Summary of Contents for RINGSPANN DR 085 FHM-50

- Page 1 Installation and operating instructions for Rail Clamp DR 085/088 FHM E 09.797e Schaberweg 30-38 Phone +49 6172 275 0 www.ringspann.com 61348 Bad Homburg +49 6172 275 275 info@ringspann.com Germany...

- Page 2 Disregarding or misinterpreting these installation and operating instructions invalidates any product liability or guarantee by RINGSPANN; the same applies if the product is taken apart or changed. These installation and operating instructions should be kept in a safe place and should accompany the product if it is passed on to others -either on its own or as part of a machine- to make it accessible to the user.

-

Page 3: Table Of Contents

Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 3 Contents DESCRIPTION OF THE RAIL CLAMP Operating principle INSTALLATION Delivery condition Installing the rail clamp Hydraulic connection For rail clamps without built-in hydraulic power unit... -

Page 4: Description Of The Rail Clamp

Furhter to these instructions, please also consider the catalogue data for the brake at www.ringspann.com and the drawings in the individual sections. The rail clamps can be optionally delivered with an integrated hydraulic power unit type HCO2R or type HTP3 (see Fig. -

Page 5: Installation

Strongly pre-loaded pressure springs are installed in the springed thrusters of the brake. The spring thruster may only be disassembled by the factory. INSTALLATION RINGSPANN rail clamps are easy to use and do not require extremely stringent mounting tolerances. 2.1 Delivery condition The rail clamp is delivered: •... -

Page 6: Installing The Rail Clamp

• To be removed with the retaining screw on the roller holder according to assembly (see 2.2.3). • Please also note the brake catalogue data at www.RINGSPANN.de and the drawings in the individual paragraph. 2.2 Installing the rail clamp 2.2.1 Tooling list 1. - Page 7 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 7 2.2.3 Installing pads with guide rollers 1. Check screws V1 and V2. Make sure they do not extend into the inside of the roller support. Do the same for V3 and remove it, if necessary.

- Page 8 Important! If these conditions are not complied with, the caliper cannot be assembled or will not operate to standard. Contact RINGSPANN for more details. Important! Make sure that pads are mounted on the rail clamp before to installation on the rail.

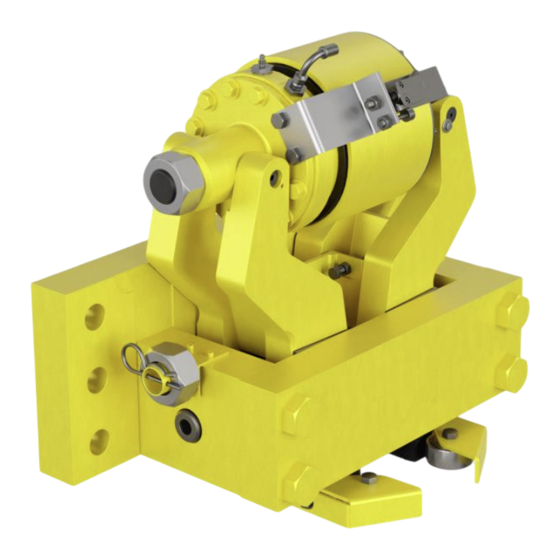

- Page 9 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 9 Rail clamp DR 085 FHM-050/100 Fig. 2.6...

- Page 10 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 10 Rail clamp DR 085 FHM-200/300/400 Fig. 2.7...

- Page 11 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 11 Rail clamp DR 088 FHM-500 Fig. 2.8 Image description: - Pos. 6 Manual release - Pos.

- Page 12 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 12 Railtolerance...

- Page 13 +/-5 60E1 +2/-5 Other types Please consult RINGSPANN Tab. 2.1 Observe the dimensions B with ±2,5 indicated (see Tab. 2.1). Center the rail clamp transversely in relation to the rail. Guide pads/rollers or pads alone (optional) carefully on either side of the rail when engaging the rail clamp on the rail.

- Page 14 Rail thickness + 3 mm (complete opening of the rail clamp). Fit the attachment screws of the rail clamp without tightening them and if all screws hand mounted tightenning with the correct tighenning torque Cs. Rail clamp DR 085 FHM-50/100/200/300/400 4 screws M30 class 10.9 Rail clamp DR 088 FHM-500 6 screws M30 class 10.9...

-

Page 15: Hydraulic Connection

G3/8“ Rail clamp DR 088 FHM-500 As well as these instructions, please also consider the catalogue data for the brake at www.RINGSPANN.com and the drawings in the individual sections. Important! Opening pressure min.: DR 085-FHM-050 110bar Opening pressure min.: DR 085-FHM-100 110bar Opening pressure min.: DR 085-FHM-200 105bar... - Page 16 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 16 Connection bleed screw G1/4“ or G3/8“ Fig. 2.12 For rail clamps DR 085/088 FHM with HCO2R built-in hydraulic power unit: Refer to the hydraulic power unit HCO2R manual for more information.

- Page 17 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 17 Fig. 2.13 Plug Breather plug Fig. 2.14...

- Page 18 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 18 For rail clamps DR 085/088 FHM with HTP3 built-in hydraulic power unit: Refer to the hydraulic power unit HTP3 manual for more information.

-

Page 19: Electrical Connection

Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 19 2.4 Electrical connection HCO2R power unit: Only for Rail clamp with power unit type. 1. - Page 20 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 20 2.5 Hydraulic circuit bleed Tools: Spanner, 6mm ID flexible hose. Important! Take the necessary precautions to avoid the oil being sprayed onto the drail.

-

Page 21: Deactivating The Manual Release

Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 21 2.6 Deactivating the manual release Important! Manual release must be deactivated for the rail clamp to operate correctly. -

Page 22: Adjusting The Pad Clearance

Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 22 2.7 Adjusting the pad clearance Important! THE PAD GAP IS NOT FACTORY-SET. TO OPERATE THIS SETTING, FOLLOW THE PROCEDURE BELOW. -

Page 23: Rail Clamp Balancing Procedure

Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 23 Fig. 2.19 Important! Manual release must be deactivated for the rail clamp to operate correctly. - Page 24 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 24 Tooling: 16 mm A/F wrenches Procedure: 1. Unlock the 2 locknuts 18 on the two balancing screws 17 (16 mm A/F) 2.

-

Page 25: General Operational Check

Check gap pads indicated on the identification plate => PG=X mm Check for correct balancing of the rail clamp (see chapter 2.8). Check the correct function of the sensor Identification plate RINGSPANN Fig. 2.24 Information! THE SYSTEM IS NOW OPERATIONAL. -

Page 26: Hand Pump Operation Oft He Rail Clamp

The air gap must be adjusted after replacing the friction block. Attention! When changing the friction block, replace the friction block according to chapter 5. If this instruction is not observed, braking force may be lost. Only original RINGSPANN friction pads may be used. -

Page 27: Maintenance Level 1

Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 27 Maintenance frequency Standard environnement Hard working environment* Maintenance level 1 Every year Every 3 months Maintenance level 2 Every 2 years... - Page 28 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 28 Contact faces between levers and support Axle lubricaters of the levers (optional) Fig.

- Page 29 - Replacing oil of hydraulic pack 4.3 Maintenance level 3 - Perform level 1 and level 2 maintenance. - Replacing Spring washers. (Consult RINGSPANN maintenance service) - Replacing seals. (Consult RINGSPANN maintenance service) - Replacing Pads + rollers. (Consult RINGSPANN maintenance service)

-

Page 30: Maintenance

Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 30 Maintenance 5.1 Manual release: Activation 1. Supply the rail clamp with minimum pressure See table in chapter 2.3 to open i and maintain the pressure during the entire operation. -

Page 31: Adjusting The Pad Gap

Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 31 Attention! Manual release must be deactivated for the rail clamp to operate correctly. Attention! MOVEMENTS ARE STILL POSSIBLE EVEN AFTER THE OPENING PRESSURE HAS BEEN SWITCHED OFF. - Page 32 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 32 Fig. 5.3 4. Unlock the counternut 8 (see Fig. 5.4). 5. Undo the screw 2 (see Fig. 5.4) by means of the hexagon end in order to maximize the pad gap.

- Page 33 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 33 To change one pad, swing the rail clamp to the opposite side Fig.

- Page 34 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 34 Fig. 5.7 8. Remove the pads as shown below Fig. 5.8...

-

Page 35: Setting The Braking Force

Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 35 Areas to be greased Fig. 5.9 9. Grease the new pads with copper paste type MOLYSLIP area (see Fig. 5.9) and insert them on the levers 16. -

Page 36: Opening Switch

It is triggered by the stop plate 13 connected to the displacement of the piston. The switch must be pressed in when the rail clamp is released. If this switch needs to be adjusted: Please contact RINGSPANN. Fig. 5.10 5.7 Adjustment switch Information! The switch is factory-set and does not need any adjustment. -

Page 37: Flow Limiter (Optional)

Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 37 Fig. 5.11 5.8 Flow limiter (optional) Information! The limiter 1L is available only in the case of rail clamp with built-in hydraulic power unit. -

Page 38: Spare Parts

SPARE PARTS - Set of smooth pads: Rail A55 => JGS DR 085 RINGSPANN-A55-GL Rail A65 / 75 /100 => JGS DR 085 RINGSPANN-A100-GL Rail A120 => JGS DR 085 RINGSPANN-A120-GL - Set of diamond pads: Rail A55 => JGS DR 085 RINGSPANN-A55-DIAM Rail A65 / 75 /100 =>... - Page 39 Installation and operating instructions for E 09.797e Rail Clamp DR 085/088 FHM spring activated – hydraulically released Issue: 14.09.2022 Version: 2 Drawn: BAHS Checked: OHLM Pages: 39 Page: 39 TROUPLE SCHOOTING KIND OF Rail Rail clamp CHECK SOLUTION DEFECT clamp with integrated power unit...

Need help?

Do you have a question about the DR 085 FHM-50 and is the answer not in the manual?

Questions and answers