Summary of Contents for RINGSPANN DV 025 PFM

- Page 1 Installation and operating instructions for Brake DV/DH 025/030/035 PFM E 09.760e Schaberweg 30-38 Phone +49 6172 275 0 www.ringspann.com 61348 Bad Homburg +49 6172 275 275 info@ringspann.com Germany...

- Page 2 Disregarding or misinterpreting these installation and operating instructions invalidates any product liability or guarantee by RINGSPANN; the same applies if the product is taken apart or changed. These installation and operating instructions should be kept in a safe place and should accompany the product if it is passed on to others -either on its own or as part of a machine- to make it accessible to the user.

-

Page 3: Table Of Contents

Intended use Impermissible use Condition as delivered Handling and storage Technical prerequisite for reliable operation Installing the RINGSPANN brake 8.1 General instructions regarding assembly and installation 8.2 Assembly description 8.3 Adjusting/readjusting the friction pad distance 8.4 Connecting the signal cable (optional) Start-up 10. -

Page 4: General Notes

Installation and operating instructions for E 09.760e Brake DV/DH 025/030/035 PFM pneumatically activated - spring released Issue: 18.02.2022 Version: 4 Drawn: FRMA Checked: EISF Pages: 12 Page: 4 General notes 1.1 General safety instructions Read these installation/operating instructions carefully before putting the brake into operation. Consider these instructions as well as the drawings in the individual sections. -

Page 5: Drawing And Parts List

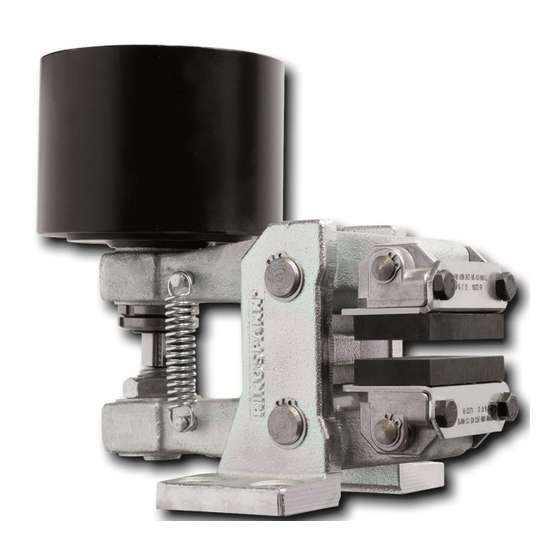

As well as these instructions, please also consider the catalogue data for the brake at www.ringspann.com and the drawings in the individual sections. 2.3 Drawing and parts list Drawing of brake DH, for model DV see catalogue data Frame: In V execution DV 035 thruster only right version Fig. -

Page 6: Intended Use

The current data can also be found on the RINGSPANN website www.ringspann.com. The brake can be stored for 12 months in an enclosed and dry place. It is to be made sure that... -

Page 7: Technical Prerequisite For Reliable Operation

Fastening the brake to stable and low-vibration machine parts will ensure quiet braking without creaking. Installing the RINGSPANN brake 8.1 General instructions regarding assembly and installation Before installing the brake, the brake disc must be cleaned with alcohol (e.g. spirit (ethanol) or isopropyl alcohol) or with water-based tenside solutions (soapy water or the like). -

Page 8: Adjusting/Readjusting The Friction Pad Distance

Installation and operating instructions for E 09.760e Brake DV/DH 025/030/035 PFM pneumatically activated - spring released Issue: 18.02.2022 Version: 4 Drawn: FRMA Checked: EISF Pages: 12 Page: 8 Fig. 8.1 The connecting plate for the brake as well as the brake disc must be checked for dimensional accuracy. -

Page 9: Connecting The Signal Cable (Optional)

Installation and operating instructions for E 09.760e Brake DV/DH 025/030/035 PFM pneumatically activated - spring released Issue: 18.02.2022 Version: 4 Drawn: FRMA Checked: EISF Pages: 12 Page: 9 • If there is wear to the friction blocks, a braking setting must be performed as well as an adjustment/readjustment of the friction pads. -

Page 10: Start-Up

Installation and operating instructions for E 09.760e Brake DV/DH 025/030/035 PFM pneumatically activated - spring released Issue: 18.02.2022 Version: 4 Drawn: FRMA Checked: EISF Pages: 12 Page: 10 Start-up Only full-face contact of the two friction pads (item 1) on the brake disc as well as a rapid heating of the friction linings to approx. -

Page 11: Permissible Friction Lining Wear And Exchanging Of The Friction Pad

If the friction pads has 5 mm thickness, the friction pads has to be change. The friction pads always change in pairs. Only original RINGSPANN friction pads may be used. Before exchanging the friction pads, ensure that the mass held by the brake is secured against moving, since parts of the brake need to be loosened for this purpose. -

Page 12: Accessories: Sensor For Operating State Monitoring

Installation and operating instructions for E 09.760e Brake DV/DH 025/030/035 PFM pneumatically activated - spring released Issue: 18.02.2022 Version: 4 Drawn: FRMA Checked: EISF Pages: 12 Page: 12 Important! After exchanging friction pads, a running-in process should be performed in order to reach the maximum brake torque.

Need help?

Do you have a question about the DV 025 PFM and is the answer not in the manual?

Questions and answers