -

Page 18: Troubleshooting

The pumped fluid contains impurities or Reverse the pump rotation direction and use the upper PULLED INTO sediments. port for inlet. THE PUMP Clamp 9 is not sufficiently tightened. Retighten the clamp. BODY AT INLET NT 1101-D00 08.10 A25 - AS25 e 18/19... -

Page 19: Certificate Of Conformity

Quality Manager MOUVEX sas : Z.I La Plaine des Isles – 2, rue des Caillottes - 89000 AUXERRE – France – SAS au capital de 8 496 855 € Tél : (33) 3.86.49.86.30 – Fax : (33) 3.86.46.42.10 – RCS AUXERRE 389 236 548 – APE 291 B – FR 85 389 236 548 – www.mouvex.com...

Need help?

Do you have a question about the AS25 and is the answer not in the manual?

Questions and answers