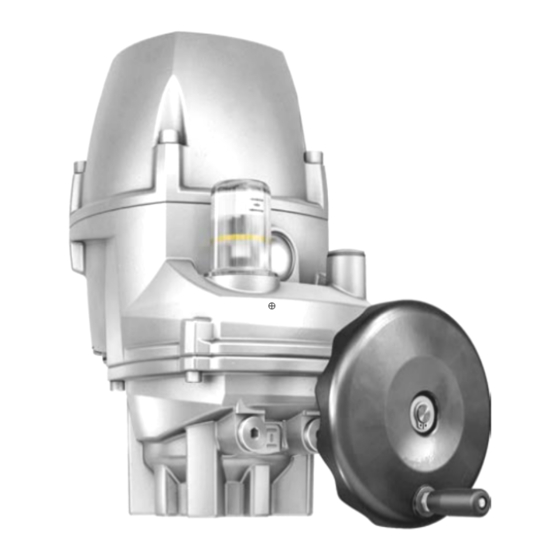

AUMA PROFOX PF-M25 Operation Instructions Manual

Multi-turn actuators

Hide thumbs

Also See for PROFOX PF-M25:

- Operation instructions manual (48 pages) ,

- Short instructions (12 pages) ,

- Short instructions (16 pages)

Summary of Contents for AUMA PROFOX PF-M25

- Page 1 Multi-turn actuators PROFOX PF-M25 PF-M100 Control Parallel Profibus DP Modbus RTU Operation instructions Assembly and commissioning...

- Page 2 Set end position OPEN 7.2. Position indicator setting 7.3. Configuration of further parameters 7.3.1. Speed setting Operation..........................8.1. Manual operation 8.2. Motor operation 8.2.1. Actuator operation via push buttons 8.2.2. Actuator operation via AUMA Assistant App 8.2.3. Actuator operation from Remote...

-

Page 3: Table Of Contents

PF-M25 PF-M100 Parallel Table of contents FOX-EYE indication light and status indication..............Corrective actions........................10.1. Faults during commissioning 10.2. Fault indications Servicing and maintenance....................Disposal and recycling......................Technical data......................... 13.1. Technical data Multi-turn actuators with integral controls for open-close and modulating duty Spare parts.......................... - Page 4 Any device modification requires prior written consent of the manufacturer. 1.2. Range of application AUMA multi-turn actuators are designed for the operation of industrial valves, e.g. globe valves, gate valves, butterfly valves and ball valves. Other applications require explicit (written) confirmation by the manufacturer.

- Page 5 PF-M25 PF-M100 Parallel Safety instructions Buried service Continuous underwater use (observe enclosure protection) Potentially explosive atmospheres Radiation exposed areas in nuclear power plants No liability can be assumed for inappropriate or unintended use. Observance of these operation instructions is considered as part of the device's designated use.

- Page 6 App and software Using the AUMA CDT software for Windows-based computers (notebooks or tablets) and the AUMA Assistant App, actuator data can be uploaded and read, settings can be modified and stored. The connection between computer and AUMA actuator is established wireless via Bluetooth interface. With the AUMA Cloud, we provide an interactive platform to collect and assess e.g.

- Page 7 AUMA actuators at moderate cost. AUMA Cloud The AUMA Cloud collects all device data of all actuators within one site and provides a clear overview at a glance. Detailed analysis provides valuable information on potential maintenance requirements.

- Page 8 PF-M25 PF-M100 Name plate Parallel Name plate Figure 4: Name plate arrangement Figure 5: PROFOX name plate (example) Product name Type designation Order number Actuator serial number Torque range in direction OPEN/CLOSE Control Speed range Current type, mains voltage, mains frequency Type of duty [10] Permissible ambient temperature...

- Page 9 Positions 3+4: Year of manufacture = 2020 NS12345 Internal number for unambiguous product identification When registered as authorised user, you may use our AUMA Assistant App to scan Data Matrix code the Data Matrix code and directly access the order-related product documents without having to enter order number or serial number.

- Page 10 PF-M25 PF-M100 Transport and storage Parallel Transport and storage 4.1. Transport For transport to place of installation, use sturdy packaging. Suspended load! Death or serious injury. Do NOT stand below suspended load. Attach ropes or hooks for the purpose of lifting by hoist only to housing and NOT to handwheel.

- Page 11 PF-M25 PF-M100 Parallel Assembly Assembly 5.1. Mounting position The product described in this document can be operated without restriction in any mounting position. 5.2. Fit ball handle to handwheel To avoid damage during transport, the ball handle is fitted at the rear of the handwheel.

- Page 12 PF-M25 PF-M100 Assembly Parallel 5.3.2. Mount actuator (with coupling) Unbored couplings or couplings with pilot bore must be machined to match the valve shaft prior to mounting the actuator to the valve (e.g. with bore and keyway, two-flat or square bore). Assemble valve and actuator in the same end position.

- Page 13 Valve shaft Grub screw Clamping washer and screw with curved spring lock washer Figure 9: Mounting positions for coupling Table 3: Mounting position of the coupling within fitting dimensions according to AUMA definition Dimensions M100 [mm] EN ISO 5211 X max.

- Page 14 PF-M25 PF-M100 Assembly Parallel Fit actuator. If required, slightly turn actuator until splines of coupling engage. Figure 10: Mounting the actuator onto valve Ensure complete contact of flanges. Information If flange bores do not match thread: 7.1 Slightly rotate handwheel until bores line up. 7.2 If required, shift actuator by one tooth on the coupling.

- Page 15 It can plan also be requested from AUMA (state order number, refer to name plate) or downloaded directly from the Internet (http://www.auma.com). The actuators are suitable for use in TN and TT networks. For IT network, a suitable, Permissible networks approved insulation monitor measuring the pulse code is required.

- Page 16 PF-M25 PF-M100 Electrical connection Parallel We recommend using connecting cables and connecting terminals according Connecting cables, to rated current (I ) (refer to motor or electrical data sheet). cable glands, reducers, blanking plugs For device insulation, appropriate (voltage-proof) cables must be used. Specify cables for the highest occurring rated voltage.

- Page 17 PF-M25 PF-M100 Parallel Electrical connection Insert cable glands [5]. The enclosure protection IP… stated on the name plate is only ensured if suit- able cable glands are used. Figure 12: Example: Name plate for enclosure protection IP68 Tighten cable glands and blanking plugs with the appropriate torque in compli- ance with the manufacturer's specifications.

- Page 18 PF-M25 PF-M100 Electrical connection Parallel Connect mains cable according to order-related wiring diagram. Table 5: Terminal cross sections Designation Wire type Cross section min. [mm²] max. [mm²] Mains cable rigid/flexible 0.08 AWG 28 AWG 12 Connect signal cables in push-in technology according to order-related wiring diagram.

- Page 19 PF-M25 PF-M100 Parallel Electrical connection PE connection In case of a fault, electric shock due to presence of hazardous voltage if the PE conductor is NOT connected! Risk of death or serious injury! Connect all protective earth conductors. Connect PE connection to external protective earth conductor of connecting cables.

- Page 20 PF-M25 PF-M100 Electrical connection Parallel 6.4. Close terminal compartment Figure 16: Terminal compartment: close Cover Screws O-ring Short-circuit and electric shock due to pinching of cables! Risk of death or serious injury! Carefully assemble cover to avoid pinching the cables. Clean sealing faces of cover [1] and housing.

- Page 21 PF-M25 PF-M100 Parallel Electrical connection Figure 17: Earth connection External earth connection (U-bracket) for connection to equipotential compensation. Application Table 8: Terminal cross sections and earth connection tightening torques Conductor type Terminal cross sections Tightening torques solid 2.5 mm² to 6 mm² 4 Nm flexible 1.5 mm²...

- Page 22 End position setting (via push buttons) In case of torque seating: Check factory torque setting! The end positions may also be set using the AUMA Assistant App or the AUMA CDT software. Valve damage at valve/gearbox due to incorrect setting! When setting with motor operation: Interrupt operation in time prior to reaching the end stop.

- Page 23 PF-M25 PF-M100 Parallel Commissioning 7.1.1. Set end position CLOSED Electric shock due to presence of hazardous voltage! Failure to observe this warning results in death or serious injury. Electrical connection and commissioning must be carried out exclusively by suitably qualified personnel if circuit is live. Do not touch any cables.

- Page 24 PF-M25 PF-M100 Commissioning Parallel While LED is flashing in blue, hold down push button for at least two seconds until the LED is illuminated in red. The end position CLOSED setting has been successfully completed. 7.1.2. Set end position OPEN Electric shock due to presence of hazardous voltage! Failure to observe this warning results in death or serious injury.

- Page 25 PF-M25 PF-M100 Parallel Commissioning Once the desired end position OPEN has been reached, release the push button The LED continues flashing in blue for approx. 10 seconds. This time span al- lows for end position setting. While LED is flashing in blue, hold down push button for at least two seconds until the LED is illuminated in green.

- Page 26 PF-M25 PF-M100 Commissioning Parallel Risk of valve damage in case of incorrect selection of stem pitch! Order position indicator suitable for the valve. The position indication is auto-adjusting during commissioning. Upon delivery, both the yellow position indication disc and the white end position indication ring are flush with the housing.

- Page 27 Commissioning 7.3. Configuration of further parameters Either the AUMA Assistant App or AUMA CDT software is required to use the complete range of configuration options. The user level defines which parameters are displayed or can be changed. For further information relating to user levels and passwords, please refer to...

- Page 28 PF-M25 PF-M100 Commissioning Parallel Speed in % of the maximum motor speed Output drive speed in rpm 1.4 rpm 14 rpm 0.6 rpm 6 rpm 36 % 83 % 43 % 100 % 50 % — 71 % — 100 % —...

- Page 29 PF-M25 PF-M100 Parallel Operation Operation 8.1. Manual operation The following description applies for clockwise closing standard version. Separate instructions are available for counterclockwise special version. The handwheel allows actuator operation even in case of power failure. Handwheel operation is only provided for occasional manual valve operation. The handwheel does not rotate during motor operation.

- Page 30 8.2.2. Actuator operation via AUMA Assistant App Alternatively, actuator operation is possible using the “AUMA Assistant” smartphone Functions App. The following table shows an overview of the menus of the AUMA Assistant App and the AUMA CDT software. Menu Description...

- Page 31 We recommend changing the password during initial commissioning. 8.2.3. Actuator operation from Remote Operation mode Remote For remote control, actuator operation mode must be set to Remote. The operation mode can be activated via AUMA Assistant App or AUMA CDT software: AUMA Assistant App Configuration Operation mode...

- Page 32 PF-M25 PF-M100 Operation Parallel Set operation mode to Remote. Now, it is possible to operate the actuator via remote control, via operation commands (OPEN, STOP, CLOSE) or analogue setpoints (e.g. 0/4 20 mA). For actuators equipped with positioner, it is possible to select between OPEN - Change-over between CLOSE control (REMOTE OPEN-CLOSE) and setpoint control (REMOTE OPEN - CLOSE control...

-

Page 33: Fox-Eye Indication Light And Status Indication

Device configuration M0053 Indication M2269 Internal control unit M2684 Configuration FOX-EYE M2685 The following profiles can be selected by means of the AUMA Assistant App or AUMA CDT: Default value: CUSTOMER Setting values: CUSTOMER, AUMA, NAMUR, FLEXIBLE The “Flexible” profile allows setting of colours and states of the signals as required. - Page 34 PF-M25 PF-M100 FOX-EYE indication light and status indication Parallel Table 15: AUMA profile Colour/state Signal Description Illuminated in white Ready for opera- The actuator: tion (REMOTE) is in operation mode REMOTE. is ready for operation. is not in any end position.

- Page 35 PF-M25 PF-M100 Parallel FOX-EYE indication light and status indication Signal Default value Options Operation in direc- blinking in green blinking in orange tion OPEN blinking in red blinking in magenta Fault flashing in red illuminated in red (fast) Warning blinking in red blinking in red (double flash) blinking in orange...

-

Page 36: Corrective Actions

Warnings have no influence on the electrical actuator operation. They only serve for information purposes. The FOX-EYE remains white. Collective signals include further indications. The FOX-EYE remains white. Faults and warnings may exclusively be read via AUMA Assistant App or AUMA CDT software. - Page 37 Check movement at actuator. the set reaction time. Internal error Collective signal 14: Use AUMA Assistant App or AUMA CDT to visualise the individual signals by means of the Diagnostics Internal error has occurred. menu. Different causes can be the reason: Memory over- If a memory overflow occurs, reboot the actuator.

-

Page 38: Servicing And Maintenance

If original AUMA screw plugs are used, original AUMA seals must also be used. They are included with the AUMA seal kit S1.The seal kit can be ordered with AUMA. Lubrication Within the device lifetime, no additional lubrication of the gear housing is required during operation. - Page 39 Number of starts The number of starts in indicated in starts/h. The exact sum of this key figure is made in the actuator and can be read via AUMA Assistant App or the AUMA CDT software in “Operational info”. AUMA recommendation...

-

Page 40: Disposal And Recycling

PF-M25 PF-M100 Disposal and recycling Parallel Disposal and recycling Our devices have a long lifetime. However, they have to be replaced at one point in time. The devices have a modular design and may, therefore, easily be separated and sorted according to materials used, i.e.: Electronic scrap Various metals Plastic materials... -

Page 41: Technical Data

The technical data sheet can be downloaded from the Internet in both German and English at ht- tp://www.auma.com (please state the order number). 13.1. Technical data Multi-turn actuators with integral controls for open-close and modulating duty... - Page 42 Communication interface Required accessories: AUMA CDT (Commissioning and Diagnostic Tool for Windows-based PC) AUMA Assistant App (Commissioning and Diagnostic Tool for Android and iOS devices) Electrical connection Cable entry: 3 x M20x1.5 threads for cable glands. Inside rail with spring clamp terminals for wire connection.

- Page 43 The generated fault and warning signals are saved within the event log. These signals can be configured as requested. An overview in the AUMA Assistant App or the CDT software shows all available fault/warning signals with option to enter the details.

- Page 44 Suitable for use in areas with extremely high salinity, permanent condensation, and high pollution. Coating Double layer powder coating Two-component iron-mica combination Colour Standard: AUMA silver-grey (similar to RAL 7037) Option: Available colours on request Lifetime Open-close 10,000 operating cycles OPEN - CLOSE - OPEN duty:...

-

Page 45: Spare Parts

PF-M25 PF-M100 Parallel Spare parts Spare parts 14.1. Multi-turn actuators PF-M25 PF-M100... - Page 46 Parallel Please state device type and our order number (see name plate) when ordering spare parts. Only original AUMA spare parts should be used. Failure to use original spare parts voids the warranty and exempts AUMA from any liability. Only the designated spare parts with reference numbers or spare parts sets for replacement are available for the customer.

- Page 47 PF-M25 PF-M100 Parallel...

- Page 48 PF-M25 PF-M100 Parallel...

-

Page 49: Index

App functions Mains cable Applications Mains connection Assembly Mains frequency 8, 15 Assistant App Mains voltage 8, 15 AUMA Assistant App 7, 9 Maintenance 4, 38, 38 AUMA Cloud Maintenance intervals Manual operation Mechanical position indcator Blanking plug Mechanical position indicator... - Page 50 PF-M25 PF-M100 Index Parallel Safety instructions Safety instructions/warnings Safety measures Safety standards Screw plugs Serial number 8, 9 Service Service conditions Short description Signal cable Size Spare parts Speed Speed range Speeds Standards Status signals Potential Storage Supply networks Support Technical data Terminal compartment: close Terminal plan...

- Page 51 AUMA worldwide...

- Page 52 AUMA Riester GmbH & Co. KG P.O. Box 1362 DE 79373 Muellheim Tel +49 7631 809 - 0 Fax +49 7631 809 - 1250 info@auma.com www.auma.com Y008.951/003/en/1.21 For detailed information on AUMA products, refer to the Internet: www.auma.com...

Need help?

Do you have a question about the PROFOX PF-M25 and is the answer not in the manual?

Questions and answers