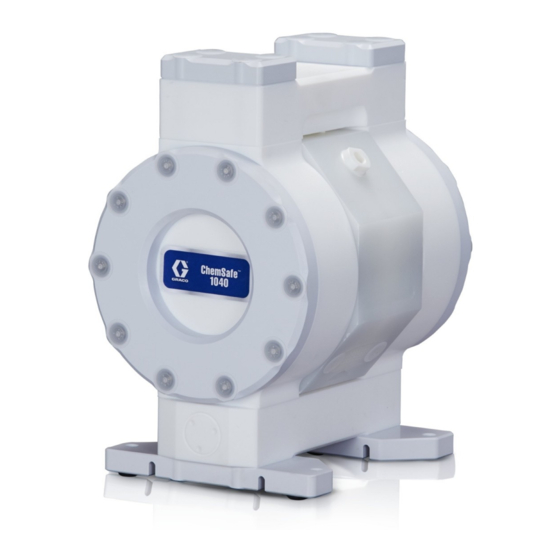

Graco ChemSafe 1040 Instructions-Parts List Manual

Air-operated diaphragm pump

Hide thumbs

Also See for ChemSafe 1040:

- Instruction manual (54 pages) ,

- Operation (32 pages) ,

- Instructions - parts manual (32 pages)

Table of Contents

Advertisement

Quick Links

Instructions-Parts

ChemSafe™ 1040

ChemSafe™

ChemSafe™

Air - - - Operated

Air

Air

Operated Diaphragm

Operated

1–inch

1–inch high

1–inch

high

high purity

purity pump

purity

Not

Not approved

Not

approved

approved for

for use

for

use in in in European

use

Important Safety

Safety Instructions

Important

Important

Safety

Read all warnings and instructions in this manual. Save

instructions.

instructions.

instructions.

100 psi (0.7 MPa, 7.0 bar) Maximum Air

Supply Pressure

100 psi (0.7 MPa, 7.0 bar) Maximum

Fluid Working Pressure

Springer Pumps, LLC

Telford, PA 18969

1040

1040

Diaphragm Pump

Diaphragm

pump

pump for

for industrial

for

industrial applications.For

industrial

applications.For professional

applications.For

European

European explosive

explosive atmosphere

explosive

Instructions

Instructions

PROVEN QUALITY. LEADING TECHNOLOGY.

Tel: 866-777-6060 / Int'l: 215-949-2900

Fax: 866-777-6383 / Int'l: 215-721-1296

Pump

Pump

professional use

professional

use only.

use

atmosphere locations.

atmosphere

locations.

locations.

Save these

Save

these

these

334795B

only.

only.

shop.springerpumps.com

info@springerpumps.com

EN

Advertisement

Table of Contents

Summary of Contents for Graco ChemSafe 1040

- Page 1 Instructions-Parts ChemSafe™ 1040 1040 ChemSafe™ ChemSafe™ 1040 334795B Air - - - Operated Operated Diaphragm Operated Diaphragm Pump Diaphragm Pump Pump 1–inch 1–inch high 1–inch high high purity purity purity pump pump pump for for industrial industrial applications.For industrial applications.For applications.For professional professional professional use...

-

Page 2: Table Of Contents

Start and Adjust the Pump ......13 Performance Charts..........30 Pressure Relief Procedure......14 Pump Shutdown .......... 14 Technical Data ........... 31 Maintenance ............15 Graco Standard ChemSafe Pump Maintenance Schedule ......... 15 Warranty..........32 334795B Springer Pumps, LLC Tel: 866-777-6060 / Int'l: 215-949-2900 shop.springerpumps.com... -

Page 3: Warnings

Warnings Warnings Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. - Page 4 Warnings WARNING WARNING WARNING EQUIPMENT EQUIPMENT MISUSE EQUIPMENT MISUSE MISUSE HAZARD HAZARD HAZARD Misuse can cause death or serious injury. • Do not operate the unit when fatigued or under the influence of drugs or alcohol. • Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

- Page 5 Warnings WARNING WARNING WARNING TOXIC TOXIC TOXIC FLUID FLUID OR FLUID OR FUMES FUMES HAZARD FUMES HAZARD HAZARD Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed. • Read MSDSs to know the specific hazards of the fluids you are using. •...

-

Page 6: Configuration Number Matrix

Configuration Number Matrix Configuration Configuration Configuration Number Number Number Matrix Matrix Matrix Check the identification plate (ID) for the Configuration Number of your pump. Use the following matrix to define the components of your pump. 1040PT 1040PT 1040PT- - - P01APT3PTPTPOPT P01APT3PTPTPOPT P01APT3PTPTPOPT Sample... - Page 7 Configuration Number Matrix Models Models Models Model Pump Balls Diaphragm Model Model Pump Pump Air & & & Fluid Fluid Fluid Fluid Fluid Covers, Fluid Covers, Covers, Balls Balls Diaphragm Diaphragm Manifold Manifold Manifold Seal Seal Seal Connection Connection Connection Seats, Seats, &...

-

Page 8: Installation

Cavitation in an AODD pump is the formation and selecting and installing system components. Contact collapse of bubbles in the pumped liquid. Frequent your Graco distributor for assistance in planning a or excessive cavitation can cause serious damage, system to suit your needs. Always use Genuine including pitting and early wear of fluid chambers, Graco Parts and accessories. -

Page 9: Mount The Pump

Installation Mount The The Pump Pump Mount Mount Pump 1. Be sure the mounting surface can support the weight of the pump, hoses, and accessories, as well as the stress caused during operation. 2. For all mountings, be sure the pump is secured To avoid serious injury from toxic fluid or fumes: with screws through the mounting feet. -

Page 10: Ground The System

Installation Air Lines Lines Ground Ground Ground The The System System System Lines 1. Install an air regulator and gauge (C) to control the fluid pressure. The fluid stall pressure will be the same as the setting of the air regulator. 2. -

Page 11: Air Exhaust Ventilation

Installation Air Exhaust Exhaust Ventilation Ventilation Exhaust Ventilation To provide provide provide a a a remote remote exhaust: remote exhaust: exhaust: 1. Use Kit 17F612 (NPT) or 17F613 (BSPT), sold separately. 2. Remove the muffler (U) from the pump air exhaust port (K). -

Page 12: Fluid Supply Line

Installation Fluid Fluid Fluid Supply Supply Line Supply Line Line install the pump as close as possible to the material source. Minimize suction requirements to maximize pump performance. 1. Use grounded, flexible fluid hoses (E). See Ground The System, page 2. -

Page 13: Operation

Operation Operation Operation Operation Start Start and Start and Adjust Adjust the Adjust the Pump Pump Pump NOTICE NOTICE NOTICE Tighten Tighten Tighten Bolts Bolts Bolts To avoid damage to your pump, be certain that all pumped fluids are compatible with wetted parts. Before mounting and using the pump for the Technical Data, page first time, check and retorque all external bolts. -

Page 14: Pressure Relief Procedure

Operation Pressure Pressure Pressure Relief Relief Procedure Relief Procedure Procedure 2. Open the dispensing valve, if used. 3. Open the fluid drain valve to relieve fluid Follow the Pressure Relief Procedure pressure. Have a container ready to catch the whenever you see this symbol. drainage. -

Page 15: Maintenance

See where they are clean, dry, and protected from Torque Instructions, page extreme temperatures, UV radiation, and vibration. Graco recommends an ambient temperature range of 60°F-80°F (15°C-25°C), with a humidity level below 65%. 334795B... -

Page 16: Troubleshooting

Troubleshooting Troubleshooting Troubleshooting Troubleshooting Problem Problem Problem Cause Solution Cause Cause Solution Solution Pump cycles but will not prime. Pump is running too fast, causing Lower inlet pressure. cavitation before prime. Check valve ball is severely warn Replace ball and seat. or wedged in seat or manifold. - Page 17 Troubleshooting Problem Cause Solution Problem Problem Cause Cause Solution Solution Moisture in exhaust air. Inlet air has high humidity. Use drier air supply. Pump exhausts excessive air at Spool valve seals are worn or Replace. stall. damaged. Pump leaks air externally. Fluid covers are loose.

-

Page 18: Repair

Repair Repair Repair Repair Disassemble the the Fluid Fluid Section Section Disassemble Disassemble Fluid Section 1. Carefully remove all cap plugs (37). Turn the pump upside-down. 2. Use a 10 mm socket to remove the base plates (12) and the inlet manifold (10). 3. -

Page 19: Disassemble The Center Section

Repair 10. To remove the nuts (28) and bolts (24), use two 10 mm wrenches to hold on one side and turn the other. The nuts (28) will come off of one side only. Then remove the bolts (24). 6. Use a 19 mm socket and the supplied tool (42) to NOTE: The nuts are permanently affixed to one NOTE: NOTE:... -

Page 20: Reassemble The Center Section

Repair Reassemble Reassemble the Reassemble the Center Center Section Center Section Section NOTE: Be careful not to clog air holes with NOTE: NOTE: lubricant. 1. Carefully lubricate the spool assembly o-rings with a thin film of the appropriate lubricant (46). NOTE: NOTE: NOTE: Be careful not to clog air holes with... -

Page 21: Reassemble The Fluid Section

Repair 6. Install the muffler media (alternating felt mufflers 11. Tighten the diaphragm shaft (5) onto one strike (15) and mesh baffle spacers (38)) into the plate (4) and diaphragm (25), hand tight only. Do muffler. Use the new felt mufflers (15) supplied not use any tools on the shaft. - Page 22 Repair 4. Slide the tie bolts (24) through the retainers (9), fluid covers (6), and body (1), all oriented as shown. Use a clamp to hold the sections together. 5. On the threaded end of each tie-bolt (24), place a flat #12 washer (26), two belleville washer (27), with the rounded side of the first belleville washer toward the flat washer and the rounded side of 8.

- Page 23 Repair 11. Turn the pump over and insert a ball retainer 14. On each screw (29), place two belleville washers (20), check ball (22), d-ring (21), and o-ring (17) (27), with the rounded side of first washer toward into the inlet side of each fluid cover (6). the screw head and the rounded side of the second washer away, then a flat #12 washer 12.

-

Page 24: Torque Instructions

Torque Instructions Torque Torque Torque Instructions Instructions Instructions If fluid cover or manifold bolts have been loosened, 3. Turn each screw by 1/2 turn or less working in a it is important to torque them using the following crisscross pattern to specified torque. procedure to improve sealing. -

Page 25: Parts

Parts Parts Parts Parts Lubricate using PFPE grease (17G558); included in all Center and Fluid Section Rebuild kits. Follow Torque Instructions, page 334795B Springer Pumps, LLC Tel: 866-777-6060 / Int'l: 215-949-2900 shop.springerpumps.com Telford, PA 18969 Fax: 866-777-6383 / Int'l: 215-721-1296 info@springerpumps.com... - Page 26 Parts NOTE: Many parts are included in one or more kits. NOTE: NOTE: Please see Kits, page 28, for the complete list of available kits and their contents. Part Part Part Description Description Description Part Part Part Description Description Description —...

- Page 27 Parts Part Part Part Description Description Description Part Part Part Description Description Description 36† SEAT, wearable, bottom 42** 17F796 TOOL, wrench, spool removal; 4–pin — PTFE 17F797 TOOL, wrench, air motor — UHMW 44** 17F799 TOOL, insertion, wear 17F259 PLUG, cap; 28–pack surface —...

-

Page 28: Kits

Kits Kits Kits Kits Ref. Ref. Ref. Description Description Description Center Center Center Section Section Section Rebuild Rebuild Rebuild Kit Kit 17F131 17F131 17F131 Kit Includes: Diaphragm Description PTFE, Kits 17F132, 17F135 Ref. Ref. Ref. Description Description EPDM, Kist 17F133, 17G051 Spool Assembly Nitrile;... -

Page 29: Dimensions

Dimensions Dimensions Dimensions Dimensions Ref. Ref. Ref. Ref. Ref. Ref. Metric Metric Metric Metric Metric Metric A A A F F F 1.9 in. 4.8 cm 14.1 in. 35.8 cm B B B 10.4 in. 26.4 cm G G G 8.0 in. -

Page 30: Performance Charts

Performance Charts Performance Performance Performance Charts Charts Charts Fluid Pressure Pressure Fluid Fluid Pressure Approximate Approximate Approximate Cycles Cycles Cycles per per Minute Minute Minute (0.69, 6.9) (0.62, 6.2) (0.55, 5.5) (0.49, 4.9) (0.42, 4.2) (0.35, 3.5) (MPa, bar) bar) (MPa, (MPa, bar) -

Page 31: Technical Data

Technical Data Technical Data Data Technical Technical Data ChemSafe 1040 1040 Diaphragm Diaphragm Pump Pump ChemSafe ChemSafe 1040 Diaphragm Pump Metric Metric Metric Maximum fluid working pressure 100 psi 0.69 MPa, 6.9 bar Minimum air startup pressure 30 psi 0.21 MPa, 2.1 bar Fluid inlet and outlet size 1 in. -

Page 32: Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of five years from the date of sale, repair or replace any part of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

Need help?

Do you have a question about the ChemSafe 1040 and is the answer not in the manual?

Questions and answers