Table of Contents

Advertisement

Quick Links

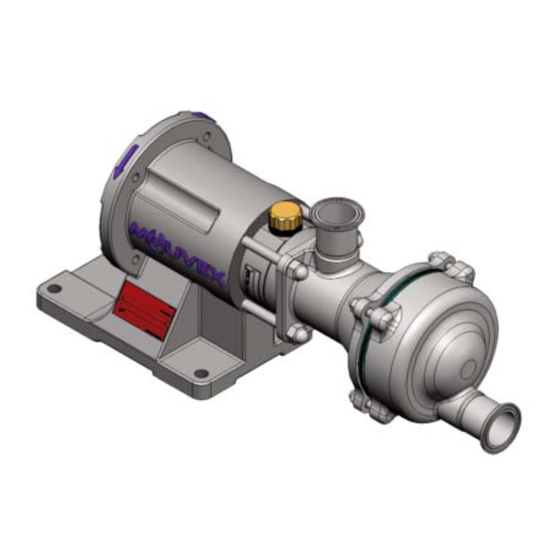

SLC1 - SLC2 - SLC3

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

contact@mouvex.com - www.mouvex.com

PUMPS

3, Poruchik Nedelcho Bonchev Str., . 5,1528 So a, Bulgaria

INSTRUCTIONS 1004-A00 e

Section

1004

Effective

February 2013

Replaces

January 2013

Original instructions

INSTALLATION

OPERATION

MAINTENANCE

Your distributor :

tel: +359 2 973 27 67

e-mail: o ce@daisglobal.eu

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Mouvex SLC1

- Page 1 INSTRUCTIONS 1004-A00 e Section 1004 Effective February 2013 Replaces January 2013 Original instructions SLC1 - SLC2 - SLC3 PUMPS INSTALLATION OPERATION MAINTENANCE Your distributor : 3, Poruchik Nedelcho Bonchev Str., . 5,1528 So a, Bulgaria tel: +359 2 973 27 67 Z.I.

-

Page 2: Table Of Contents

Pompe dis = 8,8 barg = 9,8 bara • SLC1 ....16 bar* (232 psi) ∆ • SLC2 ....10 bar* (145 psi) -

Page 3: Overall Dimensions

Pumps SLC1 - SLC2 - SLC3 with connections CROSS-SECTION B-B Filling / Breather CROSS-SECTION A-A Draining Connections Weight kg [lb] Smooth end-fitting* * CAUTION : When welding the connections, the below should be protected. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 3/32... - Page 4 CROSS-SECTION B-B Others Butt-welded pipe Ø Ø L on CROSS-SECTION A-A Filling / Breather Draining Flanges Weight kg [lb] * Connect-S ® is a registered trademark owned by NEUMO. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 4/32...

- Page 5 1. OVERALL DIMENSIONS (continued) T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 5/32...

- Page 6 1. OVERALL DIMENSIONS (continued) T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 6/32...

- Page 7 The detection bearings are adjusted in the plant and should not be modified. The transmission may only be dismantled in the plant. Weight added to the pump : 0,5 kg T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 7/32...

- Page 8 Filling / Breather Draining CROSS-SECTION A-A Connections Weight kg [lb] Smooth end-fitting* C1 interchangeable option * CAUTION : When welding the connections, the below should be protected. (1)+(2) C2 interchangeable option T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 8/32...

- Page 9 Filling / Breather Draining Ø Ø L on CROSS-SECTION A-A Flanges Weight kg [lb] C1 interchangeable option ® * Connect-S is a registered trademark owned by NEUMO. (1)+(2) C2 interchangeable option T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 9/32...

- Page 10 1. OVERALL DIMENSIONS (continued) T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 10/32...

- Page 11 1. OVERALL DIMENSIONS (continued) T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 11/32...

- Page 12 1. OVERALL DIMENSIONS (continued) T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 12/32...

- Page 13 1. OVERALL DIMENSIONS (continued) Pumps SLC1 - SLC2 - SLC3 Motor flange NEMA 145TC T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 13/32...

- Page 14 LIQUID STEAM The entry connection may be connected to one or two points. If it is done at 1 point, the warming up process will be less effective. LIQUID T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 14/32...

- Page 15 1. OVERALL DIMENSIONS (continued) T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 15/32...

- Page 16 1. OVERALL DIMENSIONS (continued) T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 16/32...

-

Page 17: Installation

(particularly if there are water hammers). This type of operation could damage the bellows and short- en its service life. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 17/32... -

Page 18: Unit Assembly

(if the need arises, use the values given on the overall dimension drawing). For staff and equipment protection, the frame includes a ground connection point that should be used. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 18/32... - Page 19 : and suitable fuses. Connect the regulatory electrical grounding. Make this check for 4 points : up - down - left - right Correct Out-of-parallelism Angular defect T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 19/32...

-

Page 20: Use

• excluding cavitation • max. differential pressure : 3.4 Stopping the pump SLC1 ..16 bar (232,11 psi) • So as not to damage the pump, make sure that the SLC2 ..10 bar (145 psi) •... -

Page 21: Clean In Place (Cip) & Sterilisation In Place (Sip)

SLC pump and is 10 m the bypass circuit. This flow corresponds to difficult cleaning (sticky and vis- cous products). It can be reduced for easier types of cleaning. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 21/32... -

Page 22: Pumps Arranged In Parallel

6 barg (87 psig). Max pressure 6 barg (87 psig) SLC Pump pump stopped when cleaning SLC pump the installation. The pump must not run during this operation. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 22/32... -

Page 23: Successive Cycles

During all these CIP stages, the average speed of the cleaning liquids in the pipes must be between 1,5 and 3 m/s (59 in/sec and 118 in/s). T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 23/32... -

Page 24: Maintenance

• M10 : ....30 Nm • M30 (piston nut) : ..40 Nm T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 24/32... - Page 25 309 with a 36 open-end spanner. It is important to keep a good grip on the piston, its rotation could lead to deterioration of the bel- lows. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 25/32...

-

Page 26: Checking The Cylinder/Piston Couple

12,9 12,9 (0,506) (0,506) (0,506) Piston 301 10,9 10,9 10,9 (0,427) (0,427) (0,427) (1,335) (1,335) (1,335) Cylinder 201 (1,256) (1,256) (1,256) * Loctite ® is a registered trade mark. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 26/32... - Page 27 When tightening nut 309, comply with the assembly torque of 40 Nm. * Loctite ® is a registered trade mark. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 27/32...

-

Page 28: Transmission Disassembly/Reassembly

• Inspect the bellows : it must be replaced if there are any traces of impact, scratches or distortion. DO NOT FORGET TO REMOVE THE PROTECTION BEFORE INSTALLING THE CYLINDER. * Loctite ® is a registered trade mark. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 28/32... -

Page 29: Draining The Bearing

* Standard oil supplied by MOUVEX : CS05 synthetic food grade oil (the safety data sheet is supplied with the new pump and available on request). * Other oil supplied by the customer. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 29/32... -

Page 30: Options

596, the temporary support 922A and screws 921 must be used. Pressure switch 922A This system can also be used for storage or transport of the transmission on its own. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 30/32... -

Page 31: Storage

This protection should also prevent condensation. The pump should be turned a few revolutions manually every two months. T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 31/32... -

Page 32: Certificate Of Conformity

10. CERTIFICATE OF CONFORMITY T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e 32/32...

Need help?

Do you have a question about the SLC1 and is the answer not in the manual?

Questions and answers