Graco SaniForce 1040e Operation

Electric-operated diaphragm pump

Hide thumbs

Also See for SaniForce 1040e:

- User manual (66 pages) ,

- Repair parts (40 pages) ,

- Repair parts (40 pages)

Table of Contents

Advertisement

Quick Links

Operation

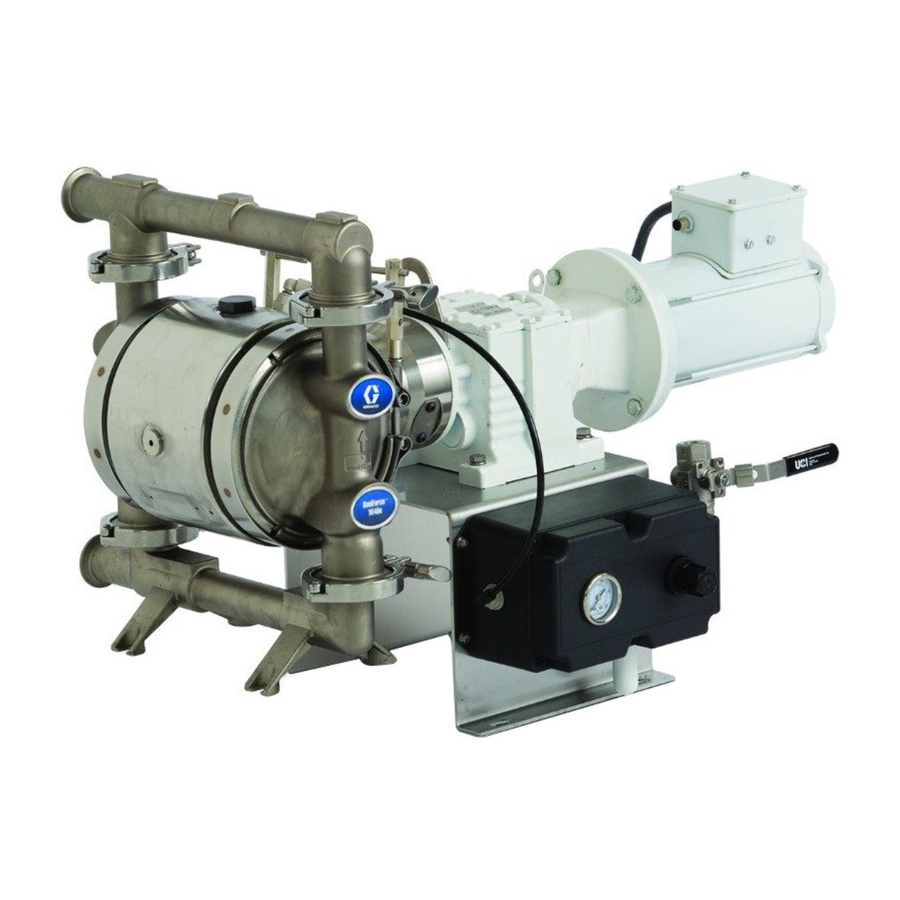

SaniForce® 1040e

Electric - Operated Diaphragm

Pump

For fluid

For

For

fluid transfer

fluid

transfer

transfer in in in indoor

indoor sanitary

indoor

hazardous locations

locations unless

unless otherwise

hazardous

hazardous

locations

unless

use only.

only.

use

use

only.

Important

Important Safety

Important

Safety Instructions

Safety

Read all warnings and instructions in this manual. Save

instructions.

instructions.

instructions.

For maximum operating pressures,

see the Performance Charts on pages

49–53.

See pages 6 and 7 for model

information, including approvals.

Tel: 866-777-6060

Fax: 866-777-6383

sanitary applications.

sanitary

applications. Not

applications.

otherwise stated.

stated. See

See approvals

otherwise

stated.

See

Instructions

Instructions

PROVEN QUALITY. LEADING TECHNOLOGY.

Springer Pumps, LLC

Not approved

Not

approved for

approved

for

for use

use in in in explosive

use

approvals page

page for

for more

more information.

approvals

page

for

more

Save these

Save

these

these

3A3167N

explosive atmospheres

explosive

atmospheres or or or

atmospheres

information. For

For professional

professional

information.

For

professional

Website: www.springerpumps.com

Int'l: +001 267 404 2910

EN

Advertisement

Table of Contents

Summary of Contents for Graco SaniForce 1040e

- Page 1 Operation SaniForce® 1040e Electric - Operated Diaphragm 3A3167N Pump For fluid fluid transfer fluid transfer transfer in in in indoor indoor sanitary indoor sanitary applications. sanitary applications. Not applications. Not approved approved approved for for use use in in in explosive explosive atmospheres explosive atmospheres...

-

Page 2: Table Of Contents

Lubrication........... 41 Wire Connections at the ATEX Motor .... 18 Tighten Connections ........41 Wire Connections at the Explosionproof Clean the Graco Motor Control ..... 41 Motor ..........18 Upgrade Graco Motor Control Leak Sensor Wiring (AC Models) ....19 Software ........ -

Page 3: Warnings

Warnings Warnings Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. - Page 4 Warnings WARNING PRESSURIZED EQUIPMENT EQUIPMENT HAZARD HAZARD PRESSURIZED PRESSURIZED EQUIPMENT HAZARD Fluid from the equipment, leaks, or ruptured components can splash in the eyes or on skin and cause serious injury. • Follow the Pressure Pressure Relief Pressure Relief Relief Procedure Procedure when you stop spraying/dispensing and before Procedure cleaning, checking, or servicing equipment.

- Page 5 Warnings WARNING THERMAL EXPANSION EXPANSION HAZARD HAZARD THERMAL THERMAL EXPANSION HAZARD Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

-

Page 6: Configuration Number Matrix

Configuration Number Matrix Configuration Number Number Matrix Matrix Configuration Configuration Number Matrix Check the identification plate (ID) for the Configuration Number of your pump. Use the following matrix to define the components of your pump. 1040FGE- - - A04AS13SSPTPOPT A04AS13SSPTPOPT 1040FGE 1040FGE A04AS13SSPTPOPT... - Page 7 Configuration Number Matrix Approvals Approvals Approvals II 2 G Ex h IIB T3 Gb ATEX T-code rating is dependent on the temperature of ‡ Pumps with code are certified to: the fluid being pumped. Fluid temperature is limited by the materials of the pump interior wetted parts.

-

Page 8: Ordering Information

Online Diaphragm Online Diaphragm Diaphragm Pump Pump Selector Pump Selector Selector Tool Tool at at at Tool www.graco.com www.graco.com. . . Go to the Process www.graco.com Process Equipment Process Equipment Equipment Page. Page. Page. To Order Order Replacement Replacement Parts... -

Page 9: Cart Systems

Cart Systems Systems Cart Cart Systems Cart systems include a stainless steel washdown cart, a BLDC motor, compressor, air control, and Graco motor controller. Two compressor input power levels are available. See table below for available systems. Cart Cart System Cart... -

Page 10: Overview

Points: Points: • Pumps are available with an AC or Brushless • BLDC motors are controlled by the Graco Motor DC (BLDC) motor, or with just a gearbox (for Control that is supplied with the pump. applications where a motor is already available). -

Page 11: Installation

Always use serious damage, including pitting and early wear of Genuine Graco Parts and Accessories. Be sure all fluid chambers, balls, and seats. It may result in accessories are adequately sized and pressure rated reduced efficiency of the pump. - Page 12 Installation Graco Graco Graco Motor Motor Motor Control Control Control Component Component Component Identification Identification Identification KEY: KEY: KEY: A Conduit Holes B Display Control Panel C Mounting Tabs D Warning Label 3A3167N Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com...

-

Page 13: Mount The Pump

NOTICE NOTICE NOTICE 3. For BLDC models, securely mount the Graco The pump is heavy. To prevent damage from Motor Control using the provided mounting tabs. dropping, always use 2 people or a lift to move the 4. For ease of operation and service, mount the pump. -

Page 14: Grounding

See true earth ground. A ground wire and clamp, Part Controller Wiring, page 238909, is available from Graco. Check your system ground continuity after the initial installation, and then set up a regular schedule for checking continuity to be sure proper grounding is maintained. - Page 15 Installation Figure 1 Typical Installation (AC Pump Shown) System System Components System Components Components Accessories/Components Accessories/Components Not Accessories/Components Not Supplied Supplied Supplied Power cord to VFD Grounded, flexible air supply hose Fluid inlet port Bleed-type master air valve Fluid outlet port Air filter/regulator assembly Mounting feet Master air valve (for accessories)

-

Page 16: Air Line

3. For maximum suction lift (wet and dry), see Technical Data, page 61. For best results, always install the pump as close as possible to the If If If using using a a a Graco Graco Compressor Compressor Kit: Kit: using... -

Page 17: Electrical Connections (Ac Models)

240V Wiring: Wiring: Move the black wire (U3), the manual. If you purchased an optional Graco VFD red wire (V3) and the blue wire (W3) as shown. (PN 16K911 or 16K912), detailed installation and Using the bridges supplied with the motor, bridge connection information is provided in the manual that W2, U2, and V2. -

Page 18: Wire Connections At The Atex Motor

Electrical Connections (AC Models) Wire Connections Connections at at at the the ATEX ATEX Motor Motor Wire Connections Connections at at at the Wire Wire Connections ATEX Motor Wire Wire Connections Explosionproof Motor Motor Explosionproof Explosionproof Motor (Optional kit 25C081) (Optional kit 25C082) Install the wiring at the motor as follows: Install the wiring at the motor as follows:... -

Page 19: Leak Sensor Wiring (Ac Models)

Length Part Part Number Cable Cable Length 6. For a non-Graco VFD, perform the following: 17H389 9.8 ft, 3.0 m a. Attach the blue and black leads to the 17H390 24.6 ft, 7.5 m detection circuit in the VFD. NOTE... -

Page 20: Electrical Connections (Bldc Models)

Graco Motor Control. qualified electrician and comply with all local codes NOTE: To maintain enclosure rating use approved... -

Page 21: Wiring Tips

EMI sources. If cables must cross, power cabling. cross at a 90° angle. • Use the shortest possible cables or wires for • The Graco Motor Control used with BLDC motors incoming power. has an integrated line filter, so no external filter is necessary. -

Page 22: Bldc Motor Wiring

Motor Motor Wiring Wiring Wiring 3. Connect the Graco Motor Control to the motor. Use minimum 14 AWG (2.5 mm ) wire. Use a 7 mm socket to loosen the terminal studs. a. Connect M1(U) of the Graco Motor Control to U1 of the motor. -

Page 23: Controller Wiring

20 in-lb (2.3 N•m). • Leakage Current may exceed 3.5mA AC. The 3. Connect the Graco Motor Control to the motor. minimum size of the protective earthing conductor Use minimum 14 AWG (2.5 mm ) wire. -

Page 24: Leak Sensor Wiring (Bldc Models)

PLC Control skip steps 3, 5, and 6. See compressor, then split it out to the Graco Motor Graco Motor Control Software Overview, page Control, to share the same circuit. for more information regarding control function. Wire 6. -

Page 25: Compressor Wiring

16A circuit and 14 AWG (2.5 ) when configured for a 12A circuit. Torque terminals to 20 in-lb (2.3 N•m). 4. When powering the Graco Motor Control or VFD on the same circuit as the compressor, connect branch wiring to L1, L2/N and Ground, then connect to the Graco Motor Control or VFD. -

Page 26: Cart Wiring

Cart Wiring Cart Wiring Wiring Cart Cart Wiring 120V Cart-Mounted Cart-Mounted Models: Models: A power cord is supplied 120V 120V Cart-Mounted Models: that can be plugged into any grounded 110V-120V wall socket. 240V Cart-Mounted Cart-Mounted Models: Models: See 240V 240V Cart-Mounted Models: Compressor Wiring, page... -

Page 27: Operation

Configure the VFD according to the motor nameplate information. 6. Follow the appropriate calibration procedure and set the pump K-Factor (menu G203). Use NOTE: If you are using a Graco VFD (Part 16K911 NOTE: NOTE: this procedure and menu to adjust the pump... -

Page 28: Start And Adjust The Pump

NOTE: This procedure applies to systems using the NOTE: NOTE: Grounding, page Graco Motor Control. If you are using a VFD, follow the instructions in that user manual. 2. Check fittings to be sure they are tight. Use a compatible liquid thread sealant on male threads. -

Page 29: Batch Calibration Procedure

NOTE: This procedure applies to systems using the NOTE: NOTE: Follow the Pressure Relief Procedure Graco Motor Control. If you are using a VFD, follow whenever you see this symbol. the instructions in that user manual. 1. The system is in Batch Control Mode. Menu G200 = 1. -

Page 30: Graco Motor Control Operation

Control Operation (BLDC Models) Display Display Display The Graco Motor Control provides the interface for NOTICE NOTICE NOTICE users to enter selections and view information related To prevent damage to the softkey buttons, do not to setup and operation. press the buttons with sharp objects such as pens, Membrane keys are used to input numerical data, plastic cards, or fingernails. -

Page 31: Graco Motor Control Software

Graco Graco Motor Control Software Overview The Graco Motor Control has two possible control Table 3 for an explanation of each method. Table 4 methods: Flow Control and Batch Dispense. See explains some key Graco Motor Control features. Table Table... - Page 32 • The system alerts the user that the pump is running at reduced performance and the reason for the reduction. • Motor Temperature Scaling – The Graco Motor Control limits power to the motor when the motor winding temperature is too hot. ♦ Limit Start – 120°C (248°F) ♦...

- Page 33 Graco Motor Control Operation (BLDC Models) Control Control Feature Control Feature Feature Details Details Details PLC Control • Input Hardware: – Digital Input (Start/Stop) — Sinking ♦ 12VDC (internally pulled-up) logic ♦ Logic Low (asserted/closed) < 4VDC ♦ Logic High (released/open) > 6VDC ♦...

-

Page 34: Operation Modes

Run Mode Mode Mode number. When in Run Mode, the Graco Motor Control displays Press on the last digit to return to the setup the current flow rate (flow mode) or volume remaining menu code options. - Page 35 Graco Motor Control Operation (BLDC Models) Table 5 5 5 Available Available Menus Menus with with Descriptions Descriptions Table Table Available Menus with Descriptions Setup Mode Mode Setup Setup Mode G100 Displays the last 20 system event codes. Use to scroll though the...

- Page 36 Graco Motor Control Operation (BLDC Models) G204 Enable this setting to change the Over Current and Motor Temperature events from Alarms to Deviations, which allows the pump to keep running with reduced performance (may not maintain flow setpoint). The pump must be stopped to edit ENABLE MAX POWER this field.

- Page 37 Graco Motor Control Operation (BLDC Models) G231 Set the desired maintenance interval in millions of cycles. • Range is 0.1 — 99.9 million cycles. SET MAINTENANCE INTERVAL 2 • Enter 0 to disable the maintenance counter. • Default is 0.

- Page 38 Graco Motor Control Operation (BLDC Models) G246 Set the highest selectable volume setpoint. • Units are user selectable. See Set Flow Units (menu G201). SET MAXIMUM VOLUME SETPOINT • Menu is visible only if Control Mode (menu G200) is set to batch (1).

- Page 39 Graco Motor Control Operation (BLDC Models) G307 Displays the motor temperature in °C. • User cannot edit. VIEW MOTOR TEMPERATURE G308 Displays the software configuration. • User cannot edit. VIEW SOFTWARE VERSION & SERIAL • Information displayed includes software part number, software version, and NUMBER serial number.

- Page 40 Graco Motor Control Operation (BLDC Models) Graco Graco Graco Motor Motor Control Motor Control Menu Control Menu Quick Menu Quick Quick Reference Reference Reference G100 G100 (View G100 (View Events) (View Events) Events) G230–G232 G230–G232 G230–G232 (Set (Set (Set Maintenance...

-

Page 41: Maintenance

Use Software Upgrade Kit 17H104 and Programming Before each use, check all hoses for wear or damage Cable Kit 24Y788 to update the Graco Motor Control and replace as necessary. Check to be sure all software. The kits include instructions and all connections are tight and leak-free. -

Page 42: Flushing And Storage

Maintenance Flushing and and Storage Storage Flushing Flushing Storage and damaging it. Flushing schedule will be based on what the pump is being used for. Use a compatible cleaning solution and always cycle the pump during the entire flushing process. Always flush the pump and relieve the pressure To avoid fire and explosion, always ground before storing it for any length of time. -

Page 43: Troubleshooting The Graco Motor Control

• Enter the correct password. G200 menus are not displayed after entering password. has been entered. • Contact Graco Technical Support for instructions on resetting a password. GFCI breaker trips when motor is run. Leakage current • Controller is not compatible with all exceeds breaker limit. -

Page 44: Diagnostic Information

Troubleshooting the Graco Motor Control Diagnostic Diagnostic Diagnostic Information Information Information Table 6 6 6 LED LED Status Status Signal Signal Table Table Status Signal Module Status Status Description Solution Module Module Status Description Description Solution Solution LED Signal Signal... -

Page 45: Power Line Voltage Surges

Readings should not regularly exceed approximately 400 Vdc to avoid tripping the 420 Vdc alarm level in the Graco Motor Control. If the power quality is suspect, it is recommended to power condition or isolate the device(s) that is causing the poor power quality. -

Page 46: Events

Troubleshooting the Graco Motor Control Events Events Events DEVIATION: The pump continues to run. The The LED displays event codes to inform the user of • DEVIATION: DEVIATION: any electrical hardware or software problems. After event requires attention and will continue to flash... - Page 47 Troubleshooting the Graco Motor Control Event Event Event Event Event Level Event Level Level Description Description Description Solution Solution Solution Code Code Code The motor control limit has been reached and Max Power Mode is enabled in menu G204. The controller...

- Page 48 Troubleshooting the Graco Motor Control Event Event Event Event Event Level Event Level Level Description Description Description Solution Solution Solution Code Code Code Ensure that the motor ambient temperature is above minimum. Ensure that the feedback cable The motor is operating out of its is correctly installed.

-

Page 49: Performance Charts

Performance Charts Performance Charts Charts Performance Performance Charts Test Test Test Conditions: Conditions: Conditions: The pump was tested in water with 2. Set the VFD frequency corresponding to the the inlet submerged. The air pressure was set 10 psi desired flow rate. Flow rates will increase with (0.7 bar) higher than the outlet pressure. - Page 50 Performance Charts Pump with with BLDC BLDC Motor Motor Pump Pump with BLDC Motor A A A Power Limit Curve Motor and gearbox configuration codes A04B & S04B B B B Net Positive Suction Head Required The shaded area is recommended for continuous duty.

- Page 51 Performance Charts Pump Pump Speed Pump Speed Speed in in in Cycles Cycles Cycles per per Minute Minute Minute (120V) (120V) (120V) (5.5, 0.55) (4.8, 0.48) (4.1, 0.41) (3.4, 0.34) Outlet Outlet Outlet NPSHr NPSHr NPSHr Pressure Pressure Pressure (feet (feet (feet (2.8, 0.28)

- Page 52 Performance Charts ATEX motor motor and and 18:1 18:1 Gearbox Gearbox ATEX ATEX motor 18:1 Gearbox Good for 2–pole, 3600 RPM, 2HP motors (pump codes A04E, A04F) Frequency — — — Hz Hz (Pump (Pump Speed Speed Cycles Cycles per per Minute) Minute) Frequency...

- Page 53 Performance Charts Low - - - Pulsation Pulsation Pulsation Mode Mode Mode A A A 20 Hz, 73 cycles per minute Two typical running conditions are shown in the curves. The curves show the relationship between B B B 40 Hz, 145 cycles per minute outlet pressure and outlet flow during Low Pulsation C C C 60 Hz, 217 cycles per minute Mode (above the transition line) and Transfer Mode...

- Page 54 Performance Charts How to to to Calculate Calculate Your Your System’s System’s Net Net Positive Positive Suction Suction Head Head – – – Available Available Calculate Your System’s Positive Suction Head Available (NPSHa) (NPSHa) (NPSHa) For a given flow rate, there must be a minimum of your system must be greater than the NPSHr to fluid head pressure supplied to the pump to prevent prevent cavitation and therefore increase efficiency...

- Page 55 Notes Notes Notes Notes 3A3167N Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com Fax: 866-777-6383 Int'l: +001 267 404 2910...

-

Page 56: Dimensions

Dimensions Dimensions Dimensions Dimensions 1040FG 1040FG 1040FG Figure 12 Food Grade models without Compressor (BLDC and motorless models shown) 3A3167N Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com Fax: 866-777-6383 Int'l: +001 267 404 2910... - Page 57 Dimensions 1040HS and and 1040PH 1040PH 1040HS 1040HS 1040PH Figure 13 High Sanitation and Pharmaceutical Pumps without Compressor (AC and motorless models shown) 3A3167N Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com Fax: 866-777-6383 Int'l: +001 267 404 2910...

- Page 58 Dimensions Table Table Table 7 7 7 Dimensions Dimensions Dimensions for for 1040FG 1040FG 1040FG Pumps Pumps Pumps Gearbox Gearbox Gearbox and and Motor Motor Motor Gearbox Gearbox Gearbox Only Only Only BLDC BLDC BLDC ( ( ( 04A) ) ) ( ( ( 04B) ) ) &...

- Page 59 Dimensions Graco Motor Motor Control Control Dimensions Dimensions Graco Graco Motor Control Dimensions Cart Cart Cart System System System Dimensions Dimensions Dimensions 3A3167N Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com Fax: 866-777-6383 Int'l: +001 267 404 2910...

- Page 60 Dimensions Compressor Dimensions Dimensions Compressor Compressor Dimensions 3A3167N Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com Fax: 866-777-6383 Int'l: +001 267 404 2910...

-

Page 61: Technical Data

Technical Data Technical Technical Technical Data Data Data Metric Metric Metric SaniForce SaniForce 1040e SaniForce 1040e 1040e Electric Electric Electric- - - Operated Operated Operated Double Double Double Diaphragm Diaphragm Pump Diaphragm Pump Pump Maximum fluid working pressure 70 psi 0.48 MPa, 4.8 bar... - Page 62 Metric Metric Weight Weight Weight Compressor 28 lb 13 kg Graco VFD 6 lb 3 kg Graco Motor Control 10.5 lb 4.8 kg Cart 33 lb 15 kg Wetted Wetted Parts Wetted Parts Parts Wetted parts include stainless steel, plus material(s) chosen for seat, ball, and diaphragm options...

- Page 63 California Proposition 65 Technical Specifications Specifications for for the the Graco Graco Motor Motor Control Control Technical Technical Specifications Graco Motor Control DC Power Supply Class 2 Power Supply only Approvals UL508C Conformity CE-Low Voltage (2006/95/EC), EMC (2004/108/EC), and RoHS (2011/65/EU) Directives Ambient Temperature -40°F –...

- Page 64 Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations. This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts.

Need help?

Do you have a question about the SaniForce 1040e and is the answer not in the manual?

Questions and answers