Advertisement

Quick Links

Advertisement

Summary of Contents for AUMA LE 12.1

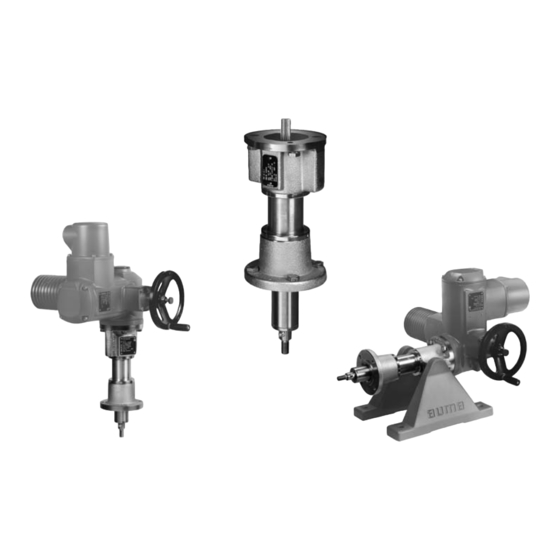

- Page 1 Linear thrust unit LE 12.1 LE 200.1 Operation instructions Assembly, operation, commissioning...

- Page 2 Maintenance intervals 6.3. Re-lubrication 6.4. Disposal and recycling Technical data......................... 7.1. Features and functions 7.2. Service conditions 7.3. Further information Spare parts..........................8.1. Linear thrust unit LE 12.1 LE 200.1 8.2. Linear thrust unit LE 12.1 LE 200.1 with base...

- Page 3 LE 12.1 LE 200.1 Table of contents Certificates..........................9.1. Declaration of Incorporation and EC Declaration of Conformity Index............................Addresses..........................

- Page 4 Any device modification requires prior consent of the manufacturer. 1.2. Range of application AUMA linear thrust units are designed for the operation of industrial valves, e.g. globe valves. Other applications require explicit (written) confirmation by the manufacturer. The following applications are not permitted, e.g.:...

- Page 5 LE 12.1 LE 200.1 Safety instructions Lifting appliances according to EN 14502 Passenger lifts according to DIN 15306 and 15309 Service lifts according to EN 81-1/A1 Escalators Continuous duty Radiation exposed areas in nuclear power plants No liability can be assumed for inappropriate or unintended use.

- Page 6 LE 12.1 LE 200.1 Identification Identification 2.1. Name plate Figure1: Arrangement of name plates Linear thrust unit name plate Additional plate, e.g. KKS (Power Plant Classification System) plate or approval plate Description of linear thrust unit name plate Figure2: Linear thrust unit name plate (example)

- Page 7 The linear thrust units convert the output torque of the multi-turn actuator into an axial thrust. As an option, AUMA linear thrust units are available with damping device to compensate for changes in lengths caused by varying temperatures, for...

- Page 8 Respect total weight of combination (gearbox, linear thrust unit, actuator, ...). Table 1: Weights linear thrust units Type Stroke Weight [kg] Base weight [kg] LE 12.1/ LE 25.1 LE 50.1 LE 70.1 / LE 100.1 LE 200.1 Refer to name plate Without actuator and base 3.2.

- Page 9 LE 12.1 LE 200.1 Transport, storage and packaging 3.3. Packaging Our products are protected by special packaging for transport when leaving the factory. The packaging consists of environmentally friendly materials which can easily be separated and recycled. We use the following packaging materials: wood, cardboard, paper, and PE foil.

- Page 10 State of delivery When AUMA actuators and linear thrust units up to size LE 50.1 and a stroke of max. 200 mm are supplied together, assembly is performed in the factory. For larger strokes and when exceeding size LE 70.1, assembly must be performed by the customer.

- Page 11 LE 12.1 LE 200.1 Assembly Mounting flange with 2 holes for pivots Extension flange F16/25 max. input torque 1,000 Nm 4.3. Linear thrust unit: mount to valve Mounting is most easily done with the valve shaft pointing vertically upward. But Mounting position mounting is also possible in any other position.

- Page 12 LE 12.1 LE 200.1 Assembly Spigot for F07 4.3.2. Linear thrust unit: mount to valve Check whether attachment of linear thrust unit suit the valve. Push thrust rod of linear thrust unit to desired position (e.g. OPEN) using the handwheel.

- Page 13 5.2. Thrust limitation Thrust limitation is made via mounted actuator. Refer to <Limit switching: set> chapter in operation instructions of suitable AUMA multi-turn actuators. Valve damage due to excessive tripping torque limit setting! The tripping torque must suit the valve.

- Page 14 LE 12.1 LE 200.1 Commissioning Information: AUMA linear thrust units LE 12.1 LE 200.1 leave the factory Verify stroke direction with retracted thrust rods (end position OPEN) Move actuator manually to intermediate position or to sufficient distance from end position.

- Page 15 Only perform servicing and maintenance tasks when the device is switched off. AUMA AUMA offer extensive service such as servicing and maintenance as well as customer Service & Support product training. For the relevant contact addresses, please refer to <Addresses>...

- Page 16 LE 12.1 LE 200.1 Servicing and maintenance Instructions for use in potentially explosive atmospheres of categories M2, 2G, 3G, 2D and 3D according to EU directive 94/9/EC The technical data as well as the ambient temperatures, type of duty and running times indicated on the name plate must imperatively be observed.

- Page 17 The following technical data includes standard and optional features. For detailed information on the customer-specific version, refer to the order-relevant data sheet. This data sheet can be downloaded from the Internet at http://www.auma.com in German and English (indication of commission number required).

- Page 18 For actual version, refer to actuator name plate. Finish coating base Standard: Paint based on polyurethane (powder coating) Colour base Standard: AUMA silver-grey (similar to RAL 7037) Ambient temperature Standard: 25 °C to +80 °C For actual version, refer to actuator name plate.

- Page 19 LE 12.1 LE 200.1 Spare parts Spare parts 8.1. Linear thrust unit LE 12.1 LE 200.1...

- Page 20 Information: Please state type and commission no. of the device (see name plate) when ordering spare parts. Only original AUMA spare parts should be used. Failure to use original spare parts voids the warranty and exempts from any liability. Delivered spare parts may slightly vary from the representation.

- Page 21 LE 12.1 LE 200.1 Spare parts 8.2. Linear thrust unit LE 12.1 LE 200.1 with base...

- Page 22 Information: Please state type and commission no. of the device (see name plate) when ordering spare parts. Only original AUMA spare parts should be used. Failure to use original spare parts voids the warranty and exempts from any liability. Delivered spare parts may slightly vary from the representation.

- Page 23 LE 12.1 LE 200.1 Certificates Certificates 9.1. Declaration of Incorporation and EC Declaration of Conformity...

- Page 24 LE 12.1 LE 200.1 Index Index Safety instructions Safety instructions/warnings Screws Actuator mounting flange Self-locking Actuators Serial number Ambient temperature 6 , 18 Service Applications Service conditions Approval plate Servicing Assembly Size Attachment dimensions Spare parts Standards Stem Certificates Storage...

- Page 25 IBEROPLAN S.A. AUMA Polska Sp. z o.o. ES 28027 Madrid PL 41-219 Sosnowiec Tel +34 91 3717130 Tel +48 32 783 52 00 AUMA Riester GmbH & Co. KG iberoplan@iberoplan.com biuro@auma.com.pl www.auma.com.pl Plant Müllheim OY AUMATOR AB DE 79373 Müllheim...

- Page 26 Tel + 673 3331269 / 3331272 Tel +968 24 636036 AUMA Argentina Rep.Office mikuni@brunet.bn r-negi@mustafasultan.com AR Buenos Aires Tel +54 11 4737 9026 AUMA Actuators (Tianjin) Co., Ltd. Beijing FLOWTORK TECHNOLOGIES contacto@aumaargentina.com.ar Branch CORPORATION CN 100020 Beijing PH 1550 Mandaluyong City AUMA Automação do Brazil ltda.

- Page 27 AUMA worldwide...

- Page 28 AUMA Riester GmbH & Co. KG P.O.Box 1362 DE 79373 Muellheim Tel +49 7631 809 - 0 Fax +49 7631 809 - 1250 riester@auma.com www.auma.com Y000.346/003/en/3.13 For detailed information on AUMA products refer to the Internet: www.auma.com...

Need help?

Do you have a question about the LE 12.1 and is the answer not in the manual?

Questions and answers