Summary of Contents for RINGSPANN HS 215 FHM

- Page 1 Installation and operating instructions for Brake HS 215 FHM E 09.777e Schaberweg 30-38 Phone +49 6172 275-0 www.ringspann.com 61348 Bad Homburg +49 6172 275 275 info@ringspann.com Germany...

- Page 2 Disregarding or misinterpreting these installation and operating instructions invalidates any product liability or guarantee by RINGSPANN; the same applies if the product is taken apart or changed. These installation and operating instructions should be kept in a safe place and should accompany the product if it is passed on to others -either on its own or as part of a machine- to make it accessible to the user.

-

Page 3: Table Of Contents

Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 3 Contents DESCRIPTION OF THE CALIPER 1.1 Principle 1.2 Delivery condition 2 INSTALLATION 2.1 Preparing the positioning area... -

Page 4: Description Of The Caliper

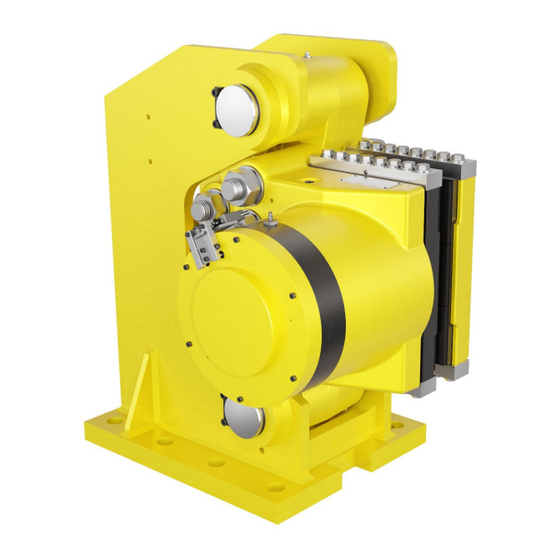

Description of the caliper 1.1 Principle The HS 215 FHM calipers are hydraulic fail-safe calipers; the braking force is applied by spring washers and hydraulic pressure is necessary to hold the brake released. The stack of spring washers is adjusted in factory. This adjustment, combined with adjustment of the pads gap, determines the braking torque value. -

Page 5: Installation

Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 5 Life-threatening danger! Disc must be absolutely degreased before all contact with the brakes linings. - Page 6 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 6 Brake HS 215 FHM-560L-H (Thrustor mounted left shown) Fig. 2.1...

-

Page 7: Installing The Disc

Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 7 Brake HS 215 FHM-560 R-V Fig. 2.2 8 Brake off monitoring switch... -

Page 8: Installing The Caliper

Weight for one caliper: HS 215 FHM-___ H = 880kg HS 215 FHM-___ R-V = 880kg 2.3.3 Alignment procedure 1. Brake HS 215 FHM-560 R-V Check the disc position 265 +/-12 mm Fig. 2.2. and that the disc is parallel // 0,3 to the brake pad use the adjustment screw between the casing and the bottom plate. - Page 9 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 9 A crowbar can be used in the area shown by the arrow 2a and 2b to slide the caliper from one side to the other.

- Page 10 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 10 Fig. 2.4 Longitudinal spacing: 0.3 mm max. over pad length. If necessary, set the support using foil 4...

- Page 11 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 11 3. Assemble the 8 screws M36 class 8.8 for caliper to the basement connection.

- Page 12 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 12 The caliper must be connected to its source at hydraulic pipe, fittings by threaded plug G 3/8’’.

-

Page 13: Initial Start-Up

Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 13 2.4 Initial start-up 2.4.1 Hydraulic circuit bleed Tools: Spanner, 6mm ID flexible hose. - Page 14 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 14 2.4.2 Deactivate the manual release The principle is to position the stopping rings in the piston groove once the pressure is applied.

-

Page 15: Operational Running

Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 15 2.4.4 Control of the general running Important! Be Careful: The disc must be degreased and free from any deposits so as not to decrease the friction coefficient. -

Page 16: Periodic Maintenance

Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 16 PERIODIC MAINTENANCE Every two months, check: - As a general rule, inspect the entire system for correct operation - Check that there is not any leakage - Also, check the brake pad gap see chapter 5.3. - Page 17 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 17 Put the 2 retaining segments 14 in the piston groove 04 Fig. 5.2.

-

Page 18: Manual Release: Deactivation

Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 18 5.2 Manual release: deactivation With the pressure cut off, remove the cover 21 with its 6 Allen screws V09. -

Page 19: Adjustment Of Brake Pad Clearance, Pad Wear Take Up

Frequently check the total gap between pads and the disc. (a 1mm increase to this gap corresponds to 7% loss of torque). Refer to the RINGSPANN Datasheet for the nominal clearance. Attention! When the remaining lining thickness reaches 3mm, proceed to pad exchange as per chapter 5.4. - Page 20 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 20 6. Screw or unscrew using a flat spanner Fig.5.5 or a socket, the adjuster screw 06 until the gap between the pad and the disc reaches the required value “PG”...

-

Page 21: Replacement Of Worn Brake Pads

Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 21 Fig. 5.5 Replacement of worn brake pads Tools: AF spanner, Allen wrench Procedure: For brake pad thrustorside Put the caliper into manual release position, see chapter 5.1 and switch off the pressure. - Page 22 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 22 Remove the pad 11 from the body 01 by pulling with the M8 screws.

- Page 23 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 23 Procedure: For the other brake padside Fit a screw M10 into the stop plate 10 to facilitate gripping.

- Page 24 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 24 Fig. 5.7...

-

Page 25: Opening And Wear Contacts (Mechanicals) Adjustment

Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 25 Opening and wear contacts (mechanicals) adjustment Information! Contacts are factory set and do not need any adjustment. - Page 26 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 26 - Cut off pressure. When the brake is close, Check the contact state (Position "closed"). If this information is not obtained, unscrew the screw V02 until change of state.

- Page 27 Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 27 5.5.2 Adjustment of ‘pad wear’ switch This switch is permanently closed and opens when the pad wear reaches 1mm.

-

Page 28: Spare Parts

Installation and operating instructions for E 09.777e Brake HS 215 FHM spring activated – hydraulically released Issue: 28.05.2021 Version: 2 Drawn: BAHS Checked: EISF Pages: 28 Page: 28 Spare parts Monitoring switches (Opening/wearing) Ref.: 12708-F05 - Set of pads: 2 pads Ordernumber: JGS RINGSPANN HW215-12662 ...

Need help?

Do you have a question about the HS 215 FHM and is the answer not in the manual?

Questions and answers