Table of Contents

Advertisement

Quick Links

INSTALLATION and OPERATION MANUAL

Submersible Non-Clog Pumps

IMPORTANT!

Read all instructions in this manual before operating pump.

As a result of Crane Pumps & Systems, Inc., constant product improvement program,

product changes may occur. As such Crane Pumps & Systems reserves the right to

change product without prior written notifi cation.

A Crane Co. Company

420 Third Street

Piqua, Ohio 45356

Phone: (937) 778-8947

Fax: (937) 773-7157

www.cranepumps.com

Manual Index

BARNES

BARNES

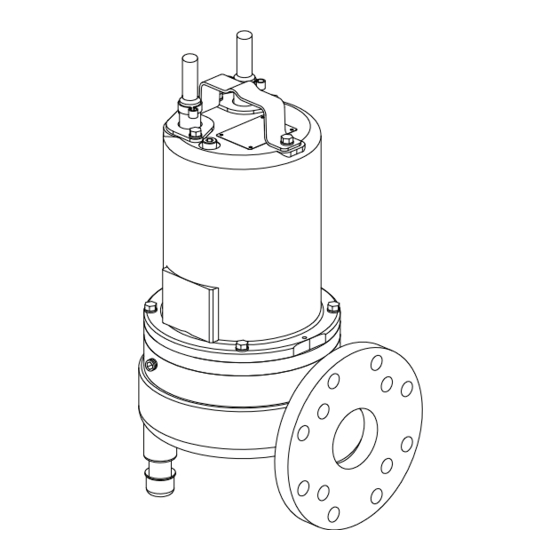

Series: 4SE-L & DS

.9, 1.4 & 1.9 HP, 1750RPM, 60 Hz.

Single and Double Seal

83 West Drive, Bramton

Ontario, Canada L6T 2J6

Phone: (905) 457-6223

Fax: (905) 457-2650

®

Form No. 105242-Rev. V

Advertisement

Table of Contents

Summary of Contents for Crane BARNES 4SE-L Series

- Page 1 Read all instructions in this manual before operating pump. As a result of Crane Pumps & Systems, Inc., constant product improvement program, product changes may occur. As such Crane Pumps & Systems reserves the right to change product without prior written notifi cation.

-

Page 2: Table Of Contents

PRESSURE GAUGE KIT (see parts list) Other brand and product names are trademarks or registered trademarks of their respective holders. ® Barnes is a registered trademark of Crane Pumps & Systems, Inc 1999, 2002, 5/04, 1/06, 9/06 Alteration Rights Reserved... -

Page 3: Safety First

WARNING! - DO NOT pump hazardous materials IMPORTANT! - Crane Pumps & Systems, Inc. is not (fl ammable, caustic, etc.) unless the pump is specifi cally responsible for losses, injury, or death resulting from a designed and designated to handle them. -

Page 4: Pump Specifications

SECTION: A - PUMP SPECIFICATIONS - SINGLE SEAL DISCHARGE ....3” (76) & 4” 125 lb. Horizontal Flange UPPER BEARING: LIQUID TEMPERATURE 104°F (40°C) Intermittent Design ..Single Row, Ball, Oil Lubricated MOTOR HOUSING ..Cast Iron ASTM A-48, Class 30 Load ..... - Page 5 SECTION: A - PUMP SPECIFICATIONS - DOUBLE SEAL DISCHARGE ....3” (76) & 4” 125 lb. Horizontal Flange LIQUID TEMPERATURE 104°F (40°C) Intermittent UPPER BEARING: MOTOR HOUSING ..Cast Iron ASTM A-48, Class 30 Design ..Single Row, Ball, Oil Lubricated VOLUTE ......

-

Page 6: General Information

For the location of the nearest Barnes Service Center, check the fl oor of the station and connect the discharge pipe to the your Barnes representative or Crane Pumps & Systems, Inc., elbow. Service Department in Piqua, Ohio, telephone (937) 778-8947 or Crane Pumps &... - Page 7 TYPICAL INSTALLATION WITH WIDE ANGLE 120 Volt 1 Phase LEVEL CONTROL Automatic Manual FIGURE 3 Automatic - Plug fl oat cord into outlet, then plug pump cord into fl oat cord. Manual - Plug pump cord directly into outlet C-4) Electrical Connections: An acceptable motor control switch shall be provided at the time of installation.

-

Page 8: Electrical Data

MODEL NO VOLT/PH NEMA INSUL. FULL LOCKED CORD CORD CORD WINDING RESISTANCE (Nom) START CLASS LOAD ROTOR SIZE TYPE Emerson Franklin G.E. CODE AMPS AMPS inch (mm) Main-Start Main-Start Main-Start 4SE914L 120/1 1750 11.6 21.3 14/3 SJTOW 0.373 (9.5) 1.51-16.10 4SE924L 240/1 1750... -

Page 9: Preventative Maintenance

D-2.1) Incorrect Rotation for Three-Phase Pumps: F-1.2) Testing Oil: In the event that the rotation is incorrect for a three-phase 1.) Place pump on it’s side, remove pipe plug (39), from motor installation, interchange any two power cable leads at the housing (6) and drain oil into a clean, dry container. - Page 10 If, after fi ve minutes, the pressure is still holding constant, and no “bubbles”/oil seepage is observed, slowly bleed the pressure and remove the gauge assembly. If the pressure does not hold, then the leak must be located and repaired. Seal Chamber (DS Units Only)- Set unit on its side with fi...

- Page 11 FIGURE 6 - SINGLE SEAL FIGURE 8 F-3.2) Reassembly: Inner Seal (DS Units Only)- Clean and oil seal cavities in seal plates (5, 29). Lightly oil (DO NOT use grease) outer surface of stationary member (28a). Press stationary member (28a) fi...

- Page 12 FIGURE 13 It is extremely important to keep seal faces clean during assembly. Dirt particles lodged between these faces will cause the seal to leak. Place spring (28c) over shaft and in place on rotating member (28b), making sure it is seated on retainer and not cocked or resting on bellows tail.

- Page 13 Check motor capacitor (9, single phase units) with an Ohm Make internal wiring connections which are independent of meter by fi rst grounding the capacitor by placing a screwdriver the terminal block as shown, using connectors (48) and wire across both terminals and then removing screwdriver. Connect assemblies (49) as required.

-

Page 14: Replacement Parts

SECTION: G REPLACEMENT PARTS G-3 MODEL NUMBER: This designation consists of numbers and letters which G-1 ORDERING REPLACEMENT PARTS: represent the discharge size, series, horsepower, motor When ordering replacement parts, ALWAYS furnish the phase and voltage, speed and pump design. This number is following information: used for ordering and obtaining information. - Page 15 FIGURE 15 - CONTIUED...

-

Page 16: Trouble Shooting

TROUBLE SHOOTING CAUTION ! Always disconnect the pump from the electrical power source before handling. If the system fails to operate properly, carefully read instructions and perform maintenance recommendations. If operating problems persist, the following chart may be of assistance in identifying and correcting them: MATCH “CAUSE”... -

Page 17: Single Seal - Cross-Section (Fig. 16)

4SE- L Series, Single Seal FIGURE 16... -

Page 18: Single Seal - Exploded View (Fig. 17)

4SE- L Series, Single Seal FIGURE 17... -

Page 19: Double Seal - Cross-Section (Fig. 18)

4SE-DS Series, Double Seal FIGURE 18... -

Page 20: Double Seal - Exploded View (Fig. 19)

4SE-DS Series, Double Seal FIGURE 19... -

Page 21: Parts List

PARTS KITS Seal Repair Kits: Single Seal ....P/N - 130180 (+) 20, 27, 28, 36 Double Seal ...P/N - 130176 (†) 20, 27, 28, 32, 36 Service Kits: Single Seal .....P/N - 130207 (◊) 19, 20, 22, 24, 25, 27, 28, 36, 49, 65, 66 Double Seal ...P/N - 130172 () 19, 20, 22, 24, 25, 27, 28, 32, 36, 44, 49, 65, 66 Seal Tool Kit ....P/N - 107271... - Page 22 † ◊ Shaft Seal: (Qty 2 for DS) 005080 Carbon/Ceramic/Buna-N (STD) 005080SB Tungsten/Tungsten/Buna-N 005080SD Silicon Carbide/Silicon Carbide/Buna-N 005080SF Carbon/Ceramic/Viton 005080SH Tungsten/Tungsten/Viton 005080SK Silicon Carbide/Silicon Carbide/Viton 005080SM Silicon Carbide/Tungsten/Buna-N 005080SN Carbon/Ni-Resistant/Buna-N 005080SP Carbon/Ni-Resistant/Neoprene 082850 Carbon/Ni-Resistant/Viton 103587 Seal Housing All double seal †...

- Page 23 TABLE 2 - POWER & SENSOR CORD SETS CABLE ITEM #16 ITEM #16 ITEM #16 ITEM #56 ITEM #56 LENGTH 240 VOLT 240 VOLT 3 PHASE (OPTIONAL) (OPTIONAL) 1 PHASE 1 PHASE Temperature Moisture and Temperature 3 Phase Sensor 3 Phase or Moisture (plug Sensor included)

- Page 24 Notes...

-

Page 26: Returned Goods Policy

Crane Pumps & Systems, Inc. Distributor. RETURNED GOODS RETURN OF MERCHANDISE REQUIRES A “RETURNED GOODS AUTHORIZATION”. CONTACT YOUR LOCAL CRANE PUMPS & SYSTEMS, INC. DISTRIBUTOR. Products Returned Must Be Cleaned, Sanitized, Or Decontaminated As Necessary Prior To Shipment, To Insure That Employees Will Not Be Exposed To Health Hazards In Handling Said Material.

Need help?

Do you have a question about the BARNES 4SE-L Series and is the answer not in the manual?

Questions and answers