Graco SaniForce 1040e Repair Parts

Electric-operated diaphragm pump

Hide thumbs

Also See for SaniForce 1040e:

- User manual (66 pages) ,

- Operation (64 pages) ,

- Repair parts (40 pages)

Table of Contents

Advertisement

Quick Links

Repair/Parts

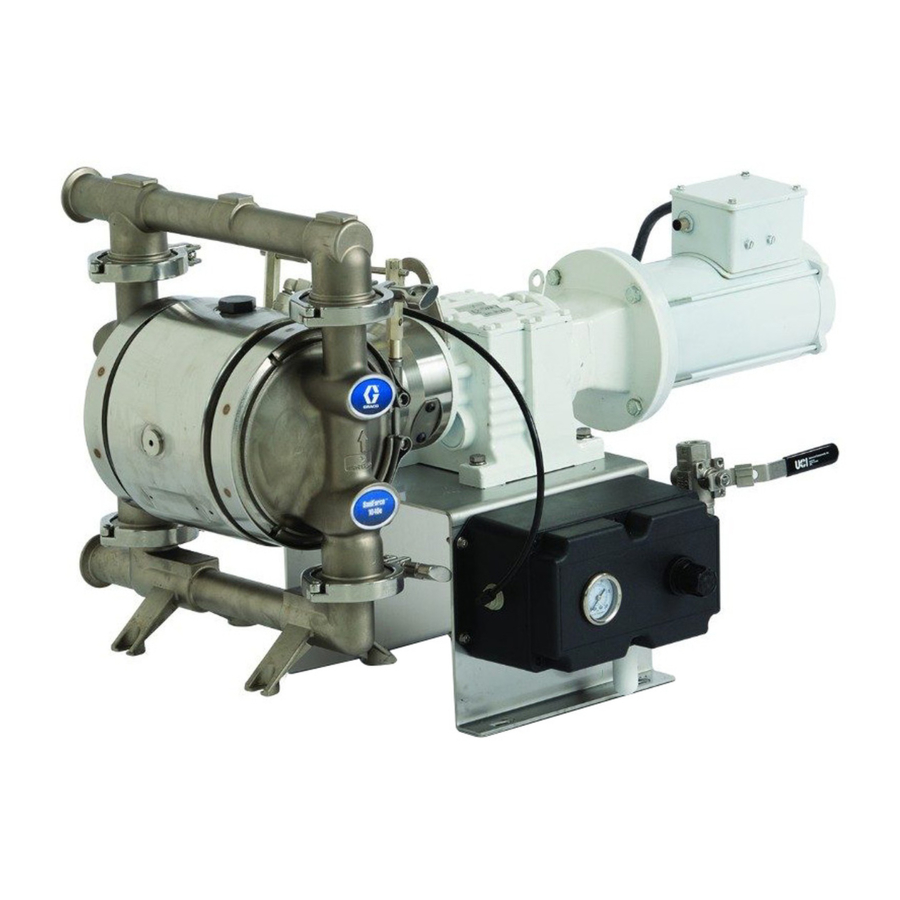

SaniForce® 1040e

SaniForce®

SaniForce®

Diaphragm

Diaphragm Pump

Diaphragm

For fluid

fluid transfer

transfer in in in indoor

indoor sanitary

For

For

fluid

transfer

indoor

hazardous

hazardous

hazardous (classified)

(classified) locations

(classified)

professional

professional use

professional

use

use only.

only.

only.

Important Safety

Important

Important

Safety

Safety Instructions

Read all warnings and instructions in this manual and in your

SaniForce 1040e Operation manual before using the equipment.

Save these

these instructions.

instructions.

Save

Save

these

instructions.

For maximum operating pressures,

see the Performance Charts in your

Operation manual.

See pages 6–8 for model information,

including approvals.

1040e Electric

Electric - - - Operated

1040e

Electric

Pump

Pump

sanitary applications.

applications. Not

sanitary

applications.

locations

locations unless

unless otherwise

unless

otherwise stated.

otherwise

Instructions

Instructions

PROVEN QUALITY. LEADING TECHNOLOGY.

Operated

Operated

Not approved

approved for

for use

use in in in explosive

Not

approved

for

use

stated. See

stated.

See Approvals

See

Approvals page

Approvals

3A3168R

3A3168R

3A3168R

explosive atmospheres

atmospheres or or or

explosive

atmospheres

page for

page

for more

for

more information.

more

information. For

information.

EN

EN

EN

For

For

Advertisement

Table of Contents

Summary of Contents for Graco SaniForce 1040e

- Page 1 Important Important Safety Important Safety Safety Instructions Instructions Instructions Read all warnings and instructions in this manual and in your SaniForce 1040e Operation manual before using the equipment. Save these these instructions. instructions. Save Save these instructions. For maximum operating pressures, see the Performance Charts in your Operation manual.

-

Page 2: Table Of Contents

Repair....................................... . 12 Related Manuals Manuals Related Related Manuals Manual Manual Number Manual Number Number Title Title Title 3A3167 SaniForce 1040e 1040e Electric Electric- - - Operated Operated Diaphragm Diaphragm Pump, Pump, Operation Operation 3A3167 3A3167 SaniForce SaniForce 1040e Electric Operated Diaphragm... -

Page 3: Warnings

Warnings Warnings Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. - Page 4 Warnings WARNING PRESSURIZED PRESSURIZED PRESSURIZED EQUIPMENT EQUIPMENT EQUIPMENT HAZARD HAZARD HAZARD Fluid from the equipment, leaks, or ruptured components can splash in the eyes or on skin and cause serious injury. • Follow the Pressure Pressure Relief Pressure Relief Procedure Relief Procedure Procedure when you stop spraying/dispensing and before...

- Page 5 Warnings WARNING THERMAL THERMAL THERMAL EXPANSION EXPANSION HAZARD EXPANSION HAZARD HAZARD Fluids subjected to heat in confined spaces, including lines, can create a rapid rise in pressure due to the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

-

Page 6: Pumps

Configuration Number Matrix for FG Pumps Configuration Number Number Matrix Matrix for for FG FG Pumps Pumps Configuration Configuration Number Matrix Pumps Check Check the Check the identification identification identification plate plate (ID) plate (ID) for (ID) for the Configuration Configuration Number Configuration Number of of of your... - Page 7 Configuration Number Matrix for HS and PH Pumps Configuration Number Number Matrix Matrix for for HS HS and and PH PH Pumps Pumps Configuration Configuration Number Matrix Pumps Check Check the Check the identification identification identification plate plate plate (ID) (ID) for (ID) for the...

- Page 8 Approvals Approvals Approvals Approvals Approvals Approvals Approvals All models models are are approved approved to: models approved *Diaphragm *Diaphragm materials *Diaphragm materials materials coded coded coded , , , PT, , , or or or combined with with ball ball materials materials coded coded EC 1935/2004...

-

Page 9: Approvals

Points: Points: • Pumps are available with an AC or Brushless • BLDC motors are controlled by the Graco Motor DC (BLDC) motor, or with just a gearbox (for Control that is supplied with the pump. applications where a motor is already available). -

Page 10: Troubleshooting

See the Operation Manual (3A3167) for troubleshooting or error information on the Graco Motor Control. Problem Cause Solution Problem Problem Cause Cause Solution Solution Pump cycles but will not... - Page 11 Determine and fix the source of the power problem. Operational parameters are See manual 3A3167 for event codes. exceeded. NOTE: NOTE: For problems with a Variable Frequency Device (VFD), see your VFD manual. For problems with the NOTE: Graco Motor Control, see your Operation Manual. 3A3168R...

-

Page 12: Repair

Repair Repair Repair Repair Pressure Relief Relief Procedure Procedure Check Valve Valve Repair Repair Pressure Pressure Relief Procedure Check Check Valve Repair Follow the Pressure Relief Procedure whenever you see this symbol. NOTE: Kits are available for new check valve balls, NOTE: NOTE: diaphragms, and manifold o-rings in a range of... - Page 13 Repair 1040FG 1040HS or or or 1040PH 1040PH 1040FG 1040FG 1040HS 1040HS 1040PH Arrow Arrow Arrow on on both both covers both covers covers must must must point point toward point toward toward outlet outlet outlet manifold manifold manifold 3A3168R...

- Page 14 Repair Diaphragm Repair Repair Diaphragm Diaphragm Repair 4. 4. 4. Loosen Loosen Loosen the the screws screws screws and and remove remove the remove the motor motor fan motor cover. Turn Turn the the motor motor fan fan by by by hand hand to to to move move the...

- Page 15 Repair Reassemble Reassemble Reassemble the the Diaphragms Diaphragms Diaphragms Follow Follow all all all notes Follow notes notes in in in the the illustrations illustrations illustrations on on the the following following following 3. 3. 3. All All Other Other Diaphragms-Metal Other Diaphragms-Metal Pumps Diaphragms-Metal...

- Page 16 Repair 2 2 2 - - - Piece Piece Piece ( ( ( PS) ) ) Models Models Models Rounded side side faces faces diaphragm. diaphragm. Rounded Rounded side faces diaphragm. Apply Apply Apply medium medium- - - strength medium strength strength (blue) (blue)

- Page 17 Repair Center Section Section Repair Repair Center Center Section Repair 7. 7. 7. Use Use a a a 3/4–16 3/4–16 3/4–16 bolt, bolt, screwed bolt, screwed screwed into into the into the hole hole hole for for plug plug plug (124), to to to push push out out the...

- Page 18 Repair Apply medium-strength (blue) thread locker to threads. Torque to 15–25 ft-lb (20–34 N•m). Lips must face IN IN IN toward the center. Apply anti-seize lubricant liberally on the surfaces of the drive shaft assembly. Install the drive shaft assembly with the groove facing up.

- Page 19 Repair Reassemble Reassemble Reassemble the the Center Center Center Section Section Section See the the illustrations illustrations on illustrations on the the previous previous previous page. page. page. 5. 5. 5. Install Install Install o-ring o-ring (109†). o-ring (109†). (109†). 6.

- Page 20 Repair Replace Center Center Bearing Bearing Replace Replace Center Bearing 6. 6. 6. Place Place the the repair repair tool tool (A) (A) on on the the housing housing with with the Place repair tool housing with stepped stepped stepped side side side down.

- Page 21 Repair 9. 9. 9. Use Use an an arbor arbor press press and and the the press-fit press-fit tool tool (E) (E) to to to arbor press press-fit tool install install install the the two two bushings bushings (C). bushings (C).

- Page 22 Repair Replace the the Compressor Compressor Replace Replace Compressor To avoid avoid injury injury from from fire, fire, explosion, explosion, or or or electric electric avoid injury from fire, explosion, electric shock, shock, all all all electrical shock, electrical electrical wiring wiring must wiring must...

-

Page 23: Parts

Parts Parts Parts Parts 1040FG 1040FG 1040FG 3A3168R... - Page 24 Parts 1040FG Parts/Kits Parts/Kits Quick Quick Reference Reference 1040FG 1040FG Parts/Kits Quick Reference Use this table as a quick reference for parts/kits. Go to the pages indicated in the table for a full description of kit contents. Description Qty. Qty. Qty.

- Page 25 Parts 1040HS and and 1040PH 1040PH 1040HS 1040HS 1040PH 3A3168R...

- Page 26 Parts 1040HS and and 1040PH 1040PH Parts/Kits Parts/Kits Quick Quick Reference Reference 1040HS 1040HS 1040PH Parts/Kits Quick Reference Use this table as a quick reference for parts/kits. Go to the pages indicated in the table for a full description of kit contents.

- Page 27 Parts Drive Module Module Drive Drive Module Apply Apply medium Apply medium medium- - - strength strength (blue) strength (blue) thread (blue) thread thread locker locker locker to to to threads. threads. threads. 3A3168R...

- Page 28 Parts Part Part Part Description Description Description Part Part Part Description Description Description — — — WASHER HOUSING, center, assembly; includes items — — — SCREW, cap, hex head, (Ref. 123, 124, 134) M6 x 16 mm (A A A 24Y781 Aluminum —...

- Page 29 Parts Cart - - - Mounted Mounted Models Models Cart Cart Mounted Models 3A3168R...

- Page 30 25A706 25A706 25A706 25A879 25A879 25A879 24Y922 24Y922 24Y922 – – – 240V 240V 240V None None None 24Y514 CONTROLLER, Graco Motor 25A707 25A880 24Y922 – – – 240V 240V None None None 25A707 25A707 25A880 25A880 24Y922 24Y922 240V —...

- Page 31 Parts Cart Cart Cart This parts breakdown reflects item 201. Part Description Part Part Description Description — — — ◊ FRAME, cart — — — †◊ WASHER, flat — — — †◊ WASHER, spring — — — †◊ WHEEL — — — †◊ E-RING 17H262◊...

- Page 32 Parts Seats and and Check Check Balls Balls Seats Seats Check Balls Sample Configuration Number Pump Wetted Drive Center Gear Box Fluid Seats Balls Diaphragms Manifold Certifica- Model Section Covers and Section and Motor Gaskets tion Material Material Manifolds 1040 Ball Ball Kits Ball...

- Page 33 Parts Diaphragms Diaphragms Diaphragms Sample Configuration Number Pump Wetted Drive Center Gear Box Fluid Seats Balls Diaphragms Manifold Certifica- Model Section Section and Motor Covers and Gaskets tion Material Material Manifolds 1040 Overmolded Overmolded Overmolded Diaphragm Diaphragm Diaphragm Kits Kits Kits Bolt Bolt- - - Through...

- Page 34 Parts Fluid Repair Repair Kits Kits Fluid Fluid Repair Kits Fluid Section Section Repair Repair Kits, Kits, for for FG FG Pumps Pumps only only Fluid Fluid Section Repair Kits, Pumps only Description Description Description Qty. Qty. Qty. Kit descriptions appear in the following order: Pump model, seat material, ball material, FK1232 1040FG --,CW,SP,EP...

- Page 35 9.8 ft; ft; ft; 3.0 3.0 m m m 17S306 17S306 selections. selections. For selections. For systems systems systems using using a a a Graco using Graco Graco Motor Motor Control, Motor Control, Control, order an an extension extension cable...

-

Page 36: Saniforce 1040E 1040E Electric Electric

Technical Specifications Technical Specifications Specifications Technical Technical Specifications SaniForce SaniForce SaniForce 1040e 1040e 1040e Electric Electric Electric- - - Operated Operated Operated Double Double Double Diaphragm Diaphragm Diaphragm Pump Pump Pump Metric Metric Metric Maximum fluid fluid working working pressure... -

Page 37: Compressor

Technical Specifications SaniForce SaniForce SaniForce 1040e 1040e 1040e Electric Electric Electric- - - Operated Operated Operated Double Double Double Diaphragm Diaphragm Diaphragm Pump Pump Pump Metric Metric Metric Noise Data Data Noise Noise Data Sound Sound Sound Power Power (measured... - Page 38 Technical Specifications Fluid Temperature Temperature Range Range Fluid Fluid Temperature Range NOTICE NOTICE NOTICE Temperature Temperature limits Temperature limits are limits are based based on based on mechanical mechanical mechanical stress stress only. stress only. only. Certain Certain chemicals Certain chemicals chemicals will will...

-

Page 39: Specifications

California Proposition 65 Technical Specifications Specifications for for the the Graco Graco Motor Motor Control Control Technical Technical Specifications Graco Motor Control DC Power Power Supply Supply Class 2 2 2 Power Power Supply Supply only only Power Supply Class... - Page 40 Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations. This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts.

Need help?

Do you have a question about the SaniForce 1040e and is the answer not in the manual?

Questions and answers